Method and device for purifying bromine-extracting waste liquid

A purification device and waste liquid technology, which is applied in chemical instruments and methods, neutralized water/sewage treatment, water treatment parameter control, etc., can solve the problems of failure to meet the standard for normal reception of subsequent processes, high acidity of bromine extraction waste liquid, and environmental pollution and other problems, to achieve the effect of simple raw material acquisition, significant environmental protection benefits, and reduced acid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

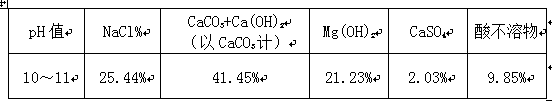

[0034] In this embodiment, the waste salt mud is obtained from the brine refining process produced by soda ash, and the contents of each component on a dry basis are:

[0035]

[0036] Refer to attached figure 1 , the waste salt mud 2 first enters the salt mud settling tank 3, discards the supernatant liquid 5 after layering, takes the lower layer suspension liquid 4, and sends it to the cyclone separator 7 through the salt mud delivery pump 6, and separates and removes the mud with a larger specific gravity. sand 8 to obtain the selected waste salt mud 9, the selected waste salt mud 9 is sent to the salt mud storage tank 10, and the salt mud storage tank 10 is equipped with stirring to ensure that the composition of the waste salt mud is uniform, and the bromine extraction waste liquid 1 is passed through the bromine extraction The waste liquid feeding control valve 12 enters the reaction tank 13, after the control valve 12, the selected waste salt mud is added, and the do...

Embodiment 2

[0041] In this example, the waste salt mud is obtained from the brine refining process of chlor-alkali production, and the content of each component on a dry basis (mass percentage):

[0042]

[0043] Refer to attached figure 1 , the waste salt mud 2 first enters the salt mud settling tank 3, discards the supernatant liquid 5 after layering, takes the lower layer suspension liquid 4, and sends it to the cyclone separator 7 through the salt mud delivery pump 6, and separates and removes the mud with a larger specific gravity. sand 8 to obtain the selected waste salt mud 9, the selected waste salt mud 9 is sent to the salt mud storage tank 10, and the salt mud storage tank 10 is equipped with stirring to ensure that the composition of the waste salt mud is uniform, and the bromine extraction waste liquid 1 is passed through the bromine extraction The waste liquid feed control valve 12 enters the reaction tank 13, and after the bromine extraction waste liquid feed control valv...

Embodiment 3

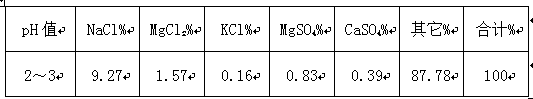

[0046] In this embodiment, the acidity, alkalinity and main components of the bromine extraction waste liquid from brine are shown in the table below, and the iron content reaches 1.9 ppm.

[0047]

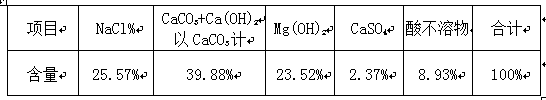

[0048] The waste salt mud used is obtained from the NaCl brine refining process produced by MVR, and the contents of each component on a dry basis are:

[0049]

[0050] Refer to attached figure 1 , the waste salt mud 2 first enters the salt mud settling tank 3, discards the supernatant liquid 5 after layering, takes the lower layer suspension liquid 4, and sends it to the cyclone separator 7 through the salt mud delivery pump 6, and separates and removes the mud with a larger specific gravity. sand 8 to obtain the selected waste salt mud 9, the selected waste salt mud 9 is sent to the salt mud storage tank 10, and the salt mud storage tank 10 is equipped with stirring to ensure that the composition of the waste salt mud is uniform, and the bromine extraction waste liquid 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com