Treatment method of carbonate-containing wastewater

A treatment method, carbonate technology, applied in the direction of alkali metal carbonate, water/sewage treatment, water treatment parameter control, etc., can solve the problems of high operating cost, large amount of miscellaneous salt, large consumption of chemicals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

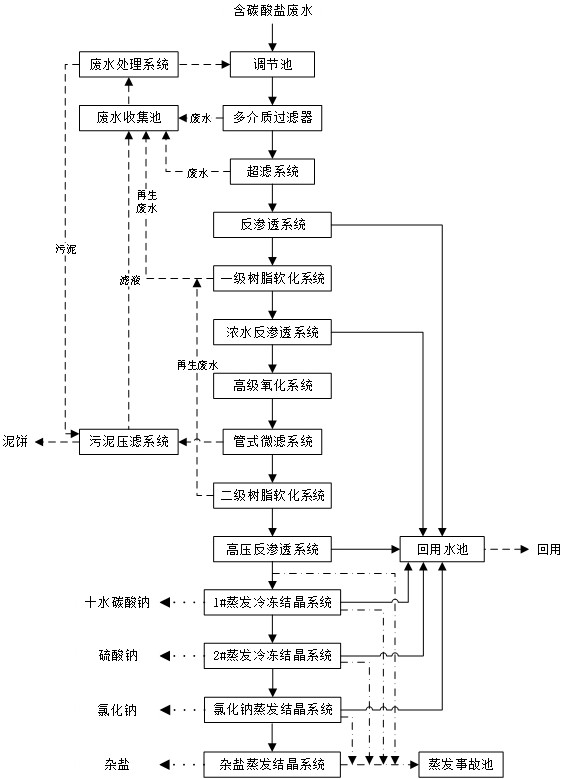

Image

Examples

Embodiment Construction

[0030] The following is an introduction to the implementation case of the mine water treatment project containing carbonate.

[0031] (1) The flow rate is 20000m 3 Mine water containing carbonate per day (TDS≤2400mg / L, carbonate≤1100 mg / L, total hardness≤90 mg / L) enters the adjustment pool through the pipeline, and after the water quality and quantity are adjusted, it enters the multi-media through the lift pump filter.

[0032] (2) After preliminary filtration by the multi-media filter, it enters the ultrafiltration system through the lifting pump, and the filtrate filtered by the ultrafiltration membrane enters the reverse osmosis system through the reverse osmosis high-pressure pump.

[0033] (3) Concentrated water volume of reverse osmosis system is 11350m 3 / d, the concentrated water of the reverse osmosis system enters the primary resin softening system through the lift pump, and the produced water of the reverse osmosis system enters the reuse pool.

[0034] (4) Thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com