Aeration pipe and self-cleaning method

An aeration tube and self-cleaning technology, applied in chemical instruments and methods, special treatment targets, sustainable biological treatment, etc., can solve problems such as membrane fouling, uneven bubbles, and sludge drying by heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

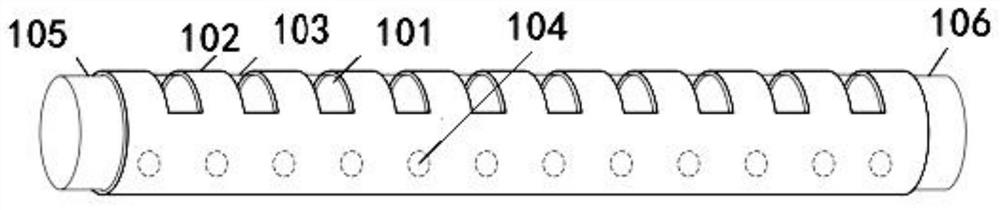

[0129] Embodiment 1: in combination with all accompanying drawings; Option 1:

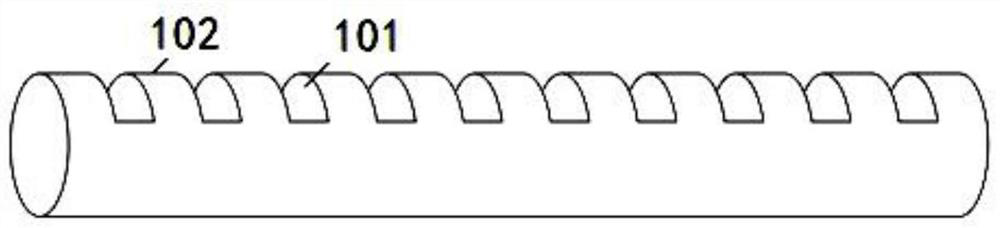

[0130] An aeration tube, characterized in that it includes an outer membrane 102 and an aeration inner tube 103; the outer membrane 102 is made of elastic material, and several diversion ports 101 are arranged on it;

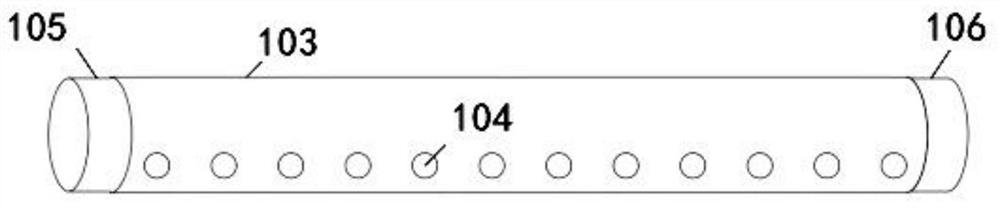

[0131] One end of the aeration inner tube 103 is sealed, and the other end of the aeration inner tube 103 is connected with the air supply pipeline of the aeration system; the aeration inner tube 103 is provided with some aeration inner tube side holes 104;

[0132] The outer membrane 102 is set on the outside of the aeration inner tube 103 .

[0133]The substantive technical effect and the realization process of the technical solution here are as follows: using the aeration tube as described in any one of the above claims, one is that the aeration inner tube is uniformly provided with a larger aeration inner tube The side holes 104 form larger air bubbles, reduce resistance and sav...

Embodiment 2

[0135] Embodiment 2: As a further improved solution or a side-by-side solution or an optional independent solution, the side hole 104 of the aeration inner tube is opened along the axial direction of the aeration inner tube 103, and the side hole 104 axis of the aeration inner tube Perpendicular to the tube wall of the aeration inner tube 103 , the opening area is located at 1 / 3-1 / 2 below the horizontal plane of the axis. The substantive technical effect and the realization process of the technical solution here are as follows: This embodiment provides specific dimensions, and similar dimensions are all within the scope of protection of this patent.

Embodiment 3

[0136] Embodiment 3: As a further improved solution or a side-by-side solution or an optional independent solution, the lower edge of the diversion port 101 is parallel to the axis of the adventitia 102, and the height of the diversion port 101 is 1 / of the diameter of the adventitia 102 3. The substantive technical effect and the realization process of the technical solution here are as follows: This embodiment provides specific dimensions, and similar dimensions are all within the scope of protection of this patent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com