Brushing disc positioning mechanism of vehicle-mounted cleaning system

A positioning mechanism and cleaning system technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems such as high labor intensity of cleaning workers, poor cleaning effect, cumbersome cleaning operations, etc. , to achieve the effect of guaranteed cleaning effect, small vibration and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

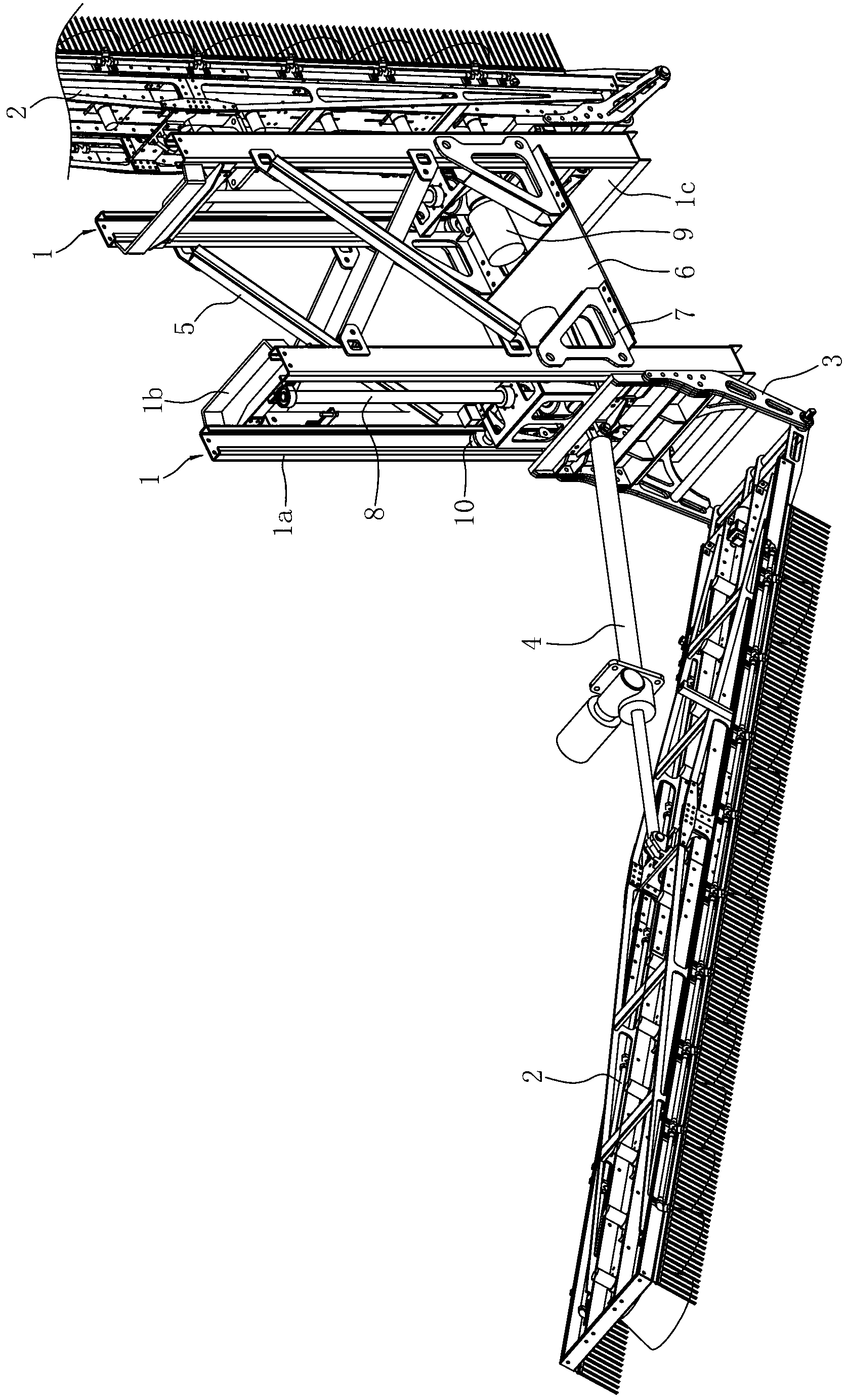

[0015] Such as figure 1 As shown, the left and right side frames 1 are arranged symmetrically, and the two side frames 1 are parallel. The side frame 1 is composed of two channel steels 1a, an upper beam 1b and a lower beam 1c, wherein the two channel steels 1a are symmetrically arranged in the front and back direction, the two channel steels 1a are parallel to each other, and the two channel steels 1a The notches of steel 1a are opposite. An upper beam 1b is connected between the tops of the two channel steels 1a, and the front and rear ends of the upper beam 1b are welded and fixed to the corresponding channel steel 1a; a lower beam 1c is connected between the bottoms of the two channel steels 1a. The front and rear ends of the beam 1c are welded and fixed to the corresponding channel steel 1a.

[0016] Such as figure 1 As shown, the upper space between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com