Preparation method of aging-enhanced copper-chromium alloy

An enhanced and alloyed technology, which is applied in the field of preparation of aging-enhanced CuCr alloys, can solve the problems of Cr agglomeration, large precipitated phase size, and low content, and achieve the effects of good alloy composition uniformity, simple operation, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

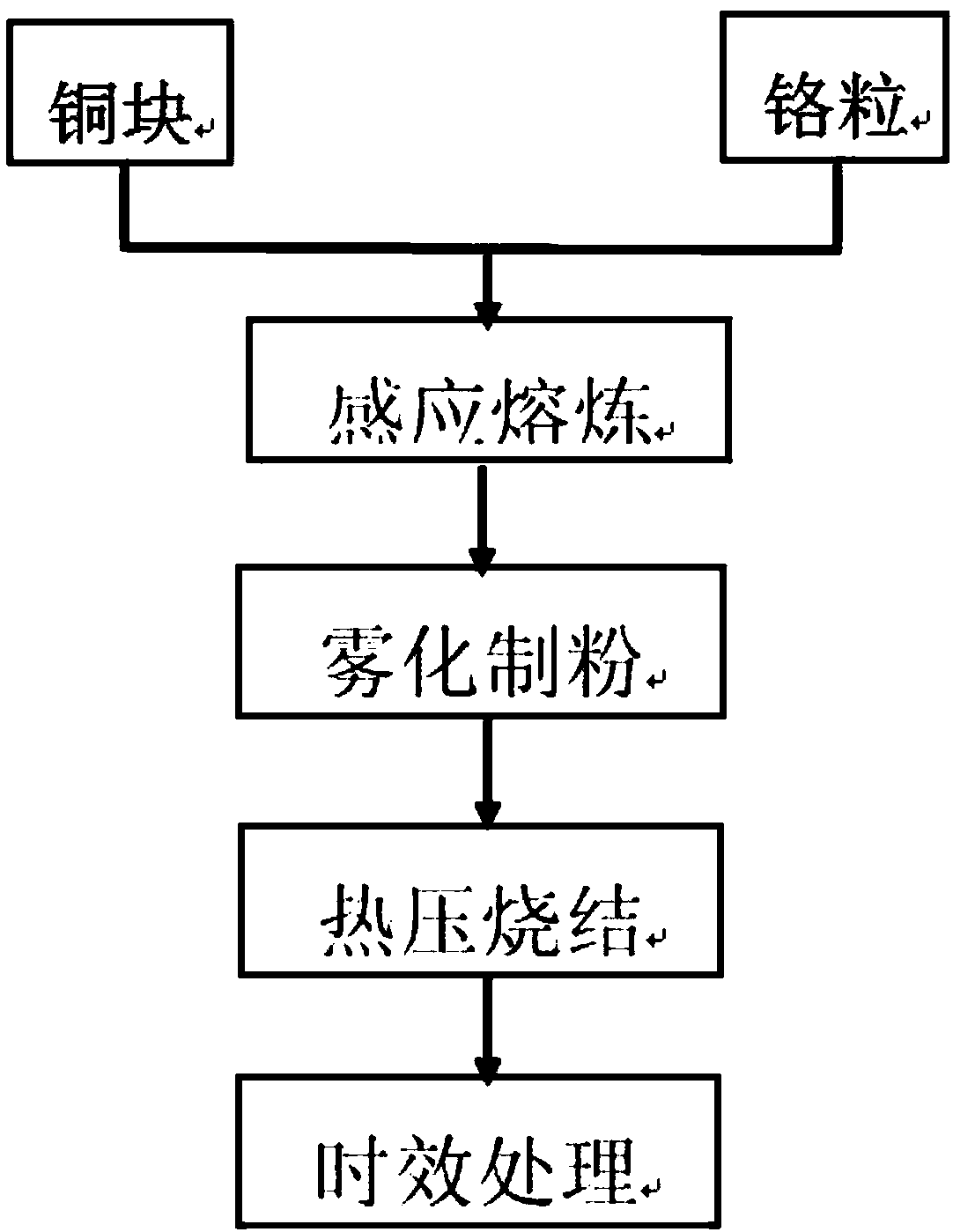

Method used

Image

Examples

Embodiment 1

[0028] Use a balance to weigh a certain proportion of copper and chromium, the mass ratio of chromium is 4%, remove the oil and impurities on the surface of the material, and melt in a vacuum induction melting furnace with a vacuum degree of 8×10 -3 Pa, nitrogen protection atmosphere + 0.05MPa, heating rate of 2°C / s, superheat of 200°C, heat preservation for 5min, and then use restricted nozzle atomization, atomization pressure 5MPa, nozzle diameter 4mm, atomization process is about 9s, for The prepared alloy powder is sieved with different particle sizes, and the alloy powder with a certain particle size is cold-pressed, and then the cold-pressed sample is placed in a Φ21 graphite mold for atmosphere-protected hot-press sintering, and the sintering temperature is 1030°C , the pressure is 30MPa, and the holding time is 1h. After the surface treatment of the hot-pressed sample, the sample is subjected to aging treatment at 450°C. The aging time is 2h. The obtained alloy sample h...

Embodiment 2

[0032] Use a balance to weigh a certain mass fraction of copper block and chromium pellets, the mass ratio of chromium is 3.5%, remove the oil and impurities on the surface of the material, and melt in a vacuum induction melting furnace with a vacuum degree of 9×10 -3 Pa, nitrogen protective atmosphere + 0.04MPa, heating rate of 2°C / s, superheat of 200°C, heat preservation for 6min, and then use restricted nozzle atomization, atomization pressure 6MPa, nozzle diameter 4mm, atomization process is about 8s, for The prepared alloy powder was sieved with different particle sizes, and 29g of alloy powder was weighed for cold-press molding, and then the cold-pressed sample was placed in a Φ21 graphite mold for atmosphere-protected hot-press sintering, and the sintering temperature was 1030°C. The pressure is 30MPa, and the holding time is 1h. After the surface treatment of the hot-pressed sample, the sample is subjected to aging treatment at 440°C. The aging time is 2h. The obtained ...

Embodiment 3

[0034] Use a balance to weigh a certain mass fraction of copper block and chromium pellets, the mass ratio of chromium is 3.5%, remove the oil and impurities on the surface of the material, and melt in a vacuum induction melting furnace with a vacuum degree of 7×10 -3 Pa, nitrogen protection atmosphere + 0.04MPa, heating rate of 2°C / s, superheat of 200°C, heat preservation for 6min, and then use restricted nozzle atomization, atomization pressure 5MPa, nozzle diameter 5mm, atomization process is about 7s, for The prepared alloy powders were sieved with different particle sizes, and 29g of alloy powders were weighed for cold-press molding, and then the cold-pressed samples were placed in a Φ21 graphite mold for atmosphere-protected hot-press sintering, and the sintering temperature was 1020°C. The pressure is 29MPa, and the holding time is 1h. After the surface treatment of the hot-pressed sample, the sample is subjected to aging treatment at 460°C. The aging time is 2h. The obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com