Patents

Literature

75results about How to "Improve organizational form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-sugar jam and preparation method thereof

InactiveCN102742754AEfficient and quick removalReduce energy consumptionFood preparationDietary fiberCalcium content

The invention provides a low-sugar jam and a preparation method of the low-sugar jam. The low-sugar jam consists of dehydrated pulp, sweetener, calcium carbonate, an acidity regulator, a thickening agent and the like. Fruit raw materials are subjected to pretreatment, osmotic dehydration and pulping, and then auxiliary materials are added into the fruit raw materials to be heated and stirred to obtain a jam finished product. The pulp subjected to osmotic dehydration is used as the raw materials to prepare the jam, thereby reducing heating energy consumption, saving jam producing time, and retaining original quality of fruits well. In addition, konjak fine meal and calcium carbonate are added, sugar content and heat are reduced, dietary fiber content and calcium content in the jam are increased, the health-care effect of the product is improved, and human health is facilitated.

Owner:HEFEI UNIV

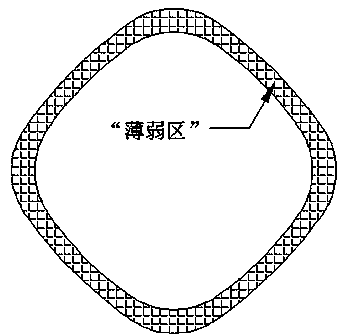

Method for improving structure homogeneity and performance of large-section nodular cast iron

ActiveCN104328239AMeet the requirementsOvercome limitationsProcess efficiency improvementDuctile ironMaterials science

The invention discloses a method for improving structure homogeneity and performance of large-section nodular cast iron, which reveals that in large-section ferrite-based nodular cast iron, a position where a graphite nodule is not round and normal, large in size and worst in performance is not in the center where the coagulation time of a large-section cast piece is longest but in a nearly-annular region which is 20mm-40mm away from the outer edge of a large-section nodular cast iron piece. According to the method, reasonable chemical components, and high-quality nodulizing agent and nucleating agent are selected, a proper amount of a trace element Sb is added, a composite nucleation mode of bottom-coated nucleation, iron discharging nucleation and metal-stream nucleation is adopted, a structure of the large-section nodular cast iron in this region is improved, the structure homogeneity and performance of the large-section nodular cast iron are improved, and a low-temperature high-toughness large-section ferrite-based nodular cast iron piece is obtained; the low-temperature high-toughness large-section ferrite-based nodular cast iron piece is excellent in impact resistance and good in tensile property under -20 DEG C and -40 DEG C; and the technical problems that the large-section nodular cast iron piece is easy to be inhomogeneous in structure and bad in strength and low-temperature impact toughness comprehensive performance are solved.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD +1

High-silicon wrought aluminum alloy material and production method thereof

InactiveCN104745897AImprove organizational formImprove mechanical propertiesIngot castingAluminium alloy

The invention provides a high-silicon wrought aluminum alloy material and a production method thereof. The high-silicon wrought aluminum alloy material comprises the following components in percentage by weight: 8.0%-11.0% of Si, 4.0%-6.5% of Cu, 2.0%-3.6% of Mg, 0.5%-2.5% of Mn, 7.5%-9.5% of Zn, Cr is less than or equal to 0.50%, Ti is less than 0.05%, Ni is less than 0.05%, and the balance of Al, wherein each other impurity monomer is less than or equal to 0.05%, and other impurities are less than or equal to 0.15%. The production method comprises the following steps and main process parameters: when the smelting temperature reaches 700-750 DEG C, adding 0.02%-0.05% of an Sr alterant according to the total weight of the raw materials in an Al-Sr intermediate alloy manner, then carrying out deaeration at 710-720 DEG C, filtering the impurities, and carrying out refining and ingot casting. According to the production method, the organization form of high-silicon aluminum alloy is effectively improved, and the mechanical property of the aluminum alloy is improved.

Owner:薛元良

Frozen surimi quality improver, and preparation method and application thereof

InactiveCN106333351ACompatibility is scientific and reasonableGood securitySugar food ingredientsFood ingredient as anti-freezing agentGel strengthFlavor

The invention discloses a frozen surimi quality improver. The frozen surimi quality improver comprises, by mass, 5-10% of an antifreeze agent, 20-30% of a water retaining agent, and the balance of a gel enhancer. The frozen surimi quality improver is obtained through continuous screening and optimization, has the advantages of scientific and reasonable compatibility, good safety, great improvement of the gel strength, the texture, the water retaining ability, the adhesion ability and other characteristics of frozen surimi on the premise of keeping the flavor of the frozen surimi, and effective improvement of the quality of the frozen surimi. The invention also provides a preparation method of the frozen surimi quality improver. The frozen surimi quality improver is obtained through compounding above components. The preparation method has the advantages of simple technologic steps, easiness in enforcement, no special requirements on devices, and low preparation cost.

Owner:ZHEJIANG OCEAN UNIV

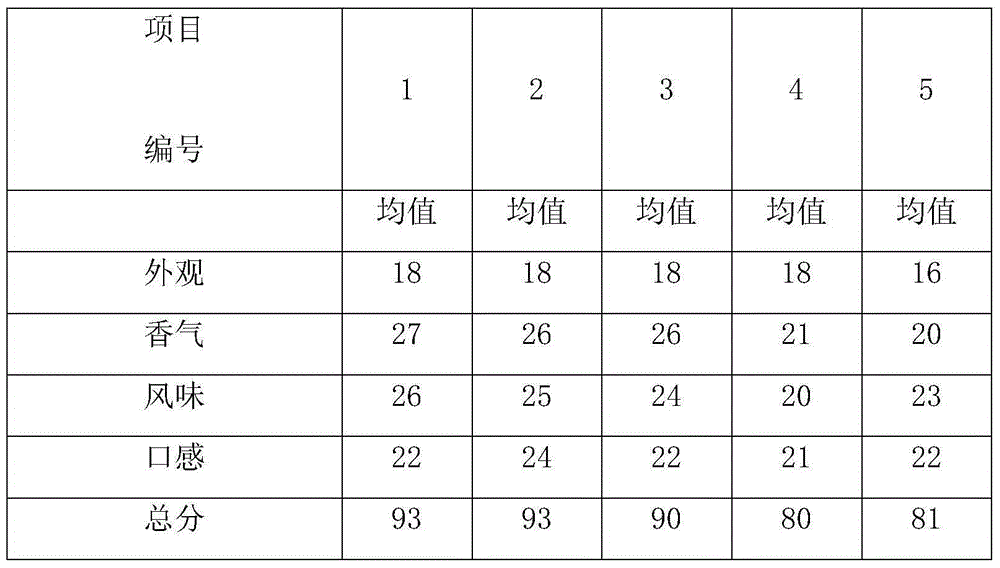

Method for making resistant starch-containing cookies

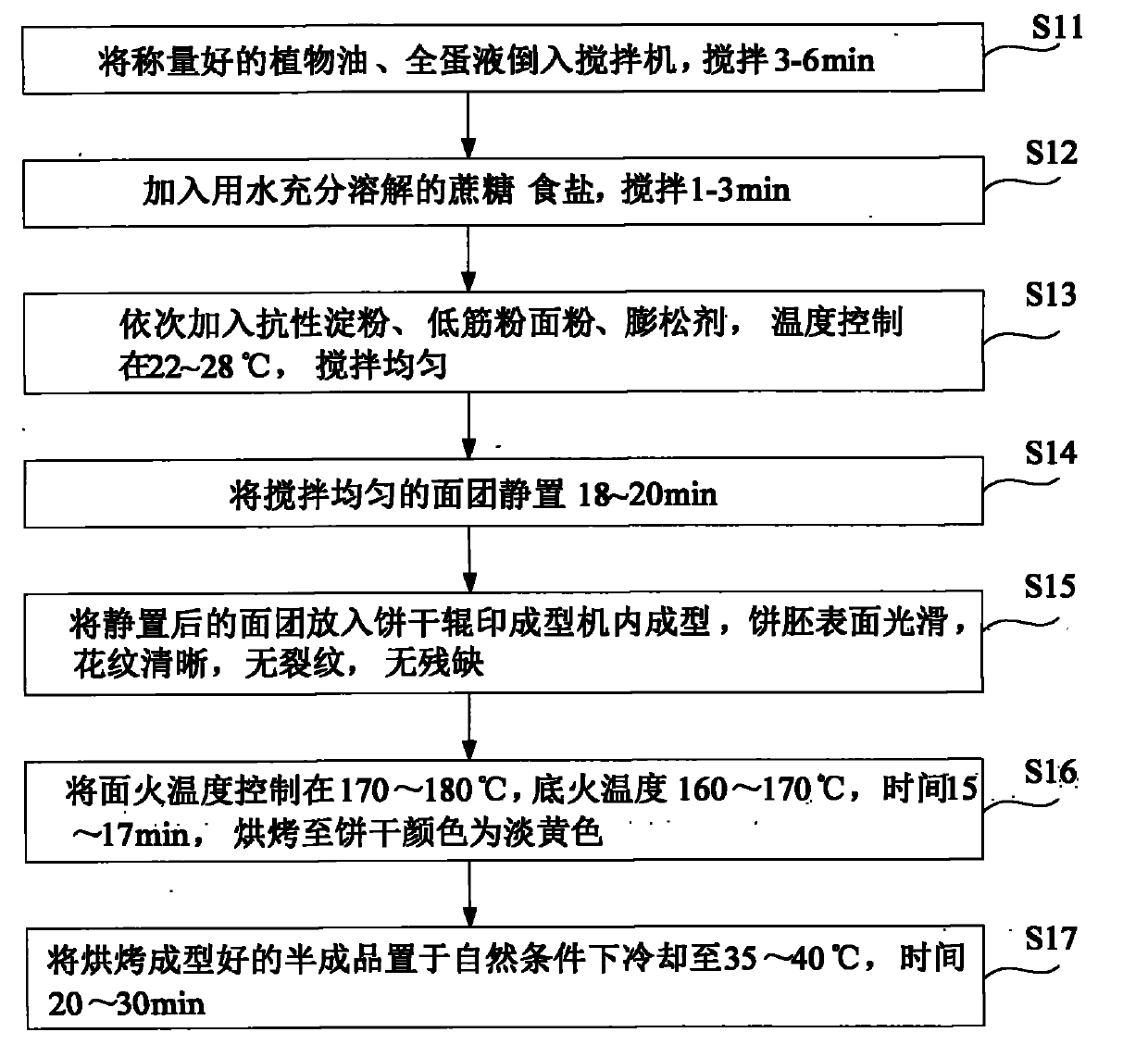

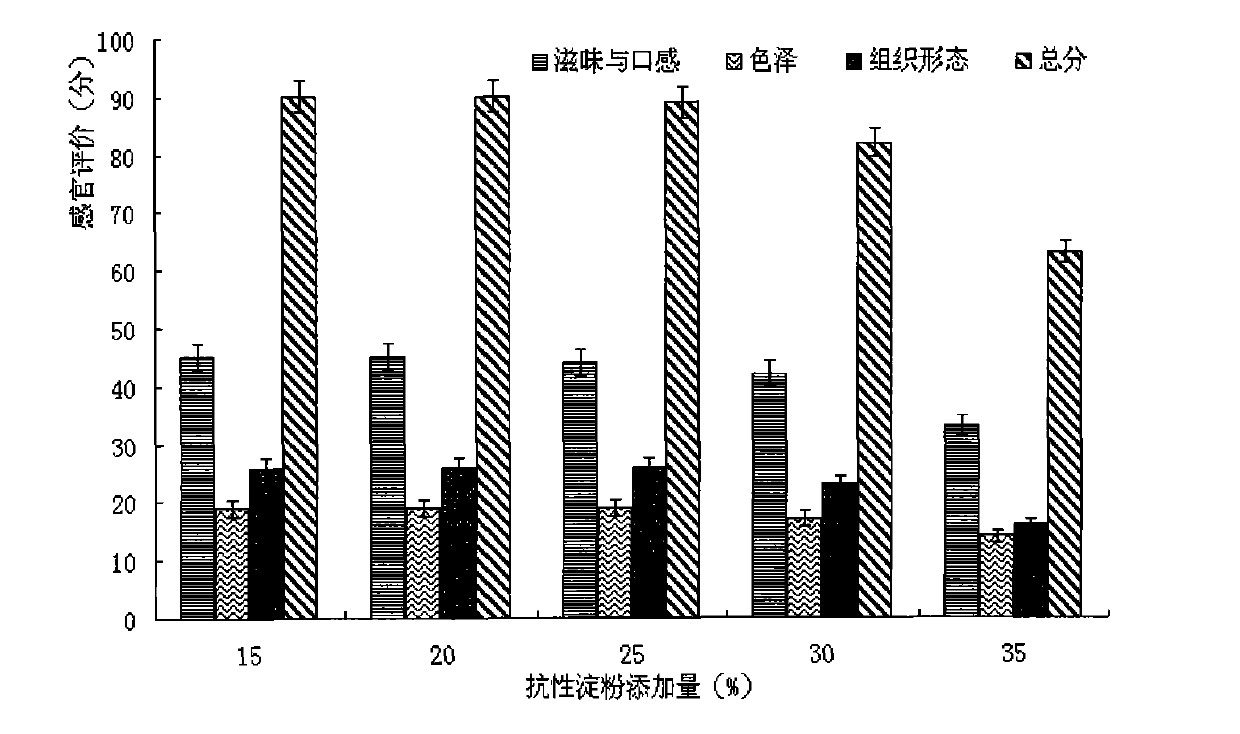

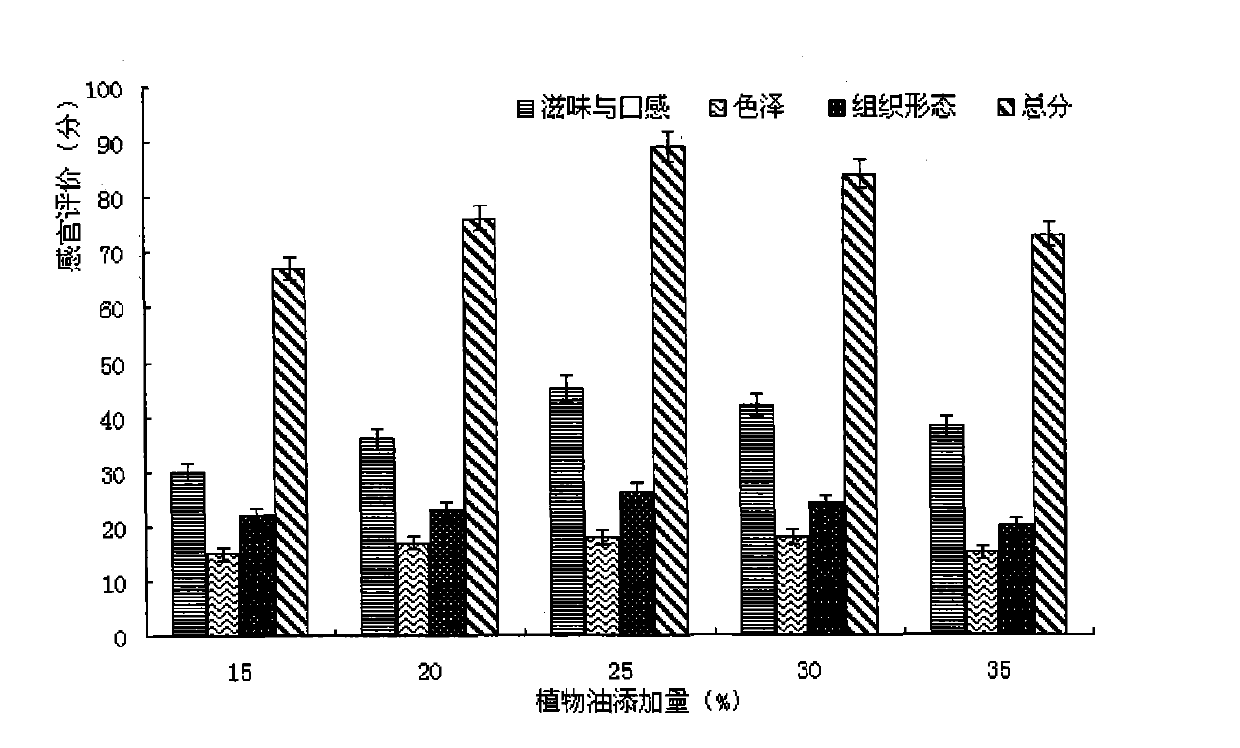

InactiveCN102986803AGood colorImprove organizational formDough treatmentBakery productsSucroseVegetable oil

The invention discloses a method for making resistant starch-containing cookies, belonging to the field of baking food processing technology; and the cookies made by the method are good in color and structural form. The method comprises the steps of: pouring the weighed vegetable oil and egg pulp into an agitator and stirring for 3-6min; adding cane sugar and table salt which are fully dissolved by water into the agitator, and stirring for 1-3min; adding resistant starch, low-gluten flour and swelling agent into the agitator, and evenly stirring; standing the evenly stirred dough for 18-20min; molding the dough into a cookie roller print molding machine; controlling the surface fire temperature to be 170-180 DEG C and the bottom fire temperature to be 160-170 DEG C for 15-17min, and baking until the cookies are faint yellow; and finally, cooling to 35-40 DEG C for 20-30min under the natural conditions. The resistant starch-containing cookies are prepared from the following raw materials in proportion: 100% of low-gluten flour taken as reference, 2.0% of egg pulp, 1.0% of table salt, 10.0% of water, 20.0-30.0% of vegetable oil, 25.0-32.0% of cane sugar, 1.3-1.9% of swelling agent and 15.0-30.0% of resistant starch. The method is suitable for making the resistant starch-containing cookies.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

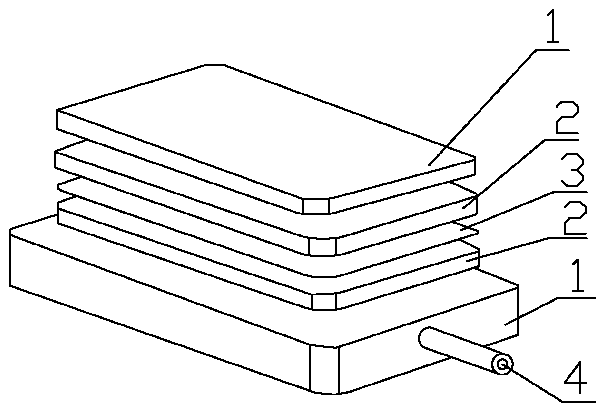

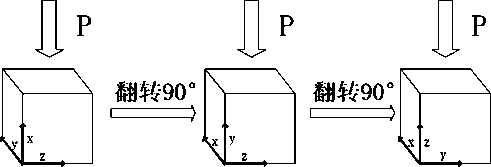

Pulse current assisting titanium-TiAl composite plate non-sheath rolling method

ActiveCN110711774AImprove organizational formImprovement ingredientsForging/pressing devicesMetal rolling arrangementsBond interfaceTitanium

The invention relates to the field of preparing of alloy materials, in particular to a pulse current assisting titanium-TiAl composite plate non-sheath rolling method. The pulse current assisting titanium-TiAl composite plate non-sheath rolling method aims at solving the problems that a plate prepared through an existing foil metallurgy method for titanium-TiAl composite plates is small in size, not uniform in thickness, large in component deviation and low in strength and plasticity, and the problems that a sheath hot rolling method is high in cost, complex in technology and high in rolling temperature, and the quality and performance of composite plates need to be further improved are solved. The pulse current assisting titanium-TiAl composite plate non-sheath rolling method includes thespecific steps that firstly, a titanium alloy plate is prepared; secondly, a TiAl alloy plate is prepared; thirdly, non-sheath assembling is conducted; fourthly, pulse current auxiliary hot rolling is conducted; and fifthly, separating and subsequent treatment are conducted, and a titanium-TiAl composite plate can be obtained. The composite plate obtained in the pulse current assisting titanium-TiAl composite plate non-sheath rolling method is good in surface quality, free of oxide layer disengagement, free of edge portion and end portion cracking, uniform and small in plate organization, good in bonding interface and good in mechanical performance.

Owner:TAIYUAN UNIV OF TECH

Health preserving whole-cereal milk and preparation method thereof

The invention relates to health preserving whole-cereal milk and a preparation method thereof, belonging to the technical field of formulated milk. The health preserving whole-cereal milk comprises the following raw materials by weight percent: 1-1.5% of compound medlar concentrated juice, 1-2% of red date concentrated juice, 2-10% of brown rice, oat and corn compound enzymatic hydrolysate, 0.1-0.3% of stabilizing agent, 0.1-0.3% of lucid ganoderma extract, 0.5-1% of longan concentrated juice, 0.1-0.2% of Chinese yam polysaccharides, 0.05-0.1% of black sesame powder, 0.01-3% of sweetening agent and the balance of raw milk. The health preserving whole-cereal milk is prepared by scientifically mixing medicinal and edible natural health care products such as medlar, Chinese dates, longan, Chinese yam, black sesame and the like with lucid ganoderma according to the principle of the traditional science of health preserving of traditional Chinese medicine and adding enzymatic hydrolysates of whole-cereals such as corn, brown rice, oat and the like to coordinate with milk. The product is nutritionally balanced and has good color, aroma and taste and prominent health care and preserving effects.

Owner:NINGXIA XIAJIN DAIRY GRP

Health preserving cereal milk and preparation method thereof

ActiveCN103271157ANutritional balanceGood health effectMilk preparationAdditive ingredientHydrolysate

The invention relates to health preserving cereal milk and a preparation method thereof, belonging to the technical field of formulated milk. The health preserving cereal milk comprises the following raw materials by weight percent: 2-3% of compound medlar concentrated juice, 1-2% of red date concentrated juice, 0.5-10% of wheat germ powder, 0.1-0.3% of stabilizing agent, 0.1-1% of lucid ganoderma extract, 0.5-3% of longan concentrated juice, 0.5-1% of Chinese yam polysaccharides, 0.05-0.5% of oat powder, 1-3% of buckwheat enzymatic hydrolysate, 0.05-0.2% of black sesame powder, 0.01-3% of sweetening agent and the balance of raw milk. The health preserving cereal milk is prepared by scientifically mixing medicinal and edible natural health care products such as medlar, Chinese dates, longan, Chinese yam and the like with lucid ganoderma called fairy grass according to the principle of the traditional science of health preserving of traditional Chinese medicine, then carrying out reasonable compatibility on the mixture and milk and adding cereals to make up for the deficiency of nutritional ingredients of milk. The health preserving cereal milk is nutritionally balanced and has good color, aroma and taste and certain health care and preserving effects.

Owner:NINGXIA XIAJIN DAIRY GRP

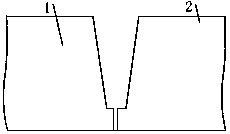

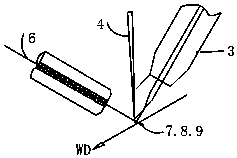

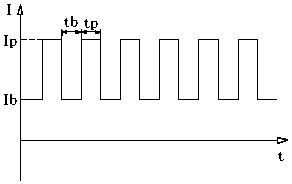

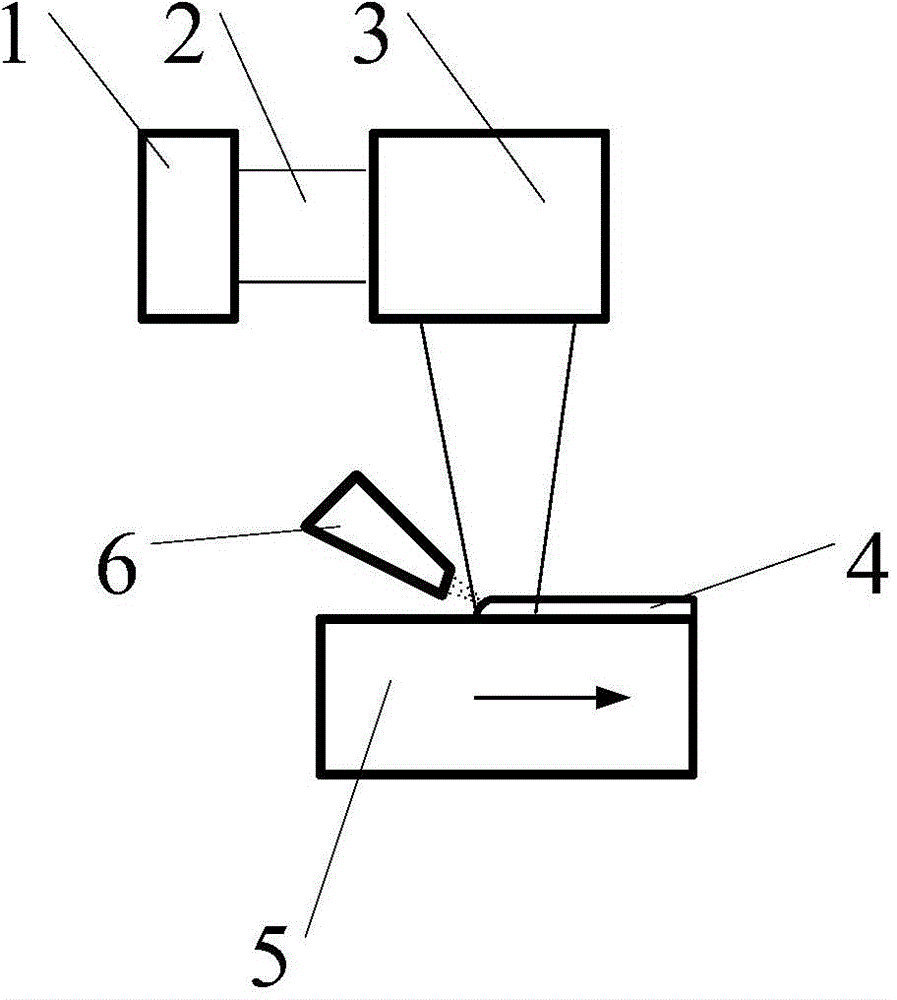

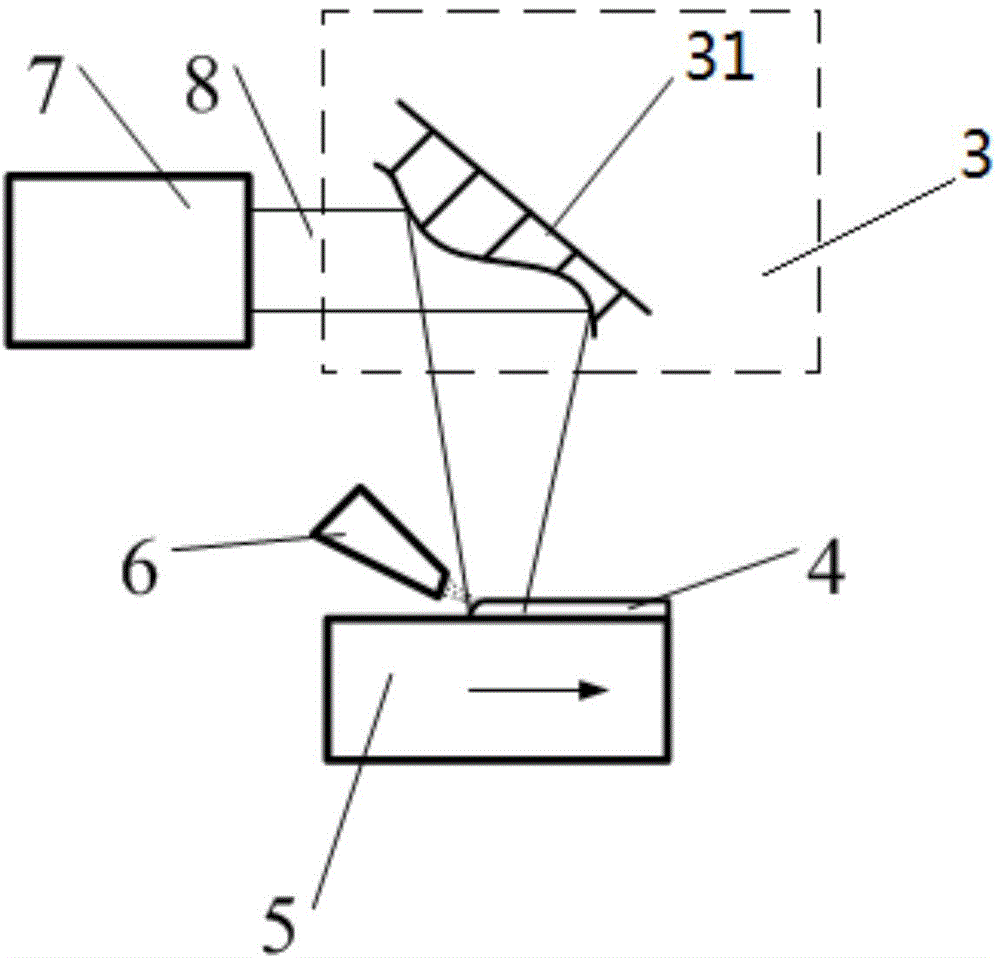

Scanning galvanometer laser-high frequency pulse TIG composite welding method

PendingCN110814552AExtended cooldownIncrease the area of actionLaser beam welding apparatusWelding accessoriesGalvanometerWeld seam

The invention provides a scanning galvanometer laser-high frequency pulse TIG composite welding method. A steel plate to be welded is made into a welding groove, and assembling and cleaning are carried out. A first workpiece to be welded is in butt joint with a second workpiece to be welded. The first workpiece to be welded and the second workpiece to be welded are thick steel plates. A welding seam to be welded with the selected width and length is formed between the two workpieces to be welded. A welding wire is used, laser beams generated by a scanning galvanometer laser-high frequency pulse TIG composite welding gun and a TIG welding gun are used for travelling welding for the welding seam in the direction from one end to the other end, and a mode of a straight-line swing, a circular swing or a "8-shaped" swing is adopted in the welding process. According to the scanning galvanometer laser-high frequency pulse TIG composite welding method, scanning galvanometer laser-high frequencypulse TIG composite welding is adopted, the probability of pore generation can be reduced, the welding seam property is improved, the welding seam heat input is reduced, and the welding deformation is reduced. The scanning galvanometer laser-high frequency pulse TIG composite welding method is suitable to be used as a method of swing laser-high frequency pulse TIG composite welding for members ofthick wall high-strength steel, stainless steel and the like.

Owner:中国船舶集团渤海造船有限公司

Making method of hot air-dried and quick-frozen tomato

InactiveCN102405959AKeep the tasteKeep the flavorFruits/vegetable preservation by freezing/coolingFruits/vegetable preservation by dehydrationFood flavorWater content

The invention relates to a making method of hot-air-dried and quick-frozen tomato. The making method mainly comprises the following steps in sequence: (1) cleaning and removing stems; (2) slicing; (3) drying; (4) quick-freezing; (5) removing scraps; (6) sorting; (7) performing metal detection; (8) packaging and sealing; and (9) freezing and storing. The water content in the tomato made according to the making method reaches 25-35%, the taste and flavor of the fresh tomato are kept, the nutrient loss is low, and the tomato can be used as basic material of pizzas, salads and sauces and is very popular in European and American areas.

Owner:YUNNAN LONGYUN DAYOU IND CO LTD

Wear-resistant vanadium-titanium gear and preparation method thereof

InactiveCN105154786AStrong oxidation and corrosion resistanceHigh bending strength and fatigue strengthSolid state diffusion coatingFurnace typesTungstenIsothermal annealing

The invention discloses a wear-resistant vanadium-titanium gear and a preparation method thereof. The wear-resistant vanadium-titanium gear is composed of the following components in percentage by weight: 0.18-0.33% of carbon, 2.3-3.8% of chromium, 0.3-0.5% of manganese, 0.17-0.25% of silicon, 3.8-4.2% of nickel, 1.0-1.8% of tungsten, 1.10-2.15% of vanadium, 1.48-2.57% of titanium, 0.21-0.34% of copper, 1.3-2.1% of molybdenum, 0.18-0.32% of rare earth, 0.0018-0.0041% of boron, at most 0.035% of sulfur and phosphorus, and the balance of iron and inevitable impurities. The method comprises the following steps: preheating treatment, isothermal annealing treatment, primary quenching, primary tempering, carburizing treatment, high-temperature tempering, secondary quenching, secondary tempering and shot blasting. The finally obtained gear has the advantages of high mechanical properties (wear resistance, fatigue resistance, hardness and the like), favorable comprehensive properties and longer service life, and is especially suitable for the high-speed heavy-load high-impact-force occasions with the gear module of greater than 6.

Owner:何鹏

Preparation method for TiAl-Ni alloy plate with high strength and toughness and high stability

ActiveCN110643853AEasy to handleImprove thermal deformation abilityMetal rolling arrangementsIngotUltimate tensile strength

The invention relates to the field of preparation of alloy materials, in particular to a preparation method for a TiAl-Ni alloy plate with high strength and toughness and high stability. The preparation method aims to solve the problems of uneven structure and poor mechanical properties caused by excessive grain growth and process heredity of a TiAl alloy plate material prepared through existing ingot metallurgy and powder metallurgy methods, especially the problems of low strength and plasticity. The preparation method comprises the following steps of 1, weighing raw materials; 2, smelting acast ingot; 3, carrying out primary pretreatment on a blank; 4, carrying out secondary pretreatment on the blank; 5, carrying out jacketing and hot rolling; 6, carrying out stabilizing treatment; and7, removing a jacket so as to obtain the TiAl alloy plate. The plate obtained through the preparation method has the advantages of being good in surface quality, fine and uniform in structure, good inmechanical property and high in repeatability.

Owner:TAIYUAN UNIV OF TECH

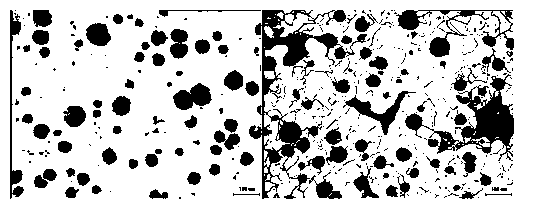

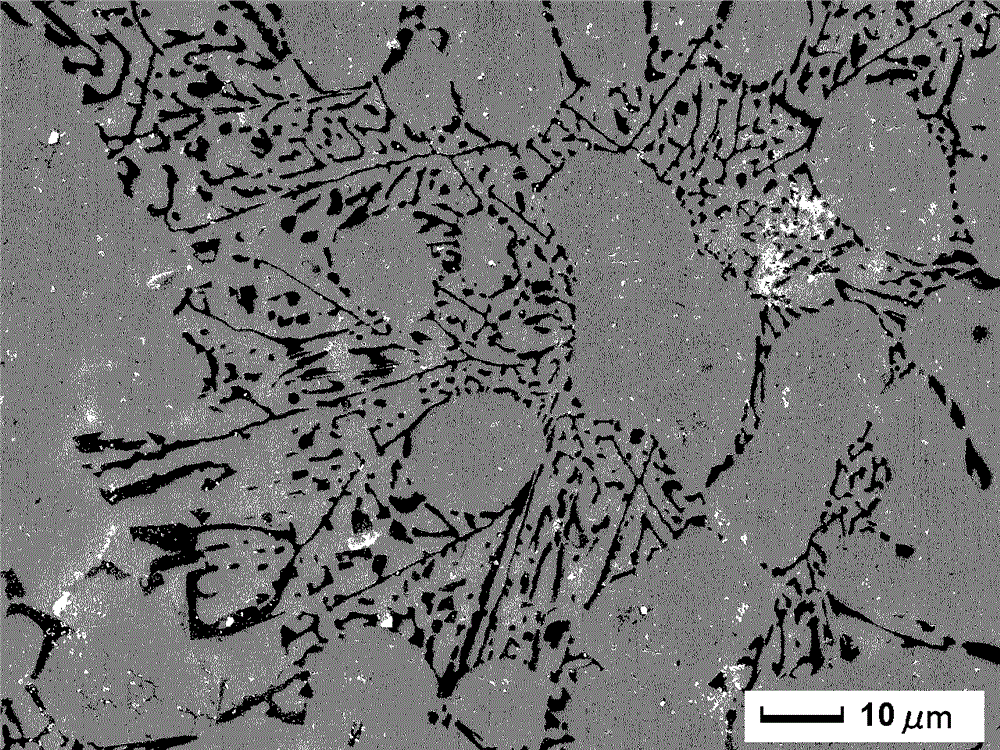

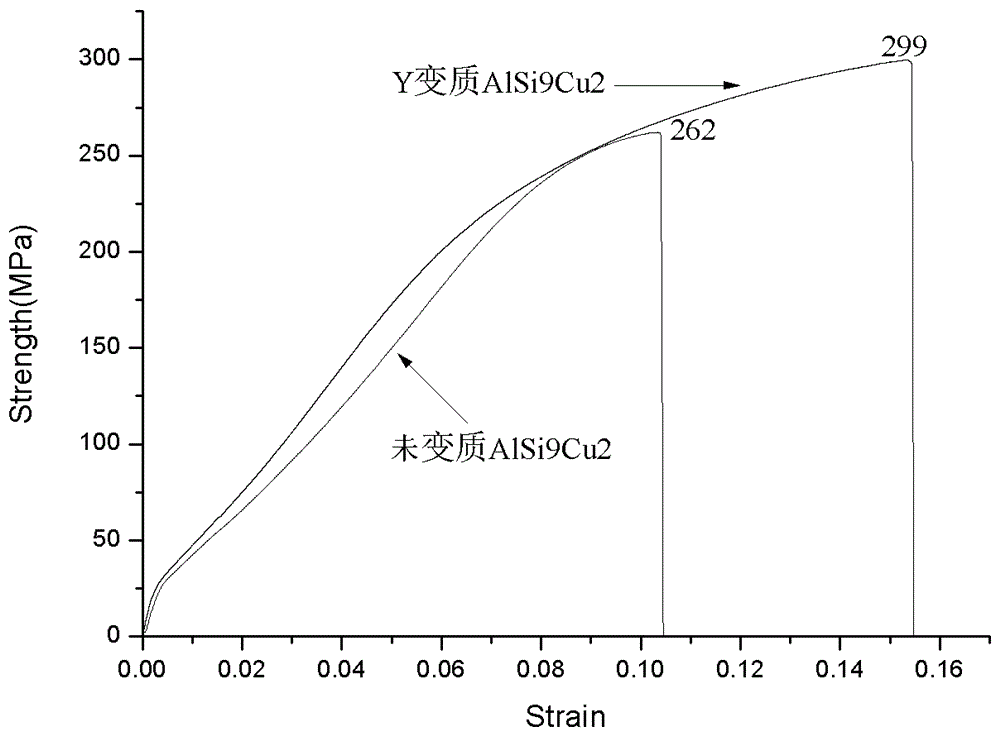

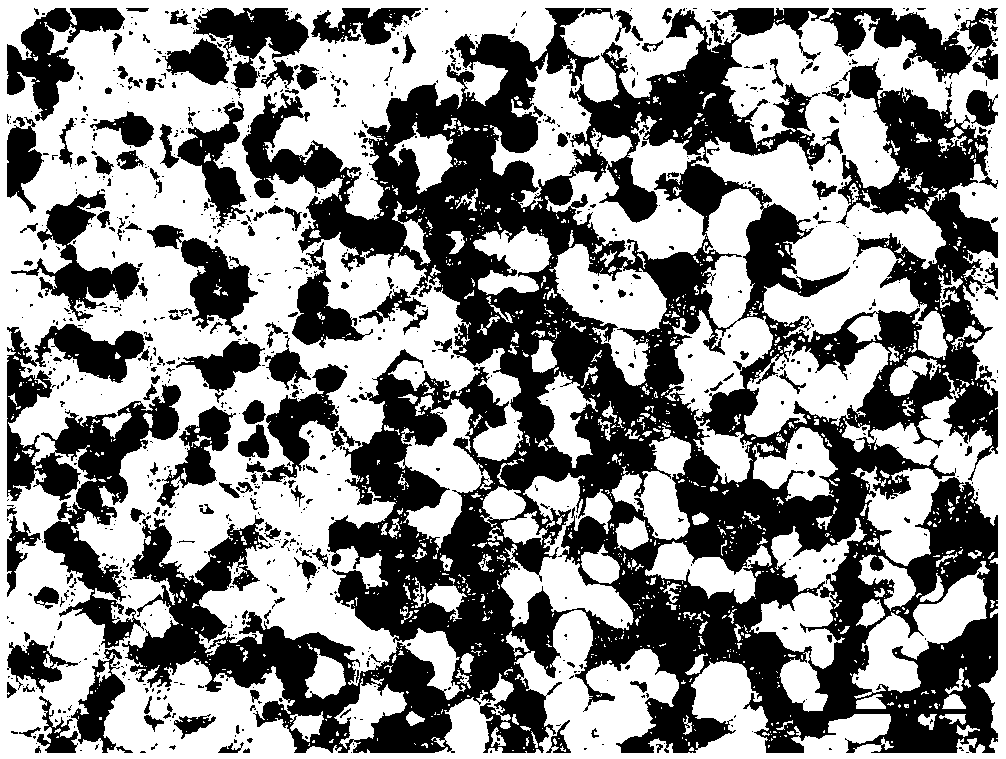

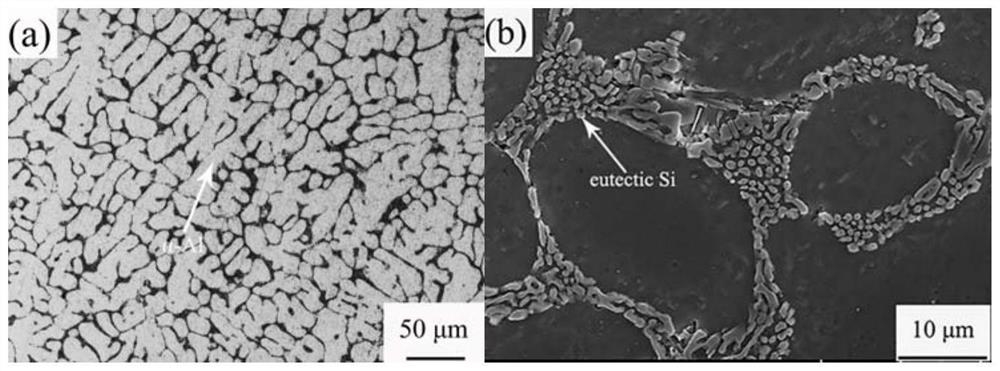

Method for modifying AlSi9Cu2 cast aluminum alloy by rare-earth Y

The invention discloses a method for modifying an AlSi9Cu2 alloy by rare-earth Y, and relates to a method for modifying a cast aluminum-silicon alloy. By using the method for modifying the AlSi9Cu2 alloy by the rare-earth Y, the problem that a gas-hole defect exists in an AlSi9Cu2 cast alloy obtained by adopting a modifier Sr is solved. The method provided by the invention comprises the following steps of weighing to take high-purity aluminum, an Al-2OSi intermediate alloy, high-purity copper and an Al-10Y intermediate alloy raw material, fusing the high-purity aluminum and the Al-2OSi intermediate alloy, then pressing the high-purity copper into an obtained first mixture, smelting an obtained second mixture to obtain a fused mass, then adding the Al-10Y intermediate alloy into the fused mass, smelting an obtained third mixture, and pouring the smelted third mixture, so that the AlSi9Cu2 alloy is obtained subsequently. The method provided by the invention is simple, and is suitable for mass production. No gas holes exist in the obtained Y-modified AlSi9Cu2 alloy; the cast structure of the alloy is obviously thinned; the obdurability of the AlSi9Cu2 alloy is improved; and the compactability of a casting is increased.

Owner:镇江创智特种合金科技发展有限公司

Plant composite enzyme and preparation method thereof

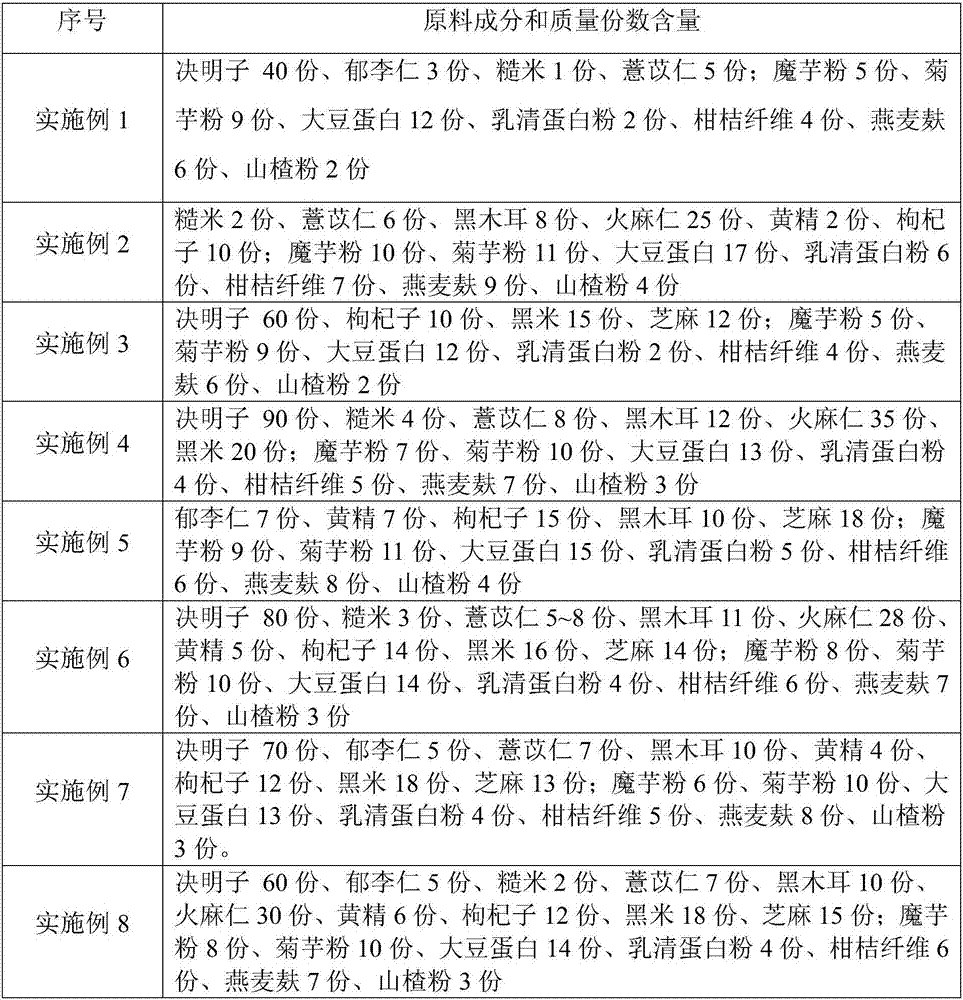

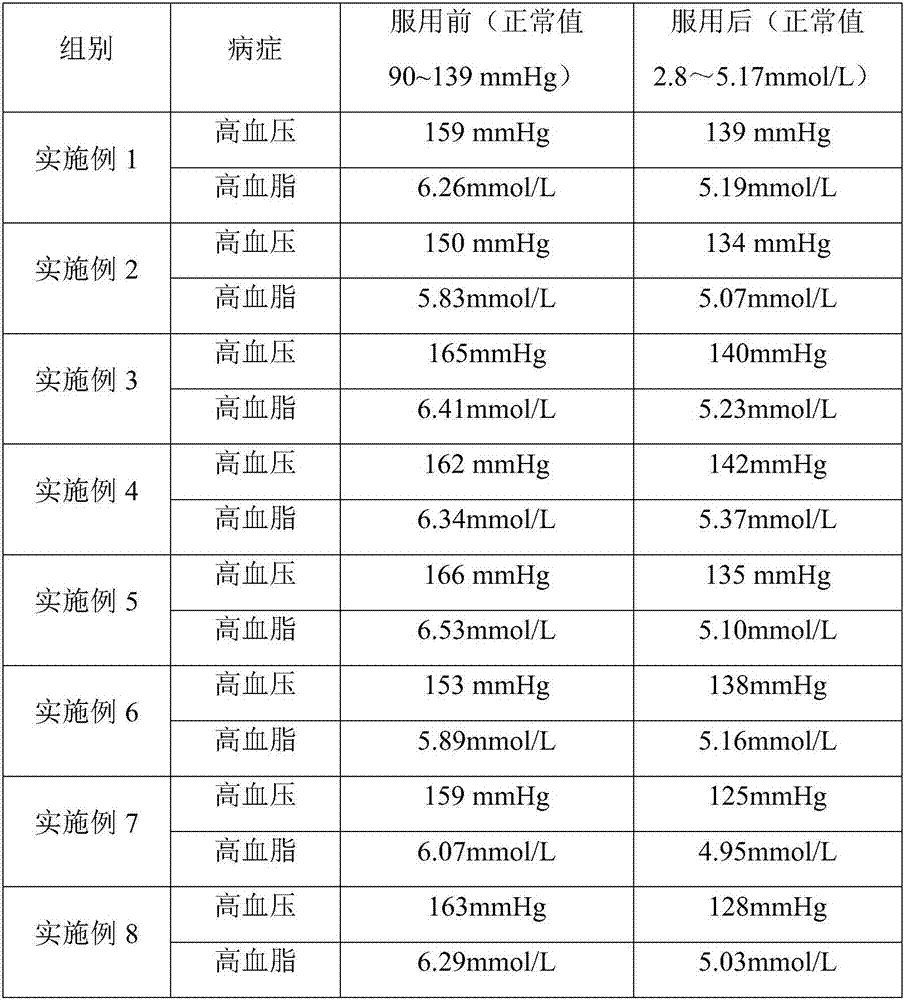

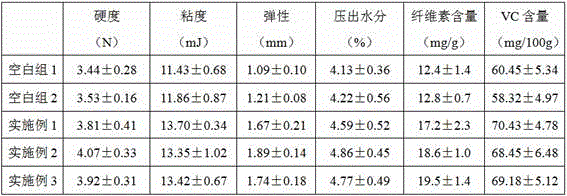

ActiveCN107183688AGood effectRegulate gut floraFood ingredient functionsPhysiological functionWhey protein powder

The invention provides a plant composite enzyme. The plant composite enzyme comprises main materials and auxiliary materials, wherein the main materials are selected from at least four types of semen cassiae, semen pruni, brown rice, semen coicis, black fungus, fructus cannabis, rhizoma polygonati, fructus lycii, black rice and sesame; the auxiliary materials comprise konjaku flour, jerusalem artichoke flour, soybean protein, whey protein powder, citrus fiber, oat bran and hawthorn powder. The plant composite enzyme has the advantages that the main raw materials are traditional Chinese medicines with medicine and food homology property, are fermented and processed, and are matched with other beneficial raw materials; by adopting the technical scheme, the main functions of relaxing bowel, clearing intestines and detoxifying, adjusting balance of intestinal flora, and balancing and nourishing intestines are realized, and other multiple physiological function of assisting for reducing blood glucose and blood pressure and the like are realized.

Owner:河北中佳本草生物技术有限公司

Processing method of instant vegetable and surimi convenient products

InactiveCN105767940ADestroy cell structureGood compatibilityFood scienceUltrasonic assistedProcess engineering

The present invention discloses a processing method of instant vegetable and surimi convenient products. The processing method includes the following steps: pre-processing, meat collecting, rinsing, pre-dehydrating, refinedly filtering and dehydrating, high pressure homogenizing to prepare a vegetable homogenate, ultrasonic assisted grinding, molding, ultrasonic assisted cooking and aging, low-pressure superheated steam drying and packaging. The obtained product is rich in nutrition, excellent in color, smell and taste and good in taste, can maintain color and luster of vegetables, and is high in dietary fiber content and a healthy food suitable for people at all ages.

Owner:FUJIAN AGRI & FORESTRY UNIV

Patterned non-woven fabric with concave-convex patterns and preparing method of patterned non-woven fabric

InactiveCN105544090AImprove organizational formEffective treatment effectPattern makingNon-woven fabricsCarbon fibersOptoelectronics

The invention provides a patterned non-woven fabric with concave-convex patterns and a preparing method of the patterned non-woven fabric. The preparing method comprises the following steps that firstly, short fibers of superfine fibers and bamboo carbon fibers are opened and carded to be fully mixed, and then the mixed fibers are laid into a mixed fiber net in a crossed net laying mode; secondly, short fibers of the superfine fibers and bamboo carbon fibers are laid into a superfine fiber net and a bamboo carbon fiber net respectively in the mode of opening, carding and crossed net laying, and then the bamboo carbon fiber net is laid on the surface of the superfine fiber net to form a composite fiber layer; thirdly, the front and back sides of the mixed fiber net prepared in the first step or the front and back sides of the composite fiber layer prepared in the second step are subjected to basic spunlace reinforcing, then the structure and number of spunlace stitches are adjusted, and a fiber net containing initial surface texture is obtained after dehydration and pre-drying; fourthly, the fiber net, containing the initial surface texture, prepared in the third step passes through a concave-convex hot roller with the concave-convex rugged surface, drying and sizing are carried out, and the patterned non-woven fabric with the concave-convex patterns is obtained.

Owner:SUZHOU INSILK CO LTD

Saccharomyces cerevisiae and application thereof in preparation of fermented food

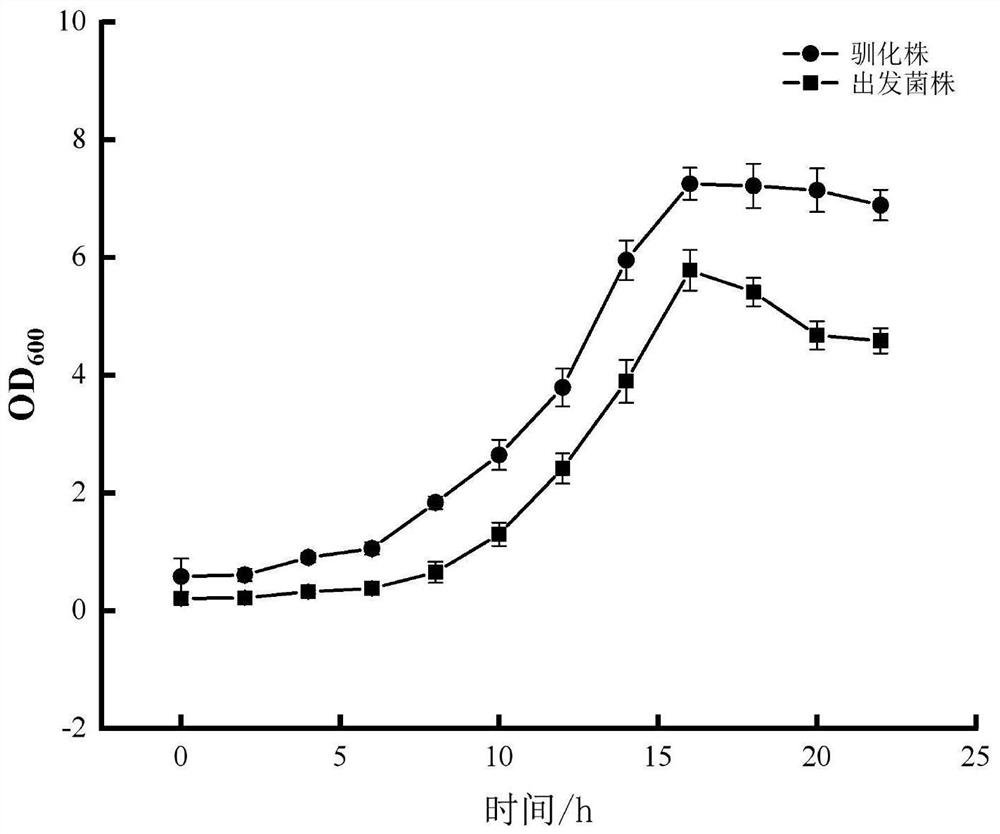

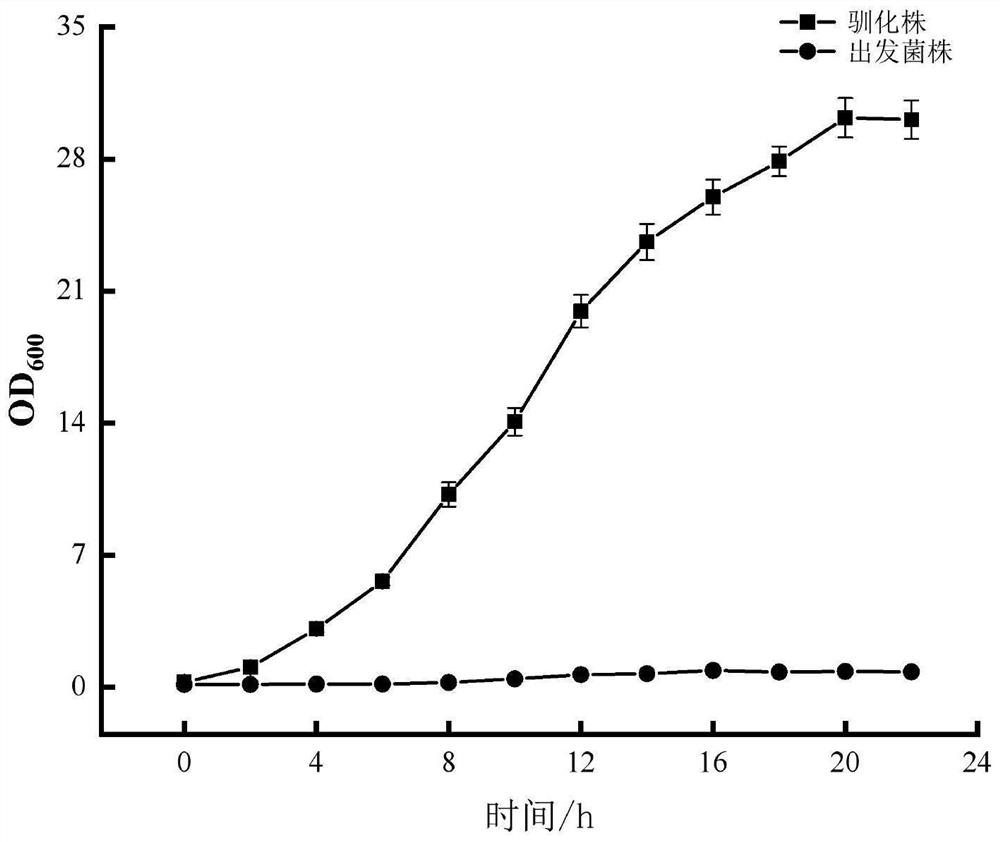

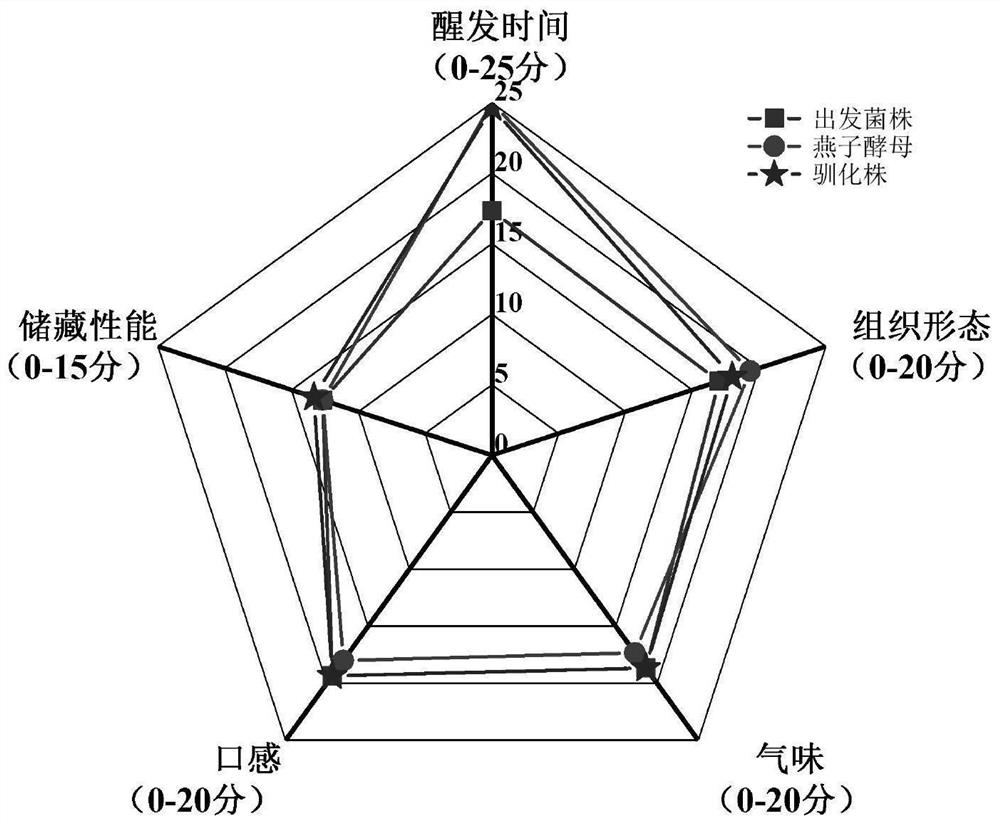

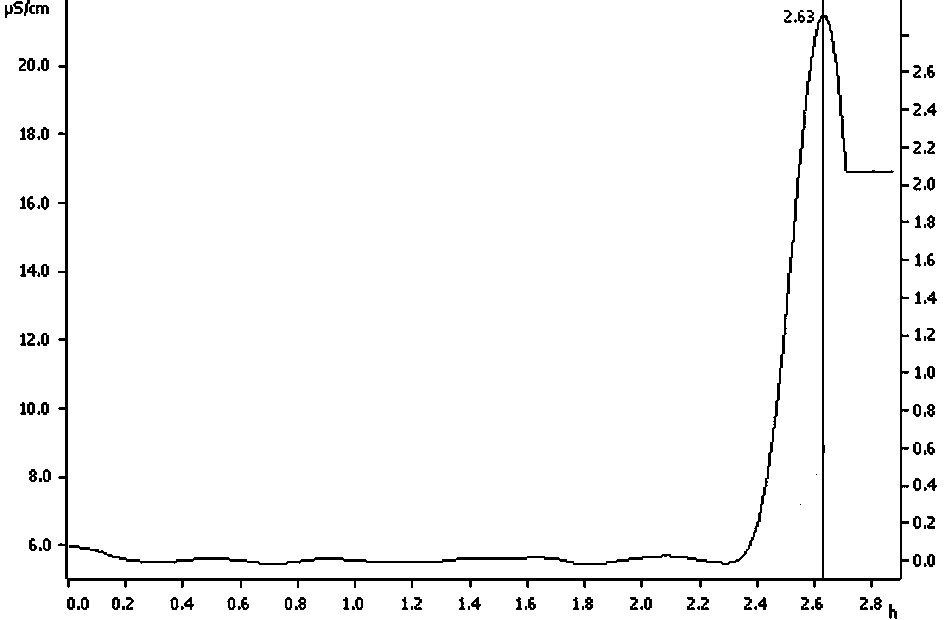

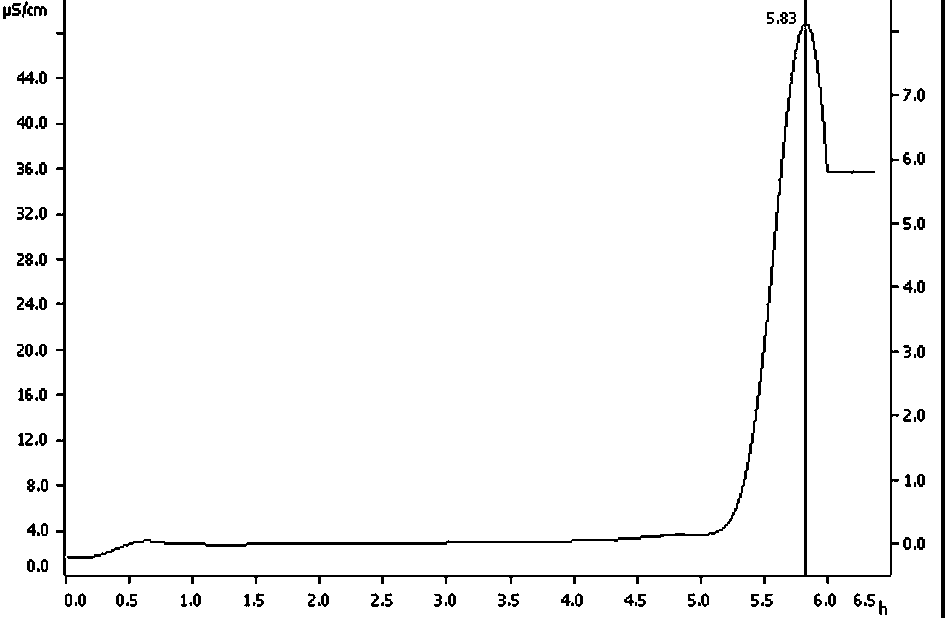

ActiveCN111607529AStrong awakening abilityGood texture and storage propertiesFungiPre-baking dough treatmentSaccharomyces cerevisiaeBiotechnology

The invention discloses saccharomyces cerevisiae and application thereof in preparation of fermented food, and belongs to the technical field of microorganisms. The saccharomyces cerevisiae LBBE-1 with the preservation number of GDMCC No:60989 disclosed by the invention can resist high sugar and high salt; the saccharomyces cerevisiae LBBE-1 is cultured in a high-sugar and high-salt environment with the glucose concentration of 300g / L and the NaCl concentration of 20g / L for 20 hours to reach a stable period; moreover, the OD600 of a culture solution obtained by culturing the saccharomyces cerevisiae LBBE-1 in a high-sugar and high-salt environment with the glucose concentration of 300g / L and the NaCl concentration of 20g / L for 20 hours is as high as 30.18 and is improved by 33.30 times compared with that of the original strain saccharomyces cerevisiae LBBE-1.

Owner:JIANGNAN UNIV

Compound thickening agent for improving texture and emulsifying property of meat product and preparation method and application thereof

The invention provides a compound thickening agent for improving the texture and emulsifying property of a meat product and a preparation method and application thereof. The compound thickening agentis prepared from Sanzan gum, sodium hyaluronate, xanthan gum, konjac glucomannan, flaxseed gum and curdlan gum, the Sanzan gum, the sodium hyaluronate, the xanthan gum, the konjac glucomannan, the flaxseed gum and the curdlan gum are weighed according to the specified weight part ratio, added in sequence and mixed, and after uniform mixing, the compound thickening agent is obtained. On the premisethat the cost is little increased, the texture property, the water binding capacity, the gel strength and the yield of the meat product can be improved by using the compound thickening agent; the compound thickening agent is used in the production process of the meat product, materials can be significantly emulsified and evenly mixed, fat separation is prevented, the water-retaining property andthe hardness of the product are improved, the tissue form of the product is improved, the elasticity of the meat product is increased, the machining operability is improved, adhesion is reduced, demoulding and slicing are facilitated, and the quality of the meat product is improved.

Owner:北京美添前景科技有限公司

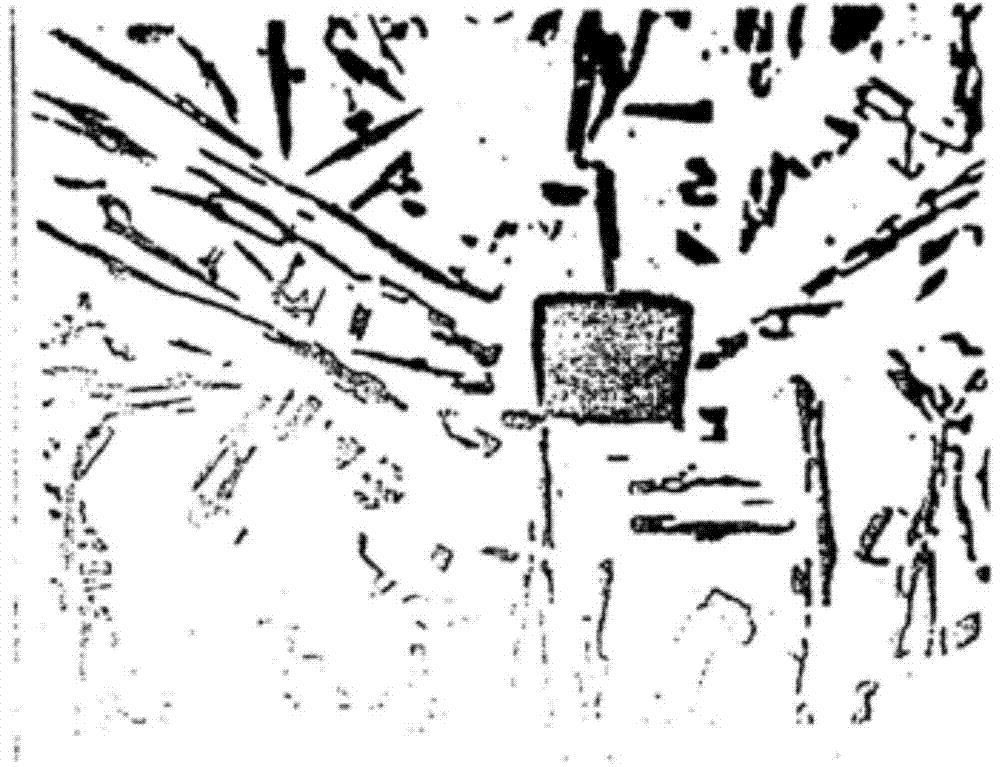

High-strength-and-ductility gray pig iron surface tissue form heating power reconstruction method

The invention discloses a high-strength-and-ductility gray pig iron surface tissue form heating power reconstruction method, and relates to metal material surface modification. The method mainly comprises the steps of gray pig iron surface magnetic control forced cooling laser fusion, laser shock and follow-up graphitization annealing treatment. Firstly, laser radiation is carried out to enable the gray pig iron surface to generate quick fusion under the action of a magnetic field, forced cooling solidification is carried out, and the wee surface white tissue is formed; secondly, laser shock is adopted for treating the gray pig iron surface obtained after laser fusion, the stress state of a fusion layer is changed, the white tissue on the surface layer is further refined, the tissue defectis increased, and tissue preparation is made of graphitization annealing; and finally, graphitization annealing is carried out to enable cementite in the surface refined whit tissue to be converted into wee spheroidal graphite, and the high-strength-and-ductility surface tissue form is prepared. By means of the method, the gray pig iron surface tissue form can be effectively improved, the graphitization time is shortened, and the surface obdurability is obviously improved. The high-strength-and-ductility gray pig iron surface tissue form heating power reconstruction method is simple in process procedure, easy to operate and suitable for large-scale batched production.

Owner:JIANGSU UNIV

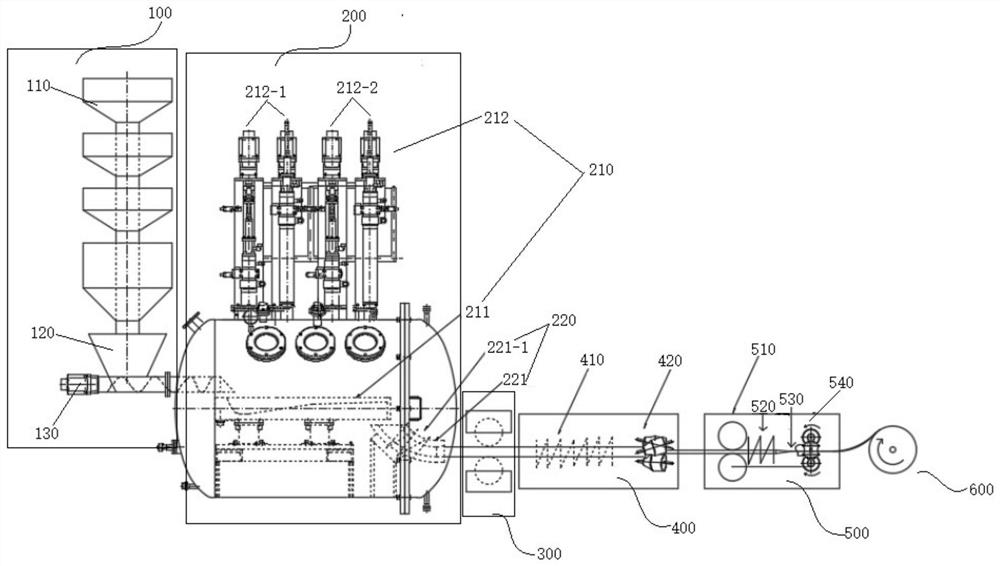

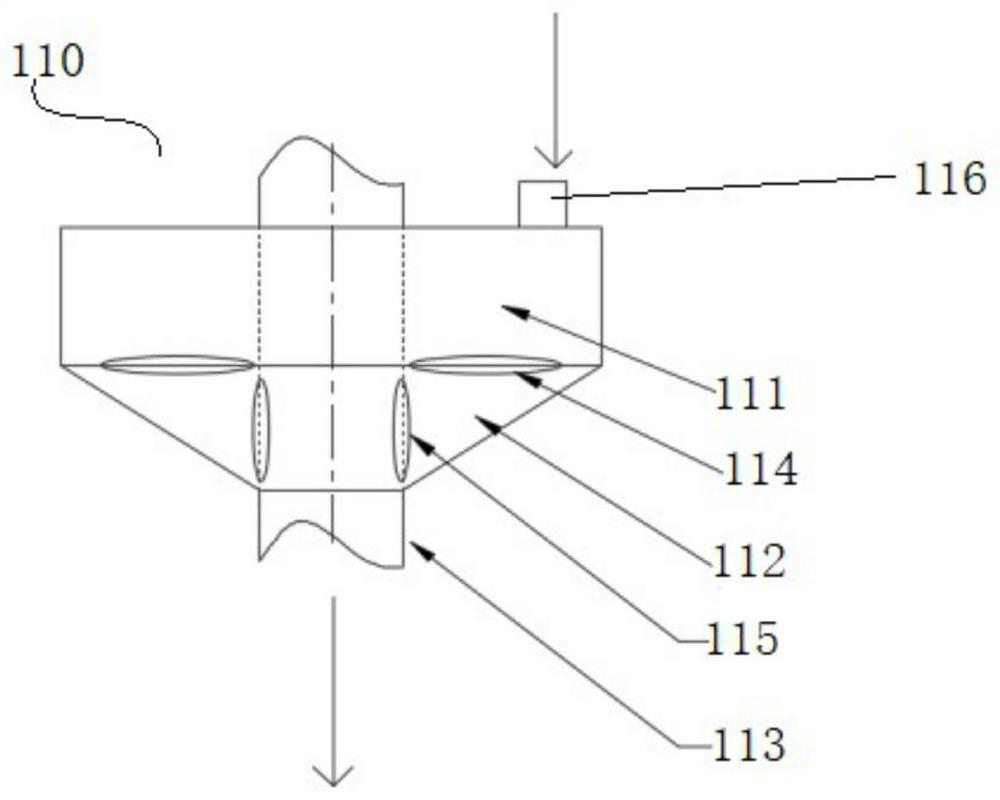

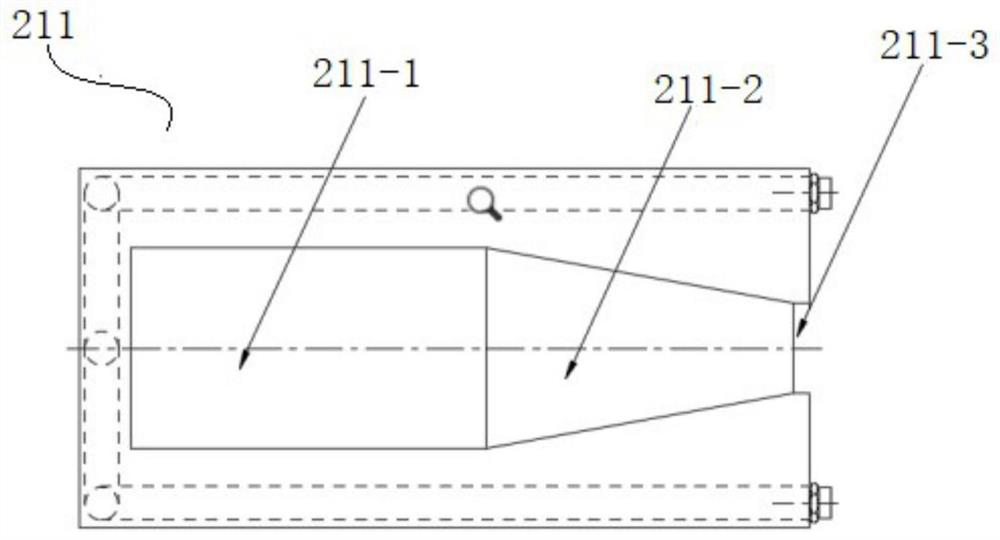

Short-process continuous casting and continuous extrusion equipment for titanium or titanium alloy wires and preparation method for wires

The invention provides short-process continuous casting and continuous extrusion equipment for titanium or titanium alloy wires. The short-process continuous casting and continuous extrusion equipment comprises a mixing and feeding device, a melting and ingot casting device, a pulling device, a continuous rod making device, a continuous wire drawing device and a wire winding device. Different kinds of raw materials enter a cooling bed in the melting and ingot casting device after being fed and mixed, metal liquid is formed through heating and smelting of a plasma gun, the metal liquid overflows into a crystallizer for ingot casting forming, formed ingots enter the continuous rod making device after being pulled out through the pulling device, the structure form needed by wire drawing is obtained through the continuous rod making device, then the ingots enter the continuous wire drawing device for wire drawing to obtain formed wires, and the formed wires are wound into a reel through the wire winding device. The invention further provides a short-process preparation method for the titanium or titanium alloy wires. According to the short-process equipment for the titanium or titanium alloy wires, the machining procedure is shortened through continuous design, and the titanium alloy wires with more uniform components and better structure forms are obtained through the specific structural design of continuous casting and continuous extrusion.

Owner:江苏宇钛新材料有限公司

High dietary fiber milk beverage and preparation method thereof

InactiveCN105166048ABalanced and reasonable nutritionEasy to digest and absorbMilk preparationProtein contentWater soluble

The invention relates to a high dietary fiber milk beverage and a preparation method thereof, belonging to the technical field of milk beverage processing. In the high dietary fiber milk beverage, the total amount of modified dietary fiber is not less than 3g / 100mL, the fat content is 1.1-1.5g / 100g, and the protein content is not less than 1.0g / 100mL; the total sweetness is 60-120g / L; the acidity is 43-48 DEG T; the dose of a stabilizing agent is 0.1-0.2g / 100mL; and the modified dietary fiber is obtained by mixing onion powder, apple fiber, oat fiber and wheat germ fiber through ultrasonic extraction and biological enzymolysis. Meanwhile, soluble dietary fiber and non-water-soluble dietary fiber are replenished, so that the high dietary fiber milk beverage is easy to digest and absorb and not easy to cause excessive internal heat.

Owner:TIANJIN ZHONGTIAN JINGKE SCI & TECH

Method for preparing cloud and mist tea

InactiveCN103238687AAdapt to industrializationAdapt to requirementsPre-extraction tea treatmentNutritive valuesFlavor

The invention discloses a method for preparing cloud and mist tea. The method comprises the following steps of: cleaning green tea leaves, heating and dehydrating the tea leaves in vacuum, then rolling and further dehydrating the tea leaves, and the like. According to the processing technology, after being picked in a tea garden, the tea leaves are sorted, cleaned, dried, withered, subjected to fine manipulation, fried, rolled and then dried for forming; and a vacuum low-temperature solid continuous dryer is adopted for producing the cloud and mist tea with faint and mellow scent and rich fragrance, and the flavor of the cloud and mist tea does not change after the tea leaves are immersed for many times. The method can meet requirements on industrial and large-scale production; and furthermore, the nutritive value of the cloud and mist tea made by the method is higher than that of cloud and mist tea manufactured by conventional methods, and thus the economical benefit of the cloud and mist tea can be greatly improved.

Owner:张立

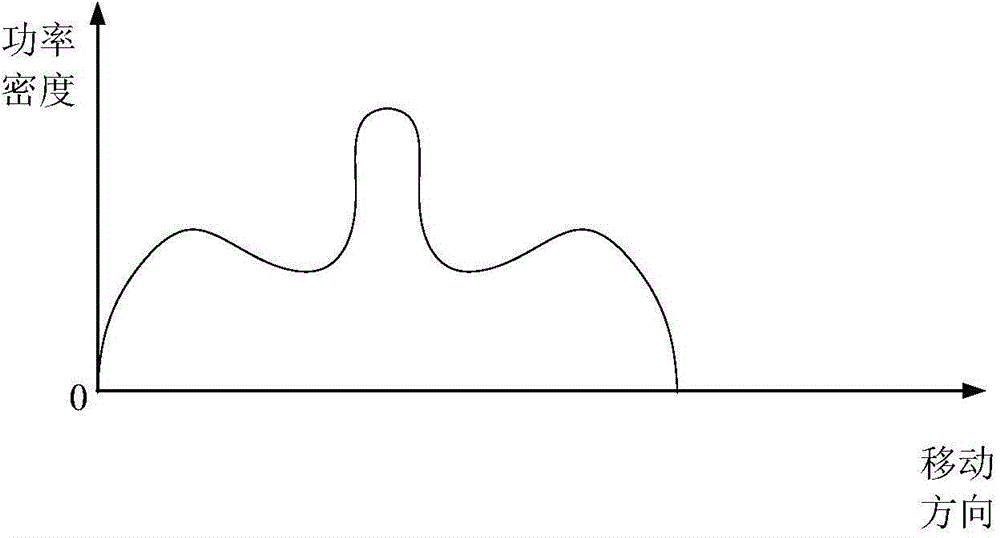

Method for heating metal material in additive manufacturing

InactiveCN105983780AImprove material structure and mechanical propertiesFlexible control of temperature curvesLaser beam welding apparatusLaser beamsPower density

The invention relates to a method for heating a metal material in additive manufacturing. Power density distribution on a cross section of a laser beam emitted by a laser is controlled by a light beam shaping technology, thereby flexibly controlling a temperature variation curve of the heated metal material; and an extra design degree of freedom is provided for a material process design of additive manufacturing, thereby improving an organization form and mechanical properties of an obtained material or realizing the organization form and the mechanical properties with special requirements.

Owner:CHINA WEAPON EQUIP RES INST

TiAl alloy sheet "heat-electricity" coupled canning-free preparation method

ActiveCN110592430ASolve the problem of segregation of high melting point β-stable elementsSolve segregationElectricityIngot

The invention relates to the field of preparation of alloy materials, in particular to a TiAl alloy sheet "heat-electricity" coupled canning-free preparation method. The method aims to solve the problems of complex process, high cost, poor plate shape and low material utilization rate of existing ingot metallurgy canning rolling method for a TiAl alloy sheet, and overcomes the problems of high impurity content, high cost, low density and low production efficiency of a powder metallurgy method. The method comprises the following specific steps of 1, weighing the raw material components; 2, carrying out vacuum induction skull melting+metal mold casting to prepare an ingot; 3, carrying out blank pretreatment I; 4, carrying out blank pretreatment II; and 5, carrying out "heat-electricity" coupled canning-free rolling on the sheet to obtain the TiAl alloy sheet. According to the method, the obtained sheet is good in surface quality, free of oxidation layer falling, free of cracking at the edge part and the end part, uniform and fine in sheet tissue, and good in mechanical property.

Owner:TAIYUAN UNIV OF TECH

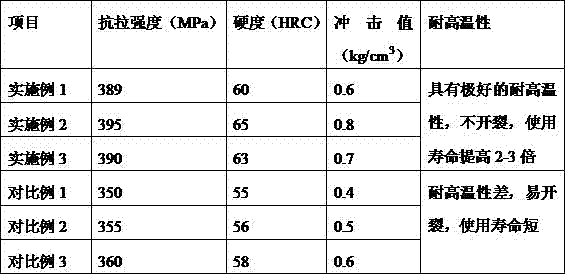

Machining method for high-temperature resistant and anti-cracking casting

InactiveCN107537974AReduce surface roughnessImprove organizational formFoundry mouldsFoundry coresWaxPyrophosphate

The invention relates to the technical field of mould shell casting and discloses a machining method for a high-temperature resistant and anti-cracking casting. The machining method comprises the following steps that (1) a wax mould is prepared, specifically, bassanite, a wax material, pyrophosphate and glass glaze powder are added in a wax material, thus, surface toughness is reduced, the organization form of the casting can be improved, an obtained mould shell is good in stability, the paste preparing efficiency is improved, and the wax material recycling rate is high; (2) materials on the inner layer and the outer layer of the mould shell casting are fused, specifically, quartz serves as a main raw material, zircon sand, zirconia, corundum and the like are added, thus, the mechanical properties such as tensile strength, harness and impact value of the casting are improved, by adding an adhesive, adhesiveness is good, the properties are not attenuated at the high temperature, and thefusion property of a fire retardant with ethyl silicate as the main component and fusion slurry is good; and (3) dewaxing treatment is conducted at the high temperature of 1000-1100 DEG C, and the required mould shell casting is obtained after the wax mould is completely fused. The machining method for the high-temperature resistant and anti-cracking casting is suitable for batch production of castings, and the production efficiency is high.

Owner:ANHUI HUSN KEWAN SPECIAL CASTING

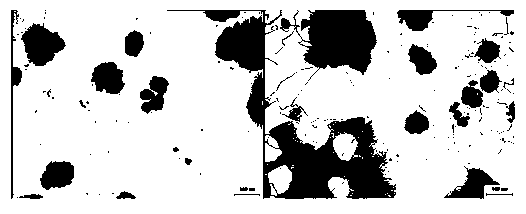

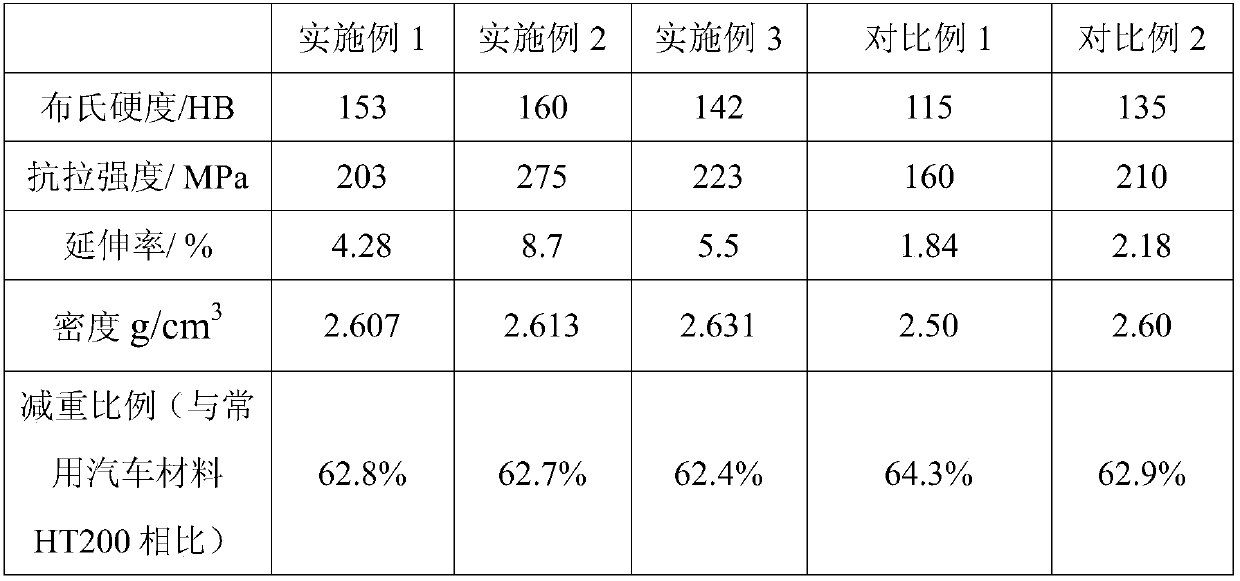

Automobile lightweight aluminum matrix composite and preparation method thereof

InactiveCN109628780AImprove organizational formImprove mechanical propertiesMetal matrix compositeMechanical property

The invention provides an automobile lightweight aluminum matrix composite and a preparation method thereof, and belongs to the technical field of metal matrix composites. The composite is made from the following raw materials: by weight part, 700-710 parts of Al-20Si intermediate alloy, 103-106 parts of industrial pure Mg, and 29-31 parts of Cu-14P intermediate alloy, wherein, the primary phase in the composite is Mg2Si accounting for the mass percentage of the composite by 20%. The invention further provides the preparation method for the automobile lightweight aluminum matrix composite. Thecomposite is high in tissue morphology and excellent in mechanical properties, the density of the composite is much lower than that of a traditional automobile engine cylinder and a cylinder sleeve material, the weight reduction effect is obvious, and the automobile lightweight aluminum matrix composite can serve as the lightweight composite to apply to the components such as an automobile enginecylinder and a cylinder sleeve.

Owner:BEIHUA UNIV

Processing method of soybean yogurt

InactiveCN106720386AStrong bean flavorGreat tasteMilk substitutesFood scienceNutritive valuesSucrose

The invention relates to a processing method of yogurt, particularly a processing technique of soybean yogurt. The soybean yogurt is characterized by comprising soybeans (commercially available), SH-481 lactobacillus (Nanjing Shenghe Science and Technology Ltd.), CM1011 pectin (Shanghai Tongyuan Food Technology Ltd.), S13 sucrose ester (Guangxi Nanning Sucrose Ester Plant) and sucrose (commercially available). The soybean yogurt prepared by the processing technique has the advantages of rich bean aroma, favorable mouthfeel, favorable appearance and high nutritive value.

Owner:SHAANXI YUHANG ELECTRONICS

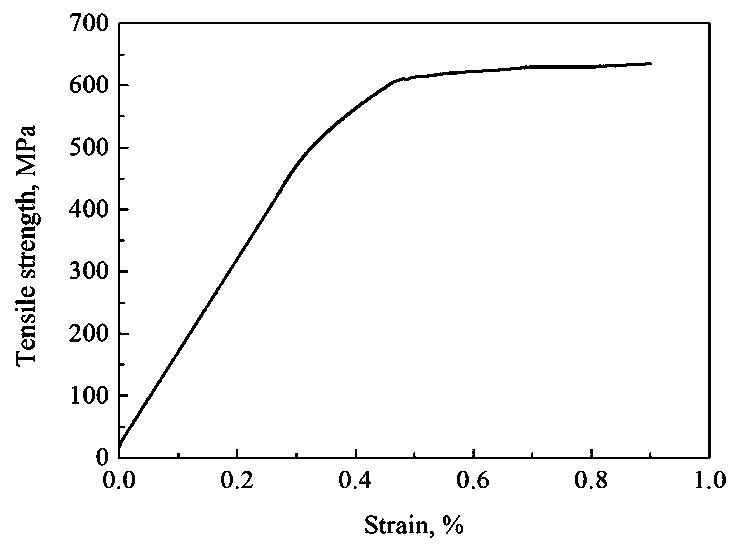

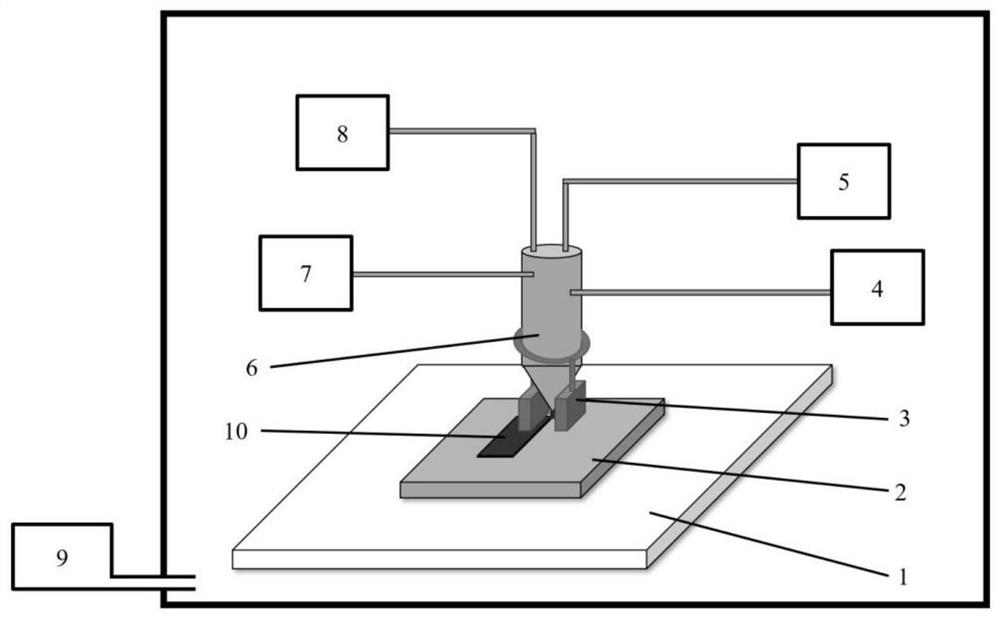

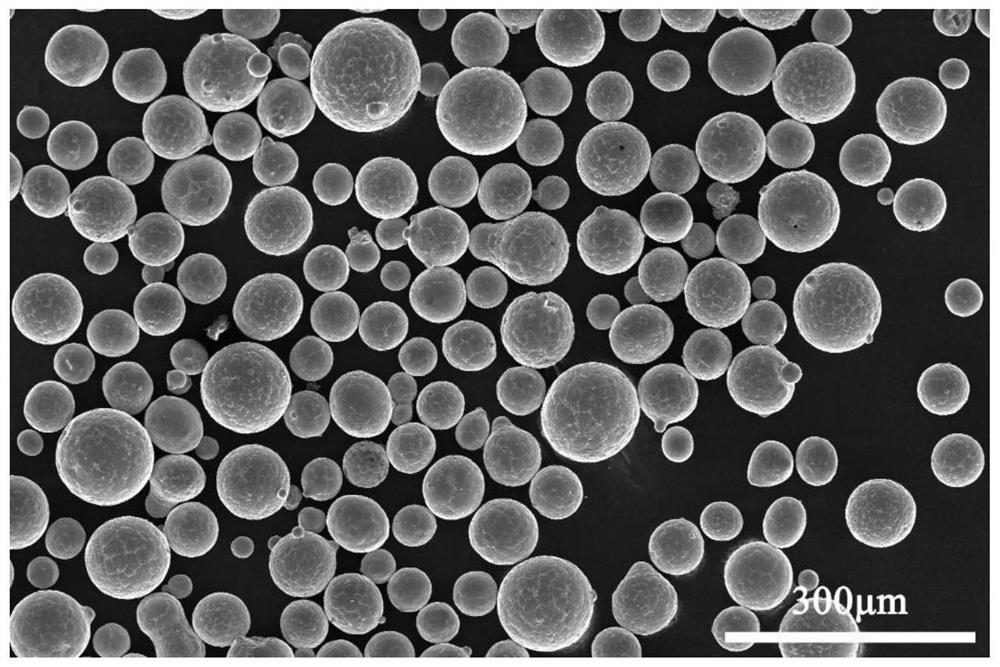

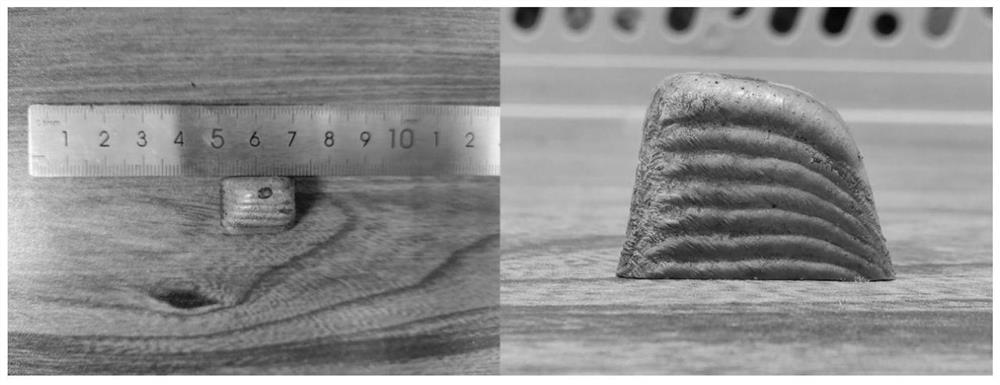

Method and device for 3D printing of gamma-TiAl alloy in static magnetic field

InactiveCN112872364AImprove flexibilityShorten the production cycleAdditive manufacturing apparatusHeat treatedMagnetic field

The invention provides a method for 3D printing of a gamma-TiAl alloy in a static magnetic field. 3D printing is carried out on pre-alloyed powder according to three-dimensional data of a gamma-TiAl alloy formed part to obtain the gamma-TiAl alloy, and 3D printing is carried out in the static magnetic field. When the gamma-TiAl alloy is prepared, an external magnetic field is applied to obtain the compact high-performance gamma-TiAl alloy, and the external magnetic field can further improve the internal structure form of the alloy, reduce residual stress, obtain higher mechanical properties and reduce the cracking risk which may be caused by subsequent heat treatment; and the gamma-TiAl alloy prepared through a 3D printing technology has the characteristics of being high in flexibility, high in material utilization rate, short in production period and the like, and the solidification structure in the gamma-TiAl alloy is small. The result of the embodiment shows that the tensile strength of the gamma-TiAl alloy prepared through the method is larger than 560 MPa, the hardness is larger than 420 HV, and the ductility ranges from 0.5% to 0.8%.

Owner:SHANGHAI UNIV

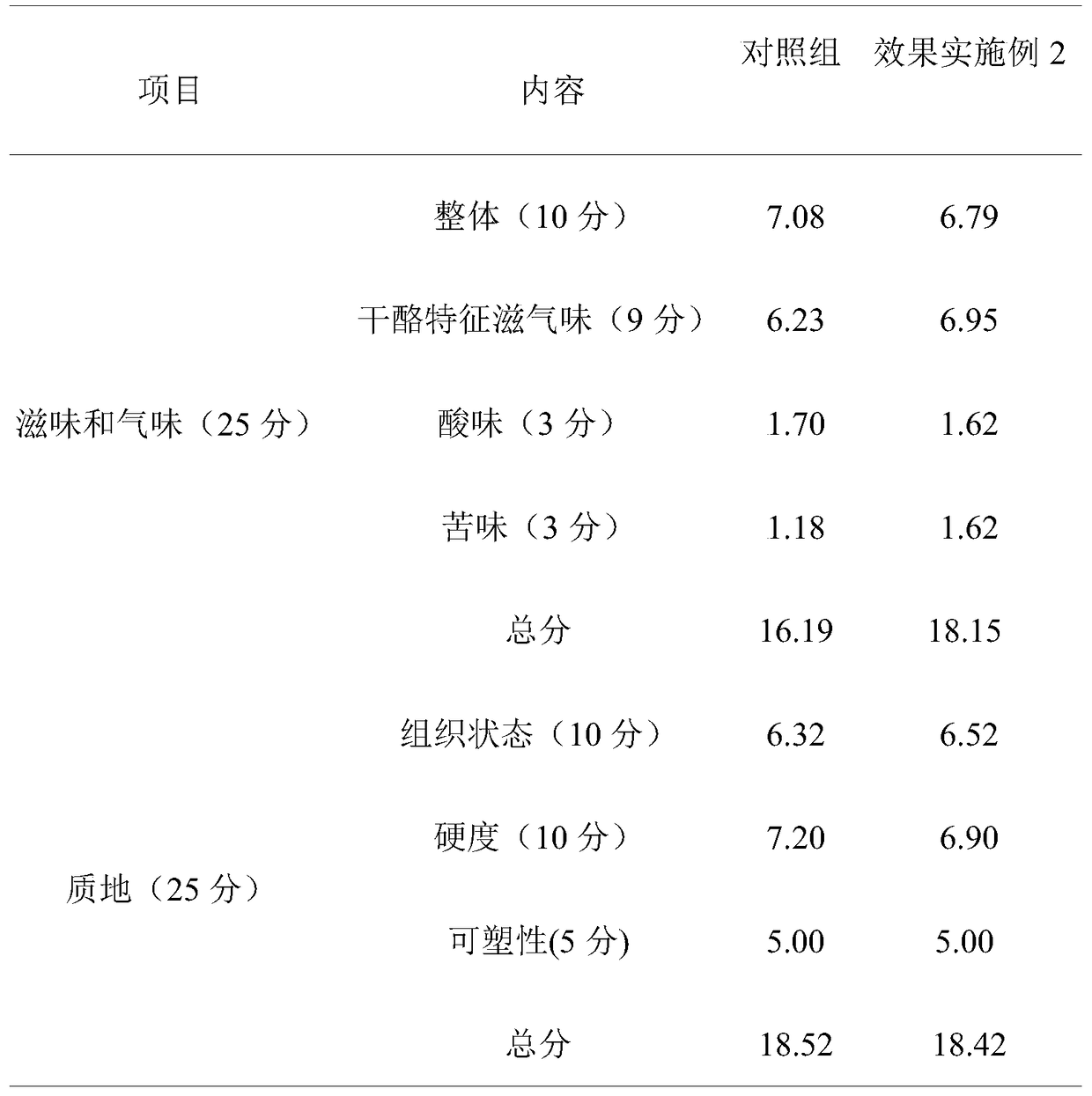

A kind of Leuconostoc enterica and its application in cheese production

ActiveCN104911134BStrong fragranceImprove organizational formBacteriaMicroorganism based processesMicroorganismLeuconostoc mesenteroides

The invention discloses leuconostoc mesenteroides as well as a preparation method and application thereof in cheese production. The leuconostoc mesenteroides is collected in the China General Microbiological Culture Collection Center (CGMCC), with a collection number CGMCC No.10750. The leuconostoc mesenteroides has good growth property and excellent phage resistance in milk, and the acid generation speed is moderate; and the cheese which is produced by using the leuconostoc mesenteroides has good flavor, and the yield is high. The leuconostoc mesenteroides can be used for preparing a starter of cheese and is applied to the processing technology of cheese or other fermented foods.

Owner:BRIGHT DAIRY & FOOD CO LTD

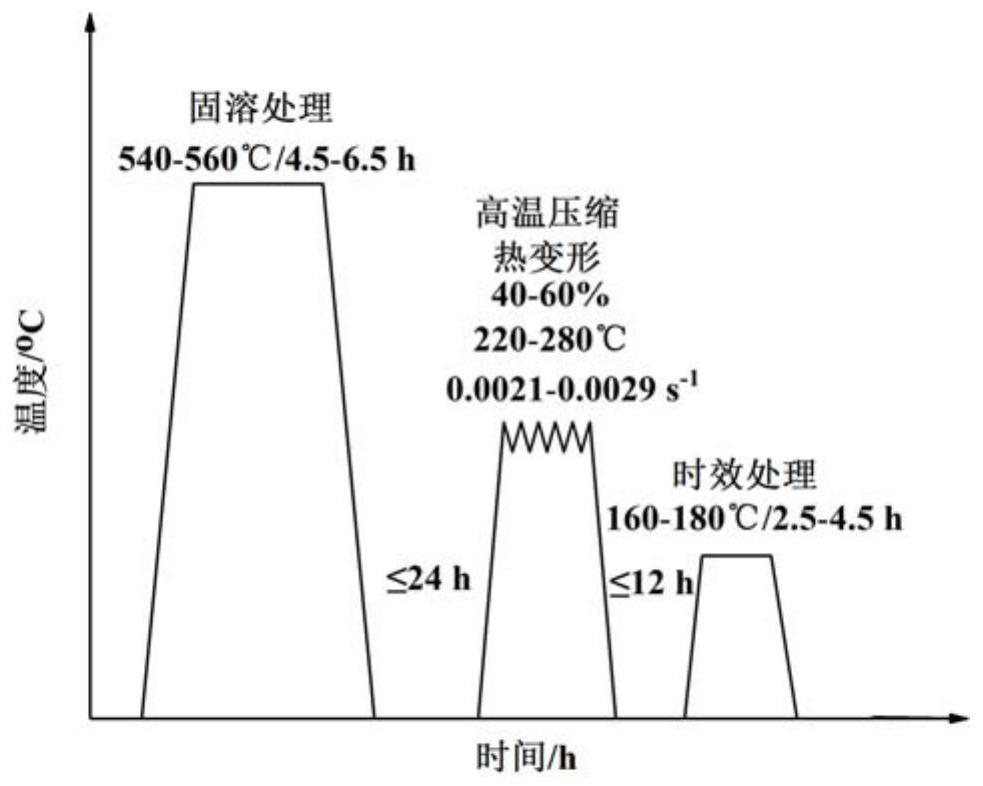

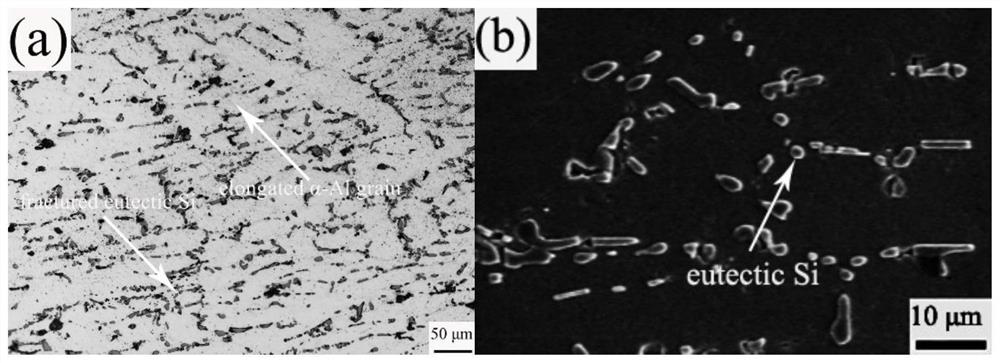

Method for improving strength of (Ce + Yb) composite modified hypoeutectic Al-Si-Mg-Cu-Cr alloy

The invention discloses a method for improving the strength of a (Ce + Yb) composite modified hypoeutectic Al-Si-Mg-Cu-Cr alloy, which is characterized in that on the basis of the (Ce + Yb) composite modified hypoeutectic Al-Si-Mg-Cu-Cr alloy, after the alloy is smelted and cast by adopting a gravity casting method, the alloy is firstly subjected to high-temperature solution treatment, then is subjected to high-temperature heat treatment, and finally is subjected to high-temperature heat treatment, so that the strength of the (Ce + Yb) composite modified hypoeutectic Al-Si-Mg-Cu-Cr alloy is improved. Secondly, carrying out high-temperature compression thermal deformation treatment at a constant temperature and a constant strain rate; and finally, carrying out aging treatment. According to the method, the strength of the alloy can be further improved, meanwhile, the plasticity of the alloy is improved more obviously, the comprehensive mechanical property of the alloy is excellent, the application range of the alloy is widened, and the method is easy and convenient to operate, high in feasibility and remarkable in effect.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com