Automobile lightweight aluminum matrix composite and preparation method thereof

An aluminum-based composite material and composite material technology, applied in the field of automotive lightweight aluminum-based composite materials and its preparation, can solve the problems of matrix splitting, affecting the mechanical properties of composite materials, unfavorable promotion and practical application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

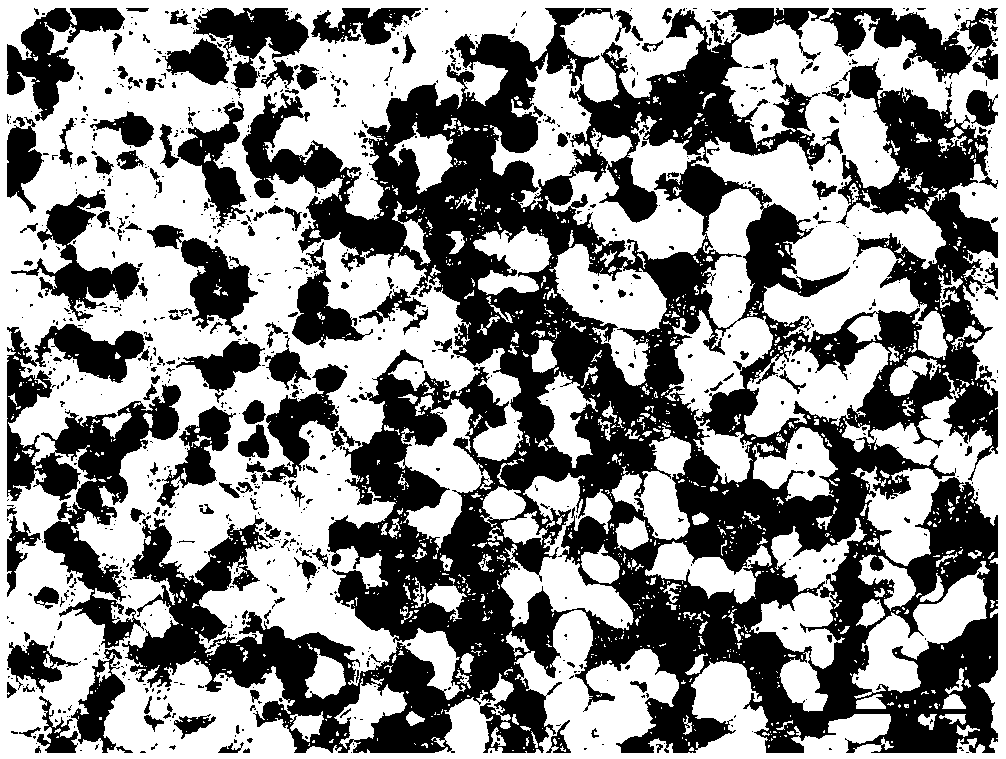

Image

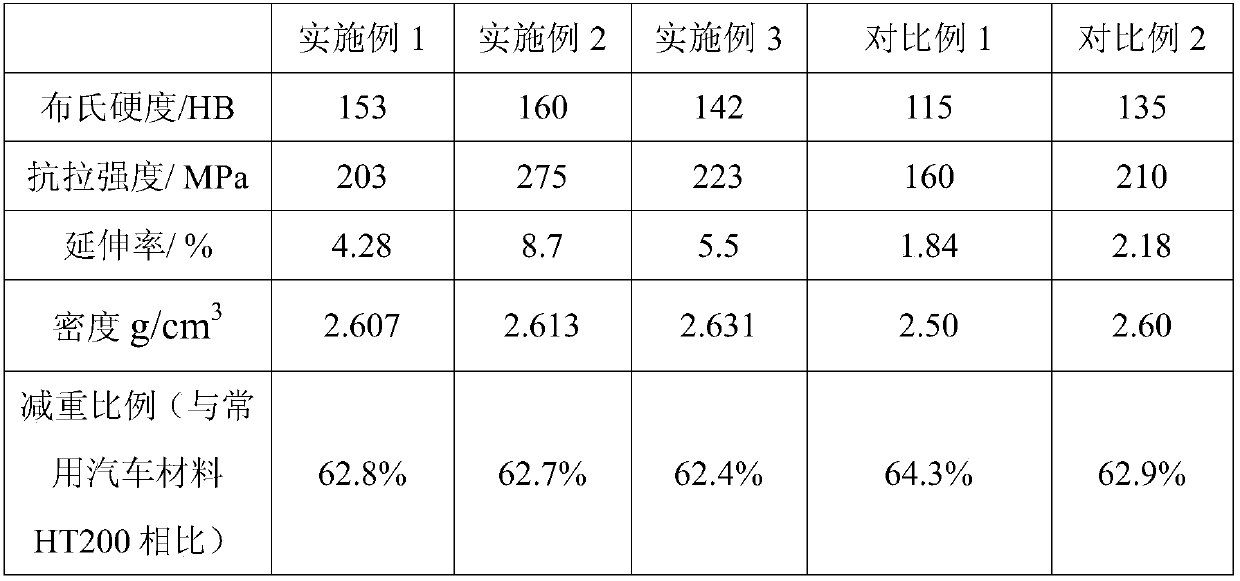

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing an automobile lightweight composite material, comprising:

[0034] (1) Place the graphite crucible in a resistance furnace and heat it to 190-210°C, preferably 200°C, put the Al-20Si master alloy into the crucible and continue to heat up to 760-780°C to completely melt the alloy, keep it warm for 5-10min and then cool down to 700-720°C, preferably 710°C, to obtain an Al-20Si alloy melt;

[0035] (2) After preheating the process pure Mg covered by aluminum foil, press it into the Al-20Si alloy melt obtained in step (1), preferably heat up to 780-800°C for heat preservation, and the heat preservation time is preferably 10min. After the Mg is completely melted, the slag is removed by refining to obtain a melt; the preheating temperature of the process pure Mg is preferably 280-300°C, and the preheating time is preferably 30-40min;

[0036] (3) be heated up to 730-750 ℃, the Cu-14P master alloy after preheating is ...

Embodiment 1

[0042] A lightweight aluminum-based composite material for automobiles, the composite material is made of the following raw materials:

[0043] 709g Al-20Si master alloy, 106g industrial pure Mg and 31g Cu-14wt.%P master alloy, wherein the primary phase in the composite material is Mg 2 Si, accounting for 20% by mass of the composite material;

[0044] The Al-20Si master alloy includes Si: 20%, Mn: 0.230%, Cr: 0.036%, Fe; 0.8%, Zn: 0.012%, Ni; 0.001%, and the balance is Al.

[0045] The industrially pure Mg includes Si: 0.005%, Mn: 0.001%, Cr: 0.002%, Fe; 0.001%, Zn: 0.006%, Ni; 0.001%, Cu: 0.001%, Al: 0.002%, and the balance is Mg .

[0046] The Cu-14P master alloy is a modifier, and the amount of P added is 0.5% of the total amount of the composite material.

[0047] The preparation method of the automobile lightweight composite material, its steps are as follows:

[0048] (1) Place the graphite crucible in a resistance furnace and heat it to 200°C, put the Al-20Si inter...

Embodiment 2

[0055] A lightweight aluminum-based composite material for automobiles, the composite material is made of the following raw materials:

[0056] 700g Al-20Si master alloy, 103g industrial pure Mg and 29g Cu-14wt.%P master alloy, wherein the primary phase in the composite material is Mg 2 Si, accounting for 20% by mass of the composite material;

[0057] The Al-20Si master alloy includes Si: 20%, Mn: 0.230%, Cr: 0.036%, Fe; 0.8%, Zn: 0.012%, Ni; 0.001%, and the balance is Al.

[0058] The industrially pure Mg includes Si: 0.005%, Mn: 0.001%, Cr: 0.002%, Fe; 0.001%, Zn: 0.006%, Ni; 0.001%, Cu: 0.001%, Al: 0.002%, and the balance is Mg .

[0059] The Cu-14P master alloy is a modifier, and the amount of P added is 0.5% of the total amount of the composite material.

[0060] The preparation method of the automobile lightweight composite material, its steps are as follows:

[0061] (1) Place the graphite crucible in a resistance furnace and heat it to 200°C, put the Al-20Si inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com