Method for improving strength of (Ce + Yb) composite modified hypoeutectic Al-Si-Mg-Cu-Cr alloy

A technology of al-si-mg-cu-cr and compound modification, which is applied in the field of improving the strength of compound modified hypoeutectic Al-Si-Mg-Cu-Cr alloy, can solve the problem that synergy cannot be fully exerted, strength, Problems such as limited improvement of plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

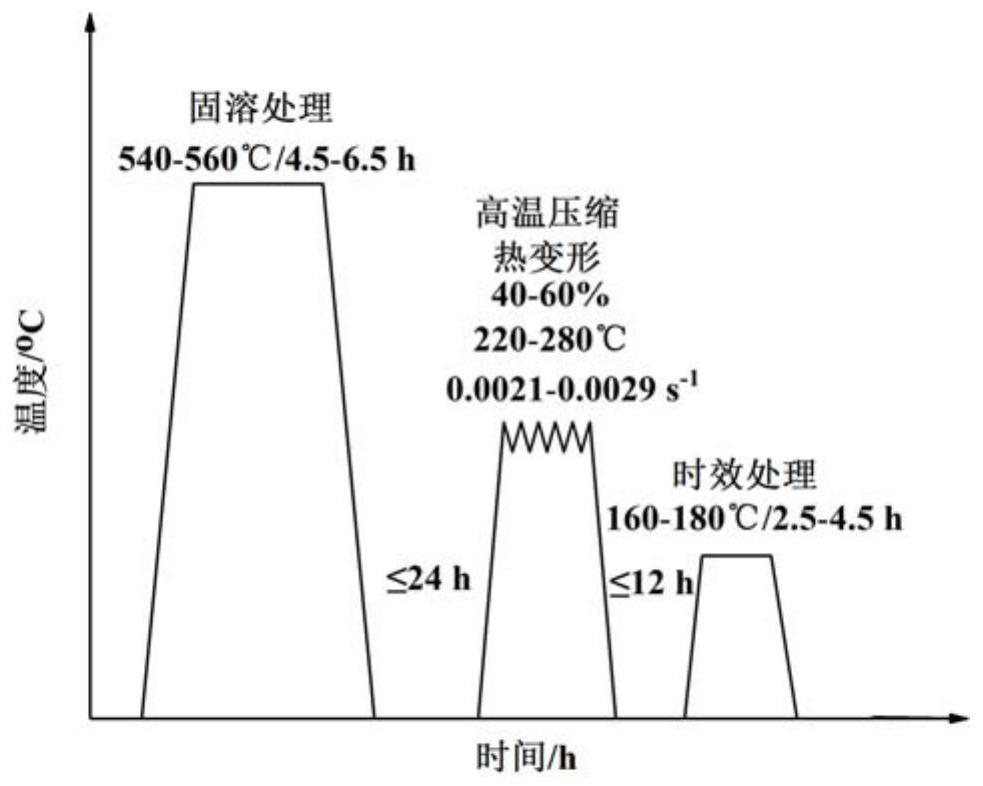

[0035] step one:.

[0036] Carry out solid solution treatment with Al-6Si-0.6Mg-0.6Cu-0.2Cr-0.2Ce-0.2Yb (wt.%) as-cast alloy cylindrical sample in electric resistance furnace, take out after solid solution time (stay in air Time ≤ 10s) Quenching with warm water at 60°C;

[0037] Step two:

[0038] The interval time does not exceed 24 hours, and the solid solution alloy sample is subjected to high-temperature compression and thermal deformation on a hydraulic press that can control the strain rate until the deformation reaches the set deformation amount, and immediately cools down with room temperature water to retain the thermally deformed structure;

[0039] Step three:

[0040] The interval time does not exceed 12h, and the high-temperature compression heat-deformation alloy sample is subjected to aging treatment in a resistance furnace, and after the aging time is up, it is taken out and air-cooled.

[0041] The alloy sample after the "solid solution-high temperature com...

Embodiment 2

[0043] Step 1, Step 2 and Step 3 in this embodiment are the same as those in Embodiment 1, except that the process parameters of "solid solution-high temperature compression thermal deformation-aging" treatment are different, as shown in Table 1. The alloy sample after the "solid solution-high temperature compression thermal deformation-aging" treatment was tested for tensile properties at room temperature, and the results were: the ultimate tensile strength of the alloy in this example was 353.1 MPa, and the uniform elongation was 14.3%. In this embodiment, the strength of the alloy is increased by 9.2%, and the elongation is increased by 134.4%.

Embodiment 3

[0045] Step 1, Step 2 and Step 3 in this embodiment are the same as those in Embodiment 1, except that the process parameters of "solid solution-high temperature compression thermal deformation-aging" treatment are different, as shown in Table 1. The alloy sample after the "solid solution-high temperature compression thermal deformation-aging" treatment was tested for tensile properties at room temperature, and the results were: the ultimate tensile strength of the alloy in this example was 346.3 MPa, and the uniform elongation was 13.4%. In this embodiment, the strength of the alloy is increased by 7.1%, and the elongation is increased by 119.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com