Sn-containing austenitic stainless steel and manufacturing method thereof

A kind of technology of austenitic stainless steel and manufacturing method, which is applied in the field of Sn-containing austenitic stainless steel, can solve the problems of unsuitable environment for sulfuric acid corrosion resistance, poor sulfuric acid corrosion resistance, severe corrosion, etc., so as to improve sulfuric acid corrosion resistance, good The effect of mechanical properties, good plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

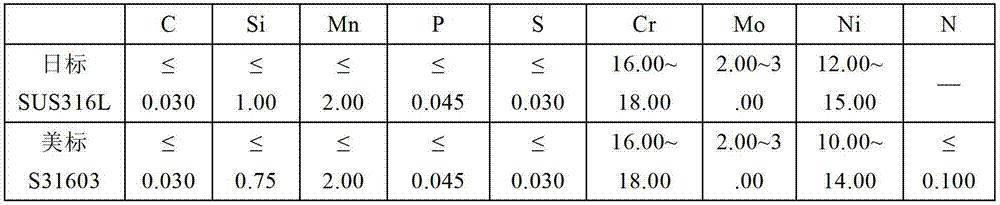

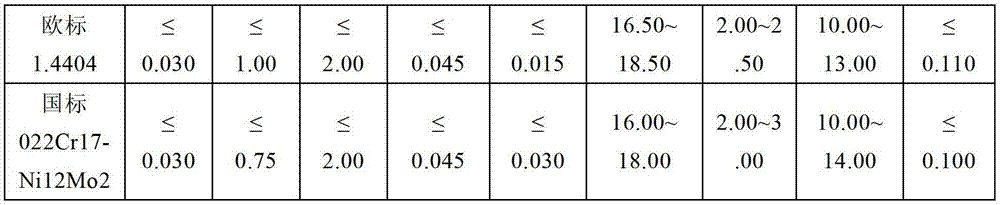

Method used

Image

Examples

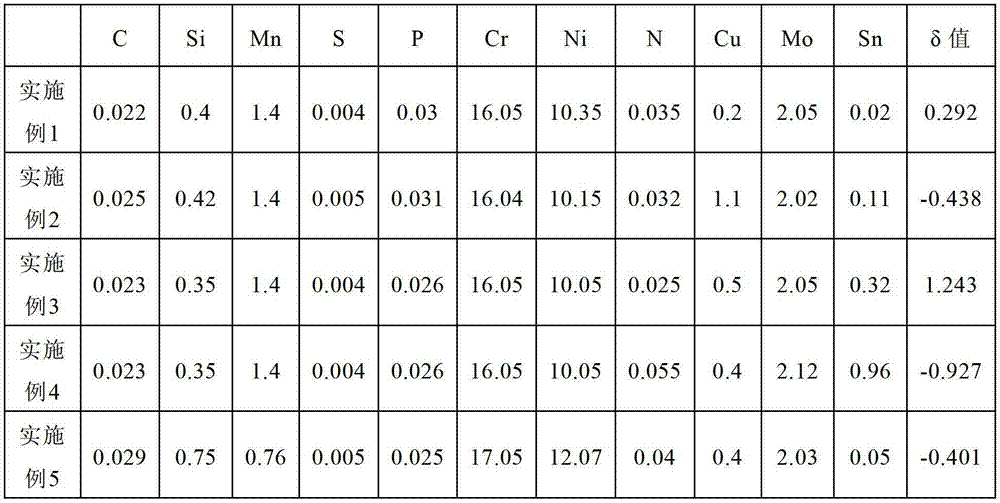

Embodiment 1

[0049] Adopt the steel of chemical composition shown in embodiment 1 in the vacuum furnace smelting table 2, mold cast into steel ingot, Sn is with Fe 60 sn 40 The alloy is added; the steel ingot is opened into a 50mm thick square ingot, and the heating furnace is heated to 1250°C with the furnace and then kept for 1 hour. , air cooling; the hot-rolled sheet was solution annealed at 1050°C for 3 minutes, cooled to room temperature in water, and then descaled by scale breaking, shot blasting, electrolytic pickling, and mixed acid pickling; the pickled sheet was cold-rolled to a thickness of 1mm, The rolled sheet was solution annealed at 1080°C for 1 min, and then water-cooled to room temperature; the cold-rolled annealed sheet was descaled, shot blasted, electrolytic pickling, mixed acid pickling and other processes to remove scale and obtain Sn-containing austenitic stainless steel.

[0050] The tensile properties of the Sn-containing austenitic stainless steel obtained in th...

Embodiment 2

[0052] Adopt electric furnace, AOD duplex to smelt the steel of chemical composition shown in embodiment 2 in table 2, continuously cast into 200mm thick billet, Sn is with Fe 60 sn 40 The way of alloy is added in AOD; the continuous casting slab is added into the furnace, heated to 1260°C and kept for 2.5h, hot rolled to 4mm thick, the final rolling temperature is 950°C, then laminar water cooling to 700°C coiling, air cooling; hot rolled plate Solution annealing at 1080°C for 5 minutes, water cooling to room temperature, and then remove the scale by scale breaking, shot blasting, electrolytic pickling, mixed acid pickling and other processes; the pickled plate is cold rolled to a thickness of 1.5mm, and the cold rolled plate is solidified at 1100°C Solution annealing for 1.5min, water cooling to room temperature; scale breaking, shot blasting, electrolytic pickling, mixed acid pickling and other processes to remove scale on the cold-rolled annealed sheet to obtain Sn-contain...

Embodiment 3

[0055] The steel with the chemical composition shown in Example 3 in Table 2 was smelted by electric furnace, AOD, and VOD three-step method. During VOD, Fe-Sn alloy wire was fed, and continuous casting was made into a 180mm thick billet; the continuous casting billet was added to the furnace and heated to 1220°C After heat preservation for 2 hours, hot rolling to 2mm thickness, the final rolling temperature is 950°C, then laminar water cooling to 670°C coiling, air cooling; hot-rolled sheet is solution annealed at 1080°C for 3 minutes, water cooled to room temperature, and then subjected to scale breaking and shot blasting , electrolytic pickling, mixed acid pickling and other processes to remove scale, and obtain Sn-containing austenitic stainless steel hot-rolled annealed sheets.

[0056] The tensile properties of the Sn-containing austenitic stainless steel obtained in this example are tested according to GB / T228-2002, and the mechanical properties fully meet the product st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com