Method and device for 3D printing of gamma-TiAl alloy in static magnetic field

A 3D printing, static magnetic field technology, applied in the direction of additive manufacturing, additive processing, etc., can solve the problems of small laser three-dimensional forming structure, difficult laser three-dimensional forming, and increase the process flow, so as to reduce the risk of cracking, the solidification structure is small, and flexible. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

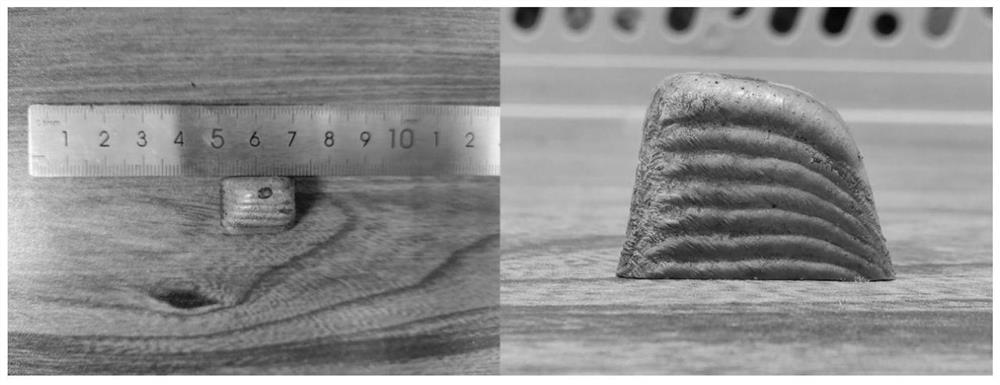

[0050] Preparation of titanium alloy substrate: select TC4 alloy as the substrate material, cut it into a plate, perform sandblasting on the plate and then clean it with ethanol to obtain a titanium alloy substrate with a smooth and clean surface.

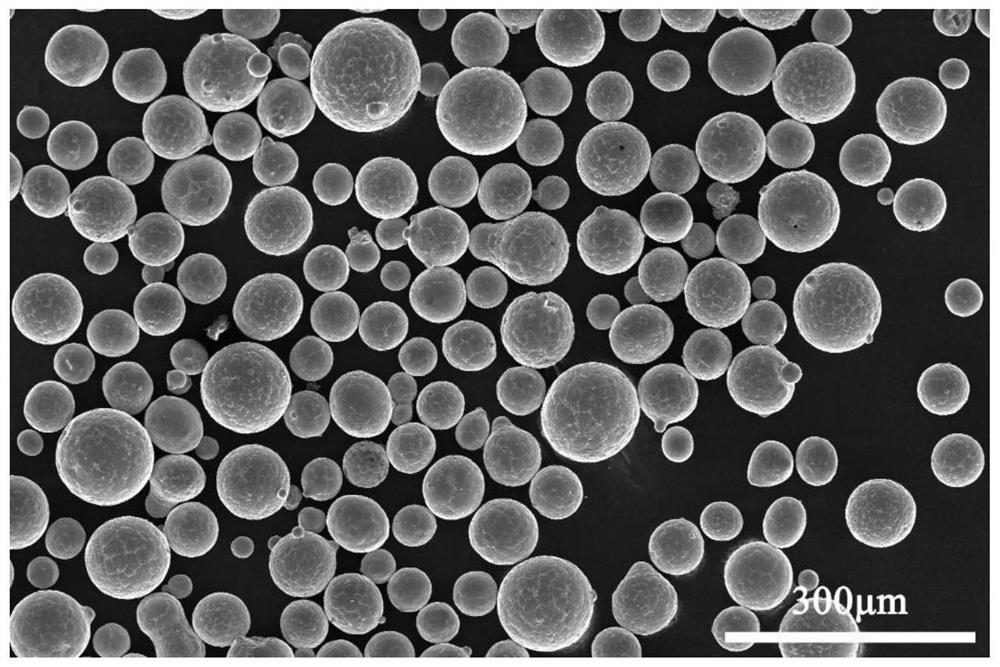

[0051] Preparation of pre-alloyed powder: use Ti-48Al-2Cr-2Nb alloy powder, the alloy powder atomic percentage content is: 48% Al, 2% Nb, 2% Cr, the balance is Ti and unavoidable impurities, O The N content is 533ppm, the N content is 481ppm, the particle size distribution range of the alloy powder is 53-150μm, and the D50 is 88.6μm; the pre-alloyed powder is put into a vacuum oven and baked at 100°C for 2 hours to obtain a dry pre-alloyed powder.

[0052] The laser used in the 3D printing device is a 2000W fiber-coupled semiconductor laser from Laserline, Germany.

[0053] The method for 3D printing gamma-TiAl alloy consists of the following steps:

[0054] (1) Put the pre-alloyed powder into the powder feeder, and adjust the po...

Embodiment 2

[0065] The temperature in step (3) of Example 1 was changed to 350°C, the magnetic field strength in step (5) was changed to 0.5T, and the parameters of 3D printing in step (7) were changed to: laser scanning speed 8mm / s, laser power 1200W , the powder feeding gas flow rate is 8L / min, the lifting amount of the laser cladding head is 1.5mm, and other conditions are the same as in Example 1.

Embodiment 3

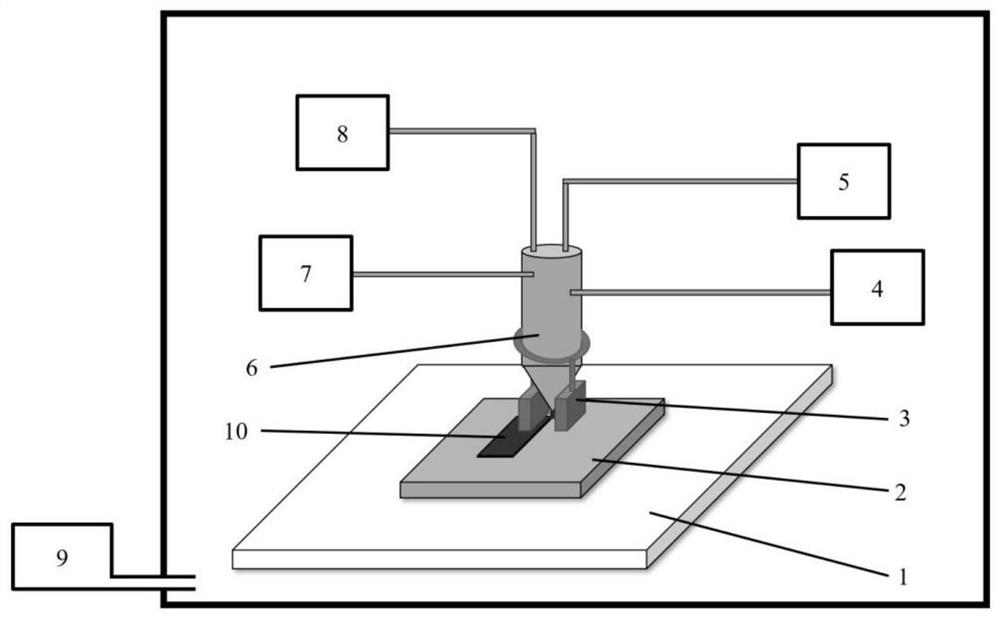

[0067] Such as figure 1 As shown, the device for 3D printing γ-TiAl alloy provided in this embodiment includes a substrate heating device 1, a titanium alloy substrate 2, a magnet device 3, a laser 4, a powder feeder 5, a laser cladding head 6, a water cooling system 7, Numerical control system 8 and gas circulation system 9;

[0068] The exterior of the substrate heating device 1 is provided with a coating formed of a high-permeability shielding alloy;

[0069] The magnet device 3 includes two static magnets, and the two static magnets are relatively arranged on both sides of the nozzle of the laser cladding head;

[0070] The laser 4 is a fiber laser;

[0071] The substrate heating device 1, titanium alloy substrate 2 and laser cladding head 6 are located inside the forming chamber; the traveling system of the numerical control system 8 is located inside the forming chamber, and the console of the numerical control system 8 is located outside the forming chamber;

[0072]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com