Machining method for high-temperature resistant and anti-cracking casting

A processing method and high temperature resistant technology, applied in the field of mold shell casting, can solve the problems of large gas generation in the clay sand cavity, insufficient compactness of the molding sand, and reduced dimensional accuracy of castings, etc., so as to improve the efficiency of paste making and good adhesion. , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

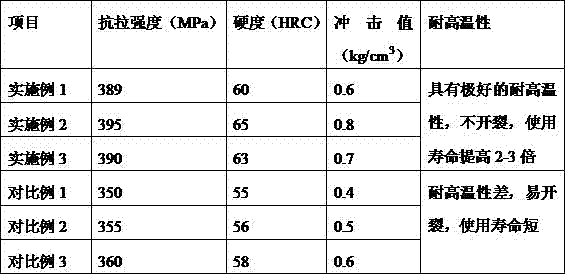

Examples

Embodiment 1

[0016] A processing method for a high-temperature-resistant crack-resistant casting, comprising the following steps:

[0017] (1) Crush calcined gypsum, wax, pyrophosphate, and glass enamel powder into fine powders with a size of 200 meshes, make the mixture into flakes through a wax machine, and then add the flakes of wax to the glycerin Heat and stir in the paste making barrel, the heating temperature is 80°C, the stirring speed is 1000 rpm, and the stirring time is 60 minutes to obtain a paste wax paste, which is injected into the pressure cavity through the wax injection machine, and the wax film is extruded and immediately put in 10 ℃ cold water;

[0018] (2) Melt the inner and outer layer materials of the shell casting to obtain a slurry, which is made of the following components in terms of mass percentage: 50% quartz, 10% mullite, 10% kaolinite, 3% zircon sand, oxidized Zirconium 2%, the rest is corundum, after mixing and stirring at 600 rpm for 10 minutes, reduce the...

Embodiment 2

[0025] A processing method for a high-temperature-resistant crack-resistant casting, comprising the following steps:

[0026] (1) Crush calcined gypsum, wax, pyrophosphate, and glass enamel powder into fine powders with a size of 250 meshes, make the mixture into flakes through a wax machine, and then add the flakes of wax to the glycerin Heat and stir in the paste making barrel, the heating temperature is 85°C, the stirring speed is 1100 rpm, and the stirring time is 65 minutes to obtain a paste wax paste, which is injected into the pressure cavity through the wax injection machine, and the wax film is extruded and immediately put in Cold water at 12°C;

[0027] (2) Melt the inner and outer layer materials of the shell casting to obtain the slurry, which is made of the following components in terms of mass percentage: 55% quartz, 12% mullite, 12% kaolinite, 4% zircon sand, oxidized Zirconium 2.5%, the rest is corundum, after mixing and stirring at 700 rpm for 12 minutes, red...

Embodiment 3

[0034] A processing method for a high-temperature-resistant crack-resistant casting, comprising the following steps:

[0035] (1) Crush calcined gypsum, wax, pyrophosphate, and glass enamel powder into fine powders with a size of 300 mesh, and make the mixture into flakes through a wax machine, and then add the flakes of wax to the glycerin Heat and stir in the paste making barrel, the heating temperature is 90°C, the stirring speed is 1200 rpm, and the stirring time is 70 minutes to obtain a paste wax paste, which is injected into the pressure cavity through the wax injection machine, and the wax film is extruded and immediately put in Cold water at 15°C;

[0036] (2) Melt the inner and outer layer materials of the shell casting to obtain a slurry, which is made of the following components in terms of mass percentage: 60% quartz, 15% mullite, 15% kaolinite, 5% zircon sand, oxidized Zirconium 3%, the rest is corundum, after mixing and stirring at 800 rpm for 15 minutes, reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com