Compound thickening agent for improving texture and emulsifying property of meat product and preparation method and application thereof

A technology of meat products and thickeners, which is applied in the field of food additives. It can solve the problems of affecting product appearance and texture, unfavorable product sales, and lack of meat flavor, etc., and achieves the advantages of reducing adhesion, increasing elasticity, and easy demoulding and slicing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example provides a compound thickener for improving the texture and emulsification properties of meat products. The ratio of parts by weight of each raw material is:

[0031] Sanzan glue 10

[0032] Sodium Hyaluronate 5

[0033] Xanthan Gum 20

[0034] Konjac gum 30

[0035] Flaxseed Gum 20

[0036] curdlan gum 15.

[0037] Sanzan gum is produced by Sphingomonas sanzan ( Sphingomonas sanxanigenes ) to synthesize an exopolysaccharide product with thickening, pseudoplastic and emulsifying properties. Sanzan gum polysaccharide is composed of 4 kinds of monosaccharides, and its main chain structure is -4--D-mannose-1-4--D-glucuronic acid-1-3--L-rhamnose-1-3 --D-glucose, Sanzan gum solution can form a helical winding grid structure after heating and cooling, which is an elastic gel and has the properties of acid resistance and high temperature resistance. Sanzan gum was provided by Hebei Xinhe Biochemical Co., Ltd.

Embodiment 2

[0071] This example provides a compound thickener for improving the texture and emulsification properties of meat products. The ratio of parts by weight of each raw material is:

[0072] Sanzan glue 15

[0073] Sodium Hyaluronate 10

[0074] Xanthan Gum 25

[0075] Konjac gum 15

[0076] Flaxseed Gum 30

[0077] curdlan gum 5.

[0078] The source and preparation method of each raw material in the compound thickener, and the method for preparing sausage products using the compound thickener are all the same as in Example 1.

[0079] The intestinal body prepared by the technical scheme of this embodiment is compared with the detection results of the control group intestinal body as follows:

[0080]

[0081] The accelerated oxidation method was used to determine the induction period of the fat emulsion, and the measurement results were as follows:

[0082] induction time

[0083] group

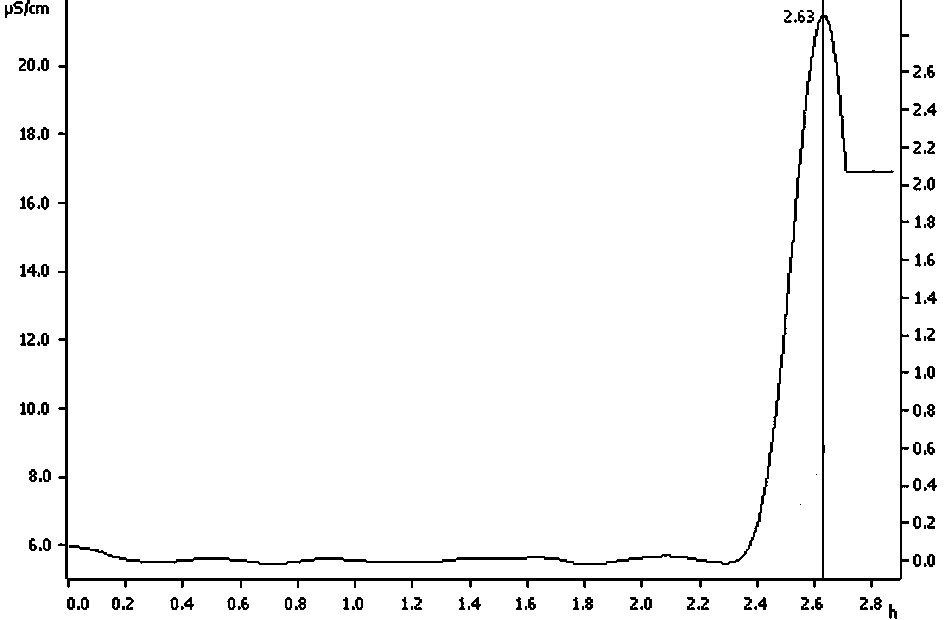

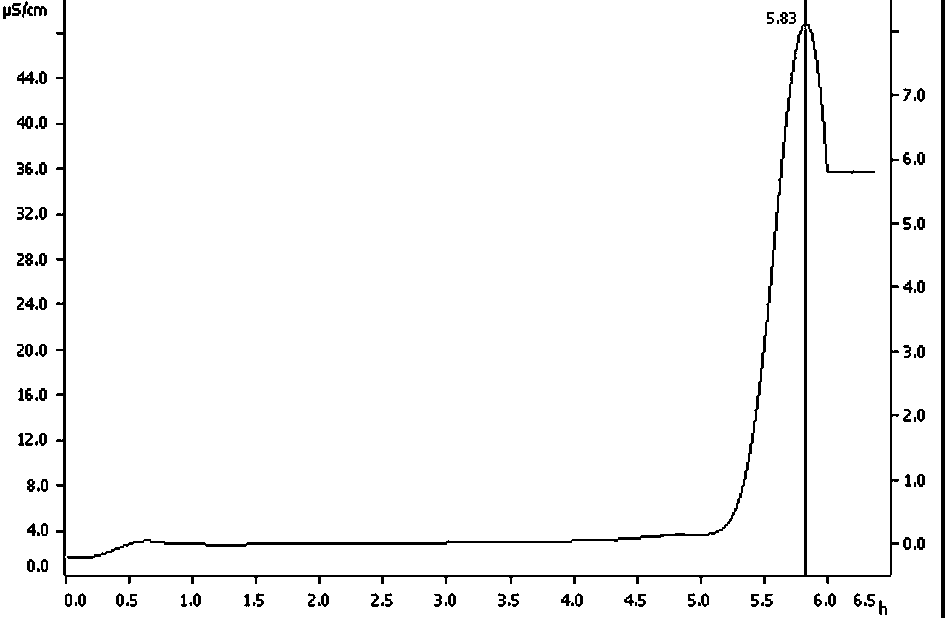

[0084] Depend on figure 1 , image 3 It can be seen from the compariso...

Embodiment 3

[0089] This example provides a compound thickener for improving the texture and emulsification properties of meat products. The ratio of parts by weight of each raw material is:

[0090] Sanzan glue 20

[0091] Sodium Hyaluronate 7.5

[0092] Xanthan Gum 30

[0093] Konjac gum 7.5

[0094] Flaxseed Gum 25

[0095] curdlan gum 10.

[0096] The source and preparation method of each raw material in the compound thickener, and the method for preparing sausage products using the compound thickener are all the same as in Example 1.

[0097] The intestinal body prepared by the technical scheme of this embodiment is compared with the detection results of the control group intestinal body as follows:

[0098]

[0099] The accelerated oxidation method was used to determine the induction period of the fat emulsion, and the measurement results were as follows:

[0100] induction time

[0101] group

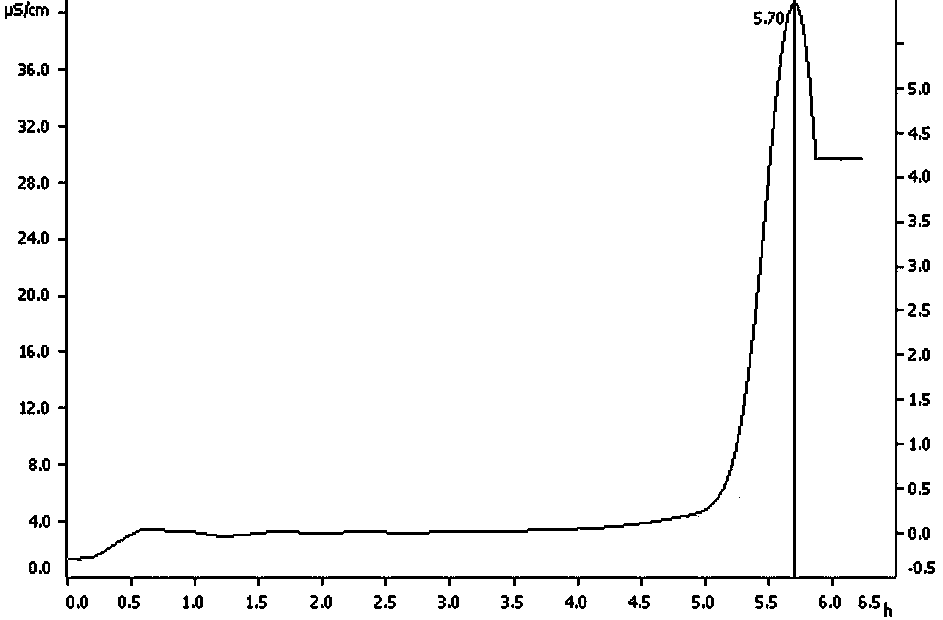

[0102] Depend on figure 1 , Figure 4 It can be seen from the compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com