Method for making resistant starch-containing cookies

A technology of resistant starch and a production method, applied in the field of biscuit production, can solve the problems of reducing the overall acceptability of food by consumers, changing the sensory properties of food, etc., and achieve the effects of good color and good tissue shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

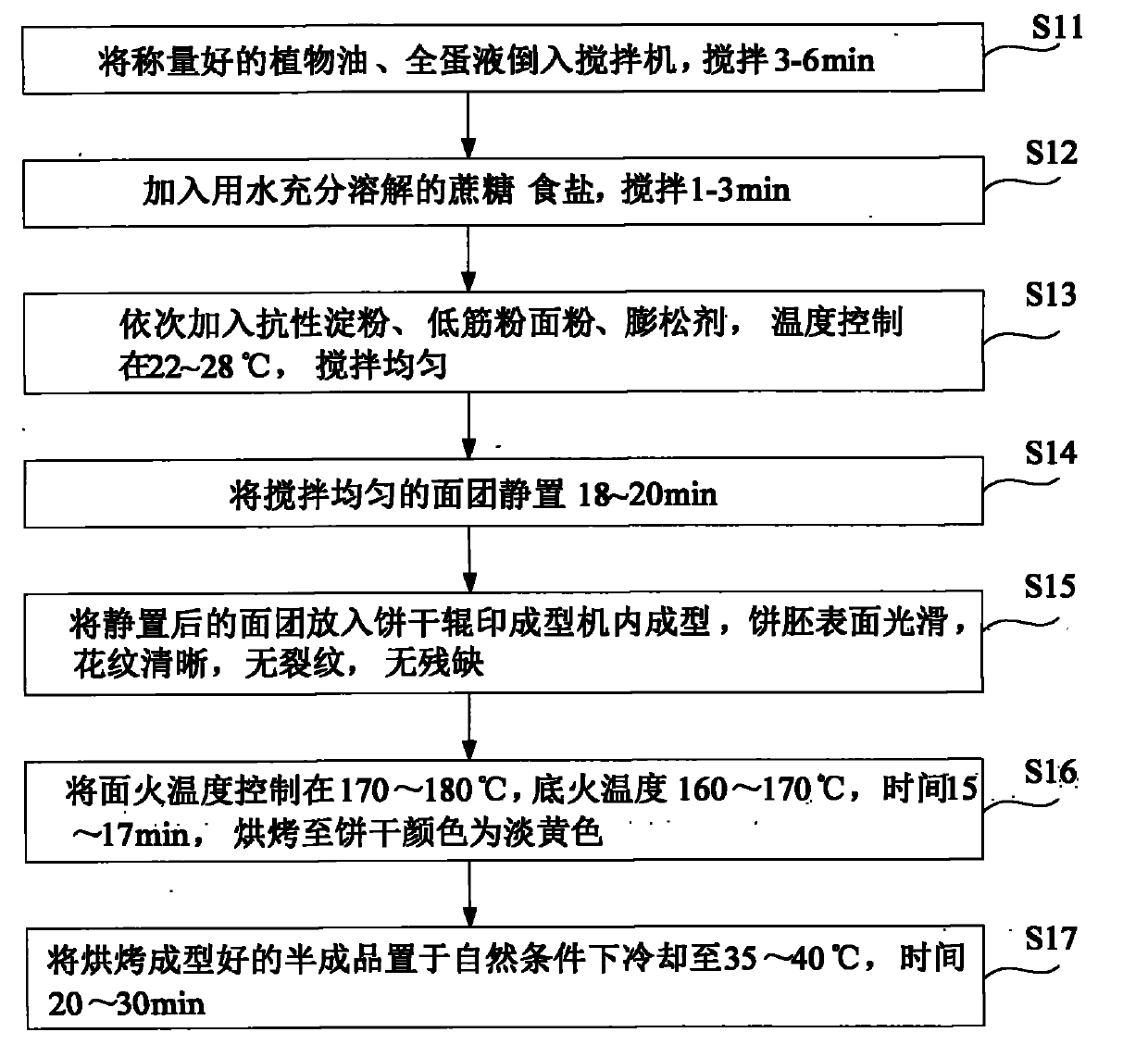

Method used

Image

Examples

Embodiment 1

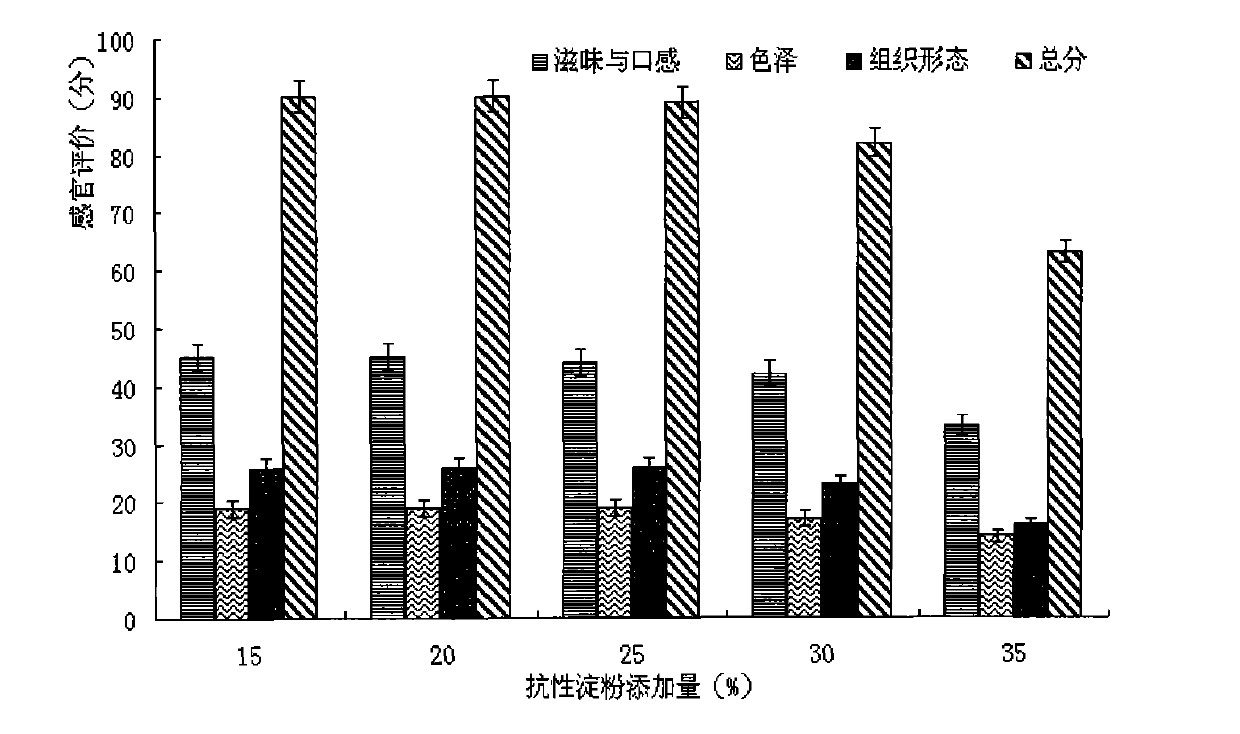

[0050] This example is mainly to determine the impact of the amount of resistant starch added on the quality of biscuits.

[0051] Under the condition of 25.0% of vegetable oil, 25.0% of white granulated sugar, and 1.6% of leavening agent (according to the weight ratio of 1.0:0.6 to weigh baking soda and ammonium bicarbonate), add 15.0%, 20.0%, and 25.0% respectively. %, 30.0% and 35.0% resistant starch to make biscuits, and evaluate the sensory properties of biscuits with different added amounts of resistant starch, the results are as follows figure 2 shown.

[0052] Depend on figure 2 It can be seen that within a certain range (<30.0%), the added amount of resistant starch has little effect on the sensory quality of biscuits. When the added amount of resistant starch exceeds 30.0%, the taste and tissue state are significantly reduced, mainly manifested as The brittleness is weakened, the taste is rough, the cross-section pores are large and uneven, and the color uniformity...

Embodiment 2

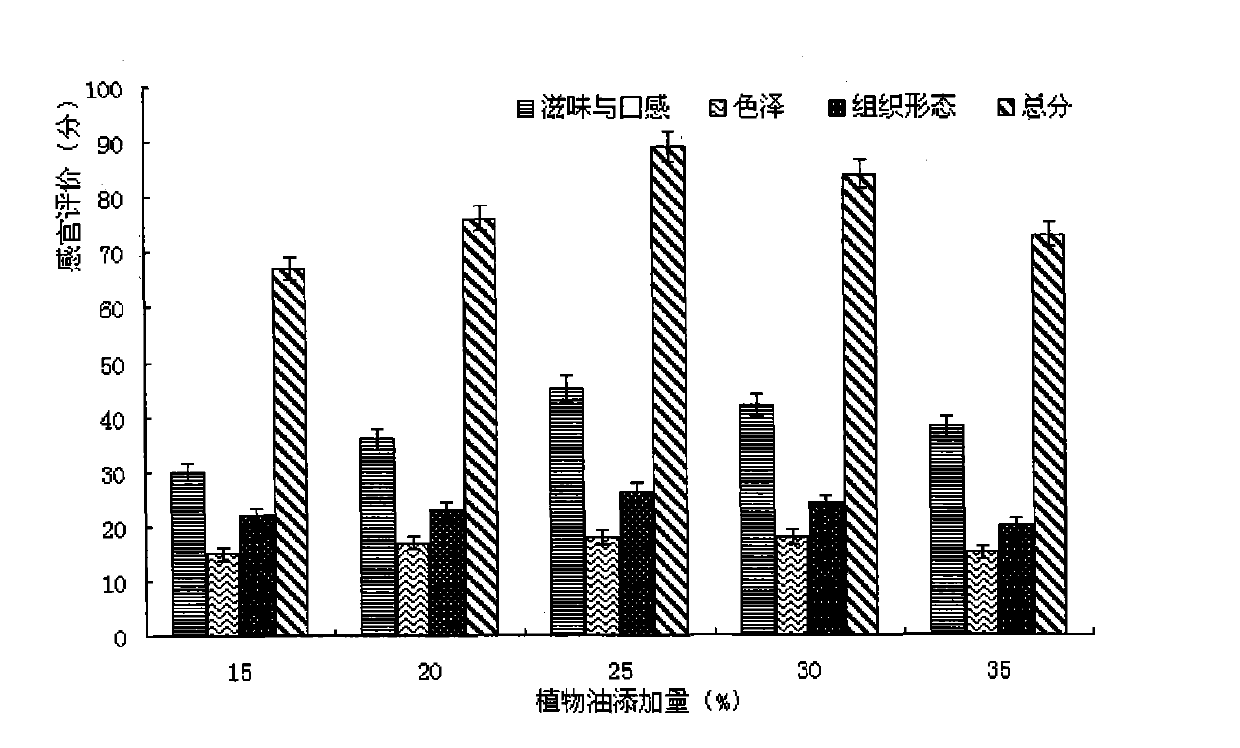

[0054] This embodiment is mainly to determine the effect of the amount of vegetable oil added on the quality of biscuits.

[0055] Under the conditions of 25.0% resistant starch, 25.0% sucrose, and 1.6% leavening agent (obtained by weighing baking soda and ammonium bicarbonate at a weight ratio of 1.0:0.6), add 15.0%, 20.0%, 25.0%, 30.0% and 35.0% vegetable oil were used to make biscuits, and the sensory properties of biscuits with different amounts of vegetable oil added were evaluated. The results were as follows: image 3 shown.

[0056] Depend on image 3 It can be seen that the amount of vegetable oil added has a great influence on the quality of biscuits. When the amount of vegetable oil added was 20.0%, the biscuits had a hard taste, rough surface and cracks. When the amount of vegetable oil added was 25.0%, the biscuits prepared had better taste and texture, color and texture. When the amount of vegetable oil added is 35.0%, although the biscuits have better crispn...

Embodiment 3

[0058] This embodiment is mainly to determine the impact of the amount of sucrose added on the quality of biscuits.

[0059] Under the conditions of 25.0% resistant starch, 25.0% vegetable oil, and 1.6% leavening agent (obtained by weighing baking soda and ammonium bicarbonate at a weight ratio of 1.0:0.6), add 15.0%, 20.0%, 25.0%, 30.0% and 35.0% sucrose were used to make biscuits, and the sensory properties of biscuits were evaluated under different sucrose additions. The results were as follows: Figure 4 shown.

[0060] Sucrose can improve the taste and mouthfeel of biscuits. At the same time, sucrose can dehydrate the dough during the mixing process to prevent the dough from forming more gluten, thereby avoiding the finished product to be hard and without loose taste. Therefore, the amount of sucrose is the most important factor. An important factor in the quality of crispy biscuits. Depend on Figure 4 It can be seen that with the increase of sucrose addition, the tas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com