Processing method of instant vegetable and surimi convenient products

A processing method and vegetable technology, applied in the field of food processing, can solve the problems of strong oxidizing easily destroying chlorophyll, vitamin loss, uneven heating, etc., and achieve the effects of ensuring flavor and nutrition, balanced nutrition, and uniform molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

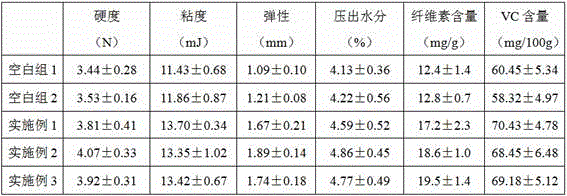

Examples

Embodiment 1

[0048] A processing method for instant vegetable surimi products, comprising the steps of:

[0049] 1) Pretreatment: select fresh fish as the raw material, wash, descale, remove the head, remove the viscera, and perform secondary cleaning;

[0050] 2) Meat harvesting: use the drum meat harvester for the second meat harvesting of the pretreated fish;

[0051] 3) Rinse: Rinse the harvested fish meat immediately, that is, add 6 times the weight of water to the fish meat, control the water temperature at 4°C, and the pH value at 6.6. After repeated rinsing for 3 times, add 0.1% of its weight in the water salt to make light salt water, and then rinse the fish once with light salt water;

[0052] 4) Pre-dehydration: Under the condition of non-pressing, the rotary sieve is used to remove the moisture attached to the surface of the fish pellets and the moisture mechanically trapped inside the fish pellets;

[0053] 5) Fine filtration and dehydration: Use a fine filter to filter out ...

Embodiment 2

[0061] A processing method for instant vegetable surimi products, comprising the steps of:

[0062] 1) Pretreatment: select fresh fish as the raw material, wash, descale, remove the head, remove the viscera, and perform secondary cleaning;

[0063] 2) Meat harvesting: use the drum meat harvester for the second meat harvesting of the pretreated fish;

[0064] 3) Rinse: Rinse the harvested fish meat immediately, that is, add water 8 times its weight to the fish meat, control the water temperature at 6°C, and the pH value at 6.8. After repeated rinsing for 4 times, add 0.2% of its weight in the water salt to make light salt water, and then rinse the fish once with light salt water;

[0065] 4) Pre-dehydration: Under the condition of non-pressing, the rotary sieve is used to remove the moisture attached to the surface of the fish pellets and the moisture mechanically trapped inside the fish pellets;

[0066] 5) Fine filtration and dehydration: Use a fine filter to filter out imp...

Embodiment 3

[0074] A processing method for instant vegetable surimi products, comprising the steps of:

[0075] 1) Pretreatment: select fresh fish as the raw material, wash, descale, remove the head, remove the viscera, and perform secondary cleaning;

[0076] 2) Meat harvesting: use the drum meat harvester for the second meat harvesting of the pretreated fish;

[0077] 3) Rinse: Rinse the harvested fish meat immediately, that is, add water 7 times its weight to the fish meat, control the water temperature at 10°C, and the pH value at 6.7. After repeated rinsing for 4 times, add 0.1% of its weight in the water salt to make light salt water, and then rinse the fish once with light salt water;

[0078] 4) Pre-dehydration: Under the condition of non-pressing, the rotary sieve is used to remove the moisture attached to the surface of the fish pellets and the moisture mechanically trapped inside the fish pellets;

[0079] 5) Fine filtration and dehydration: Use a fine filter to filter out im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com