A kind of nano antibacterial agent, preparation method and application thereof

A nano-antibacterial agent and halloysite nanotube technology, which is applied in the field of new agricultural materials, can solve the problems of loss and insignificant effect, and achieve the effect of high-efficiency inhibition or killing, and good inhibition and killing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

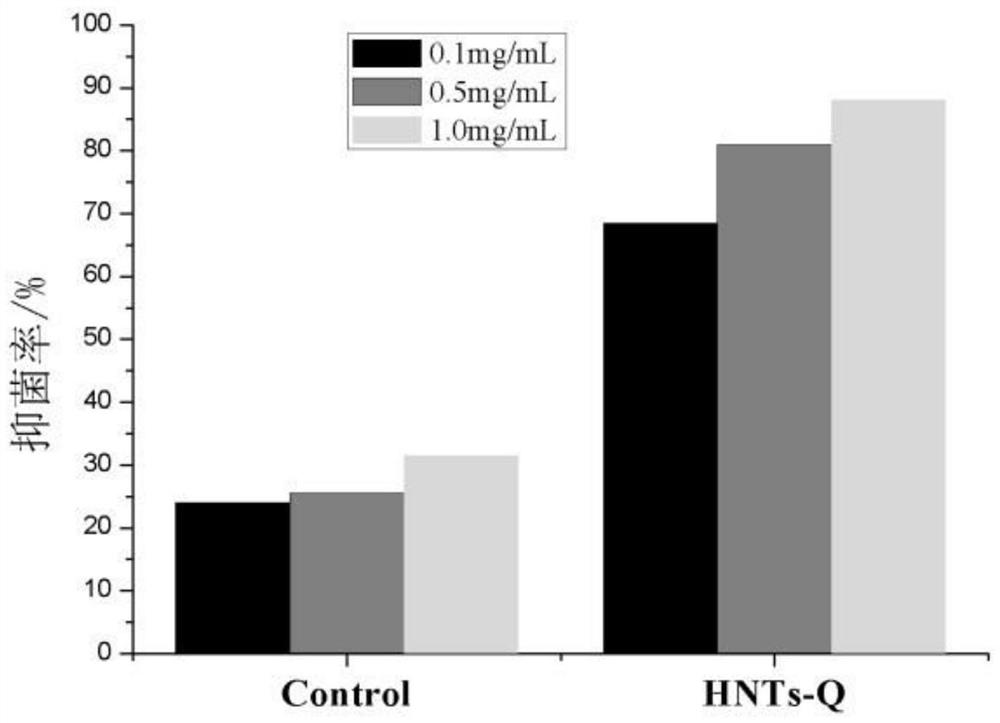

Embodiment 1

[0036] S1. first acidify 10g HNTs with hydrochloric acid, the concentration of hydrochloric acid is 3mol / L, and the addition amount of hydrochloric acid is 200mL;

[0037] S2. Disperse the acidified HNTs in 500 mL of ethanol with a volume fraction of 95%, and ultrasonically disperse for 0.5 h;

[0038] S3. Then add 20mL triethylamine and 30mL 3-aminopropyltriethoxysilane;

[0039] S4. Then heat and reflux reaction at constant temperature for 24h, the heating temperature is 80°C, after the reaction, separate the solid and liquid, wash with ethanol with a volume fraction of 95%, then dry in a vacuum oven at 60°C, and grind the 300 mesh sieves, obtain amino-modified HNTs (HNTs-NH), standby;

[0040] S5. Get 0.17g of the amino-modified HNTs-NH prepared in S4 (based on the amino group in the halloysite nanotube molecular structure, the concentration is 10mmol) and disperse it in 100mL deionized water, then add 2mL of acetyl chloride dropwise (the concentration is 20mmol) , reacte...

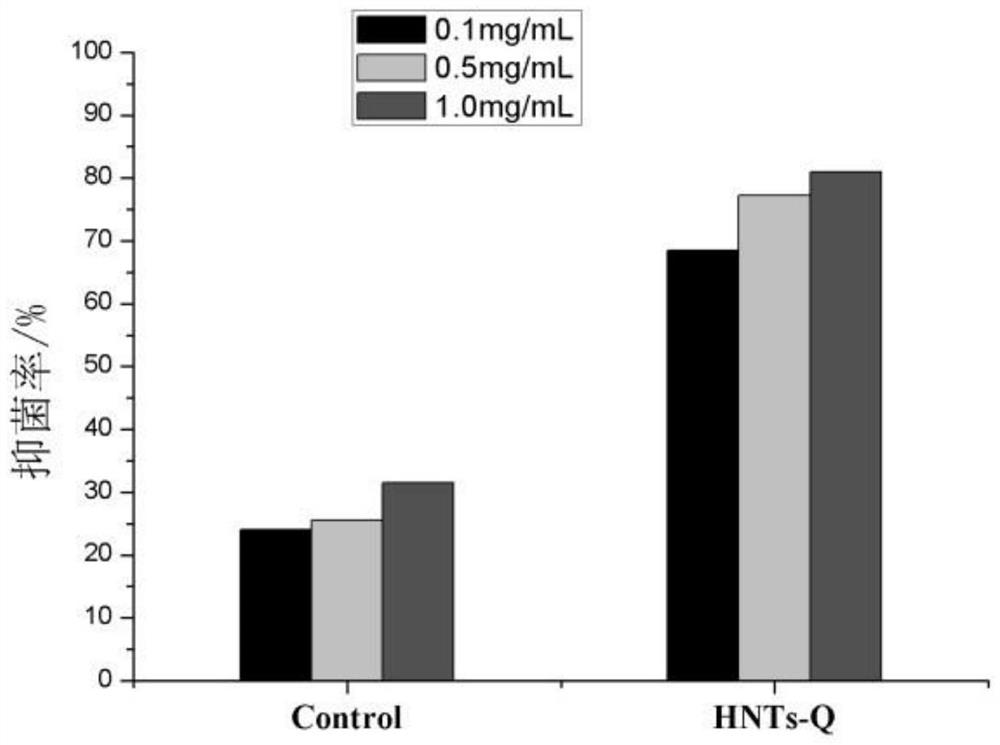

Embodiment 2

[0051] S1. first acidify 10g HNTs with hydrochloric acid, the concentration of hydrochloric acid is 3mol / L, and the addition amount of hydrochloric acid is 200mL;

[0052] S2. Disperse the acidified HNTs in 500 mL of ethanol with a volume fraction of 95%, and ultrasonically disperse for 0.5 h;

[0053] S3. Then add 20mL triethylamine and 30mL 3-aminopropyltriethoxysilane;

[0054] S4. Then heat and reflux reaction at constant temperature for 24h, the heating temperature is 80°C, after the reaction, separate the solid and liquid, wash with ethanol with a volume fraction of 95%, then dry in a vacuum oven at 60°C, and grind the 300 mesh sieves, obtain amino-modified HNTs, standby;

[0055] S5. Get 0.17g of the amino-modified HNTs-NH prepared in S4 (based on the amino group in the halloysite nanotube molecular structure, the concentration is 10mmol) and disperse it in 100mL deionized water, then add 2mL of acetyl chloride dropwise (the concentration is 20mmol) , reacted at room ...

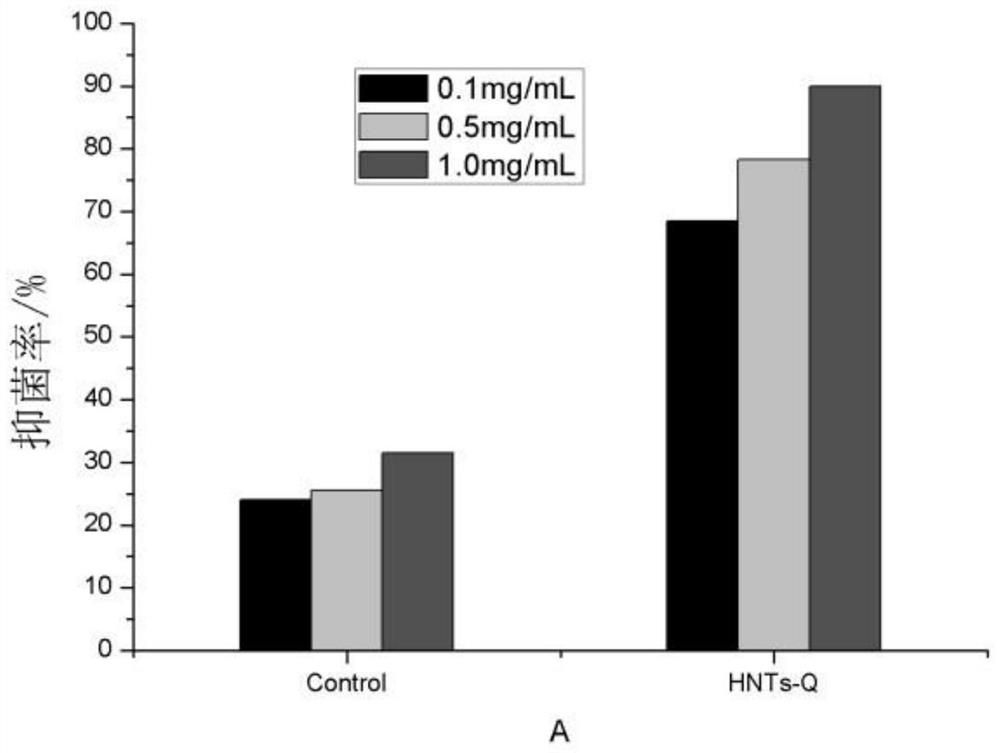

Embodiment 3

[0066] S1. first acidify 10g HNTs with hydrochloric acid, the concentration of hydrochloric acid is 3mol / L, and the addition amount of hydrochloric acid is 200mL;

[0067] S2. Disperse the acidified HNTs in 500 mL of ethanol with a volume fraction of 95%, and ultrasonically disperse for 0.5 h;

[0068] S3. Then add 20mL triethylamine and 30mL 3-aminopropyltriethoxysilane;

[0069] S4. Then heat and reflux reaction at constant temperature for 24h, the heating temperature is 80°C, after the reaction, separate the solid and liquid, wash with ethanol with a volume fraction of 95%, then dry in a vacuum oven at 60°C, and grind the 300 mesh sieves, obtain amino-modified HNTs, standby;

[0070] S5. Get 0.17g of the amino-modified HNTs-NH prepared in S4 (based on the amino group in the halloysite nanotube molecular structure, the concentration is 10mmol) and disperse it in 100mL deionized water, then add 2mL of acetyl chloride dropwise (the concentration is 20mmol) , react at room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com