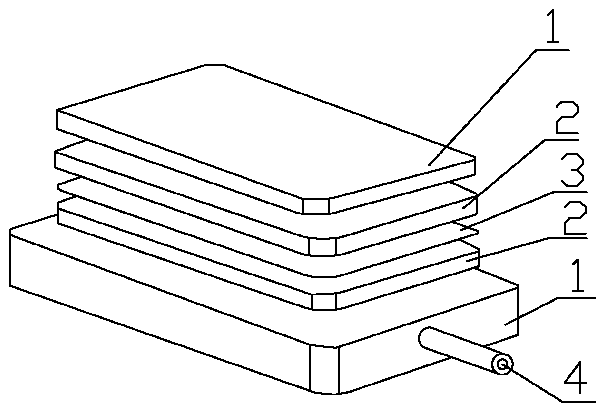

Pulse current assisting titanium-TiAl composite plate non-sheath rolling method

A pulsed current, composite plate technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of high cost, low strength and plasticity, uneven thickness, etc. control deformation, improve plastic deformation ability, uniform and fine grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

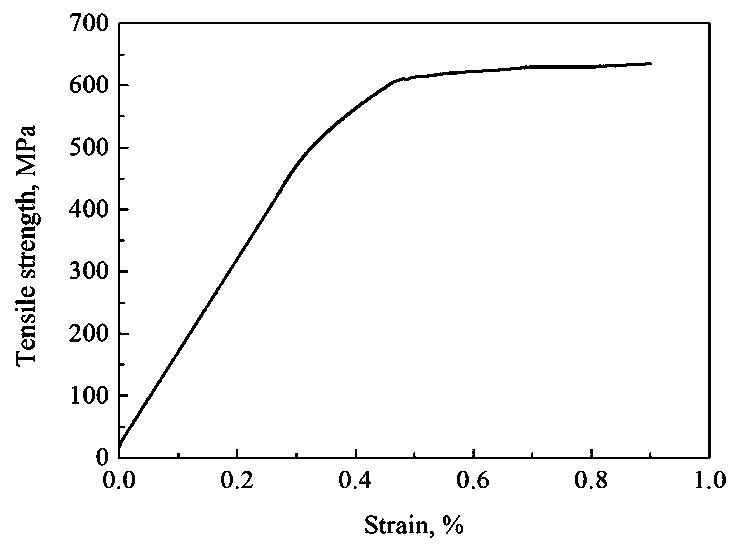

Embodiment 1

[0043] The preparation method of TC4 / Ti-44Al-8Nb-(B, Y) alloy composite plate is as follows:

[0044] Step 1. Titanium alloy sheet preparation:

[0045] a. Melting TC4 (Ti-6Al-4V) titanium alloy by vacuum induction suspension melting method to obtain a cylindrical ingot with a diameter of 100mm and a height of 180mm;

[0046] b. Cut off the riser of the ingot and remove the surface scale, then place the billet in a box-type vacuum heat treatment furnace at 950°C for 30 minutes, and use a hydraulic forging machine to -1 The strain rate of the titanium alloy billet is thickened, and the total deformation is 70%. After the thickening is completed, the billet is placed in a vacuum heat treatment furnace at 400 ° C for 2 hours, and the furnace is cooled;

[0047] c. Remove scale from the pier-thick billet, smooth the surface, cut the core of the forging cake and process it into a standard rectangular block, process chamfering at the front end of the billet deformation, place it in...

Embodiment 2

[0069] The preparation method of BT16 / Ti-43Al-4Nb-2Mo-2V alloy composite plate is as follows:

[0070] Step 1. Titanium alloy sheet preparation:

[0071] a. Melting BT16 (Ti-3Al-4.5V-5Mo) titanium alloy by vacuum induction suspension melting method to obtain a cylindrical ingot with a diameter of 100mm and a height of 180mm;

[0072] b. Cut off the riser of the ingot and remove the surface oxide skin, then place the billet in a box-type vacuum heat treatment furnace at 1000°C for 60 minutes, and use a hydraulic forging machine for 0.05s -1 The strain rate of the titanium alloy billet is thickened, and the total deformation is 80%. After the thickening is completed, the billet is placed in a vacuum heat treatment furnace at 500 ° C for 2 hours, and the furnace is cooled;

[0073] c. Remove scale from the pier-thick billet, smooth the surface, cut the core of the forging cake and process it into a standard rectangular block, process chamfering at the front end of the billet def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com