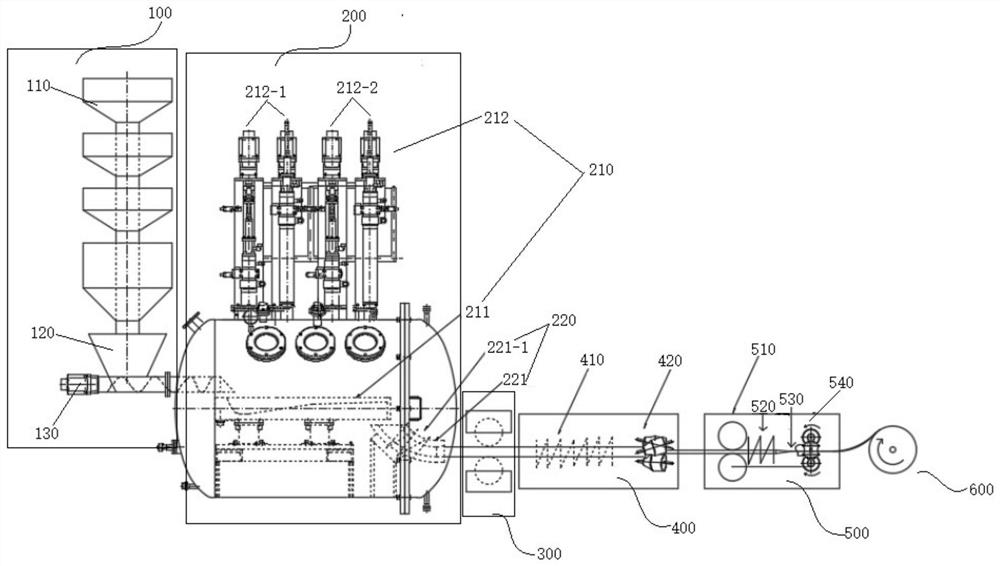

Short-process continuous casting and continuous extrusion equipment for titanium or titanium alloy wires and preparation method for wires

A technology of titanium alloy wire and short process is applied in the field of titanium or titanium alloy wire short process continuous casting and extruding equipment and wire preparation, which can solve the problem of inability to carry out continuous wire production, high input cost of tools and molds, and quality control. Difficulties and other problems, to achieve the effect of improving material utilization, high material utilization, and avoiding the pickling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

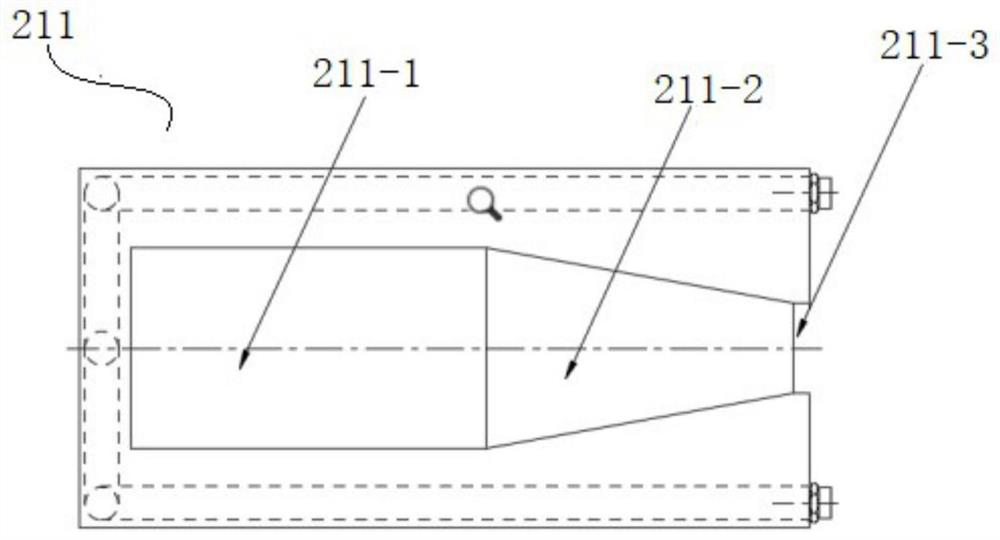

Method used

Image

Examples

Embodiment 1

[0127] Preparation of TC4 filament

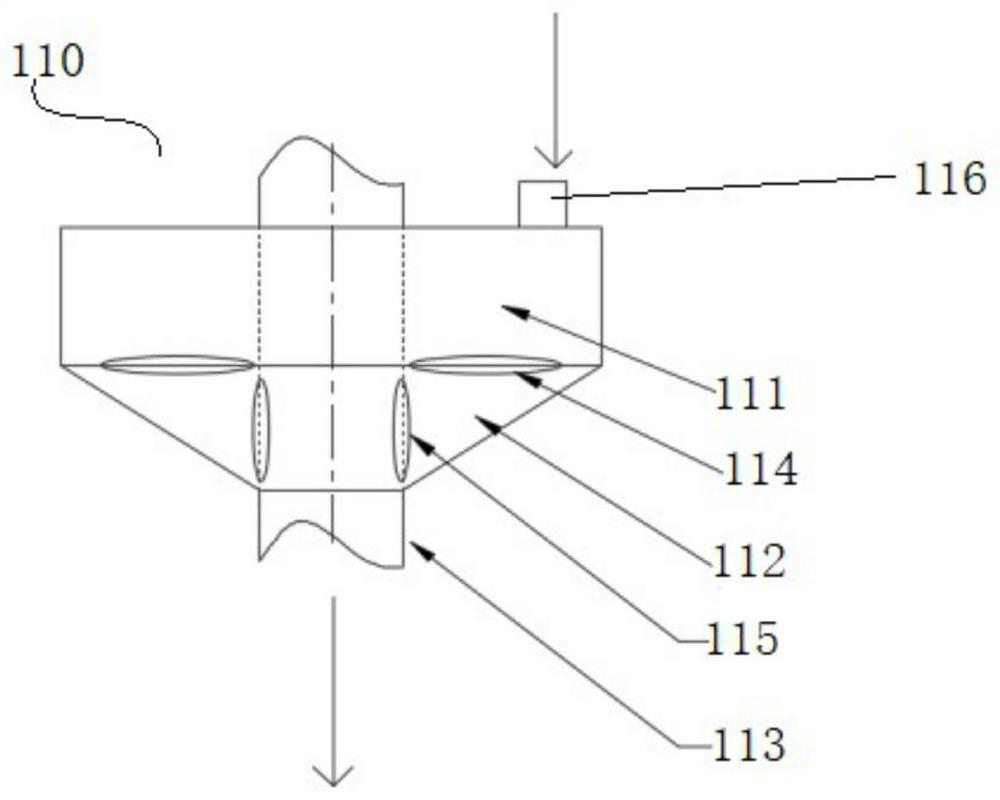

[0128] S1, mixed feeding

[0129] According to the requirement of TC4 composition (V is 4.25%, A1 is 6.2%, O is 0.1%, Fe is 0.11%), calculate the weight of raw materials, among them, sponge titanium 10kg, aluminum vanadium alloy 0.811kg, aluminum beans 0.362kg, titanium dioxide 0.011kg , the iron ball is 0.005kg, and the weighing value of each billet bin is set respectively, and then the corresponding types of raw materials are added to the bins of different billet bins, the door of the feeding bin is opened, and the raw materials enter the weighing bin evenly from the bin bin, when the raw material entering the weighing bin reaches the set weight, a signal is given to close the automatic feeding bin door, and at the same time open the discharging bin door, the raw material enters the feeding channel through the discharging bin door and is then discharged under the action of gravity. It falls into the mixing bin, and automatically closes t...

Embodiment 2

[0144] Preparation of TA1 filaments

[0145] S1, mixed feeding

[0146] Set the weighing value of the billet bin to 10kg, then add titanium sponge into the bin of the billet bin, open the door of the feeding bin, and the raw material enters the weighing bin evenly from the bin, when the raw material entering the weighing bin reaches the required After the set weight, a signal is given to close the automatic feeding bin door, and at the same time open the discharging bin door, the raw material enters the feeding channel from the discharging bin door and then falls into the mixing bin under the action of gravity, and automatically closes after the feeding is completed discharge bin door;

[0147] In the mixing bin, the different raw materials are stirred evenly by pneumatic stirring, and the mixed raw materials are fed into the waiting bin in batches through the feeding controller, and the feeding screw sends the mixed raw materials in the waiting bin into the cooling bed in ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com