Purification method of phosphoric acid

A technology of phosphoric acid and phosphoric acid solution, which is applied in the field of phosphorus chemical industry, can solve the problems of low acid purity and high content of anion impurities, and achieve the effects of simple process, good product quality, and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

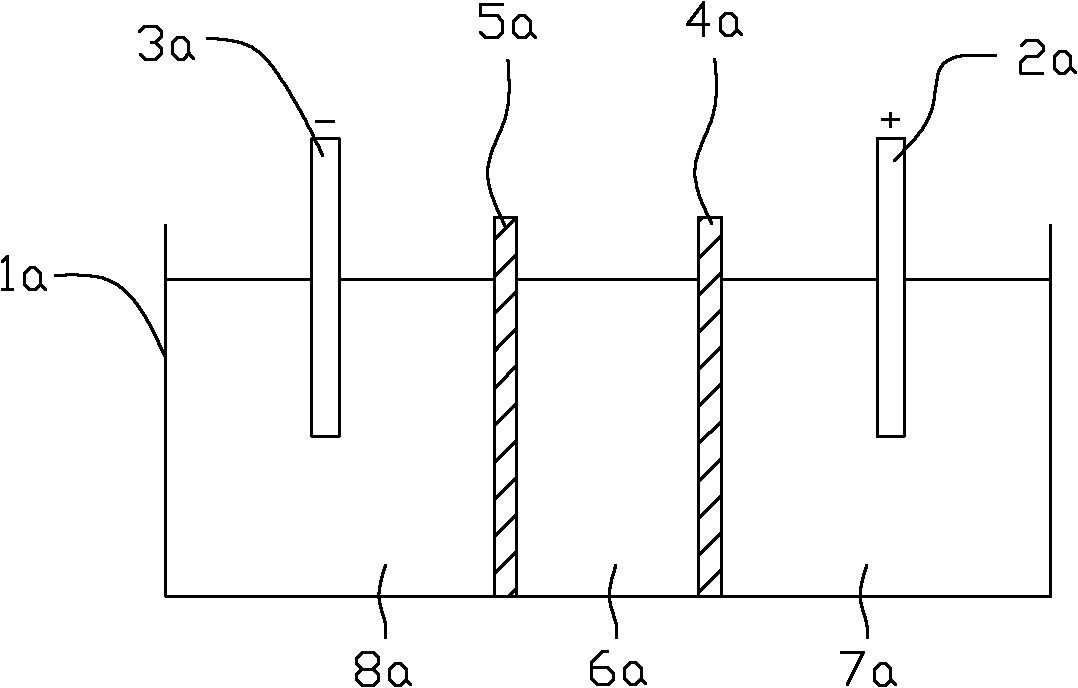

Embodiment 1

[0067] Decompose Guizhou Fuquan phosphate rock with sulfuric acid to separate gypsum to obtain wet-process phosphoric acid, which is used as raw acid for electrodialysis. Adopt a three-chamber electrodialysis device assembled according to cathode plate (cathode chamber) → positive membrane → intermediate chamber → negative membrane → anode chamber (anode chamber). The positive membrane uses polyethylene homogeneous cation exchange membrane, and the negative membrane uses polyethylene homogeneous anion exchange membrane. Add 400 grams of ultrapure water to the intermediate chamber, respectively add 900 grams of raw material phosphoric acid to be treated in the cathode chamber and the anode chamber, and its concentration is 25.52% (in P 2 o 5 count). Electrodialysis was performed under a DC power supply. Working current density 1.25A / dm 2 , the working voltage is 3V, the temperature of the liquid phase system is controlled between 25°C, and the electrodialysis operation time...

Embodiment 2

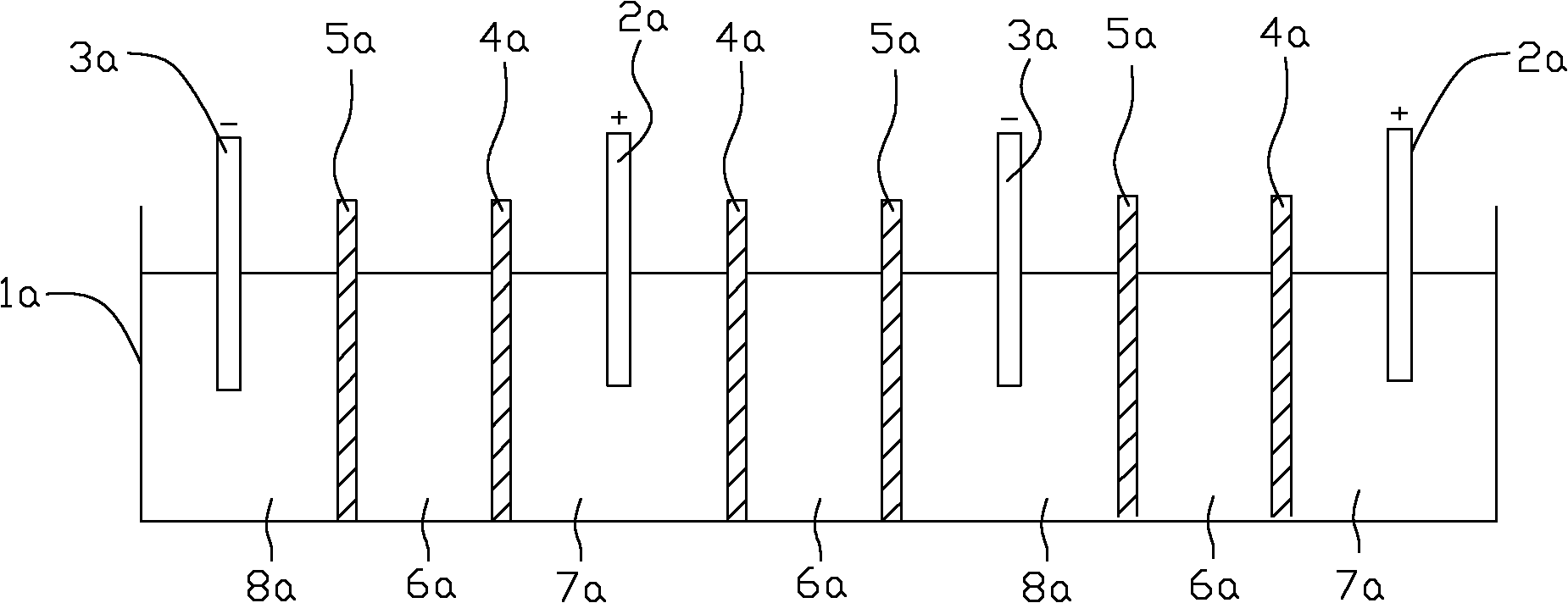

[0069]Decompose Guizhou Fuquan phosphate rock with sulfuric acid to separate gypsum to obtain wet-process phosphoric acid, which is used as raw acid for electrodialysis. A three-chamber electrodialysis device assembled by cathode plate (cathode chamber)→cation membrane→intermediate chamber→cathode membrane→anode chamber (anode chamber) is adopted. Polyethylene homogeneous cation exchange membrane is used for the positive membrane, and polyether homogeneous anion is used for the negative membrane. exchange membrane. Add 400 grams of ultrapure water to the intermediate chamber, respectively add 900 grams of raw material phosphoric acid to be treated in the cathode chamber and the anode chamber, and its concentration is 25.52% (in P 2 o 5 count). Electrodialysis was performed under a DC power supply. Working current density 1.25A / dm 2 , the working voltage is 3V, the temperature of the liquid phase system is controlled between 25°C, and the electrodialysis operation time is 3...

Embodiment 3

[0071] Decompose Guizhou Fuquan phosphate rock with sulfuric acid to separate gypsum to obtain wet-process phosphoric acid, which is used as raw acid for electrodialysis. A three-chamber electrodialysis device assembled by cathode plate (cathode chamber)→cation membrane→intermediate chamber→cathode membrane→anode chamber (anode chamber) is adopted. Polyethylene homogeneous cation exchange membrane is used for the positive membrane, and polyether homogeneous anion is used for the negative membrane. exchange membrane. Add 400 grams of ultrapure water to the intermediate chamber, respectively add 900 grams of raw material phosphoric acid to be treated in the cathode chamber and the anode chamber, and its concentration is 25.52% (in P 2 o 5 count). Electrodialysis was performed under a DC power supply. Working current density 1.25A / dm 2 , the working voltage is 3V, the temperature of the liquid phase system is controlled between 25°C, and the electrodialysis operation time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com