Test target and test method for testing targeting precision of laser device

A laser device and precision testing technology, applied in the field of laser inertial confinement fusion, can solve problems such as errors, deviations in test results, and increase the testing time of targeting accuracy, so as to improve testing efficiency, save testing time, and reduce errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

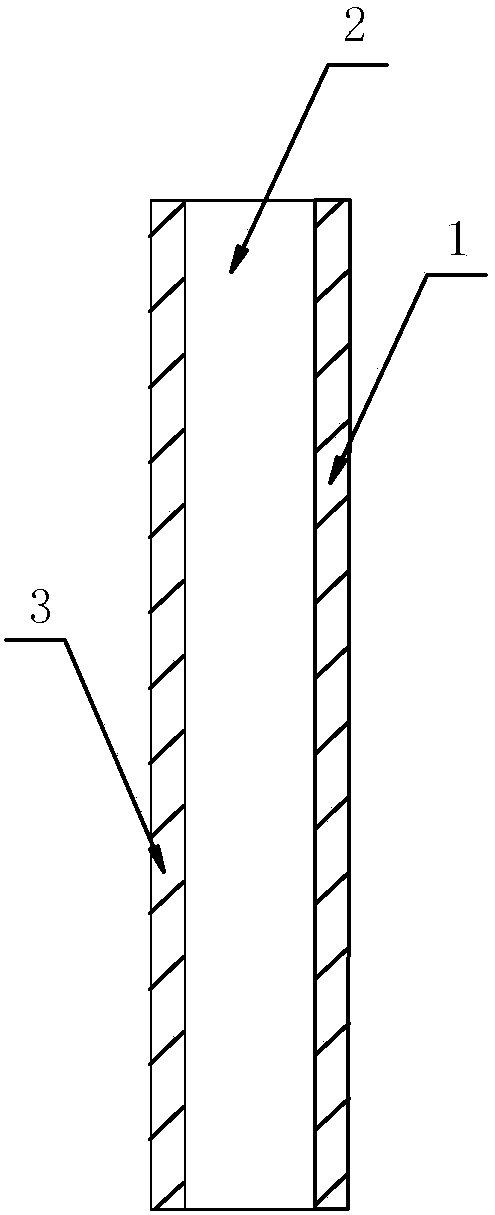

[0031] Such as Figure 1-3 As shown, a test target used for testing the accuracy of laser device targeting includes a target surface, which in turn includes a gold foil layer 1, a hydrocarbon film layer 2, and a gold foil layer 3, that is, the gold foil layers are co-located Two layers, the hydrocarbon film layer 2 is located between the two gold foil layers, and the laser beam emitted by the laser device is incident on the surface of the gold foil layer 1 and the gold foil layer 3 simultaneously, that is, the laser beam is incident on the test target simultaneously The front and back sides of the laser beam can simultaneously complete the target accuracy test of many laser beams in one test, save the test time of the target accuracy, and improve the test efficiency of the target accuracy.

[0032] During the target accuracy test, the gold foil layer 1 and the gold foil layer 3 can interact with the laser to generate plasma, and the plasma region will emit high energy at the same...

Embodiment 2

[0037] The parts in this embodiment that are the same as those in the first embodiment will not be repeated, the difference is:

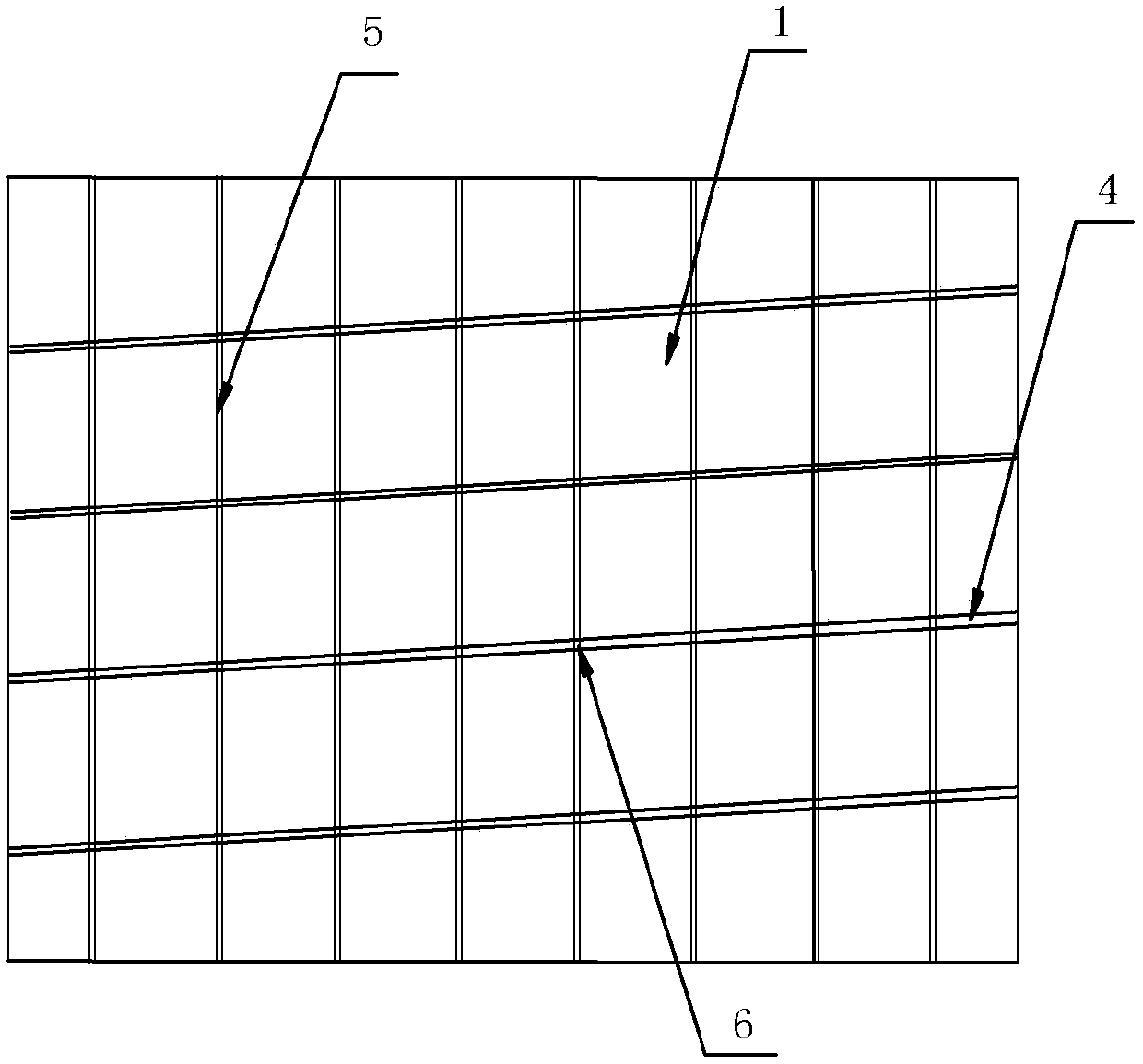

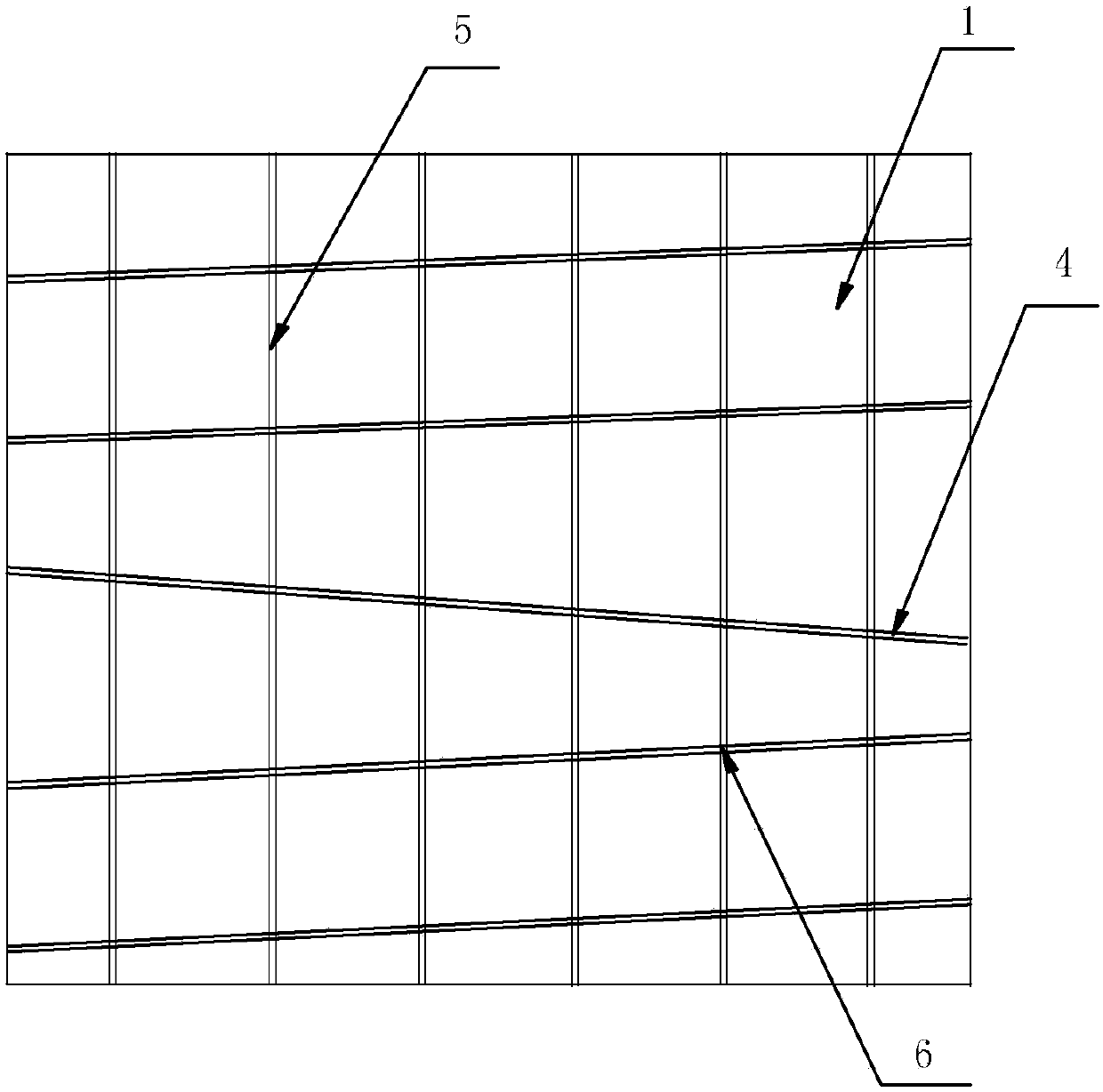

[0038] Such as Figure 4 As shown, there are 48 laser beams 9 in total, the first groove 4 and the second groove 5 are vertically staggered, and the number of both is 5, which are located on the gold foil layer 1 and the gold foil layer 3. The number of intersections is 25, and each layer of gold foil has 1 intersection in the lower right corner as a mark. The thickness of the gold foil layer 1 and the gold foil layer 3 are both 30 μm, the thickness of the hydrocarbon film layer 2 is 1000 μm, the laser beam spot diameter incident on the surface of the gold foil layer is 800 μm, and the center distance between two adjacent target holes 6 is 1600 μm. The size of the test target is 8mm×8mm.

[0039] The laser beam 9 interacts with the gold foil layer 1 and the gold foil layer 3 to excite plasma, and the plasma region will emit high energy at the same time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com