Oil gas recovery system

An oil and gas recovery system, oil and gas technology, applied in the recovery of liquid hydrocarbon mixture, vapor condensation, petroleum industry, etc., can solve the problems of reduced adsorption capacity, small processing capacity, inconvenience, etc., to reduce operating costs, reduce regeneration frequency, and increase processing. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

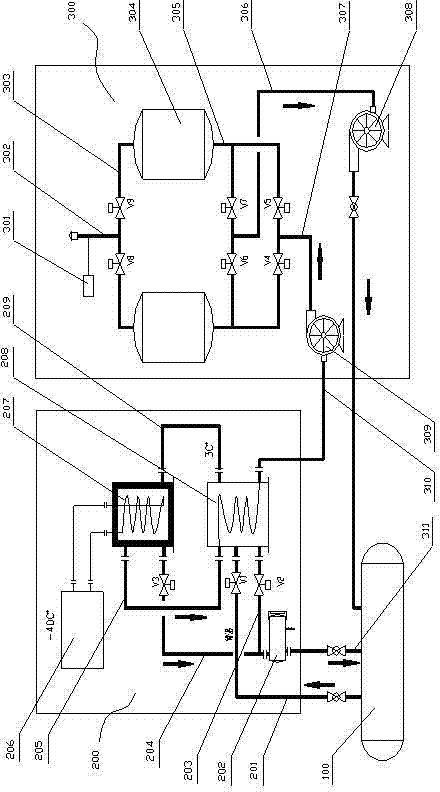

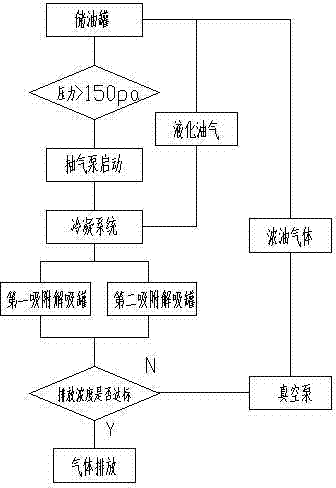

[0010] see figure 1 and figure 2 , the present invention relates to an oil and gas recovery system, which includes an adsorption device 300 and a condensation device 200. The adsorption device is provided with 307, an oil gas exhaust pipe 302 after adsorption and a desorbed oil gas return pipe 306. The condensation device is provided with a waiting Condensed oil and gas inlet pipe 201, condensed oil and gas exhaust pipe 210 and condensate return pipe 211, the condensed oil and gas exhaust pipe of the condensing device is connected to the oil inlet pipe to be adsorbed of the adsorption device. When the source of oil and gas is the oil tank 100 of the gas station and / or the fuel tank of the car, the oil and gas inlet pipe to be condensed can be connected to the oil and gas collection equipment or the discharge port of the oil tank / tank, and the desorbed oil and gas return pipe and the condensate return pipe can be connected to the oil Tank, in order to realize the treatment an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com