Patents

Literature

155results about How to "Reduce regeneration frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

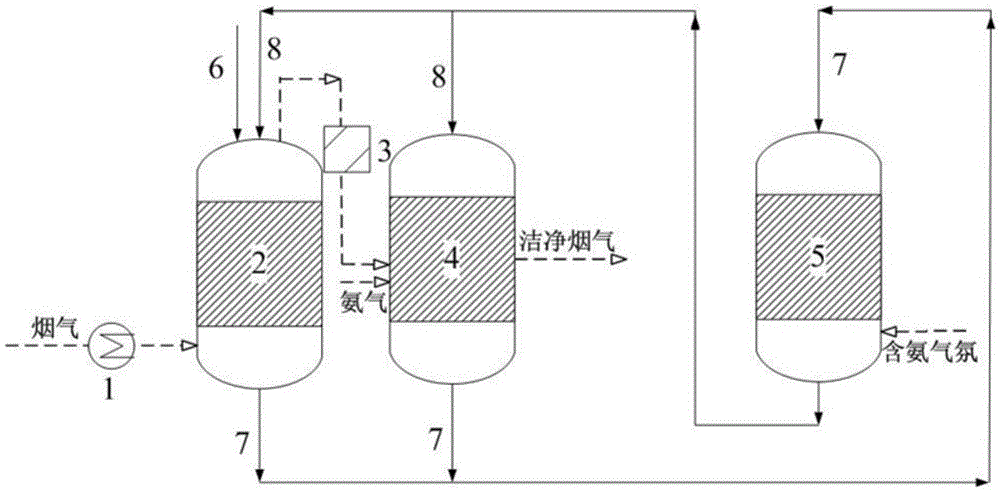

Flue gas hydrargyrum-removing method by catalytic oxidation

InactiveCN1698931ALittle matrix damageReduce pollutionDispersed particle separationPtru catalystSorbent

This invention relates to a catalytic oxidation smoke gas mercury removing method, which is used for controlling and reclaiming the gas mercury, especially for the brown coal and subbituminous coal smoke gas. The method uses the mercury oxidative catalyst and the adsorbent to oxygenize and absorb mercury in the smoke gas, then dissociate and elution the mercuric oxide in high temperature to regenerate it. The heat of the elution gas can be reclaimed by residual heat utilization device, and the high concentration mercury will be reclaimed through cold-trap or processed by the agent in the mercury reactor. The reclaimed mercury and other by-product can be sold to reduce the cost. Said invention uses the thermal instability of the mercuric oxide, and reclaims in the relative lower temperature; the recovery ratio can reach to 98%, meanwhile, it processes post-treatment with the mercury and has no secondary pollution.

Owner:SHANGHAI JIAO TONG UNIV

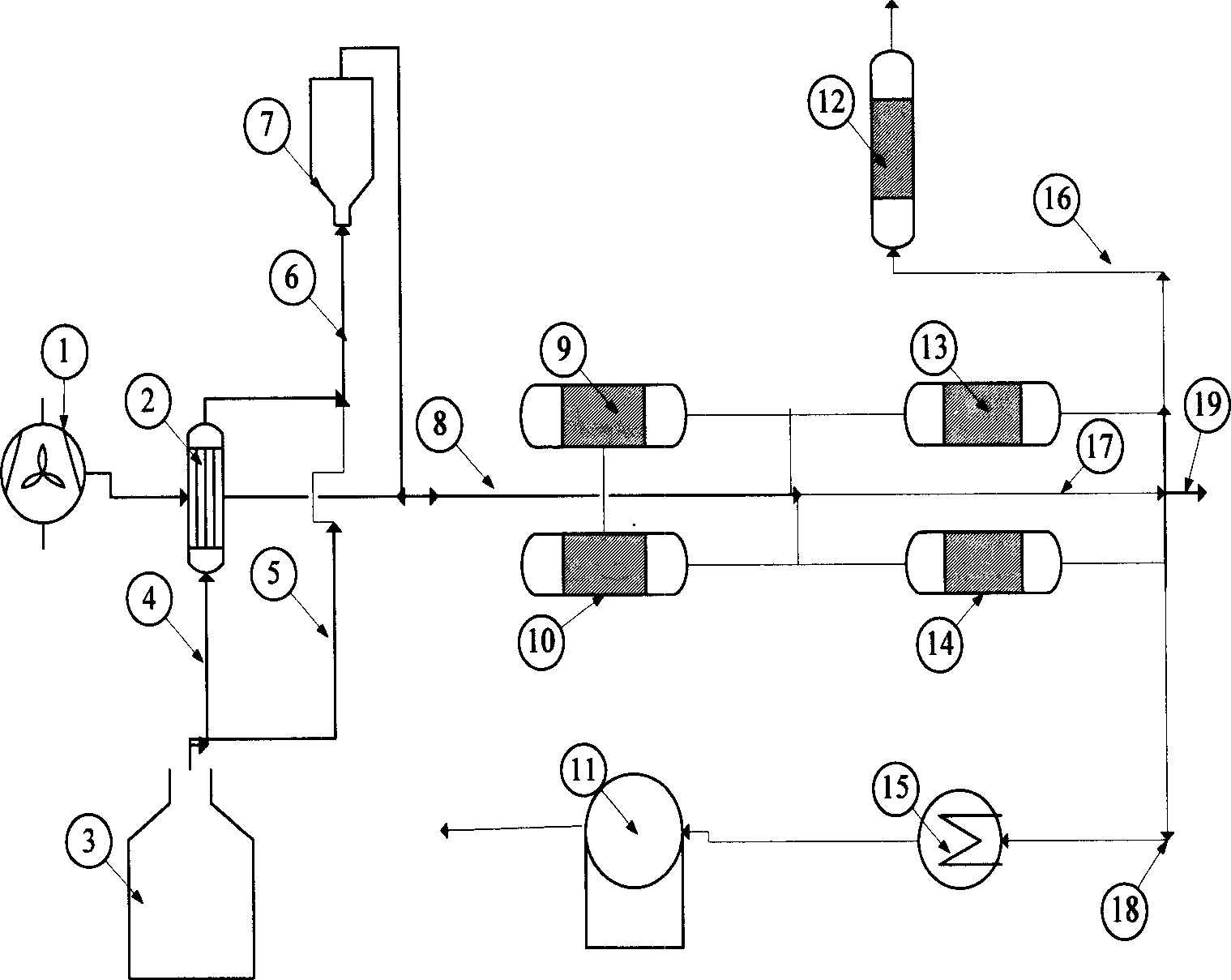

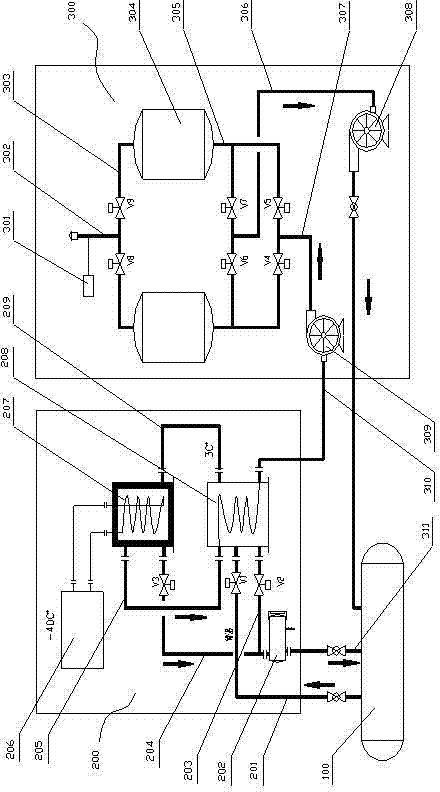

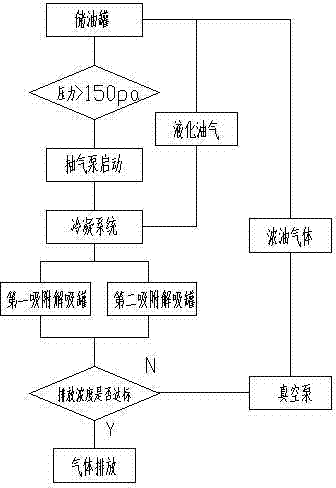

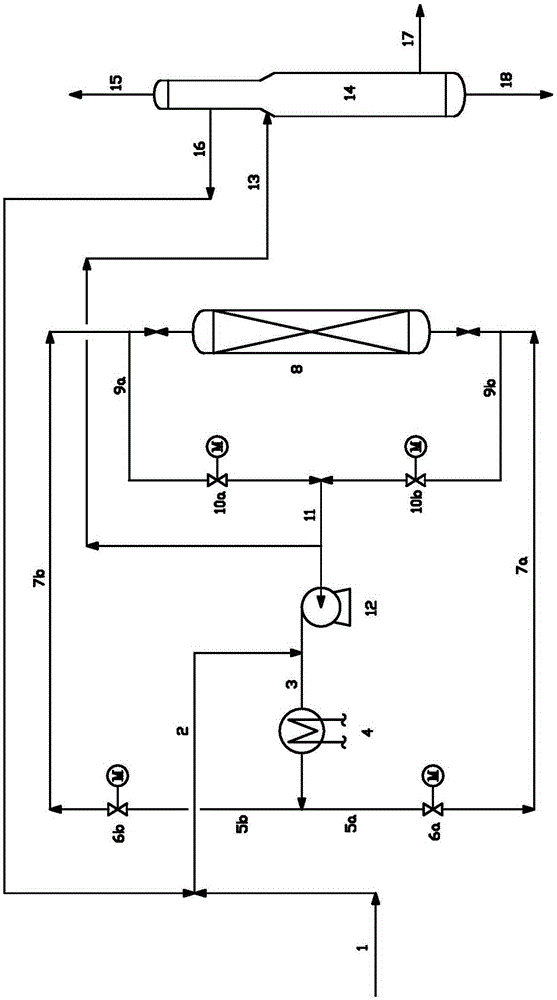

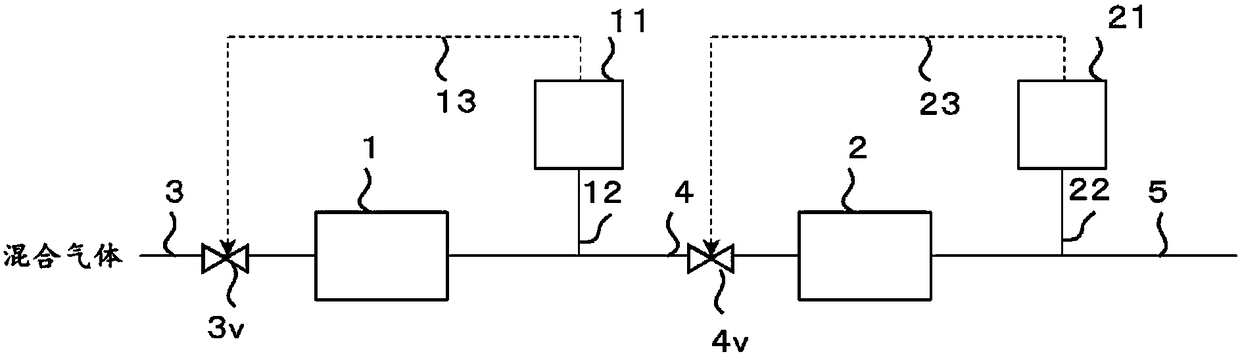

Oil gas recovery system

InactiveCN102899064AReduce oil contentReduce the use effectDispersed particle separationLiquid hydrocarbon mixture recoveryPlate heat exchangerDesorption

The invention relates to an oil gas recovery system. The oil gas recovery system comprises an adsorption unit and a condensing unit, wherein a gas inlet pipe for oil gas to be adsorbed, an exhaust pipe for adsorbed oil gas and a return pipe for desorbed oil gas are arranged on the adsorption unit; a gas inlet pipe for oil gas to be condensed, an exhaust pipe for condensed oil gas and a return pipe for condensate are arranged on the condensing unit; the exhaust pipe for the condensed oil gas of the condensing unit is connected with the gas inlet pipe of the oil gas to be adsorbed of the adsorption unit; a first adsorption / desorption tank and a second adsorption / desorption tank are arranged on the adsorption unit to alternately adsorb and desorb the oil gas; and two condensing plants namely an oil gas heat exchanger and a cold box are arranged on the condensing unit to sequentially condense the oil gas. The oil gas recovery system is high in treatment capacity and recovery efficiency, can continuously work, and is mainly suitable for recovering the oil gas generated during oil injection of a buried oil tank of a gas station and refueling of a fuel tank of an automobile.

Owner:陈玲海

Method and apparatus for determining information concerning presence of constituents of a liquid sample with oxygen demand

ActiveUS20100294672A1Reduce frequencyEndanger of be reduceImmobilised enzymesBioreactor/fermenter combinationsDiamond electrodesAdditive ingredient

Owner:ENDRESS HAUSER CONDUCTA GESELLSCHAFT FUER MESS UND REGELTECHNIK MBH CO KG

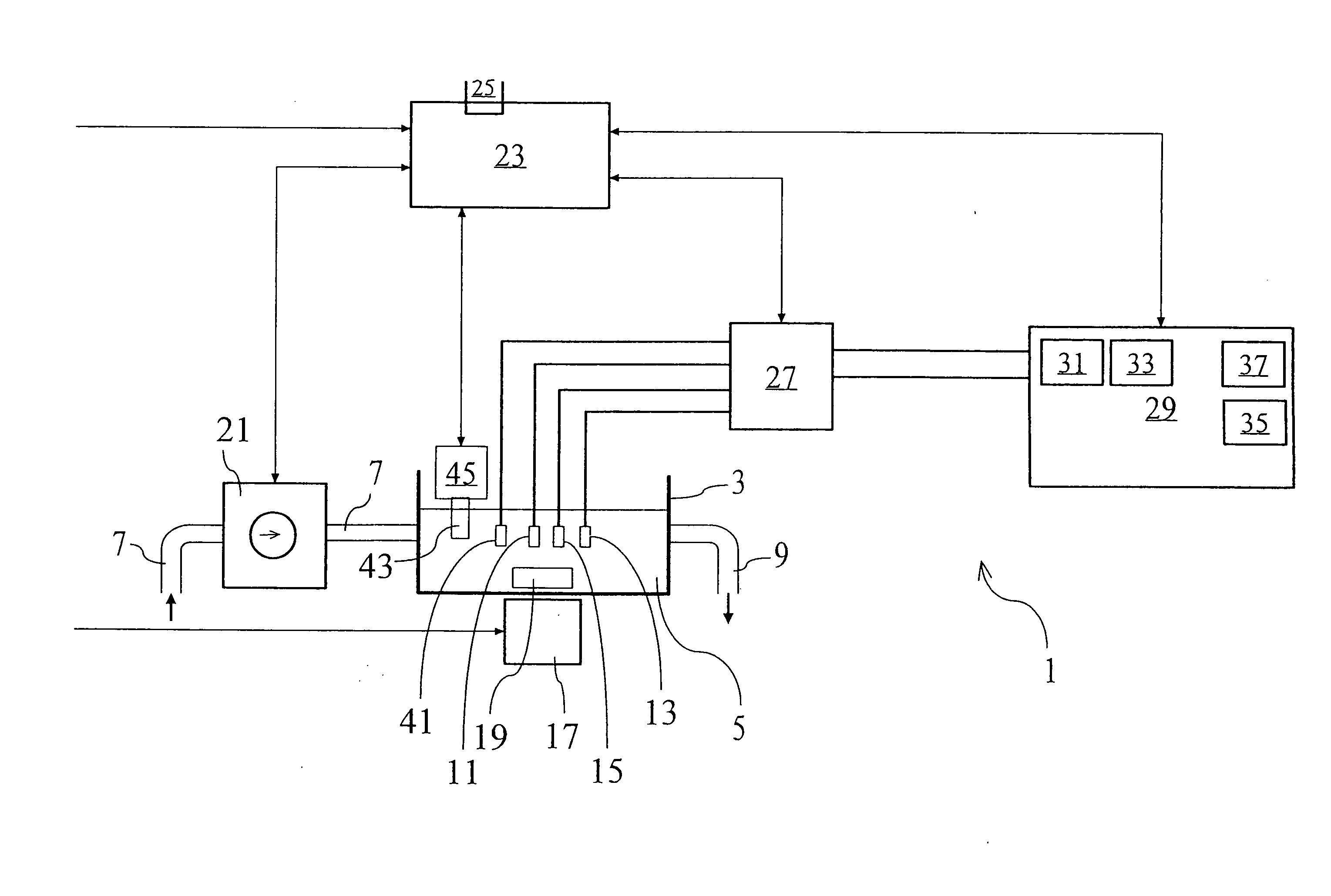

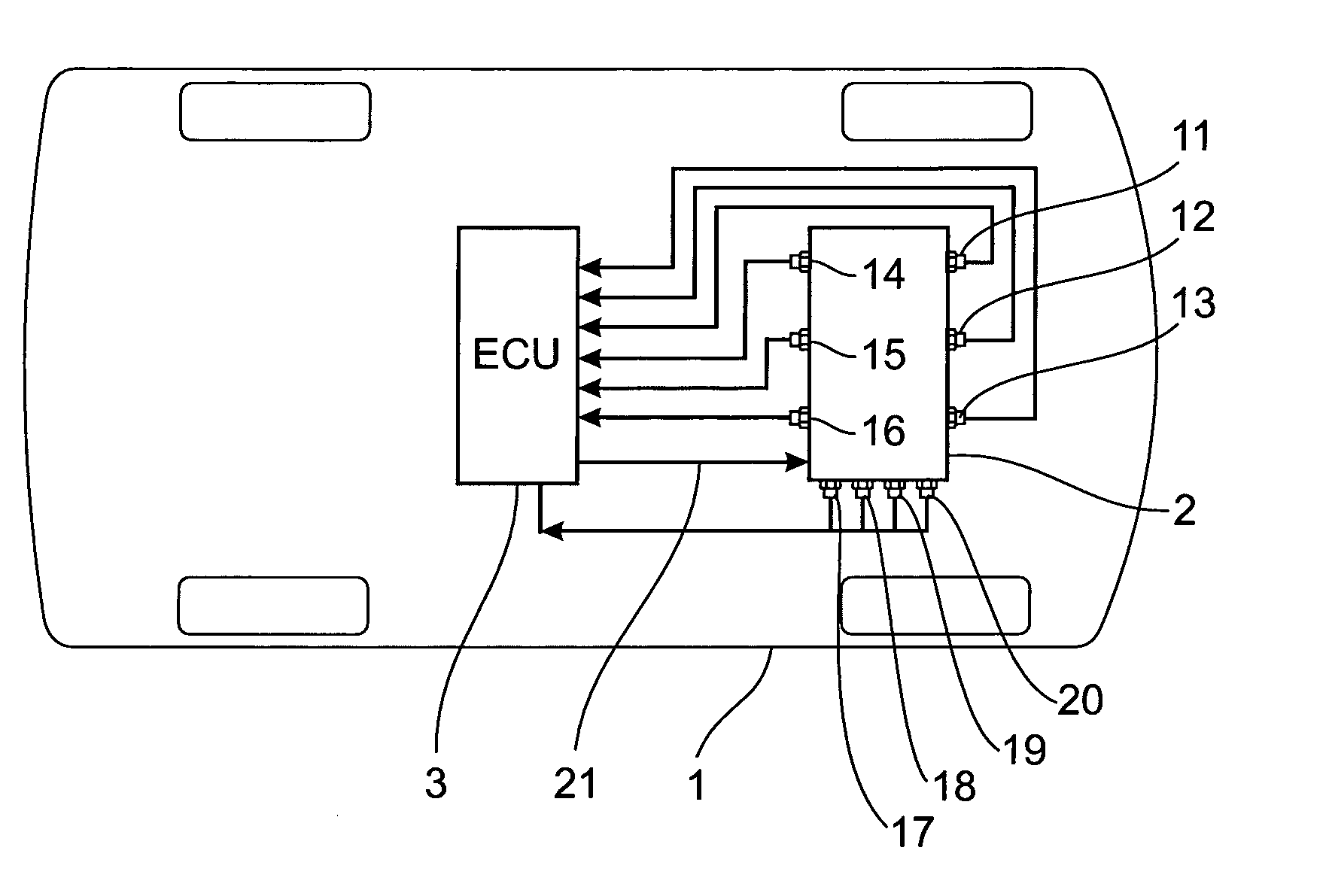

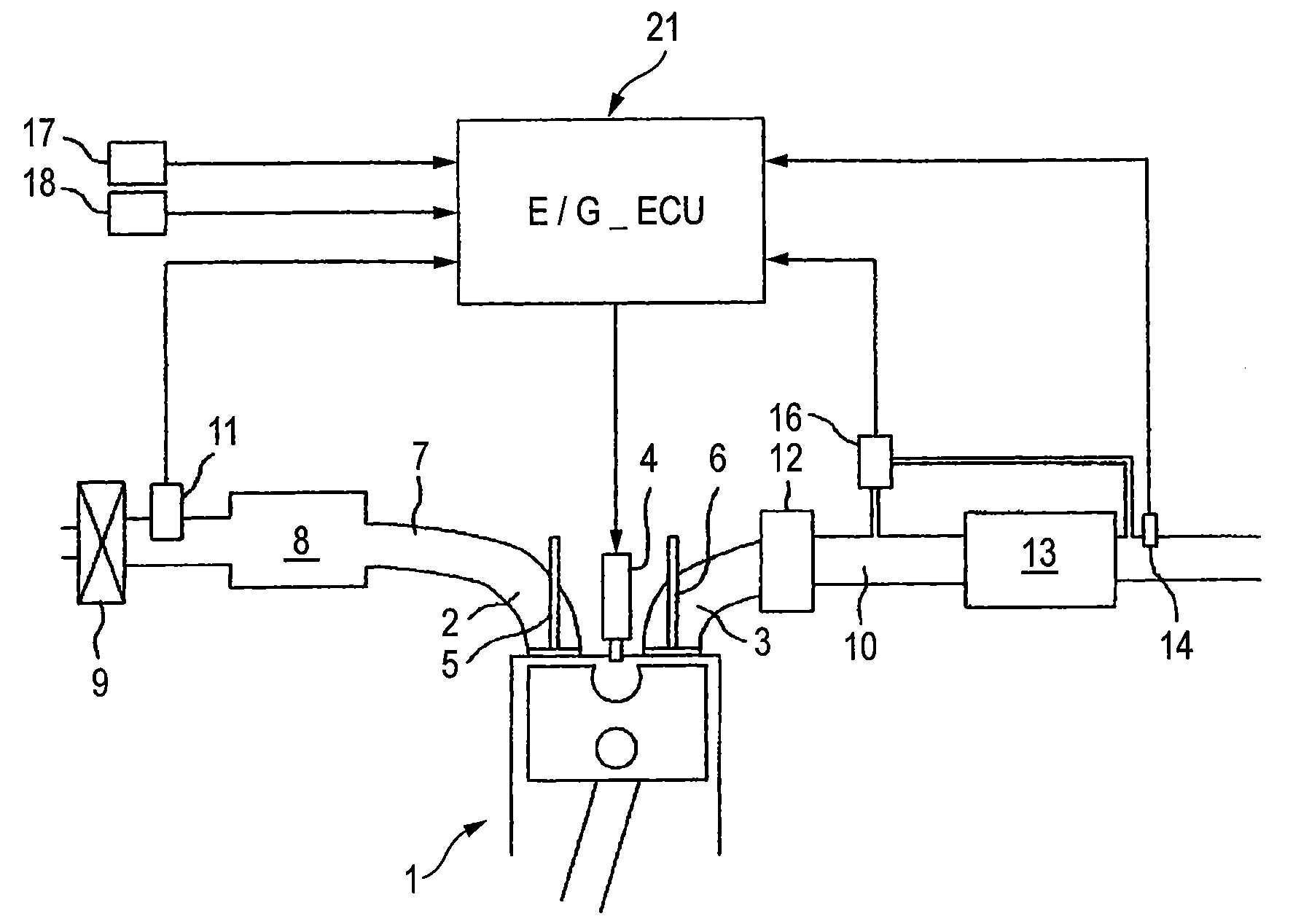

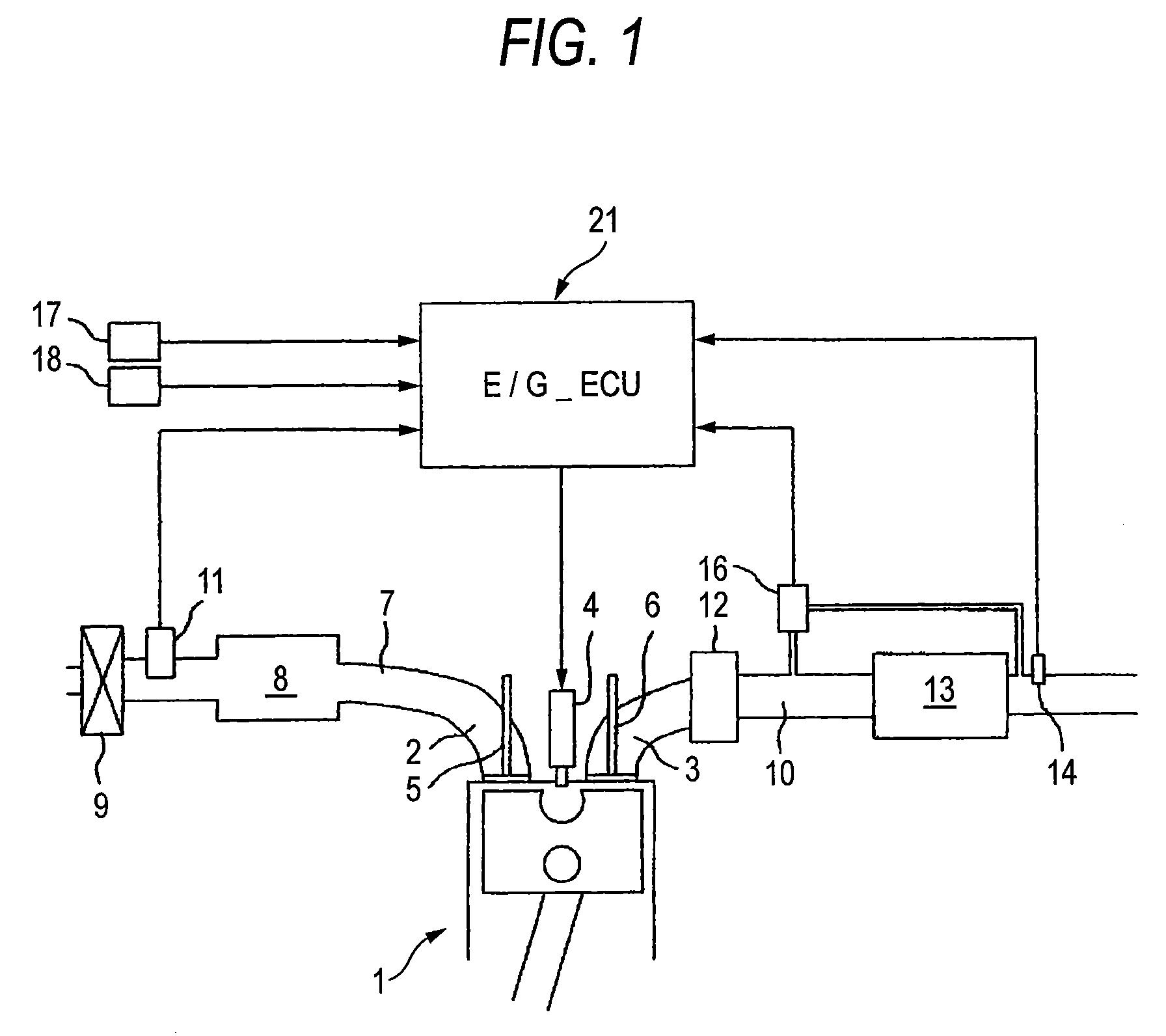

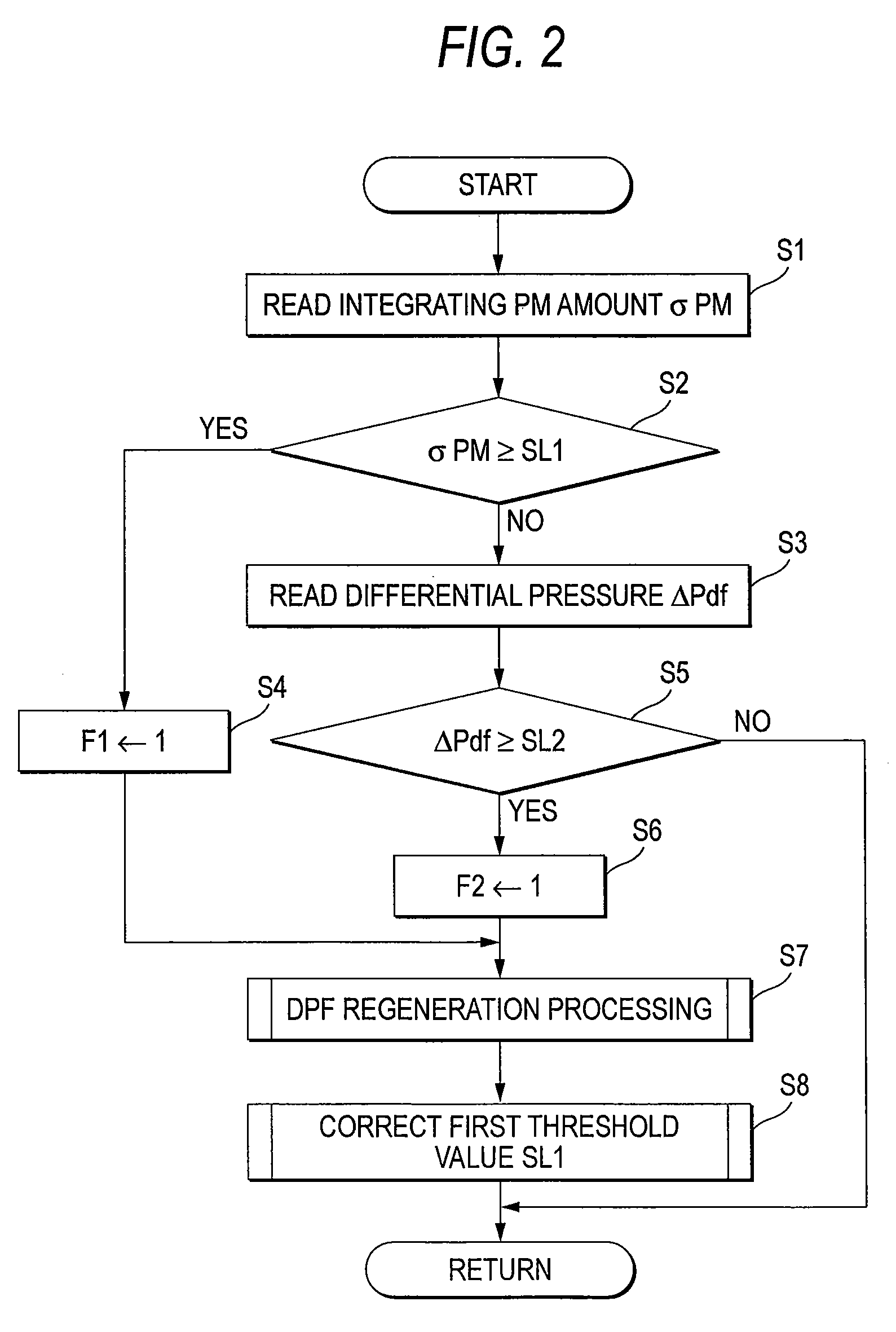

Exhaust cleaning device of diesel engine

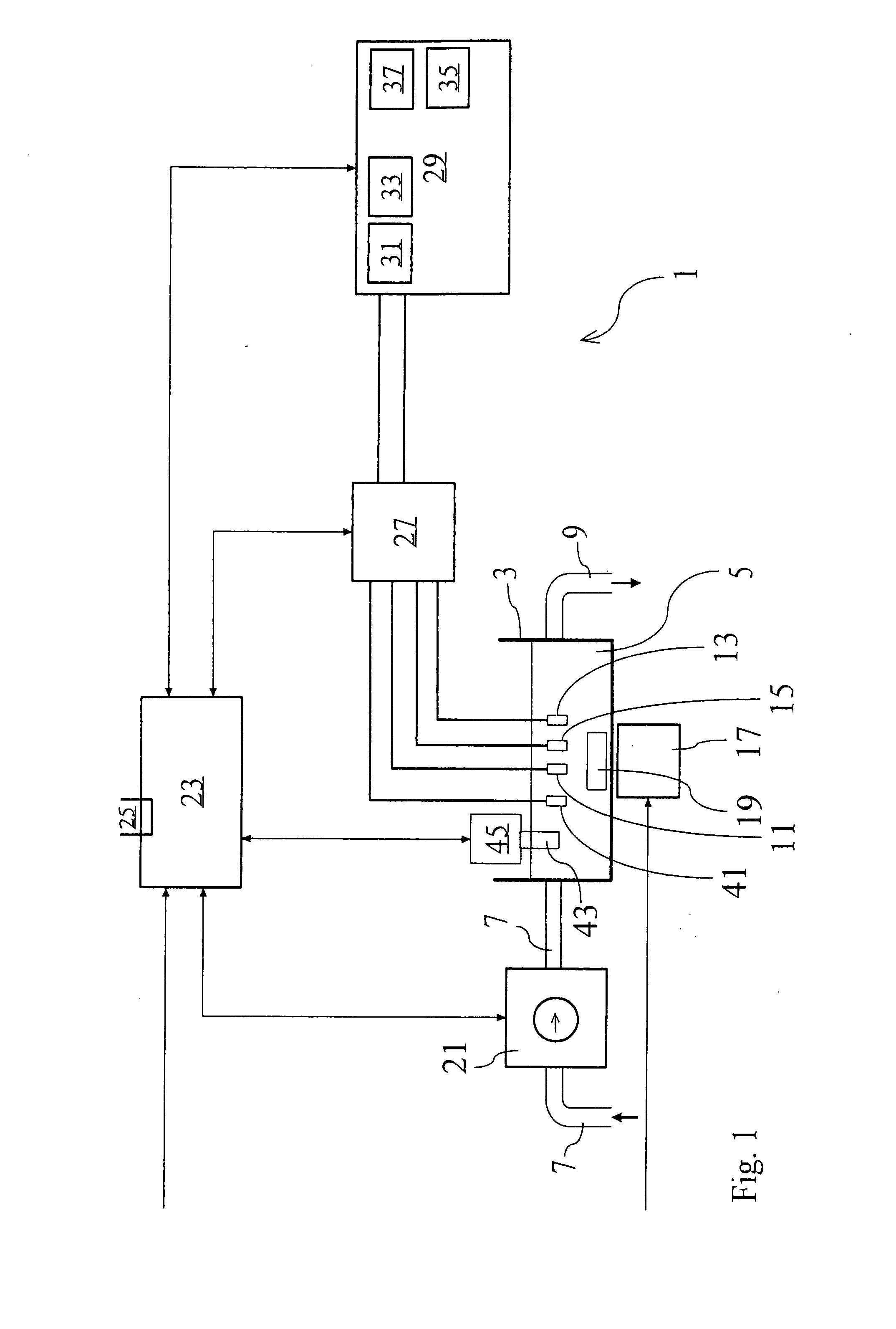

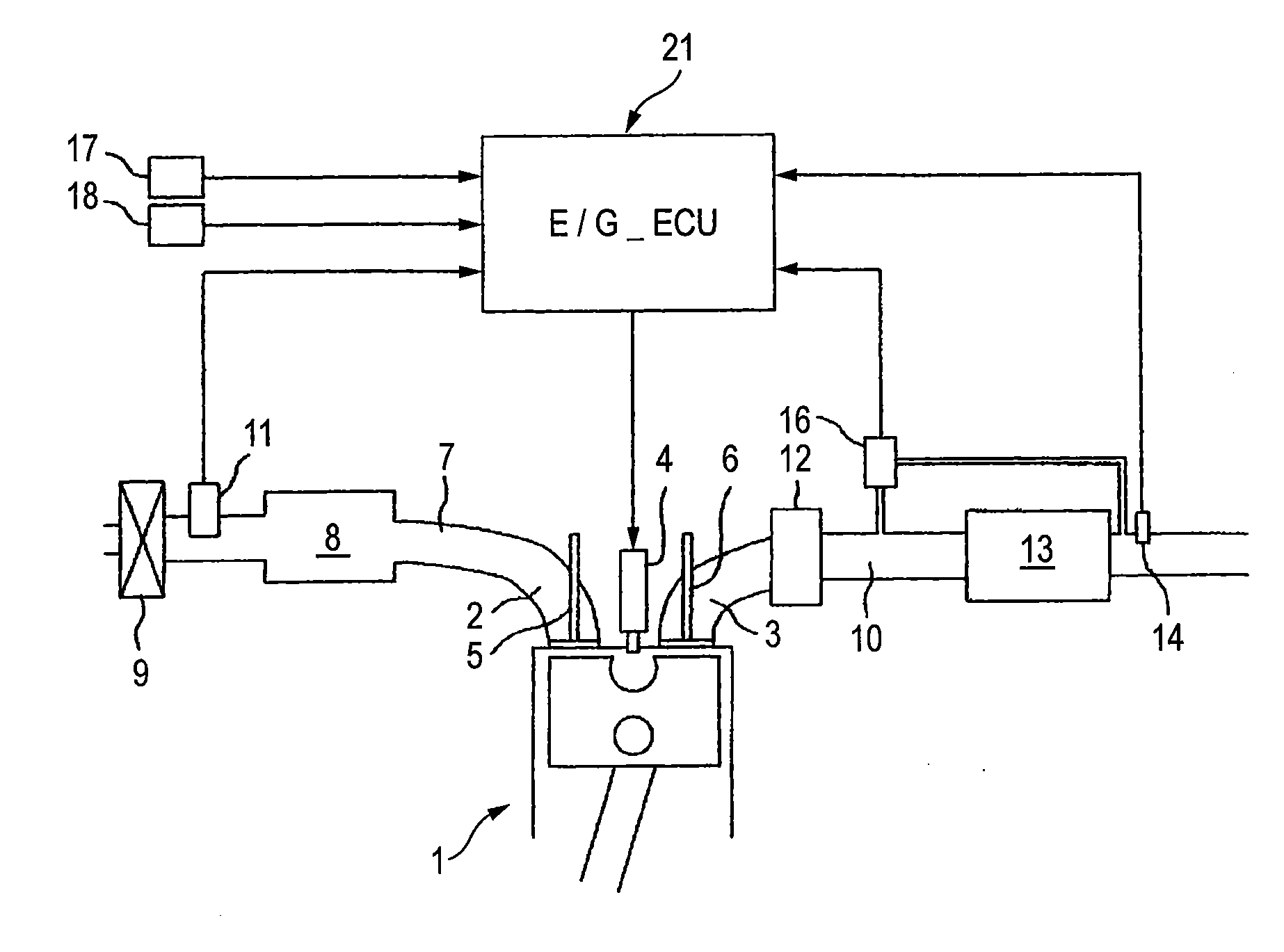

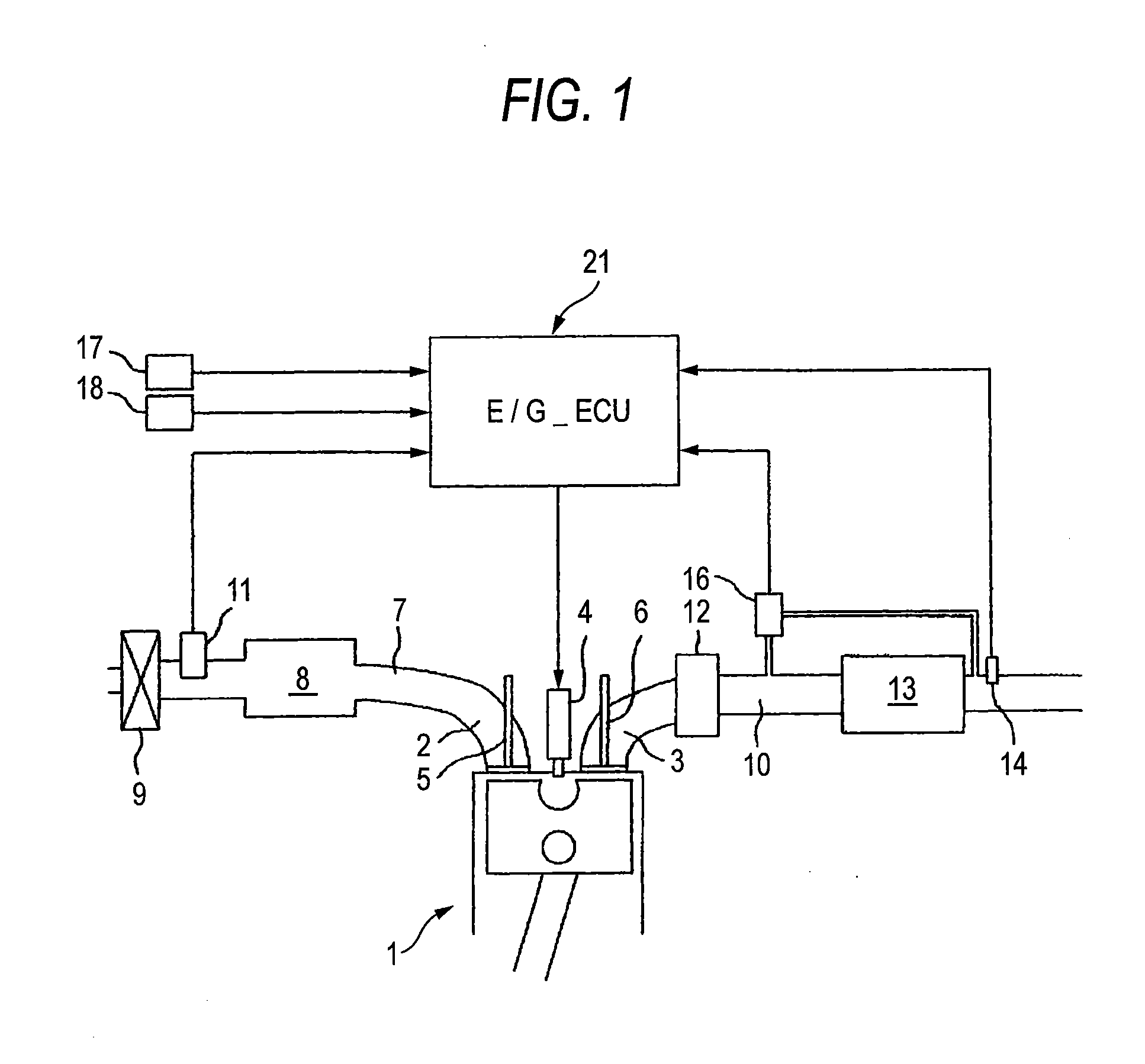

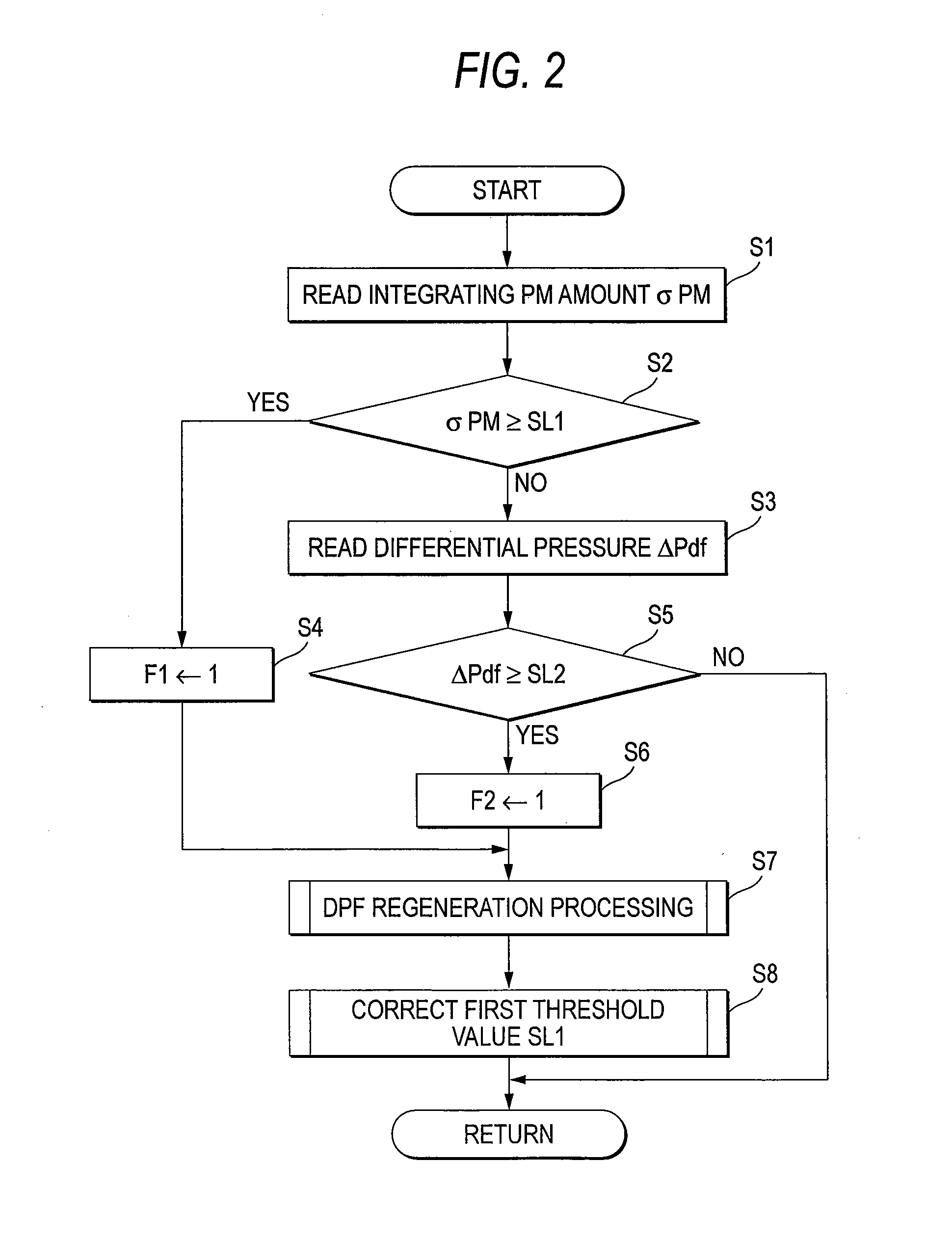

InactiveUS20070234712A1Reduce regeneration frequencyIncreased fuel costInternal combustion piston enginesExhaust apparatusDifferential pressureEngineering

An integrating PM amount σ PM as an integrating value of a PM generating amount after DPF regeneration is read (S1). The integrating PM amount and a first threshold value SL1 set in advance are compared, and the regenerating period of DPF 13 is judged (S2). Further, a differential pressure ΔPdf before and after DPF 13 detected by a differential pressure sensor 16, and a second threshold value SL2 are compared, and the regenerating period of DPF 13 is judged (S5). Regeneration processing of DPF 13 is then performed when the integrating PM amount σ PM attains the first threshold value SL1 or tore, or the differential pressure ΔPdf attains a second threshold value SL2 or more (S7).

Owner:SUBARU CORP

Method for preparing inulin

The invention relates to the technical field of processing of new resource food, and in particular relates to a method for preparing inulin by using Jerusalem artichoke or chicory as a raw material. The method for preparing the inulin is high in yield, low in water consumption and low in energy consumption. The method comprises the following steps of: sequentially peeling and dicing the artichoke or the chicory as the raw material, performing continuous countercurrent extraction, adding Ca(OH)2, CO2 and active carbon to carry out one-step impurity removal and decolorization, concentrating with a nano-filtration membrane, desalting the concentrate through a strong cation and weak anion resin exchange column, and thus obtaining the high-purity inulin. According to the method, impurity removal and decolorization are completed in one step, so that material waste caused by a double-carbon method is avoided, the process is simplified, and the production efficiency is improved.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

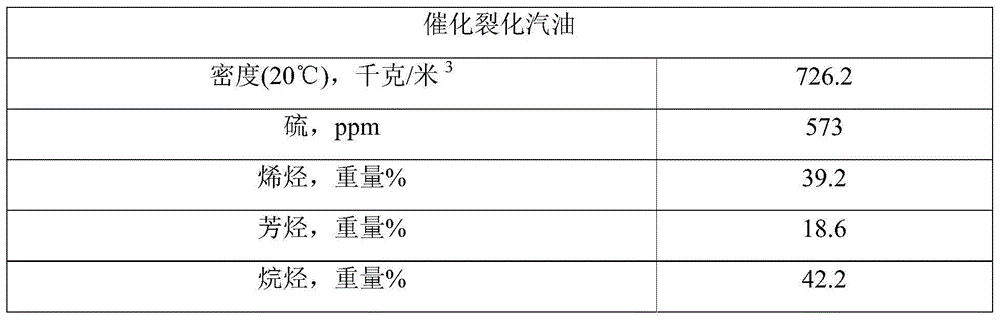

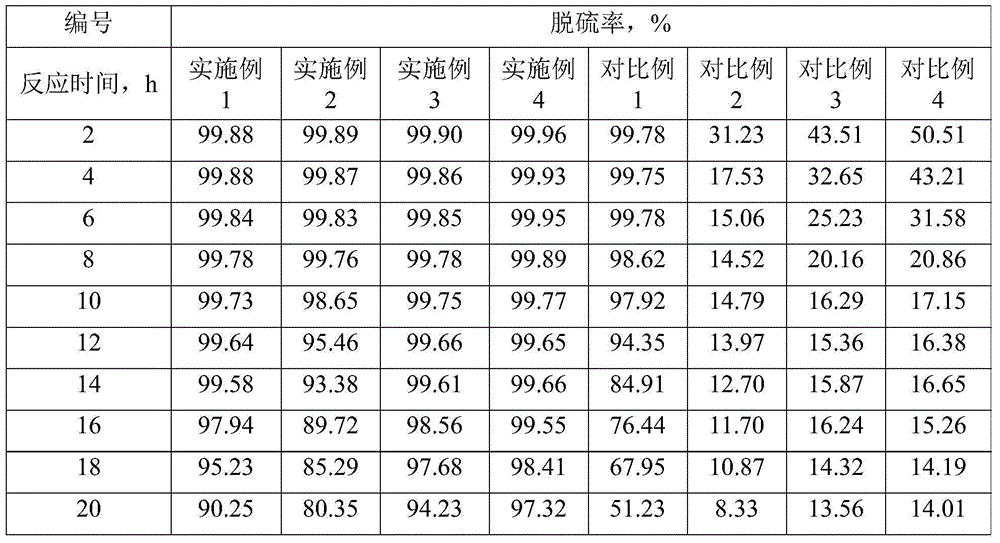

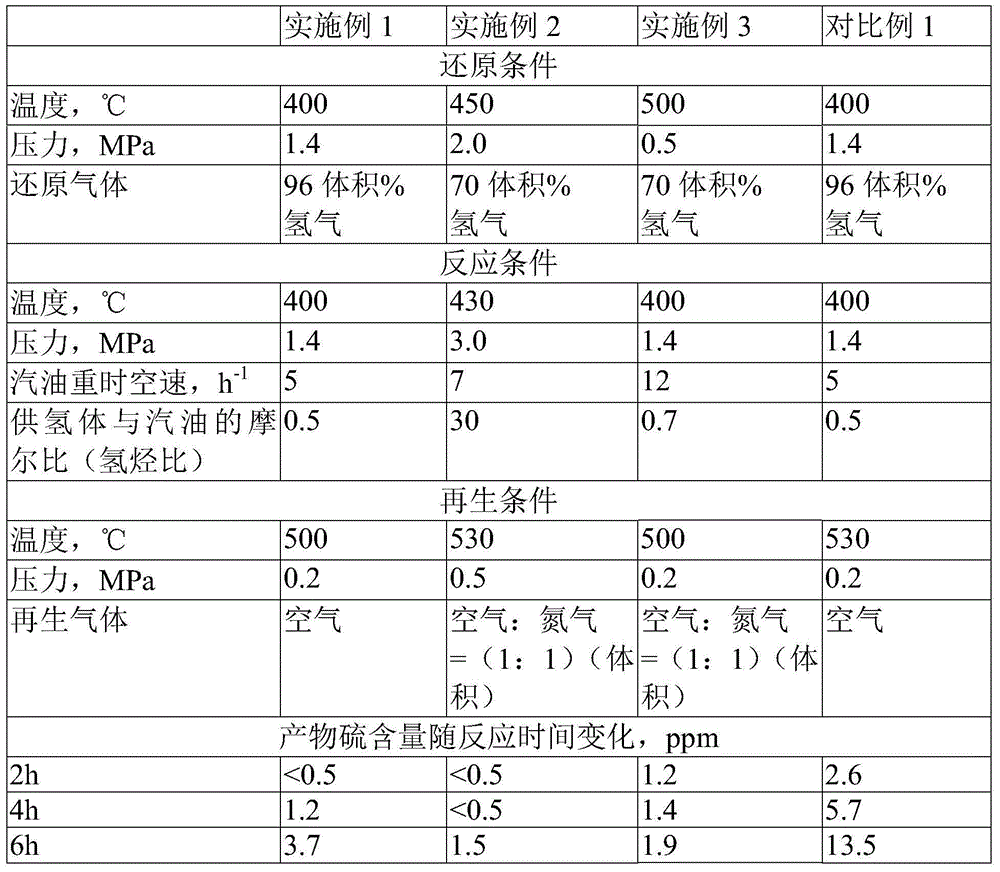

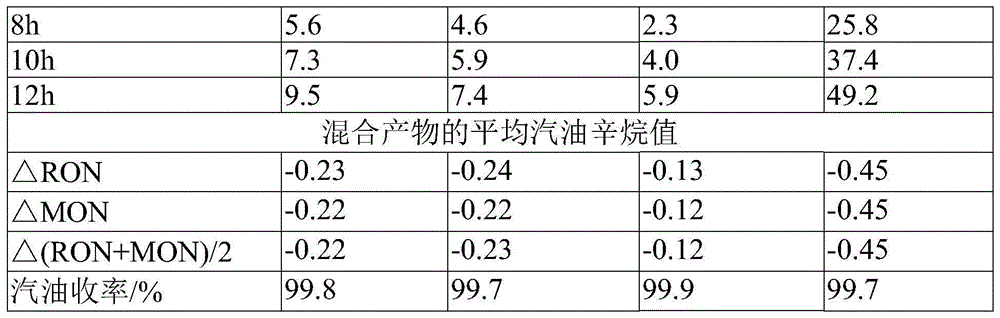

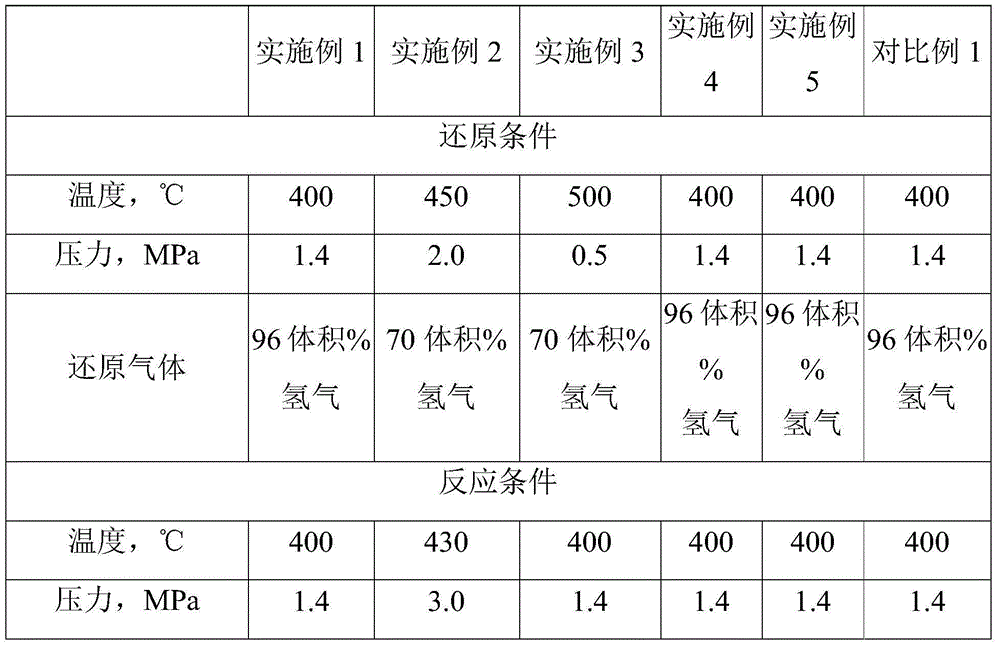

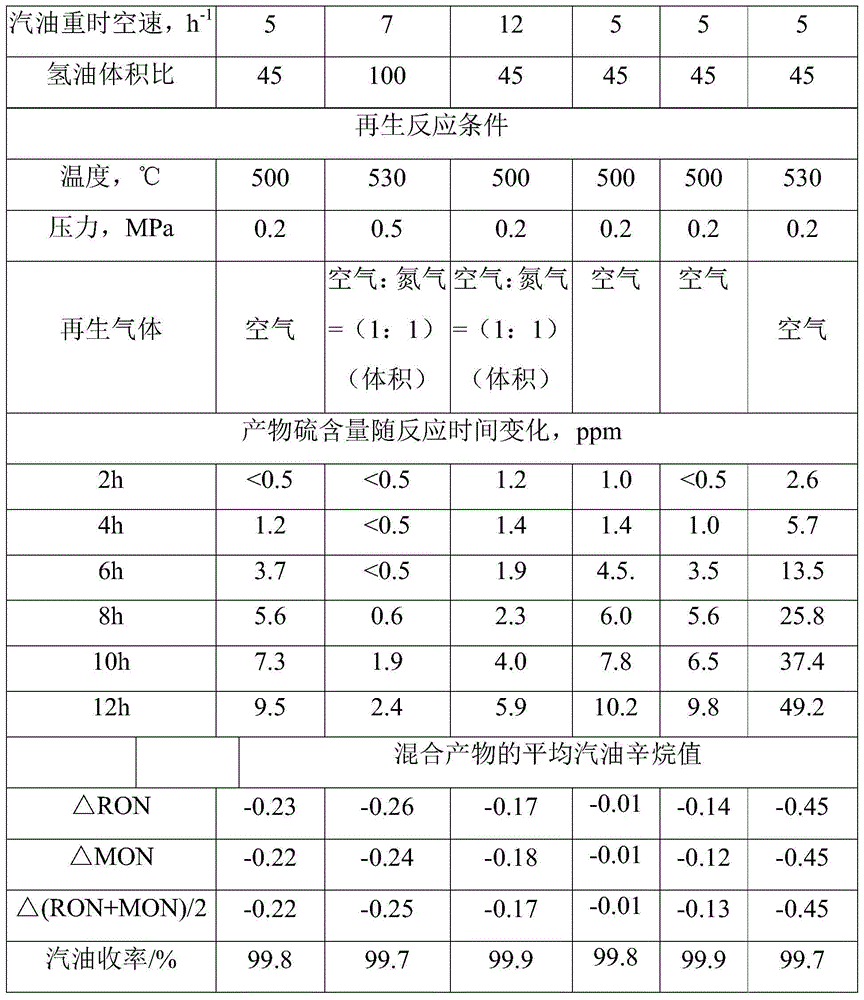

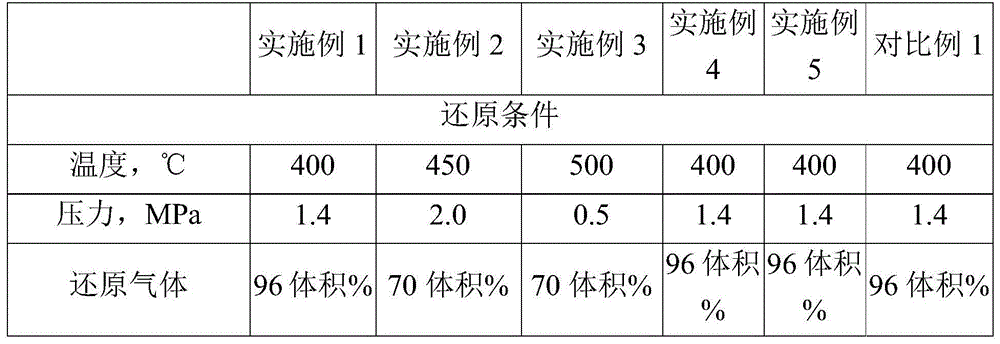

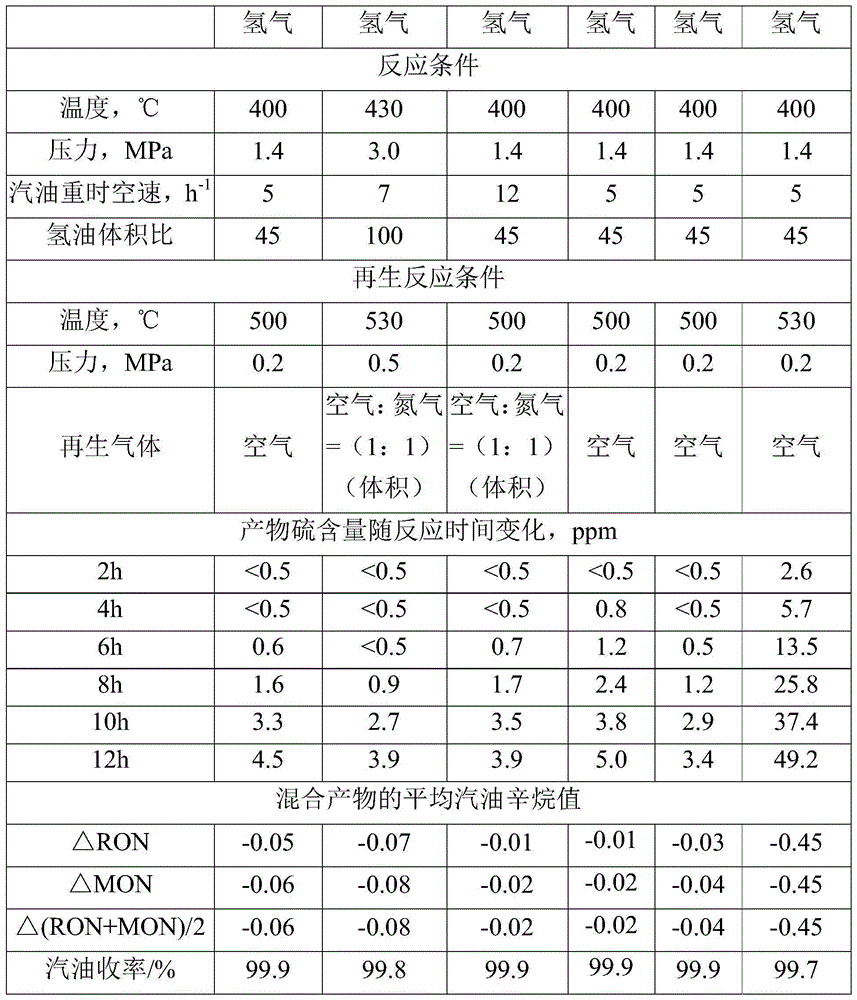

Adsorption desulfurization method

ActiveCN104560123AImprove the stability of desulfurization activityImprove utilization efficiencyHydrocarbon oils refiningHydrocarbon oils treatmentSilicon oxideCopper oxide

The invention provides an adsorption desulfurization method. The method comprises the step of carrying out contact reaction on sulfur-containing hydrocarbon oil, a hydrogen donor, a desulfurizer adsorbent and an adsorption desulfurization assistant, wherein the adsorption desulfurization assistant contains a metal oxide component which contains an adsorption desulfurization assistant carrier and is loaded on the adsorption desulfurization assistant carrier; the adsorption desulfurization assistant carrier is a mixture of aluminum oxide and silicon oxide; and the metal oxide component is selected from one or more of sodium oxide, potassium oxide, magnesium oxide, calcium oxide, titanium oxide, vanadium oxide, chromic oxide, manganese oxide, iron oxide, copper oxide, zinc oxide, zirconium oxide, lanthanum oxide, cerium oxide, praseodymium oxide and neodymium oxide. The desulfurization method provided by the invention has an excellent desulfurization effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

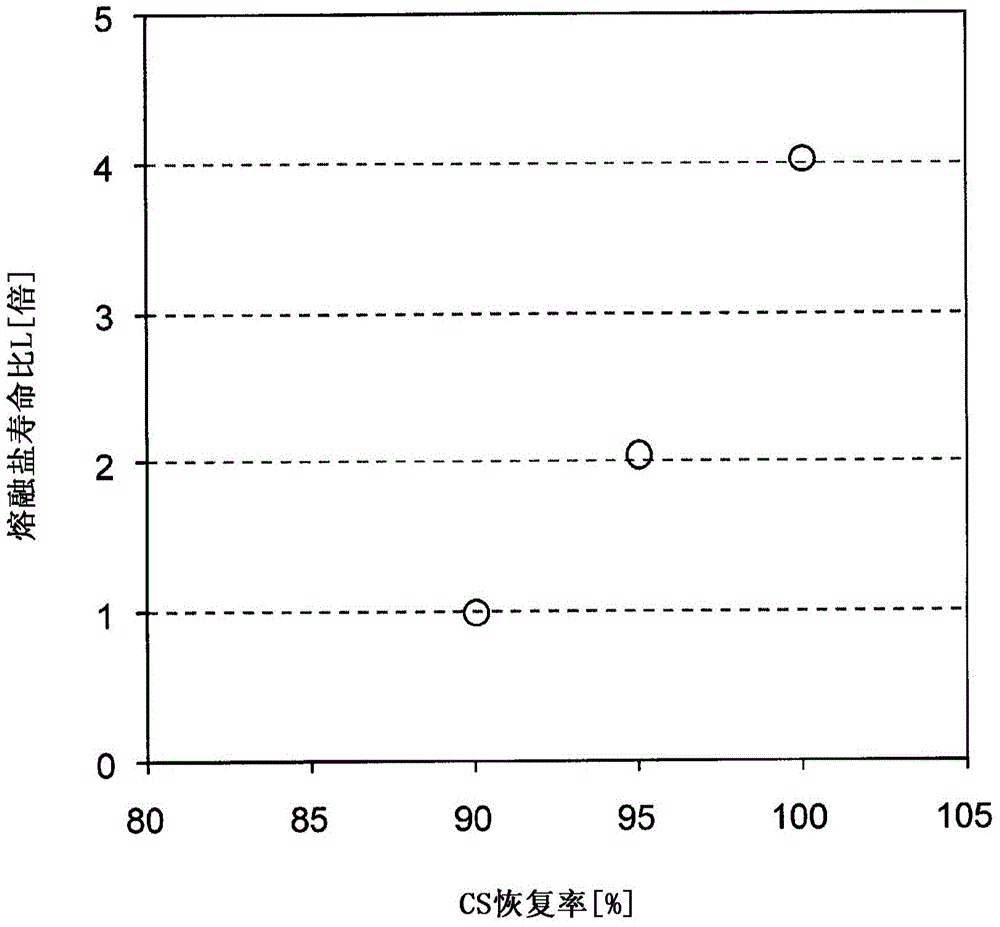

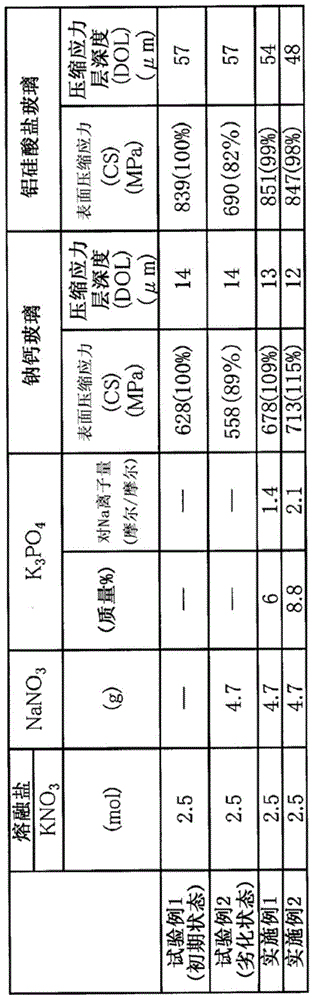

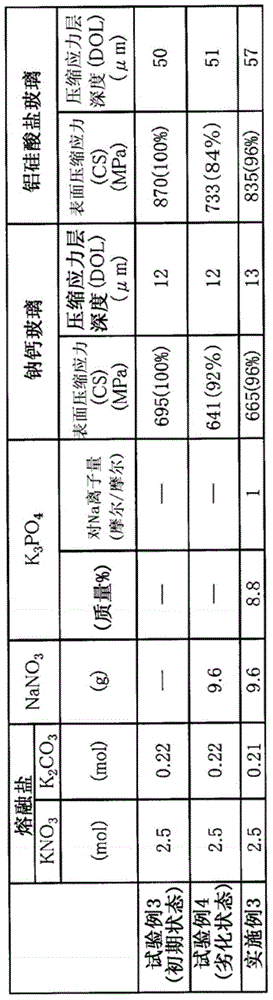

Method of regenerating molten salt for chemically toughening glass, and production method of toughened glass

The purpose of the present invention is to provide a method of regenerating molten salt which, when there is a reduction in the CS value of molten salt containing potassium nitrate used for chemically toughening glass, can restore said salt to a state in which a high CS value can be imparted. The present invention relates to a method of regenerating molten salt for use in glass strengthening which is used for forming a compressive stress layer on the glass surface by means of ion exchange, and involves a step in which the aforementioned molten salt contains potassium nitrate and a potassium orthophosphate is added to the molten salt after ion exchange treatment.

Owner:ASAHI GLASS CO LTD

Low-cost high-activity catalytic type desulphurization active coke and preparation method thereof

ActiveCN104028218AImprove desulfurization effectReduce usageOther chemical processesDispersed particle separationPyrolusiteWater vapor

The invention provides a low-cost high-activity catalytic type desulphurization active coke. The low-cost high-activity catalytic type desulphurization active coke is a material which is activated, extruded and formed by mainly components comprising carbonization soft coal and pyrolusite; the percentage of weight of manganese is not less than 1.6%; the saturated sulphur capacity of the desulphurization active coke is 140-181mg / g; the specific surface area is 319-363m<2> / g; the iodine value is 344-393mg / g. The preparation method of the low-cost high-activity catalytic type desulphurization active coke comprises the following steps: firstly carbonizing smoke, crushing the pyrolusite and the soft coal carbonization material into powder, adding the soft pyrolusite powder into the soft coal carbonization material powder and uniformly mixing, then adding water to mix till the material is free of powder aggregate, adding coal tar, fully kneading and then extruding, forming and drying, causing the dried material to be subjected to activation reaction under the conditions with N2 protection and water vapor, finally cooling the material along with a furnace to room temperature under the N2 protection to obtain the low-cost high-activity catalytic type desulphurization active coke. By virtue of the low-cost high-activity catalytic type desulphurization active coke, the problems of low desulfuration capacity, regeneration frequency, large use amount and high operation cost of the currently-used desulfuration active coke can be solved.

Owner:SICHUAN UNIV

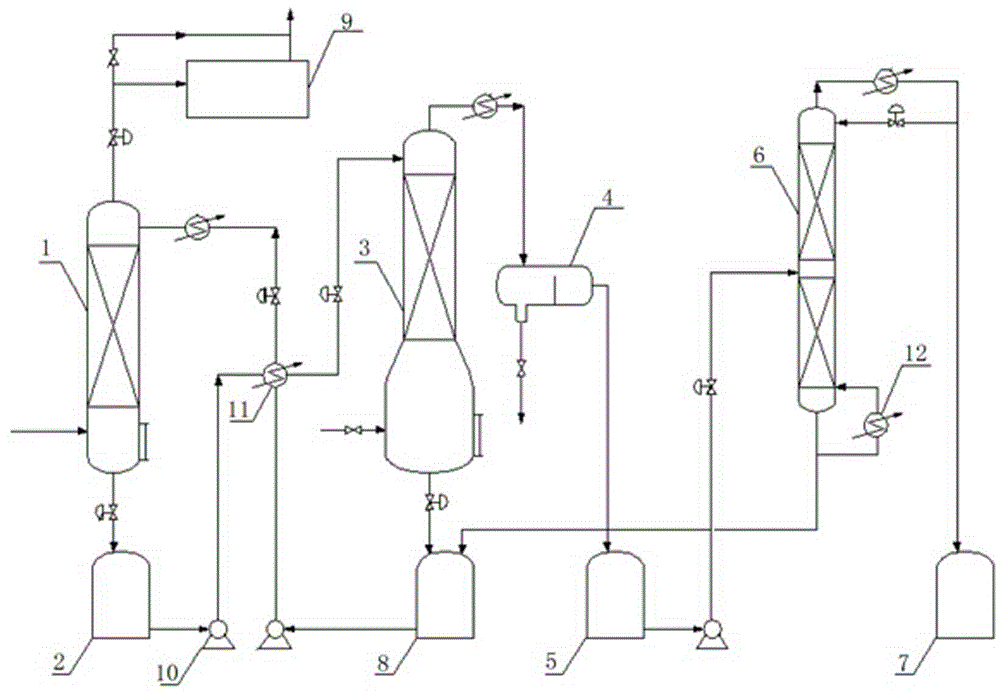

Method for recycling hydrogen peroxide oxidized tail gas

InactiveCN106139824AHigh recovery rateReduce dosageDispersed particle separationSteam distillationFiberCarbon fibers

The invention discloses a method for recycling hydrogen peroxide oxidized tail gas. The device comprises an absorption tower, a liquid-rich tank, a stripping tower, a separator, a recycling tank, a rectifying column and a refining tank which are sequentially connected through a pipeline. The device is further provided with a barren liquid tank, a discharging port of the barren liquid tank is connected to the absorption tower, the stripping tower and the rectifying column are provided with pipelines to be connected to a feeding port of the barren liquid tank, and an evacuation pipeline is arranged at the top of the absorption tower. An adsorption tank is arranged at the top of the absorption tower, and the adsorption tank is filled with carbon fibers. The method can be applied to the oxidized tail gas treatment process during hydrogen peroxide production, arene is recycled from the oxidized tail gas, the raw material consumption of the device is reduced, meanwhile, energy consumption can be reduced, and environmental protection can be achieved.

Owner:HUBEI SANNING CHEM

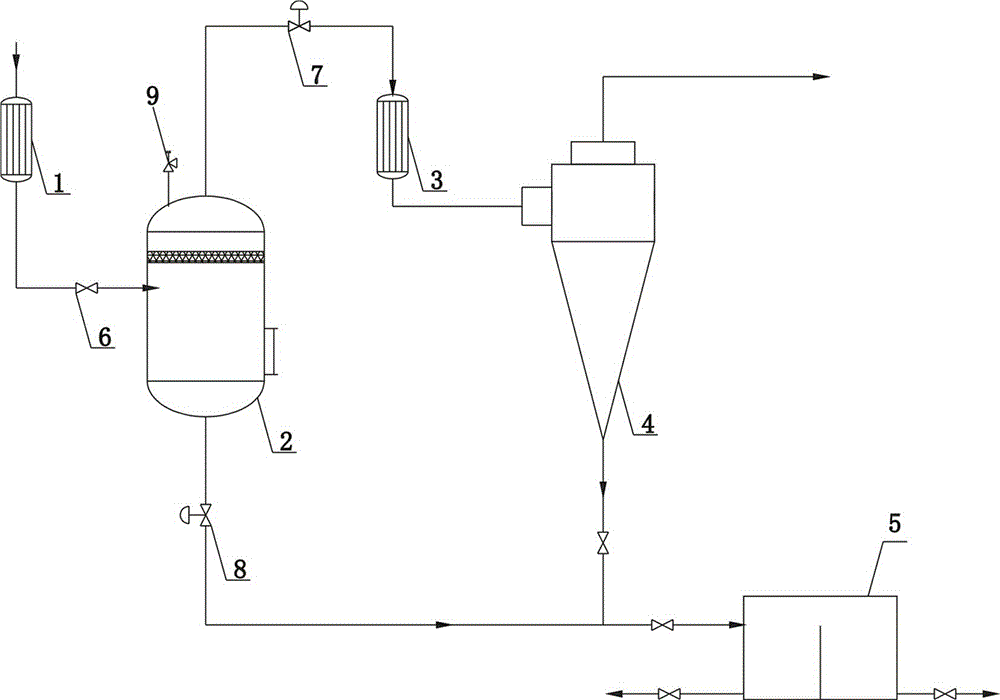

Device for increasing recovery rate of aromatic hydrocarbons of oxidized tail gas of hydrogen peroxide

InactiveCN106139789AReduce moisture contentLow cooling temperatureCombination devicesVapor condensationFluid phasePhysical chemistry

A device for increasing the recovery rate of aromatic hydrocarbons of oxidized tail gas of hydrogen peroxide comprises a primary condenser, an intermediate separation tank, a secondary condenser, a cyclone separator and an oil-water separator, wherein the primary condenser is connected with the intermediate separation tank through a pipeline; a gas phase outlet at the top of the intermediate separation tank is connected with the top of the secondary condenser through a pipeline; a liquid phase outlet at the bottom of the intermediate separation tank is connected with the oil-water separator through a pipeline; an outlet of the secondary condenser is connected with an inlet of the cyclone separator; a liquid phase outlet at the bottom of the cyclone separator is connected to the oil-water separator through a pipeline. With the adoption of the device for increasing the recovery rate of the aromatic hydrocarbons of the oxidized tail gas of hydrogen peroxide, entrainment of the tail gas can be effectively reduced, the water content of the tail gas can be reduced, the recovery effect of the aromatic hydrocarbons can be enhanced, and the recovery rate can be increased.

Owner:HUBEI SANNING CHEM

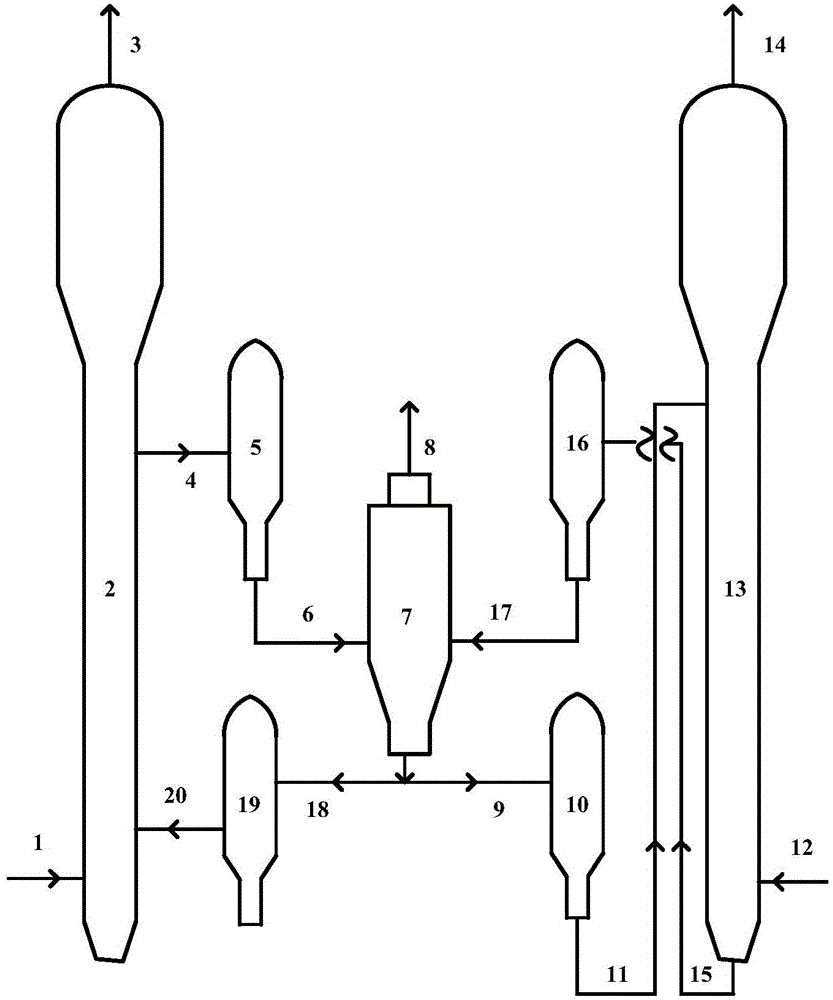

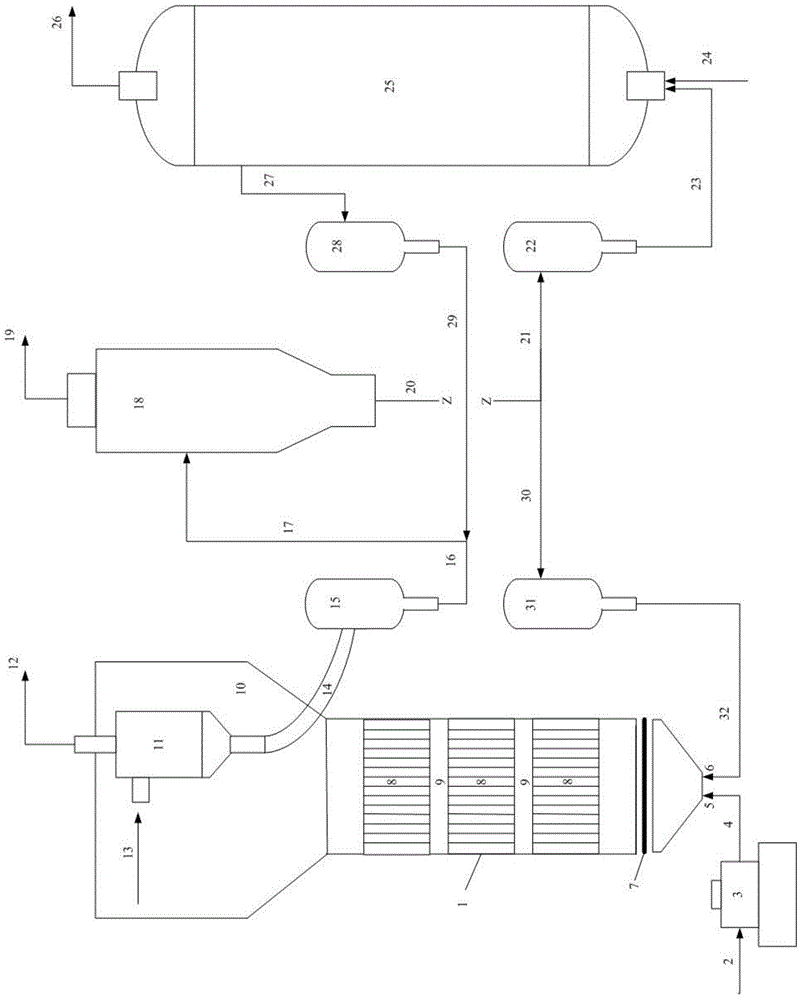

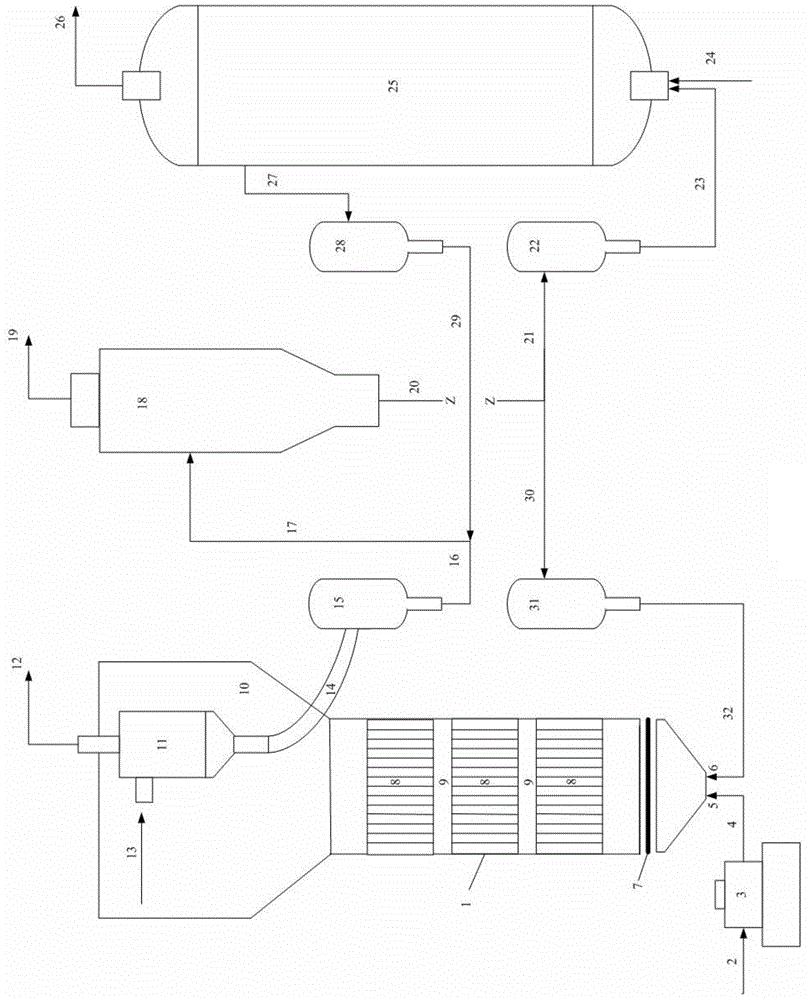

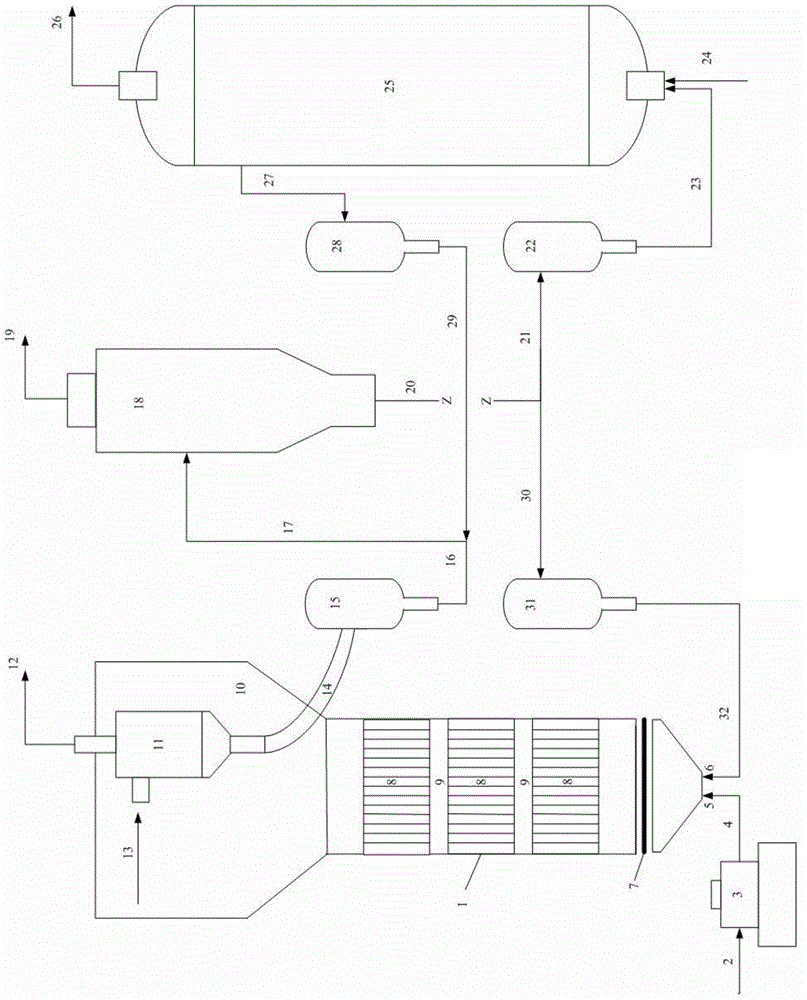

Catalyst system for sulfur-hydrocarbon-containing desulfurization, sulfur-hydrocarbon-containing desulfurization method and device for method

ActiveCN104549303ANot easy to loseReduce unit consumptionMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsMicrosphereSulfur

The invention discloses a catalyst system for sulfur-hydrocarbon-containing desulfurization, a sulfur-hydrocarbon-containing desulfurization method using the catalyst system and a device for implementing the method. The catalyst system comprises a desulfurization auxiliary and a monolithic catalyst, wherein the active ingredient coating of the monolithic catalyst comprises 30-90wt% of active metal and 10-70wt% of substrate; the desulfurization auxiliary comprises 5-35wt% of alumina, 5-35wt% of a silicon oxide source and 30-90wt% of oxide of at least one metal of IIB, VB and VIB families; the desulfurization auxiliary is microspheres having average grain size of 20-200 microns; the weight ratio of the desulfurization auxiliary to the active ingredient coating of the monolithic catalyst is (1-9):1. The catalyst system provided by the invention has better desulfurization activity and desulfurization stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst system and method for desulfurization of sulfur-containing hydrocarbon

ActiveCN106147827AReduce regeneration frequencyHigh activityRefining to eliminate hetero atomsPtru catalystEngineering

The invention relates to the field of desulfurization, and particularly discloses a catalyst system for desulfurization of sulfur-containing hydrocarbon. The catalyst system is applied to a method for desulfurization of sulfur-containing hydrocarbon. The catalyst system comprises a desulfurization assistant and a monolithic catalyst, wherein the monolithic catalyst comprises a monolithic carrier and an active component coating distributed on the inner surface and / or outer surface of the carrier; with the total weight of the active component coating as the standard, the active component coating contains 30-90% by weight of active metal and 10-70% by weight of matrix, and the active metal is VIIB group metals and / or VIII group metals; with the total weight of the desulfurization assistant as the standard, the desulfurization assistant contains 5-35% by weight of aluminum oxide, 0.5-10% by weight of rare earth oxide, 5-35% by weight of monox source and 30-89.5% by weight of oxide of at least one kind of metal in IIB group, VB group and VIB group, and the desulfurization assistant is microspheres with average grain size being 20-200 microns. The catalyst system has higher desulfurization activity and desulfurization stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sulfur-hydrocarbon-containing desulfurization catalyst system and sulfur-hydrocarbon-containing desulfurization method

ActiveCN106140294AGood dispersionConducive to synergyCatalyst protectionMolecular sieve catalystsMicrosphereSilicon oxide

The invention relates to the field of desulfurization and particularly discloses a sulfur-hydrocarbon-containing desulfurization catalyst system. The catalyst system is used for a sulfur-hydrocarbon-containing desulfurization method. The catalyst system includes a desulfurization additive and a monolithic catalyst. The active component coating of the monolithic catalyst contains, by weight, a transition metal promoter 30-90% and a substrate 10-70%. The transition metal promoter is group VIIB and / or VIII metals. The substrate contains, by weight, a phosphorus aluminum molecular sieve 70-90% and a silica binder 10-30%. The desulfurization additive contains, by weight, aluminum oxide 5-40%, a silicon oxide source 5-40% and oxide of at least one of metals of groups IIB, VB and VIB 30-90%, and the desulphurization additive is microspheres with the average particle size of 20-200 microns. The weight ratio of the desulfurization additive to the active component coating of the monolithic catalyst is 1-9 to 1. The catalyst system can have good desulfurization activity and desulfurization stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

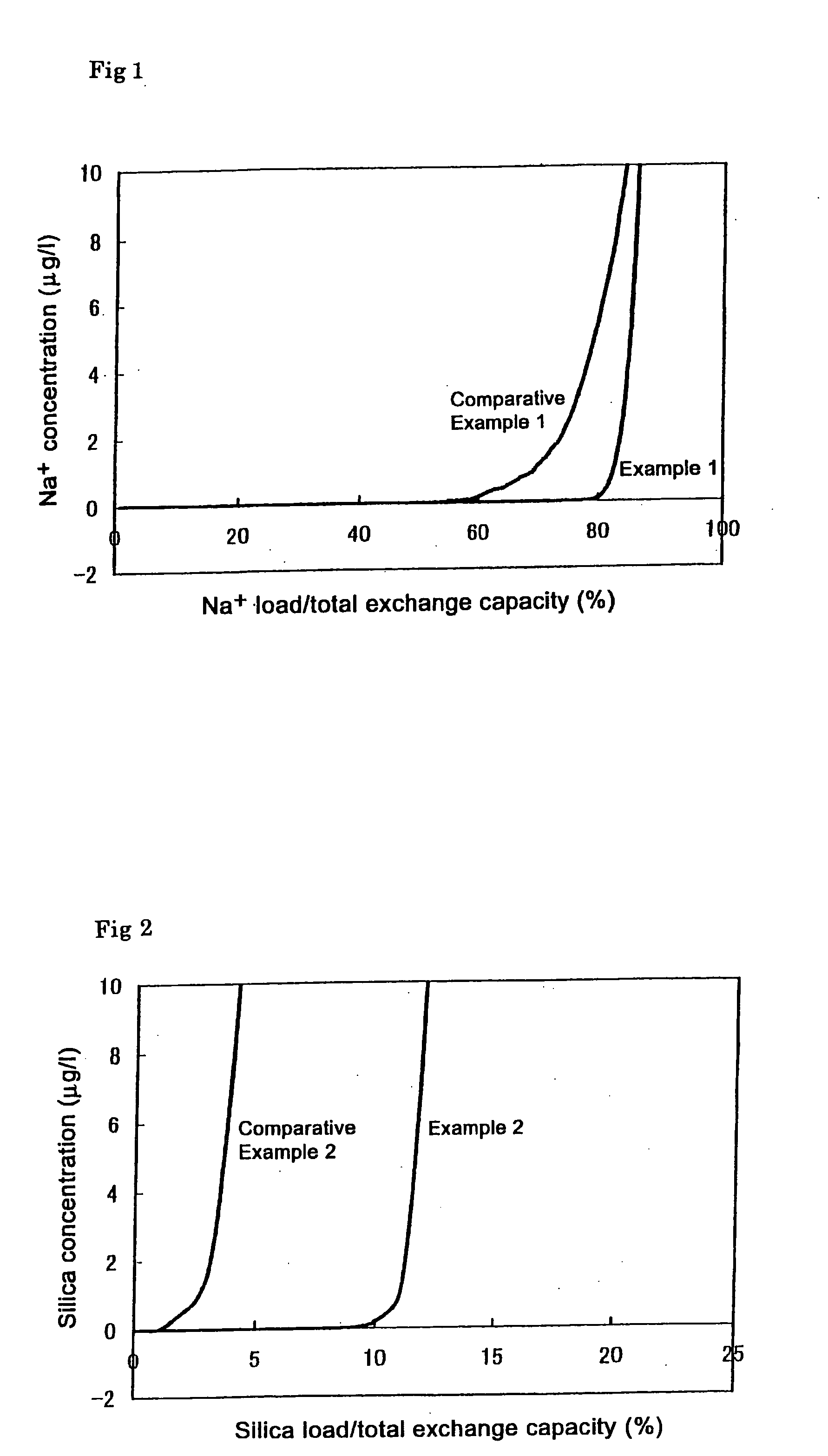

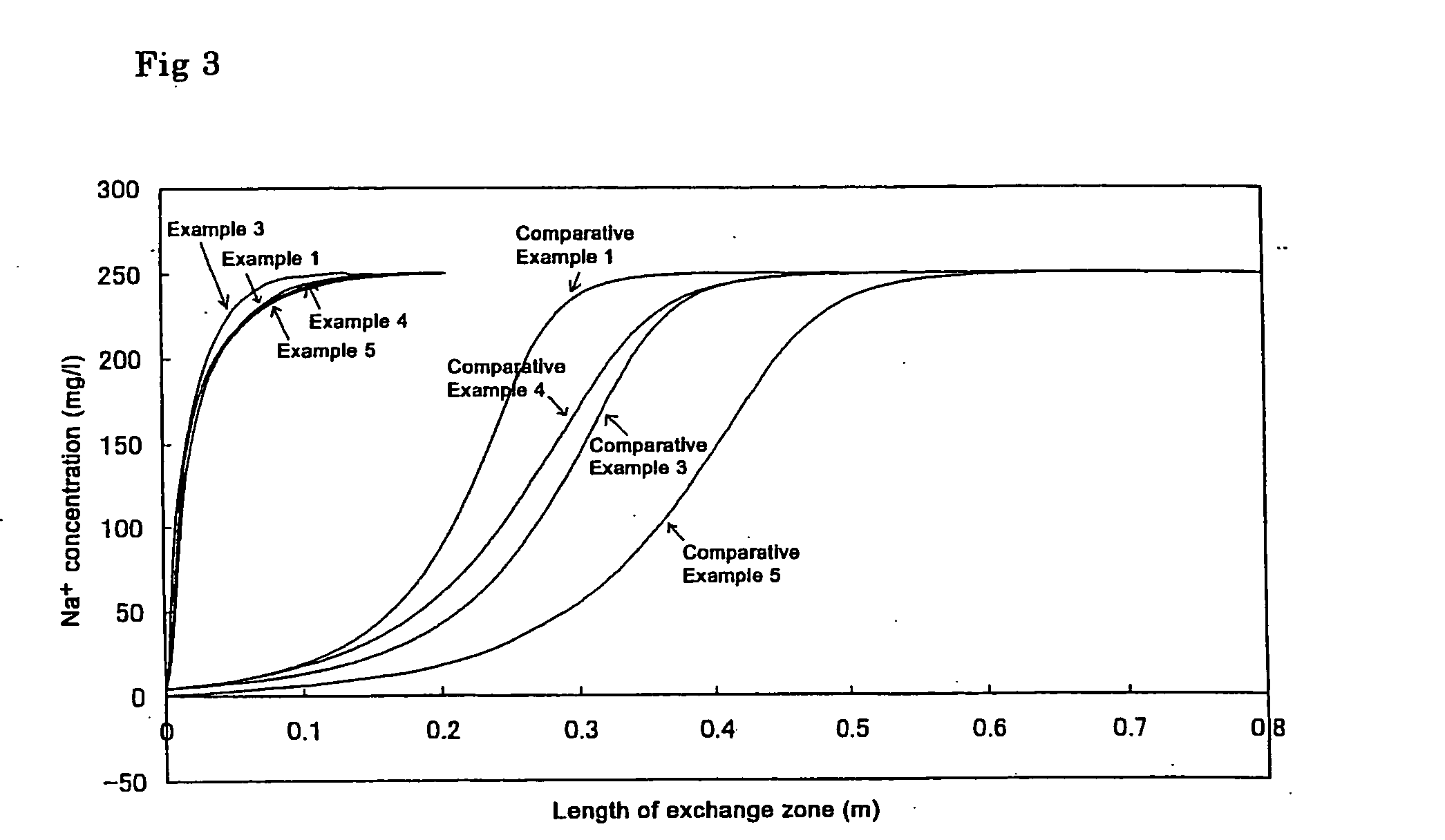

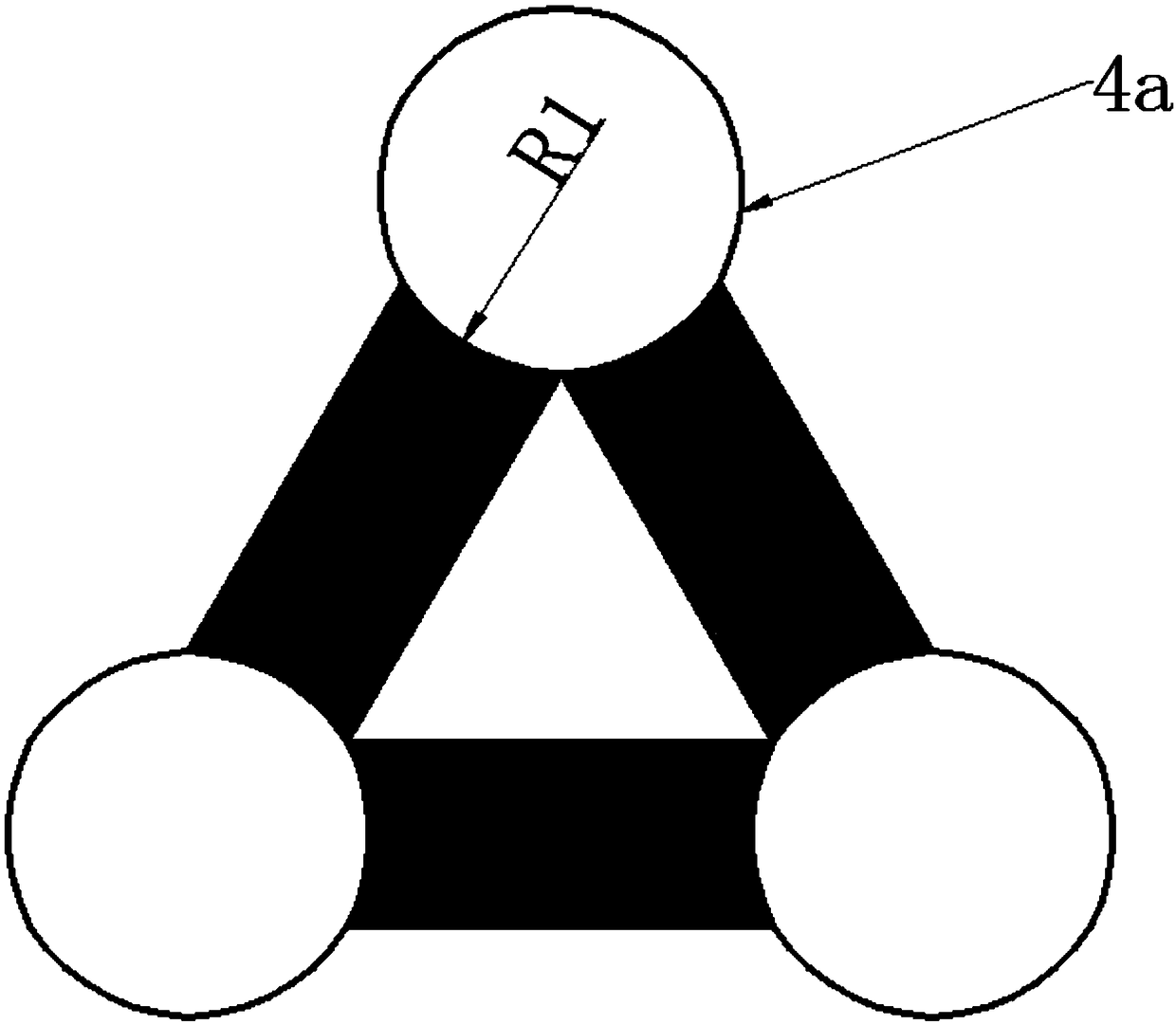

Ion adsorption module and method for water treatment

InactiveUS20050139549A1Easy to fillShorten the lengthCation exchanger materialsIon-exchange column/bed processesPhysical chemistryIon exchange

An ion adsorption module comprises a container with at least an opening into which feed water flows, and an organic porous ion exchange material having a three-dimensional reticular structure filled into the container, which has a continuous pore structure comprising macropores and mesopores, the macropores being interconnected with each other forming mesopores with an average diameter of 1-1,000 μm in the interconnected parts, has a total pore volume of 1-50 ml / g, contains uniformly distributed ion exchange groups, and has an ion exchange capacity of 0.5 mg equivalent / g or more of the porous material on a dry basis. The ion adsorption module can be extremely easily filled with the ion exchange material, and the packed layer does not move even if the layer is placed in an upward flow. The ion adsorption module and the water processing method using the ion exchange material are extremely useful.

Owner:ORGANO CORP

Desulfurization and denitration device and technology used for purifying coke oven smoke

ActiveCN105597531AReduce concentrationReduce inhibitionNitrous oxide captureGas treatmentCoke ovenEnergy consumption

The invention provides a desulfurization and denitration device and technology used for purifying coke oven smoke. The device comprises a smoke waste heat recovery device, a desulfurization reactor and an SCR denitration reactor in a sequential connection mode. The desulfurization reactor is provided with a first smoke inlet, a first smoke outlet and a bearing device, the SCR denitration reactor is provided with a second smoke inlet, a second smoke outlet and a bearing device, the bearing devices can move downwards, the first smoke inlet and the first smoke outlet enable the coke oven smoke to make countercurrent contact with active coke and / active carbon in the desulfurization reactor, and the second smoke inlet and the second smoke outlet enable the smoke which is subjected to desulfurization treatment to make cross-current contact with active coke and / or active carbon in the SCR denitration reactor. By the utilization of the device, the denitration efficiency reaches 80% or more, the desulfurization efficiency reaches 96% or more, the temperature in the regeneration reaction of active coke can be obviously decreased to 50 DEG C-75 DEG C, and therefore energy consumption is lowered.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

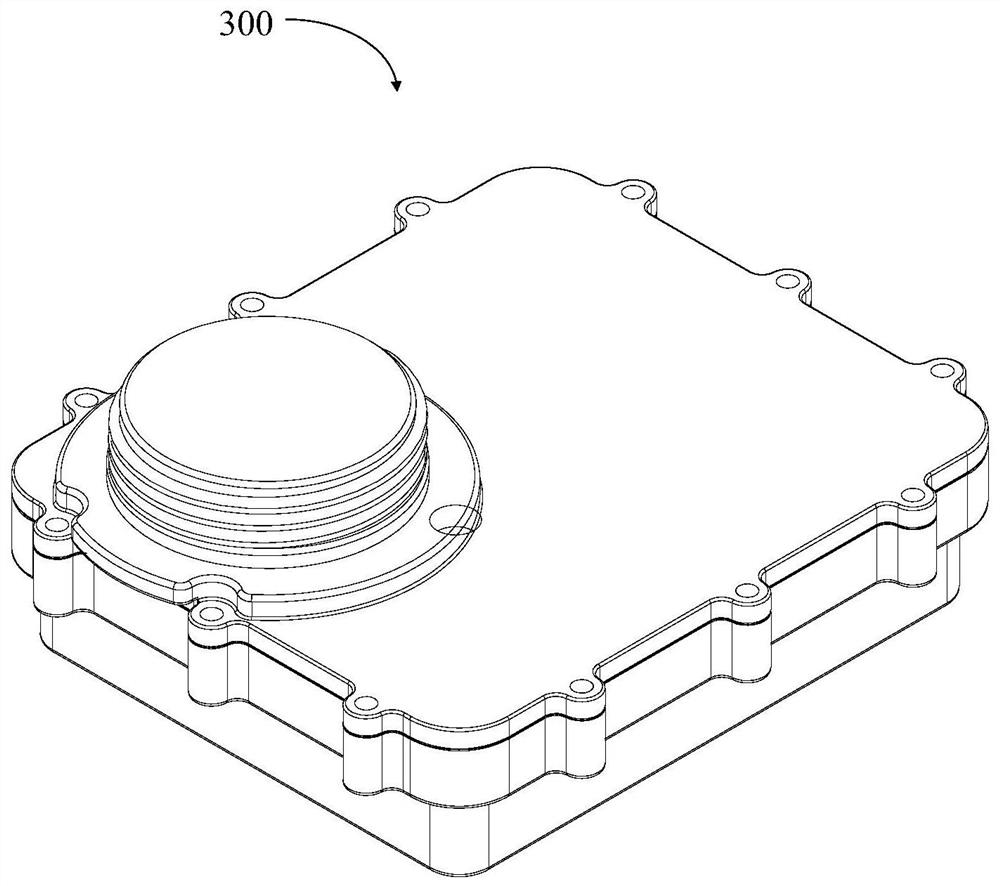

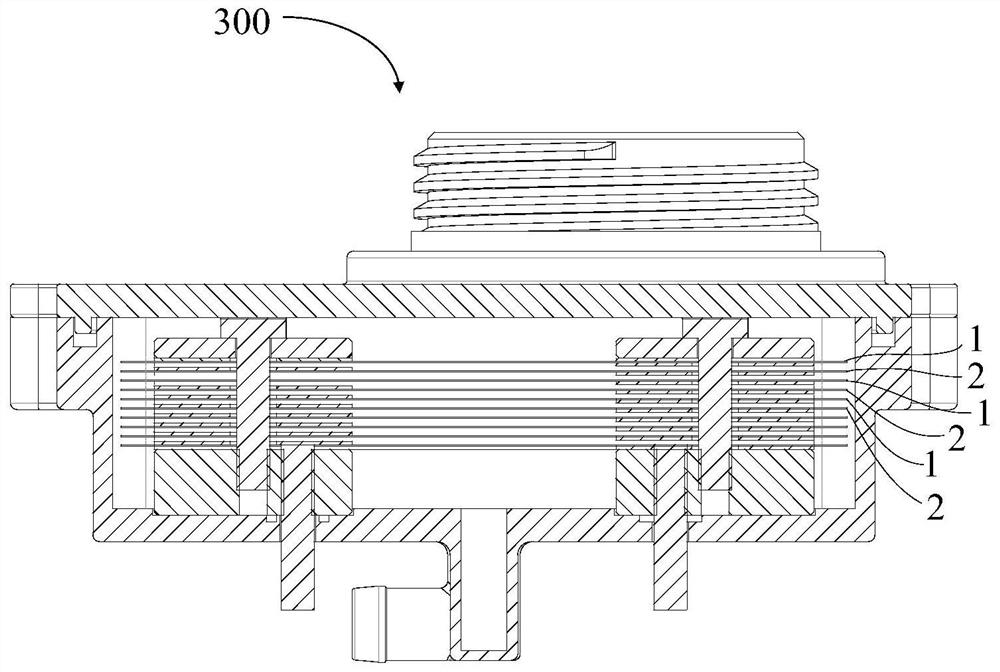

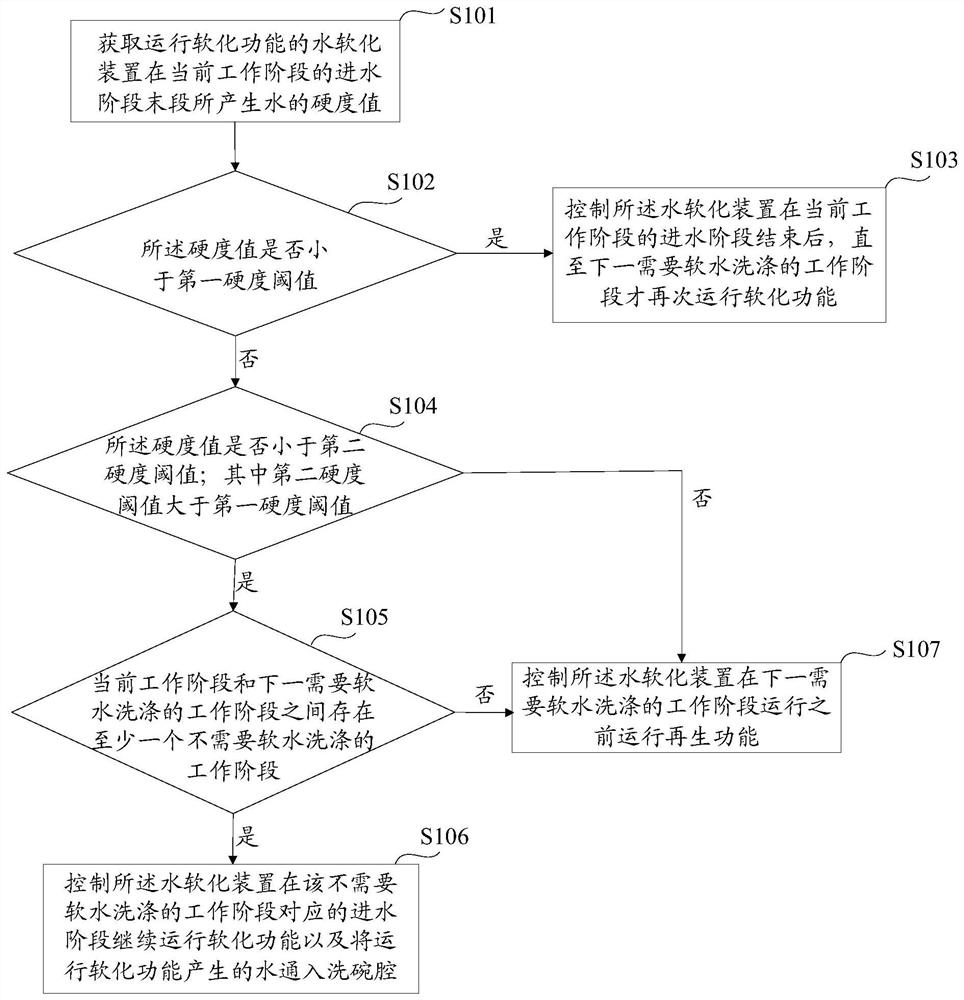

Control method of dish washing machine

ActiveCN111685702AReduce regeneration frequencyReduce wasteTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionWater softeningWater resources

The invention discloses a control method of a dish-washing machine. The single dish washing process of the dish washing machine comprises at least one working stage, each working stage comprises a water inlet stage and a washing stage, and the control method of the dish washing machine comprises the steps that the hardness value of water generated by a water softening device operating the softening function at the tail section of the water inlet stage of the current working stage is obtained; if the hardness value is smaller than a preset first hardness threshold value, it is determined that the water softening device is sufficient to generate water meeting the hardness requirement of the next working stage needing soft water washing; and the water softening device is controlled to operatethe softening function again until the next working stage needing soft water washing is finished after the water inlet stage of the current working stage is finished. In the implementation mode, thesoftening capacity of the water softening device can be effectively utilized, the regeneration frequency of the water softening device is reduced, and waste of water resources is reduced.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

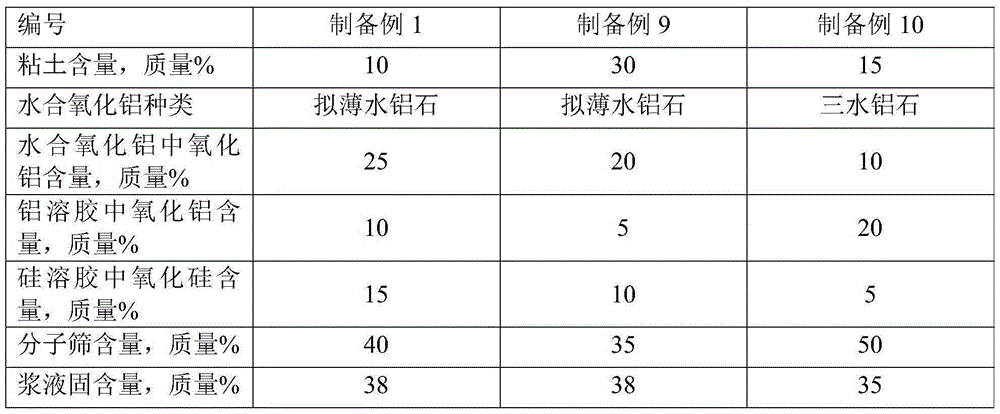

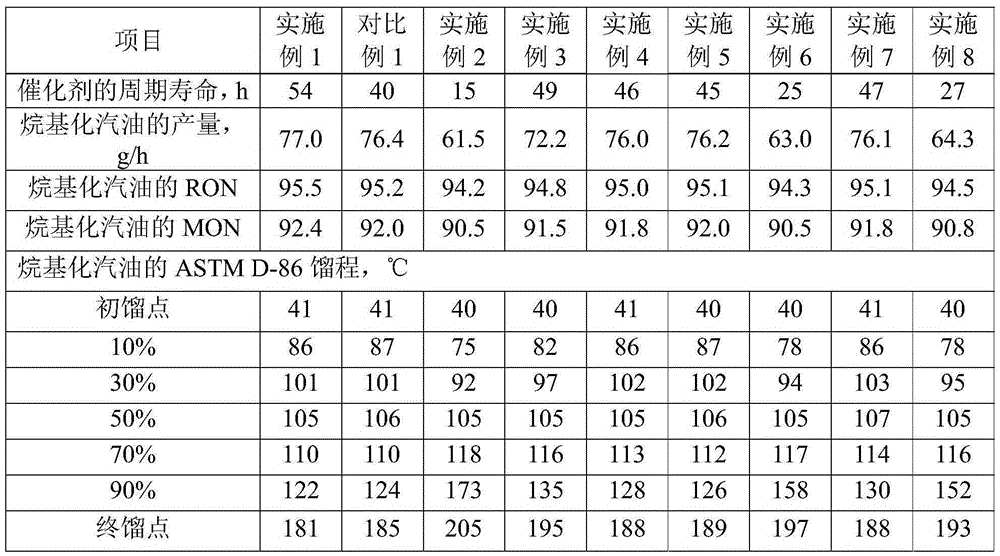

Alkylation reaction method

ActiveCN106631655AImprove cycle lifeReduce regeneration frequencyMolecular sieve catalystsMolecular sieve catalystSolid acidFixed bed

The invention discloses an alkylation reaction method. The alkylation reaction method is characterized in that a reaction material flow containing isoparaffin and alkene is sent to an alkylation reactor, under alkylation reaction condition, the material flow is contacted with an alkylation catalyst, the alkylation catalyst is the solid acid catalyst which is placed in the alkylation reactor as a fixed bed form, and a mode of a reaction material flow passes in and out of the alkylation reactor is periodically switched between two in and out reactor modes of up-out and down-in as well as up-in and down-out. According to the alkylation reaction method, the period life of the catalyst is effectively prolonged, regeneration frequency of the catalyst is reduced, on one hand, the alkylation reaction method is in favor of prolonging the entire life of the catalyst, and on the other hand, the energy consumption of the catalyst during a regeneration process is reduced. The method has simple operation, has no especial requirement on equipment, is suitable for the new devices, and makes simple reconstruction for the pipelines of the used device, and a control valve is added for performing the method.

Owner:CHINA PETROLEUM & CHEM CORP +1

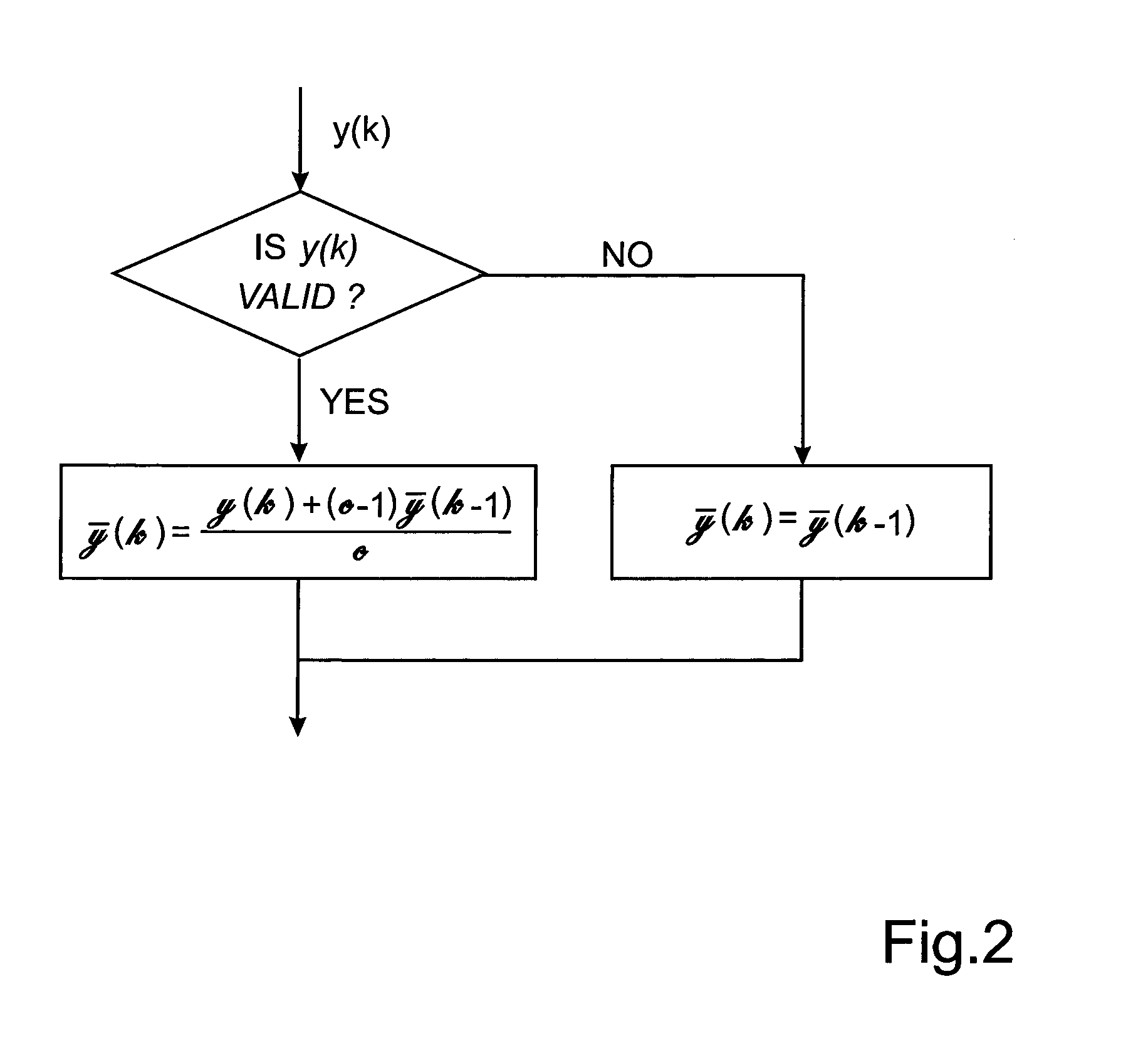

Method for determining fuel blend in a dual fuel mixture

ActiveUS20160047325A1Optimal engine operationGuaranteed uptimeElectrical controlInternal combustion piston enginesInternal combustion engineSystem identification

A method is provided for determining fuel blend in a dual fuel mixture including a first and a second fuel in an internal combustion engine. The method includes the steps of measuring multiple engine parameters using sensors during transient cycle operation for a predetermined range of engine loads and fuel blends; using system identification of transient time series of the measurements to determine one or more relevant engine parameters; determining a model for estimation of the fuel blend based on said one or more engine parameters; using the model fur determining a current fuel blend during transient operation using current measured values of the one or more engine parameters, and using the calculated current fuel blend for controlling the amount of dual fuel mixture injected into each cylinder of the internal combustion engine. A vehicle and a computer program product using the method are also provided.

Owner:VOLVO LASTVAGNAR AB

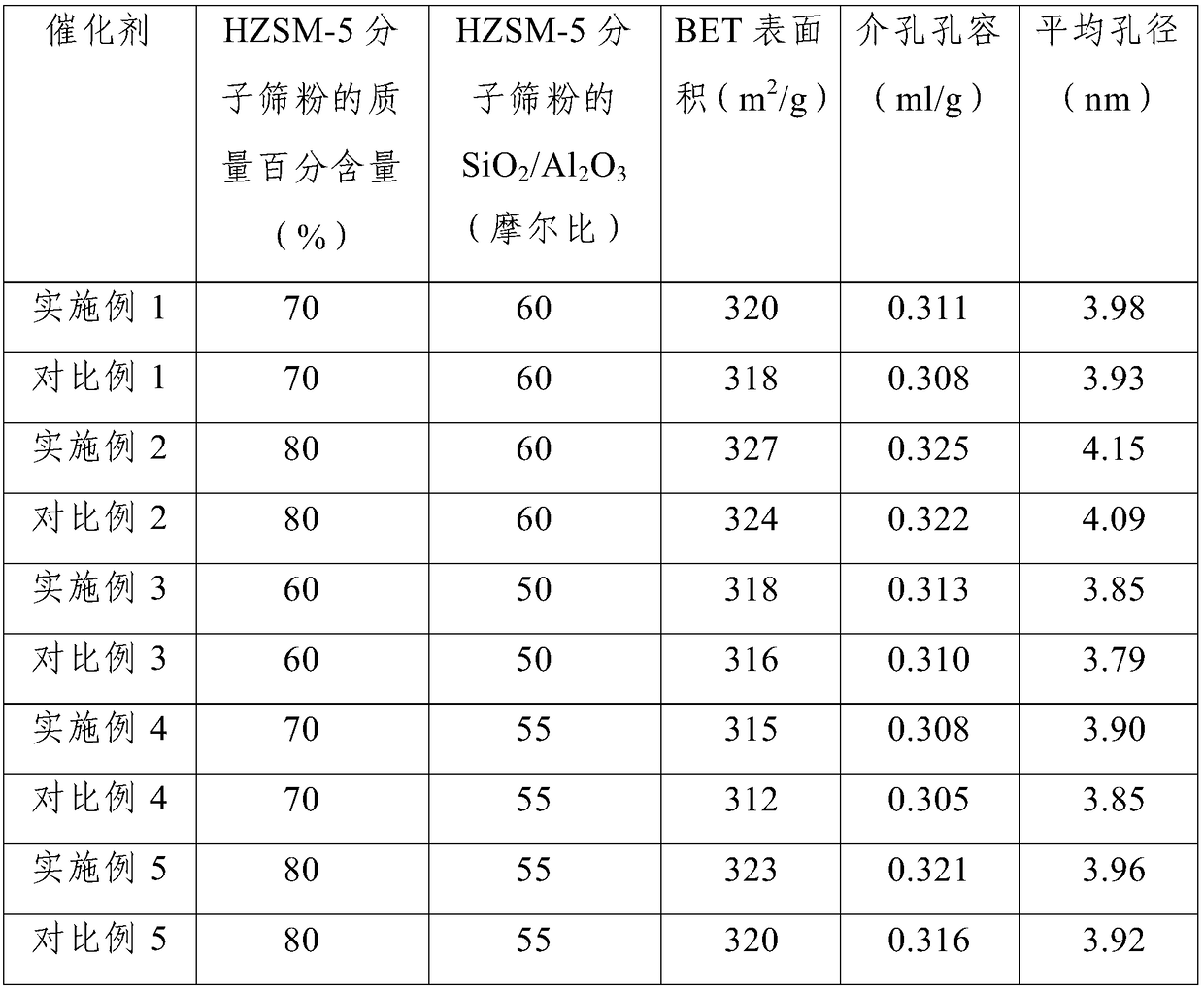

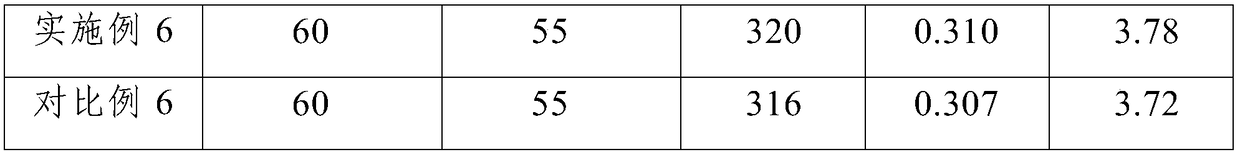

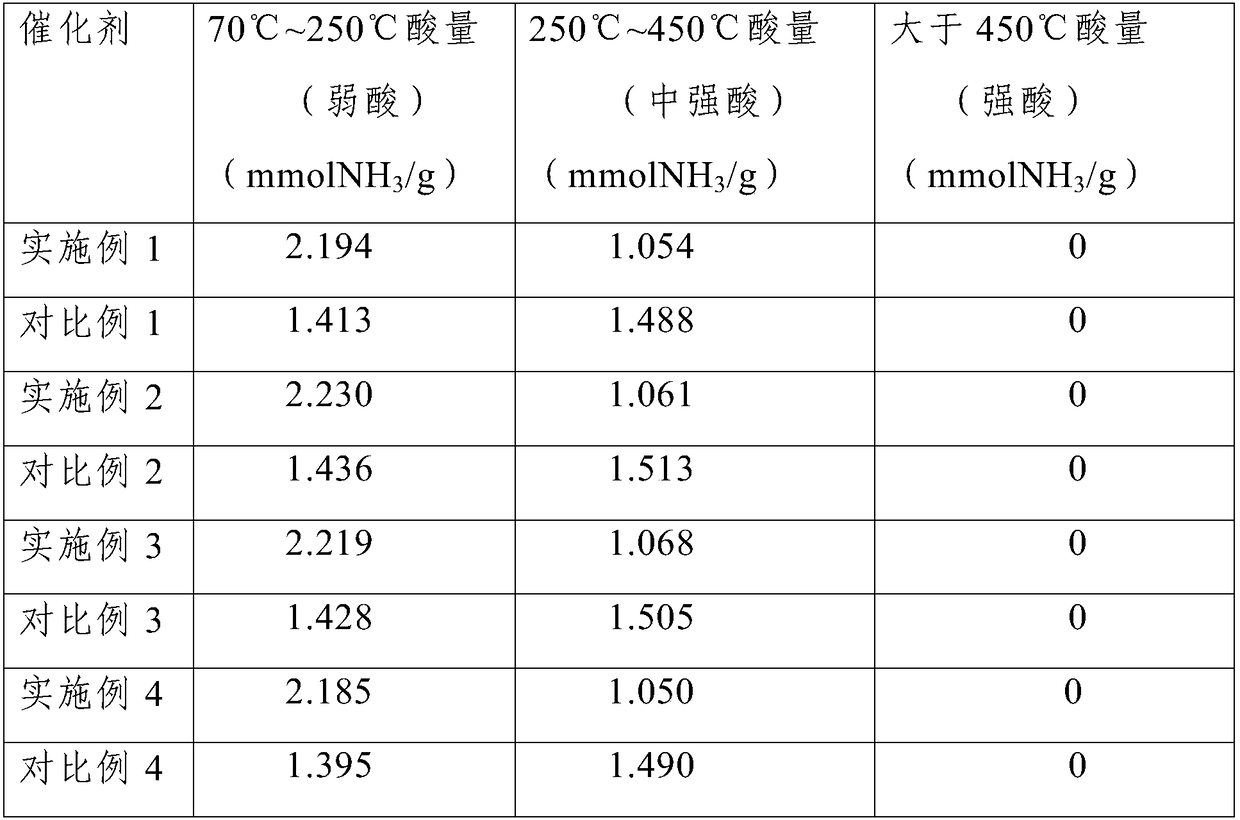

Modified molecular sieve catalyst for ethanol dehydration to produce ethylene, and application thereof

ActiveCN109174169AImprove carbon storage capacityImprove stabilityMolecular sieve catalystsCatalyst activation/preparationCooking & bakingMolecular sieve

The invention discloses a modified molecular sieve catalyst for ethanol dehydration to produce ethylene. The catalyst is prepared through the following steps: preparing an unmodified bar-shaped molecular sieve catalyst from HZSM-5 molecular sieve powder and macro-porous pseudo-boehmite powder, sequentially carrying out alkali modification and acid modification by using an aqueous Na2CO3 solution and an aqueous citric acid solution, and baking and calcining the modified bar-shaped molecular sieve catalyst. The invention also discloses an application of the modified molecular sieve catalyst forethanol dehydration to produce ethylene. The preparation modification process of the catalyst does not require a stirring process, so the preparation process is simplified, the weak acid amount of thesurface of the catalyst is greatly increased, and the medium and strong acid amount is reduced, thereby the catalysis effect of the modified molecular sieve catalyst on an ethanol dehydration reaction for producing ethylene is improved, the conversion rate of the raw material ethanol and the selectivity of the product ethylene are increased, and the service life of the modified molecular sieve catalyst is prolonged; and the modified molecular sieve catalyst has a simple application in the dehydration of ethylene to produce ethylene, and is suitable for being promoted.

Owner:XIAN ORIGIN CHEM TECH

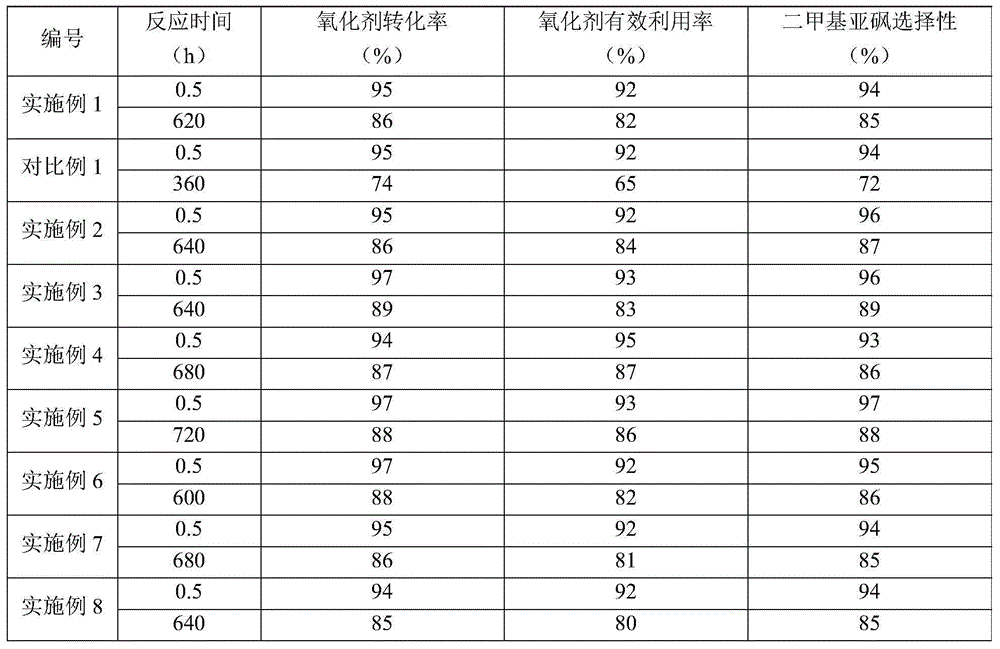

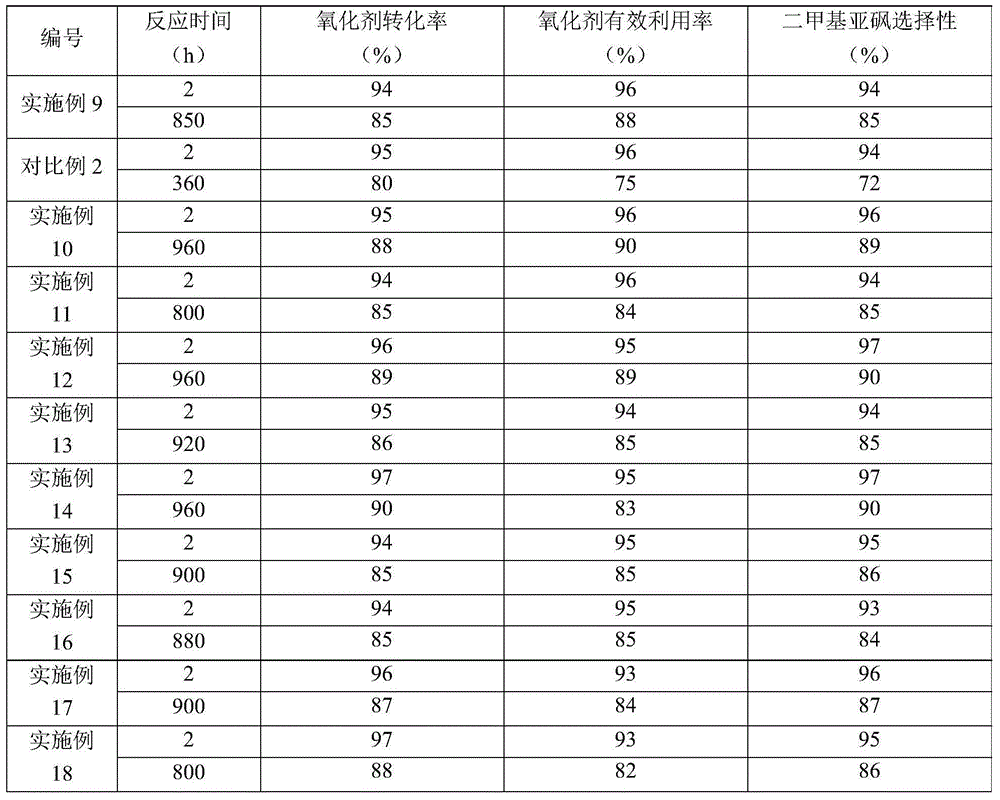

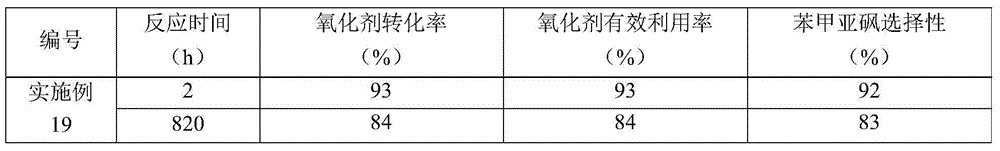

Thioether oxidation method

ActiveCN105384666AExtended one-way service lifeExtended service lifeOrganic chemistryOrganic compound preparationMolecular sieveFixed bed

The present invention discloses a thioether oxidation method, which comprises: continuously conveying a liquid mixture into a fixed-bed reactor to make the liquid mixture contact a titanium silicon molecular sieve loaded in the fixed-bed reactor under an oxidation reaction condition, wherein the liquid mixture contains thioether, at least an oxidizing agent and at least a solvent, and the method further comprises that: when the oxidizing agent conversion rate or the target oxidation product selectivity is reduced to a certain degree, the weight hourly space velocity of the solvent is improved until the oxidizing agent conversion rate and / or the target oxidation product selectivity meets the requirement. With the method of the present invention, the one way service life of the titanium silicon molecular sieve adopted as the catalyst can be effectively prolonged, the regeneration frequency of the catalyst can be reduced, the production efficiency can be improved, the operation stability can be improved, and the total service life of the catalyst can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Exhaust cleaning device of diesel engine

InactiveUS7578123B2Reduce processing frequencyReduce regeneration frequencyInternal combustion piston enginesExhaust apparatusDifferential pressureEngineering

An integrating PM amount σ PM as an integrating value of a PM generating amount after DPF regeneration is read (S1). The integrating PM amount and a first threshold value SL1 set in advance are compared, and the regenerating period of DPF 13 is judged (S2). Further, a differential pressure ΔPdf before and after DPF 13 detected by a differential pressure sensor 16, and a second threshold value SL2 are compared, and the regenerating period of DPF 13 is judged (S5). Regeneration processing of DPF 13 is then performed when the integrating PM amount σ PM attains the first threshold value SL1 or tore, or the differential pressure ΔPdf attains a second threshold value SL2 or more (S7).

Owner:SUBARU CORP

Method for synthesizing zeolite by fly ash and application thereof

InactiveCN1296129CAvoid the disadvantages that the treatment effect is affected by temperature, etc.Easy to operateOther chemical processesWater/sewage treatment by sorptionPhosphatePollution

The invention concerns a way of synthesize stone using coal powder and its applying in removing nitrogen and phosphorus in the waste water. Get the coal powder as the material, add the material including aluminum, silicon, or fluorine which can saluted in the alkaline solution, after mixing, add metal alkaline solution and synthesize fei stone by water heating reaction, then change shape by metal salt aqua, we get the fei stone after separating solid and liquid. Change the fei stone to the grains and put them in the filtering bed, achieving to remove nitrogen and phosphorus. The invention solves the environment problem, economy the resource of nitrogen and phosphorus in the coal powder, no second pollution.

Owner:SHANGHAI JIAOTONG UNIV

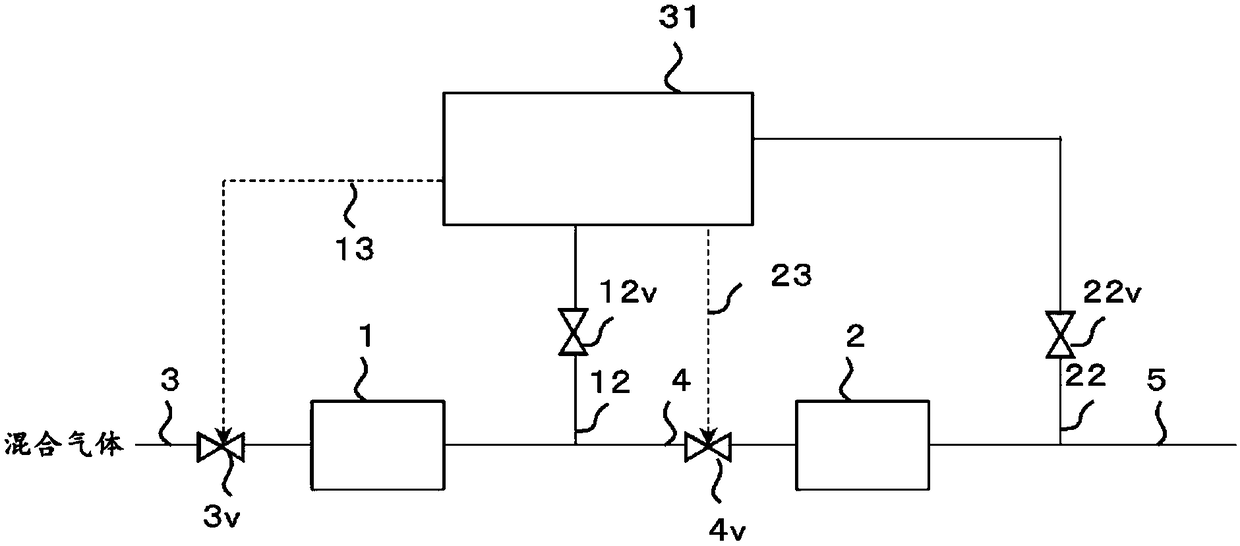

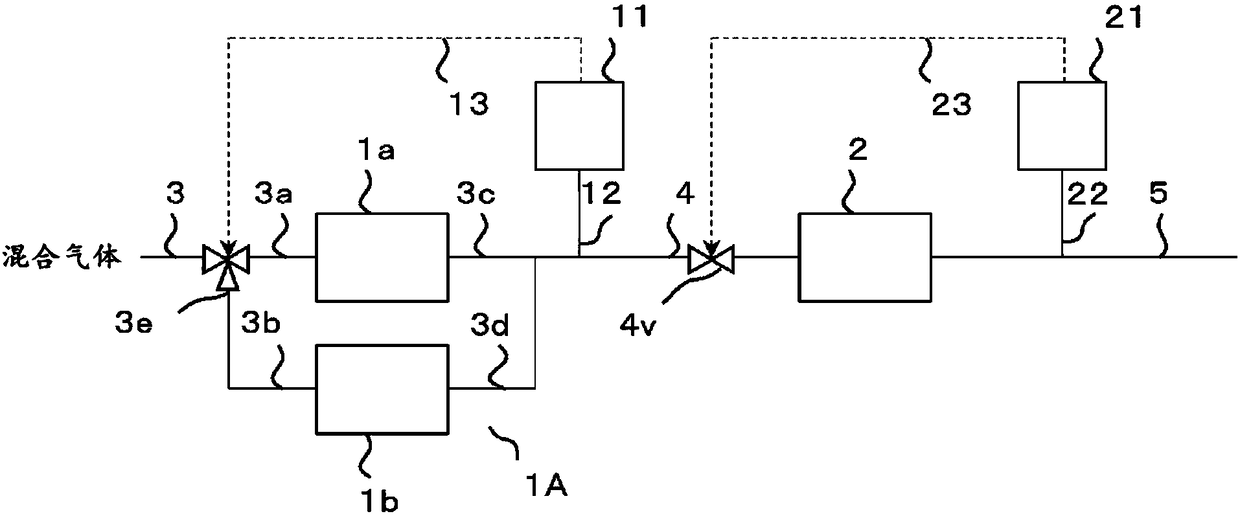

Ammonia removal equipment, ammonia removal method, and hydrogen gas production method

PendingCN108367229AReduce replacement frequencyReduce regeneration frequencyHydrogen separation by selective and reversible uptakeGas treatmentEnvironmental engineeringMixed gas

Owner:RESONAC CORPORATION +1

Flue gas hydrargyrum-removing method by catalytic oxidation

InactiveCN1331571CLittle matrix damageReduce pollutionDispersed particle separationPtru catalystSorbent

Owner:SHANGHAI JIAO TONG UNIV

A kind of anti-carbon aldol condensation catalyst and its preparation method and the method of using the catalyst to prepare methyl methacrylate

ActiveCN106423159BSuppress overrideReduce carbon deposition rateOrganic compound preparationCarboxylic acid esters preparationPtru catalystPropanoic acid

The invention discloses an anti-carbon deposition aldol condensation catalyst, which comprises an active component, an anti-carbon deposition agent, an active auxiliary agent and a carrier, and the active component is selected from one or more of inorganic salts of Cs and organic salts of Cs The anti-coking agent is selected from one or more of oxides, chlorides, nitrates, carbonates and organic acid salts of Pt, Rh, Ru, Pd, Ir, Fe, Co and Ni, and the active auxiliary The agent is selected from one or more of soluble salts of La, Ce, Nd, Pr and Pm, and the carrier is silicon dioxide. Through the controllable precursor preparation and catalyst activation process, the obtained catalyst is used to catalyze the aldol condensation reaction of methyl propionate and formaldehyde to prepare methyl methacrylate, which has high catalytic activity, good selectivity, strong anti-coking ability and Features of high stability.

Owner:WANHUA CHEM GRP CO LTD

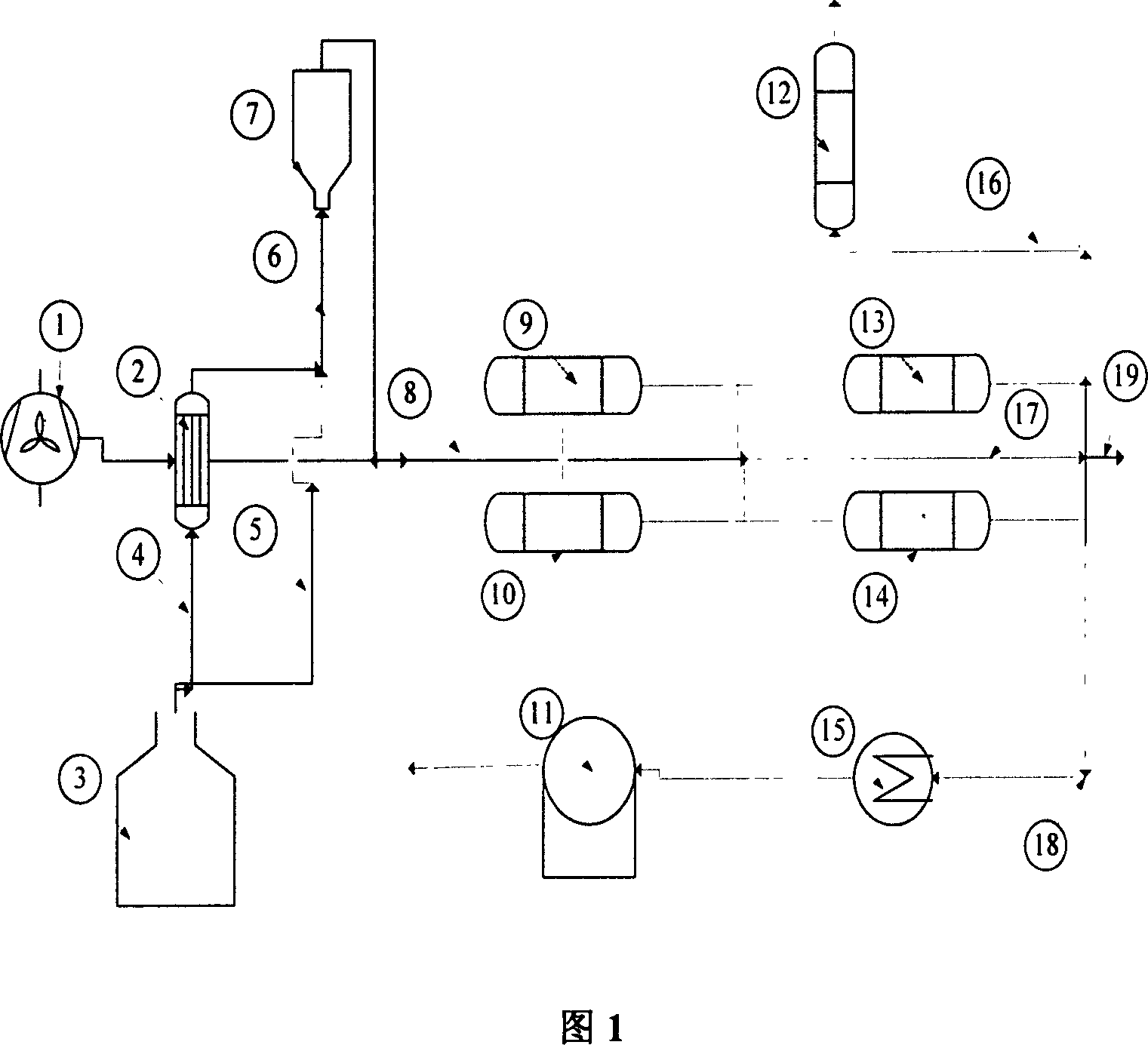

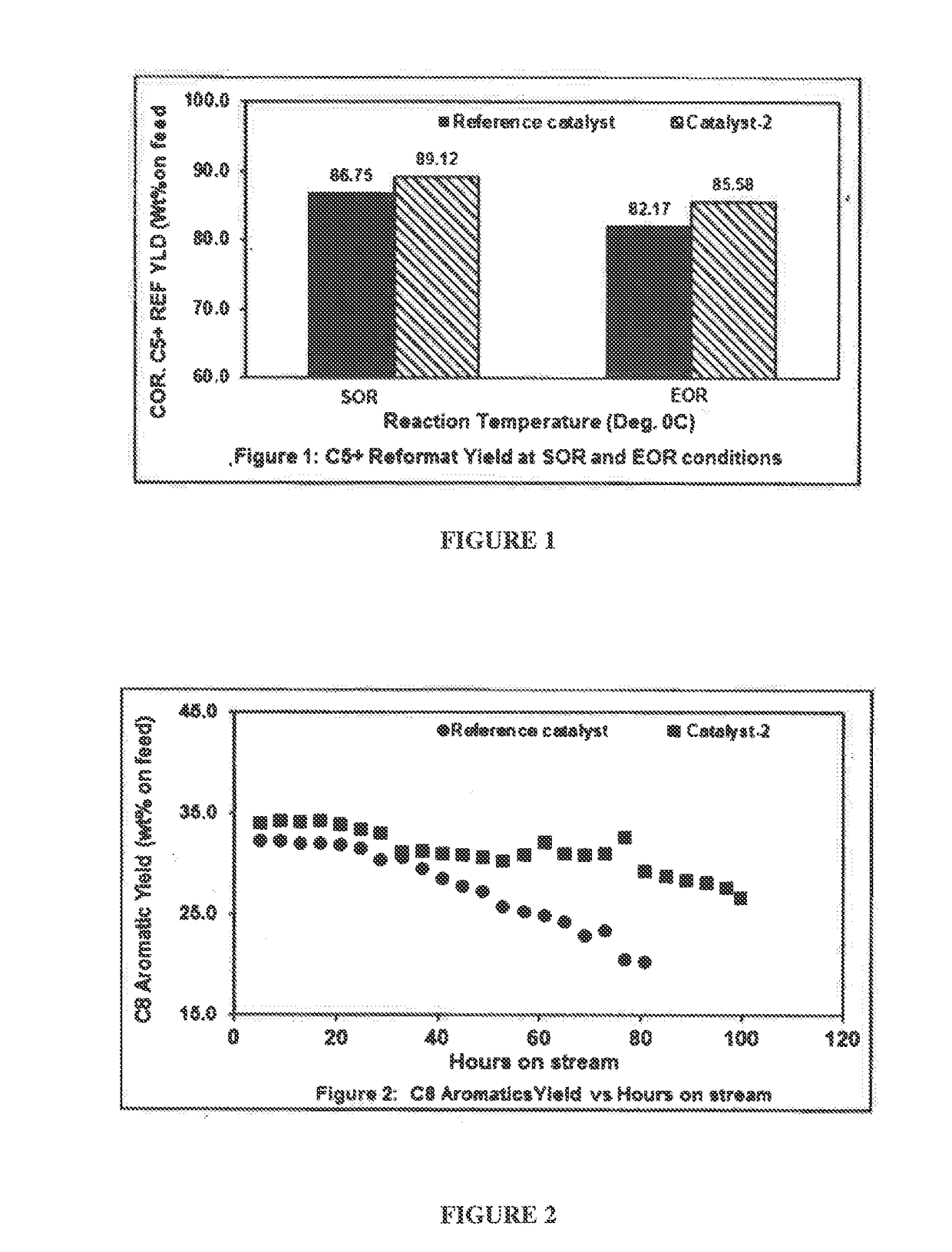

Catalyst, a process for preparation of the catalyst and application thereof

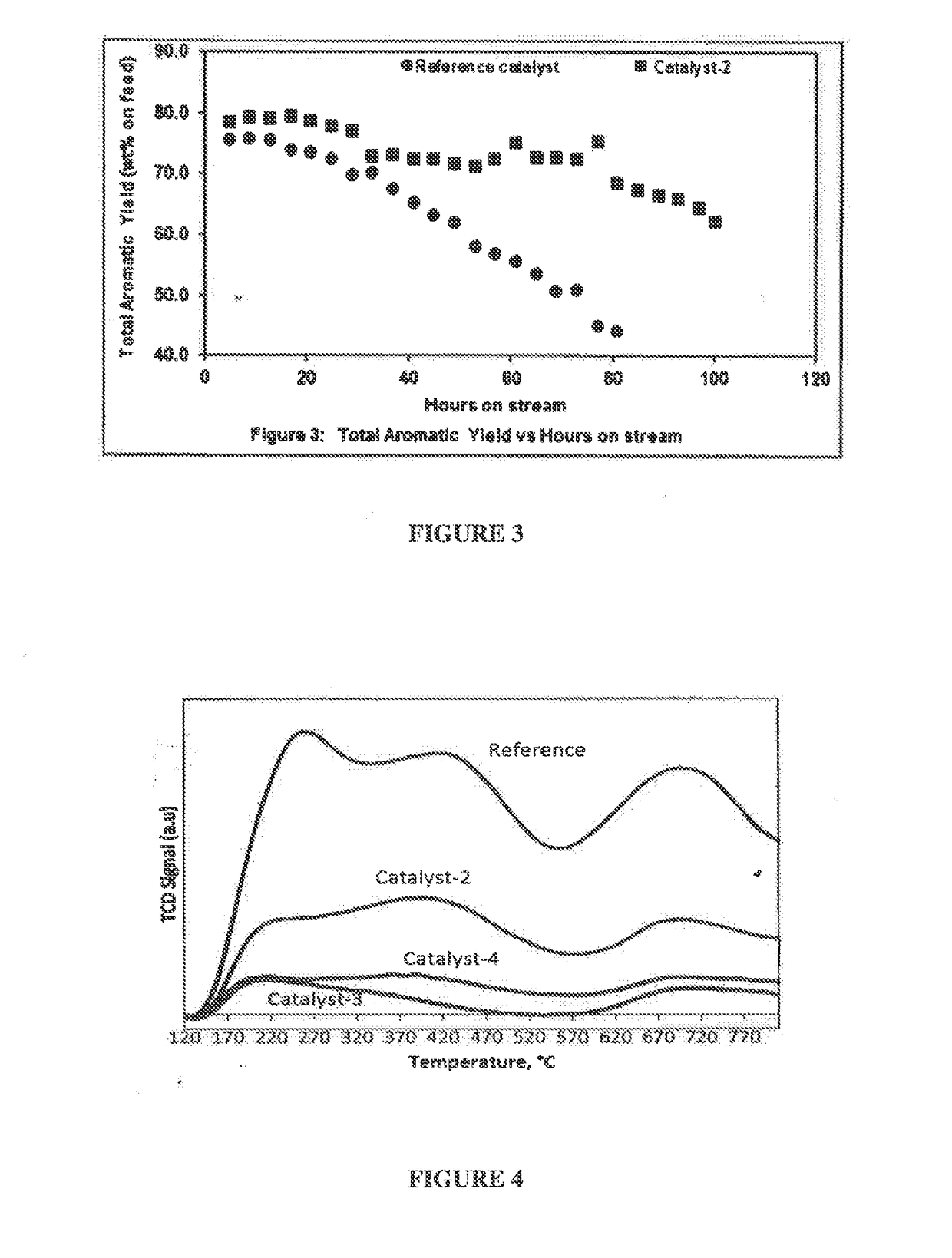

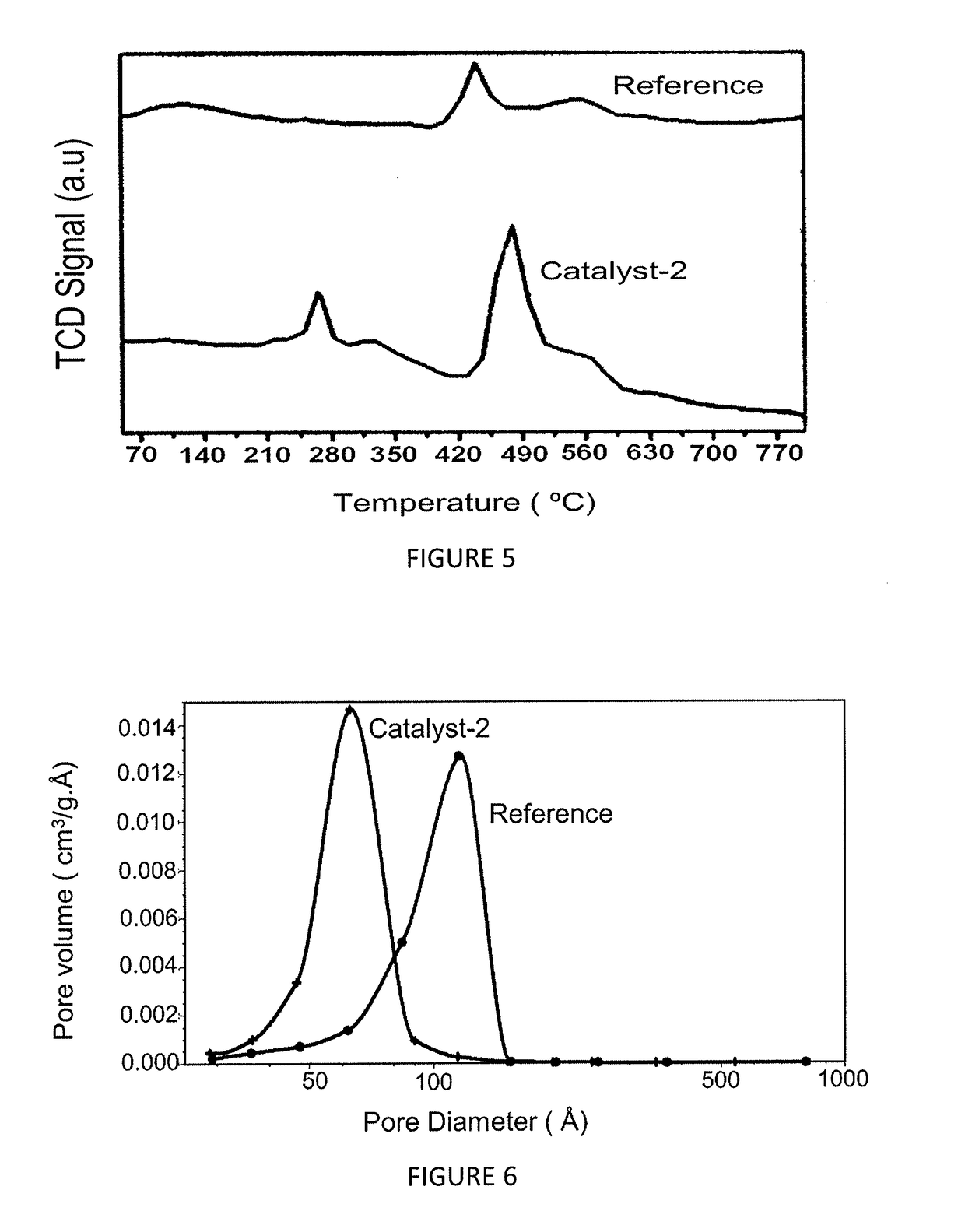

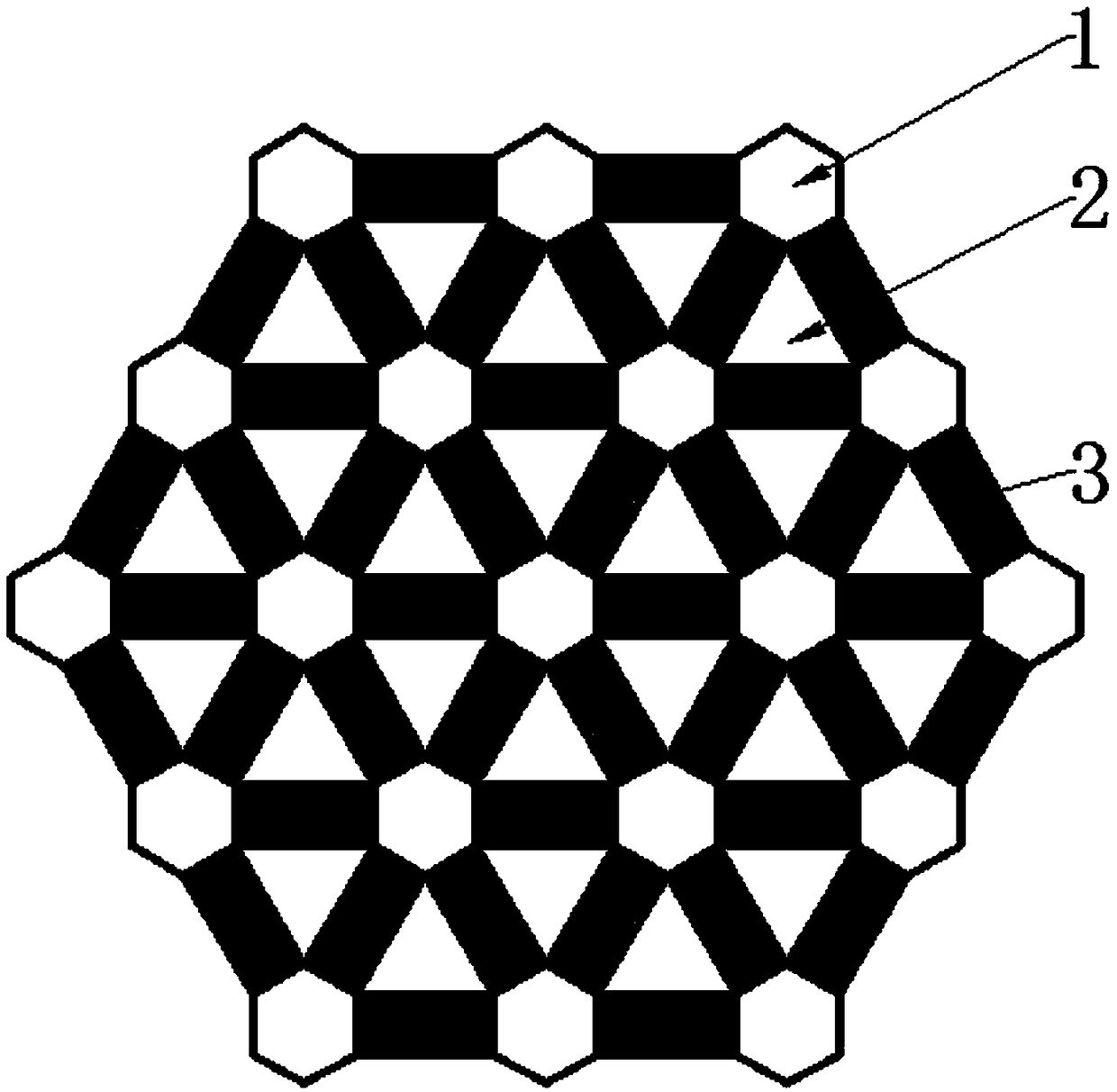

InactiveUS20170106352A1Reduces coke formationReduce inactivation rateCatalytic crackingHeterogenous catalyst chemical elementsNaphthaSupport matrix

The present disclosure relates to a composition, wherein the composition is a catalyst comprising support matrix, active metal, promoter metal and halide, wherein the support matrix is additionally subjected to a modifier to obtain a modified support matrix. The catalyst in the reaction reduces the percentage coke formation and provides for an enhanced reformate yield having an increase total aromatic yield and C8 aromatic yield when compared to the known / commercially available catalyst for naphtha reforming process, and also improves the quality of reformate obtained at end of the reaction. The disclosure further relates to process of preparation of the catalyst, the catalyst of the present disclosure derived from the process described, displays lower deactivation during the reaction demonstrating increased stability and reduction in the regeneration frequency and thereby making the catalyst economically feasible.

Owner:RELIANCE INDUSTRIES LIMITED

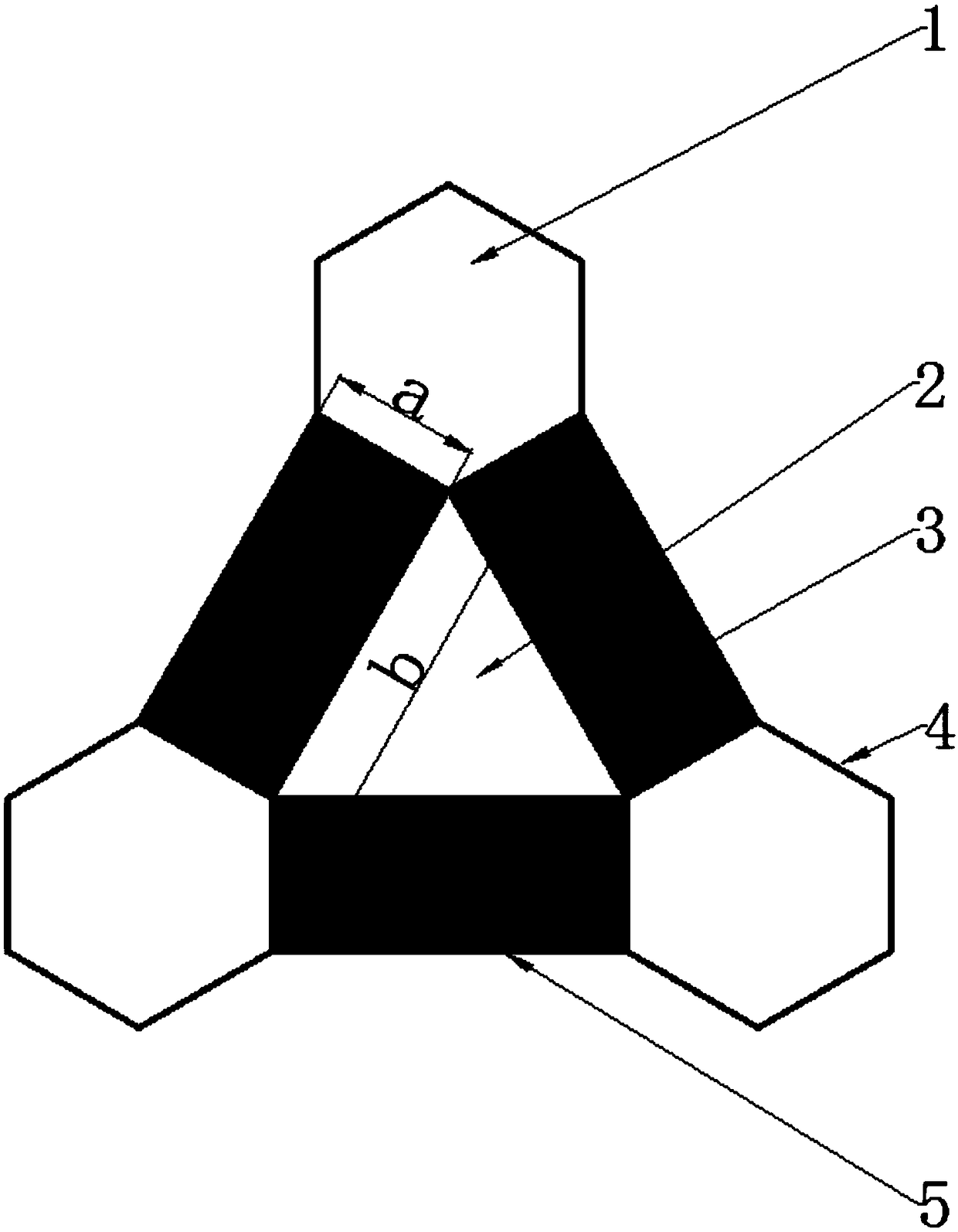

Asymmetric filter tunnel structure of grain catcher

ActiveCN109209575AIncrease volumeIncrease the areaGas treatmentInternal combustion piston enginesEngineeringAsymmetry

Owner:DALIAN UNIV OF TECH

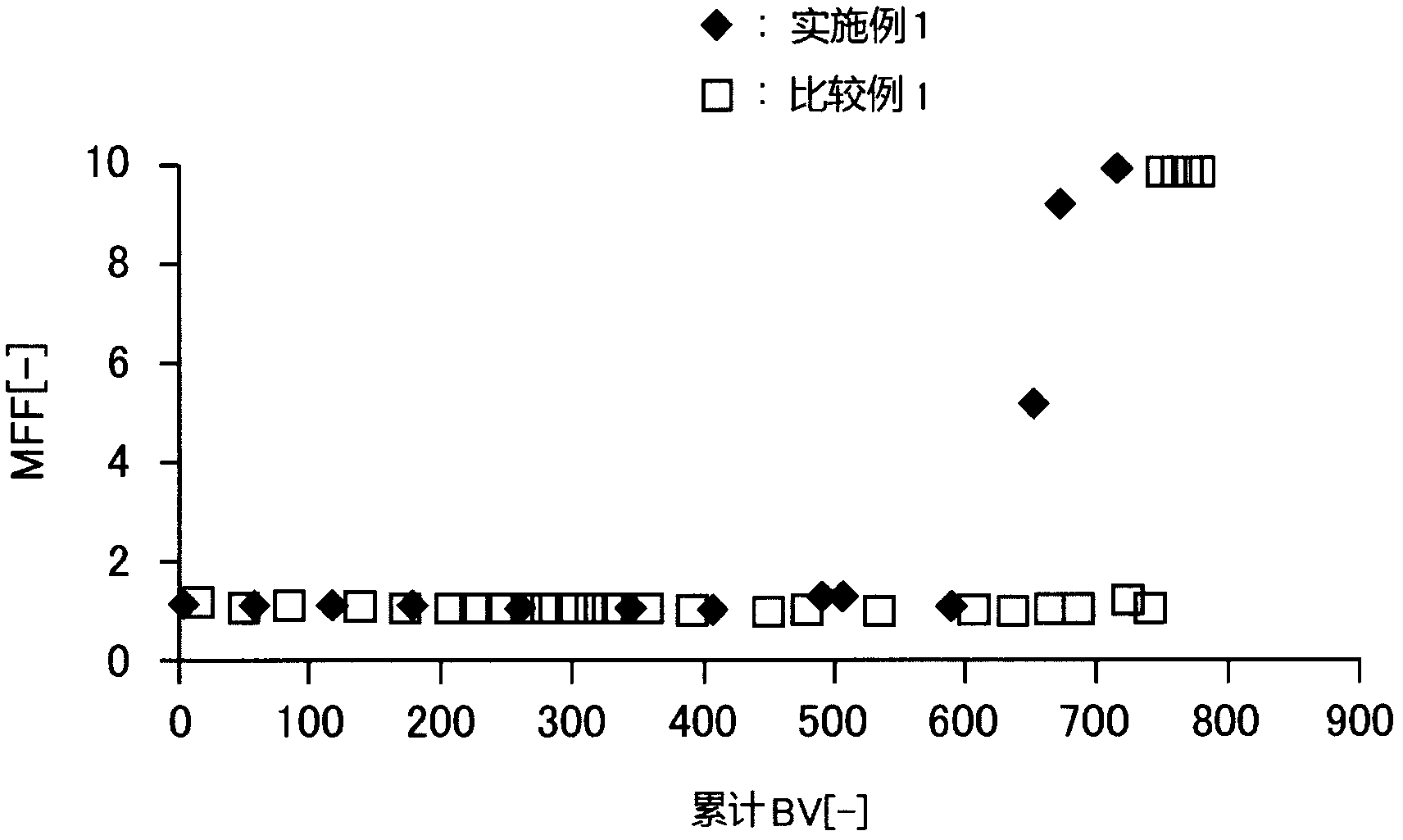

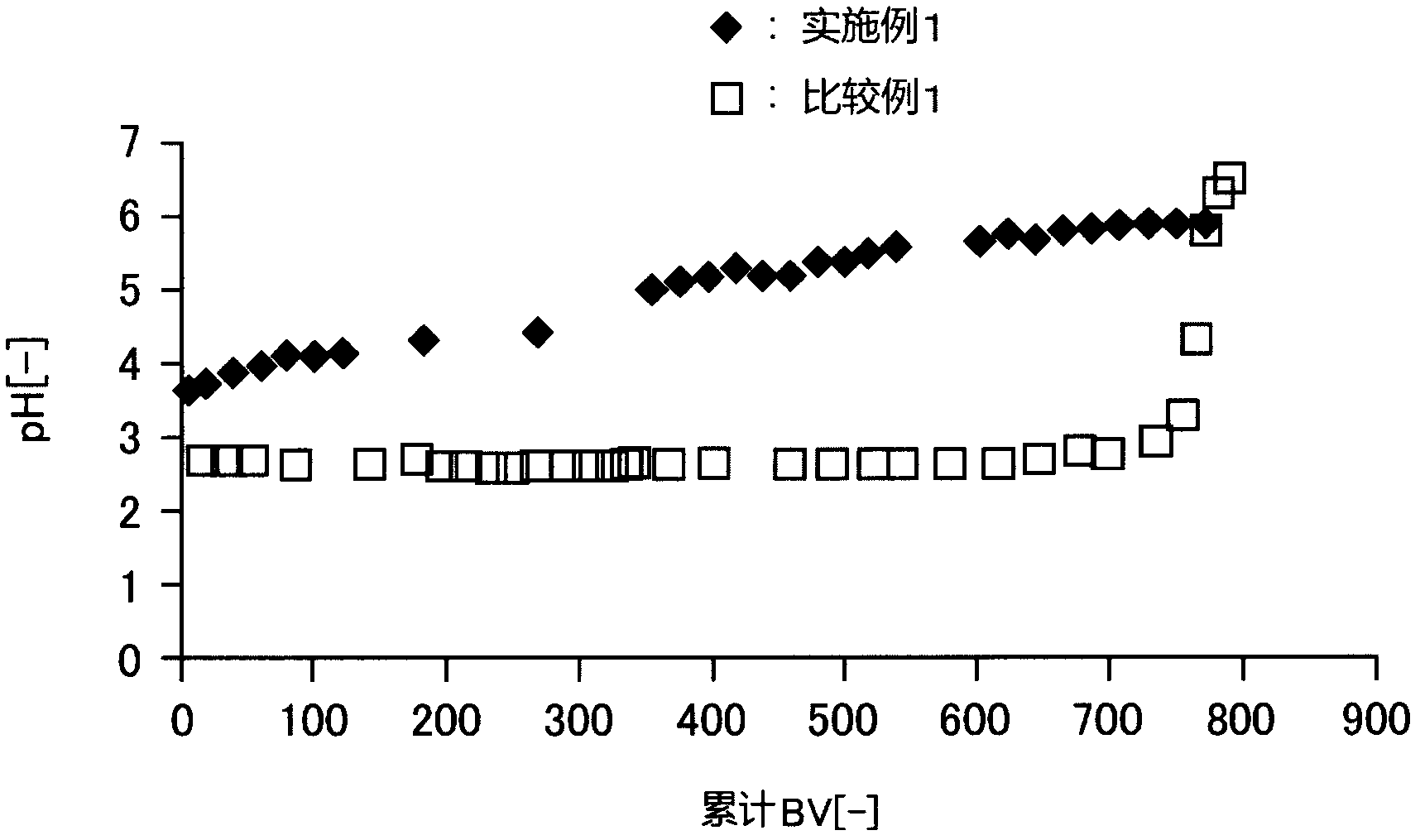

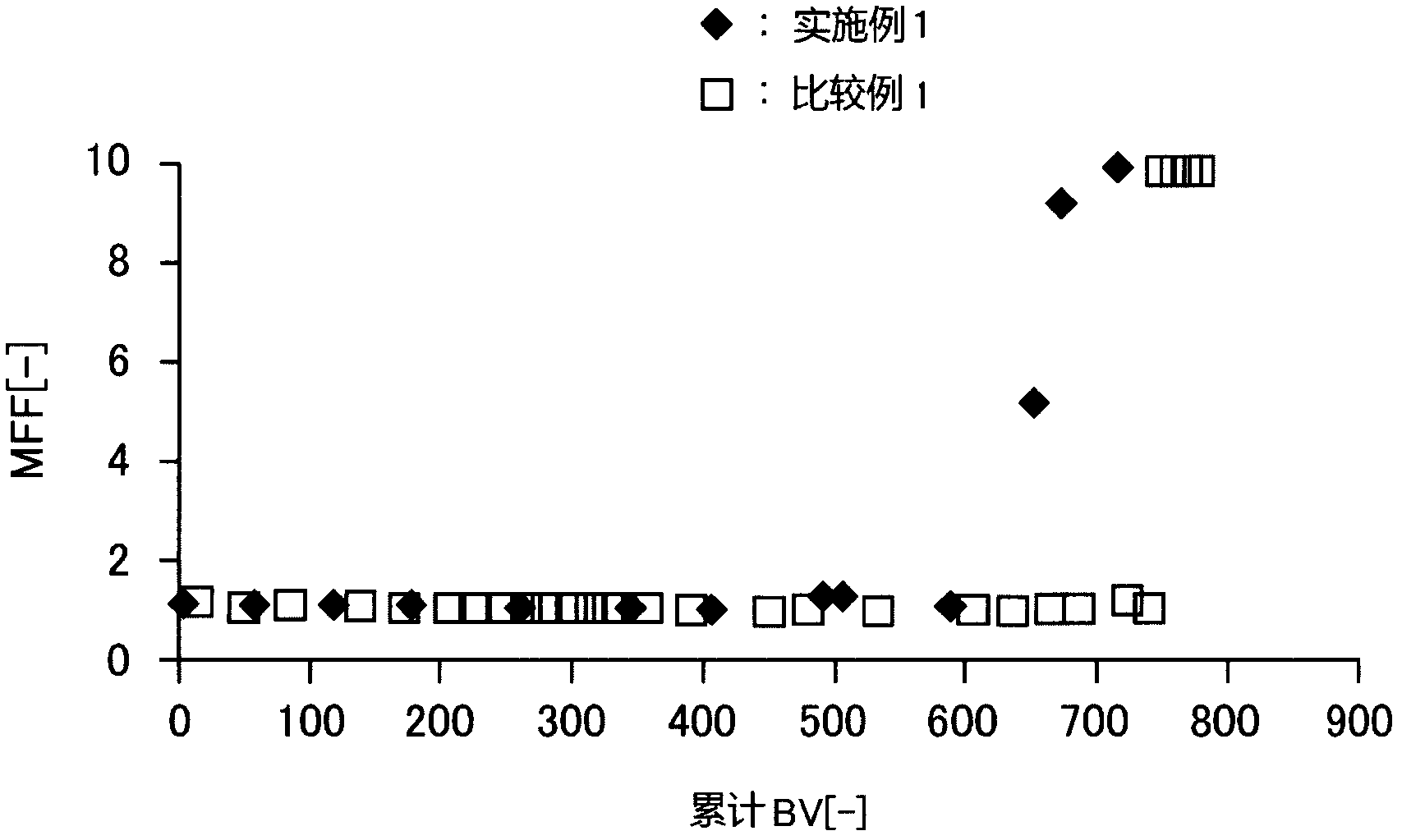

Coagulation filtering method

ActiveCN102649609AReduce regeneration frequencyReduce usageSpecific water treatment objectivesWater/sewage treatment by ion-exchangeWater qualityFilter material

Owner:KURITA WATER INDUSTRIES LTD

Condensate polishing mixed bed anion-cation resin separation filter and control method thereof

ActiveCN103253731AImprove separation rateReduce regeneration frequencyIon-exchanger regenerationWater/sewage treatment by ion-exchangeWastewaterRunning time

The invention relates to a condensate polishing mixed bed cation-anion resin separation filter. The filter comprises a resin pot, a main water inlet tube, and a resin inlet tube, a first resin outlet tube, a second resin outlet tube and a third resin outlet tube which are sequentially connected with the vertical side of the resin pot from top to bottom, the main water inlet tube is branched into a top water inlet tube and a bottom water inlet tube, the top water inlet tube is connected with a backwashing water outlet tube, the top water inlet tube is connected with the vertical top of the resin pot, and the bottom water inlet tube is connected with the vertical bottom of the resin pot. The invention also relates to a control method of the filter. The method sequentially comprises the following steps: 1, introducing resins into the resin pot; 2, backwashing the introduced resins; 3, leading out anion resins; 4, leading out middle-layer resins; and 5, regenerating to lead out cation resins. In the invention, the cation resin separation rate is increased, the mixed bed running time is prolonged, the acid and alkali consumption amounts are reduced, and the wastewater discharge is reduced.

Owner:JIANGSU NUCLEAR POWER CORP

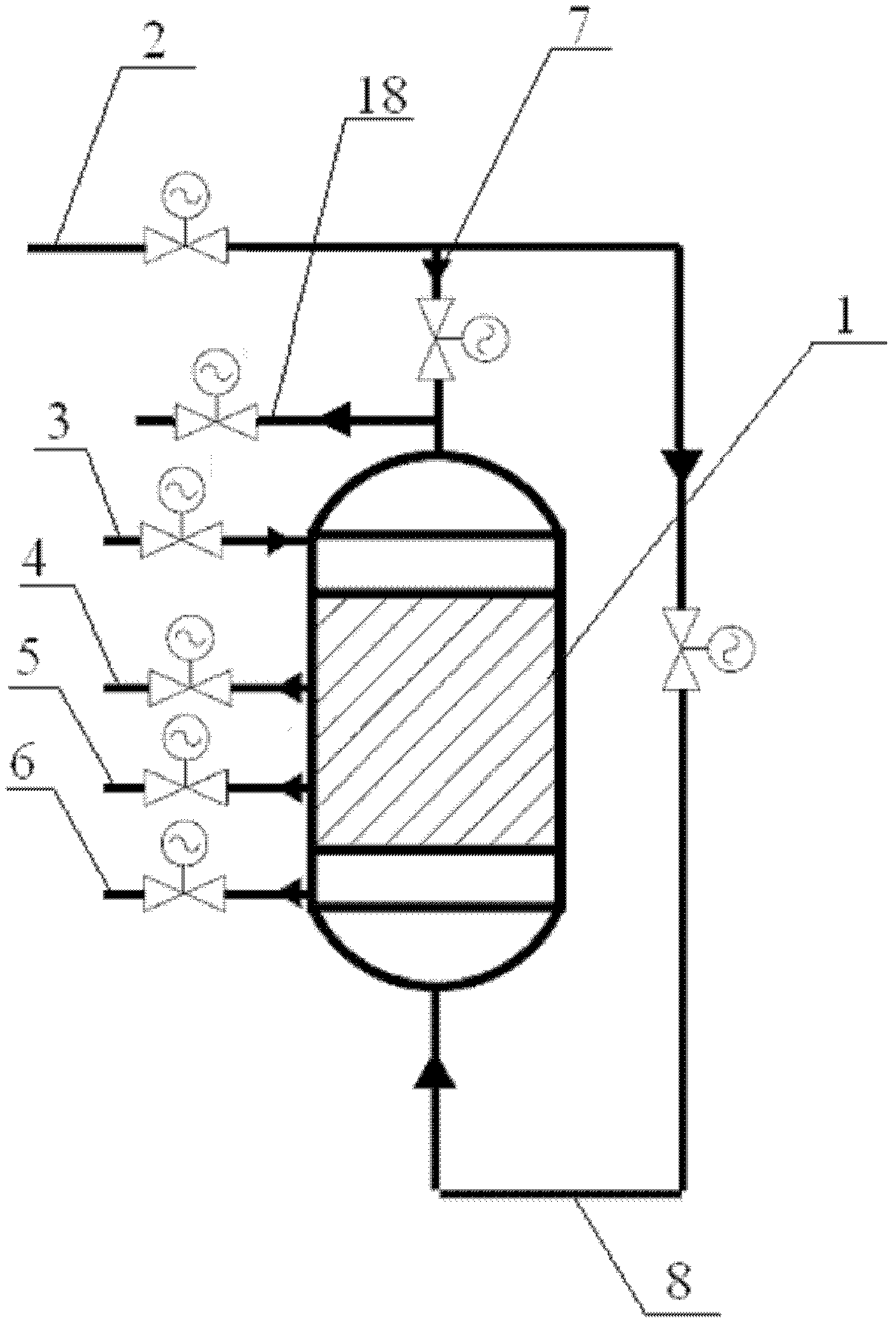

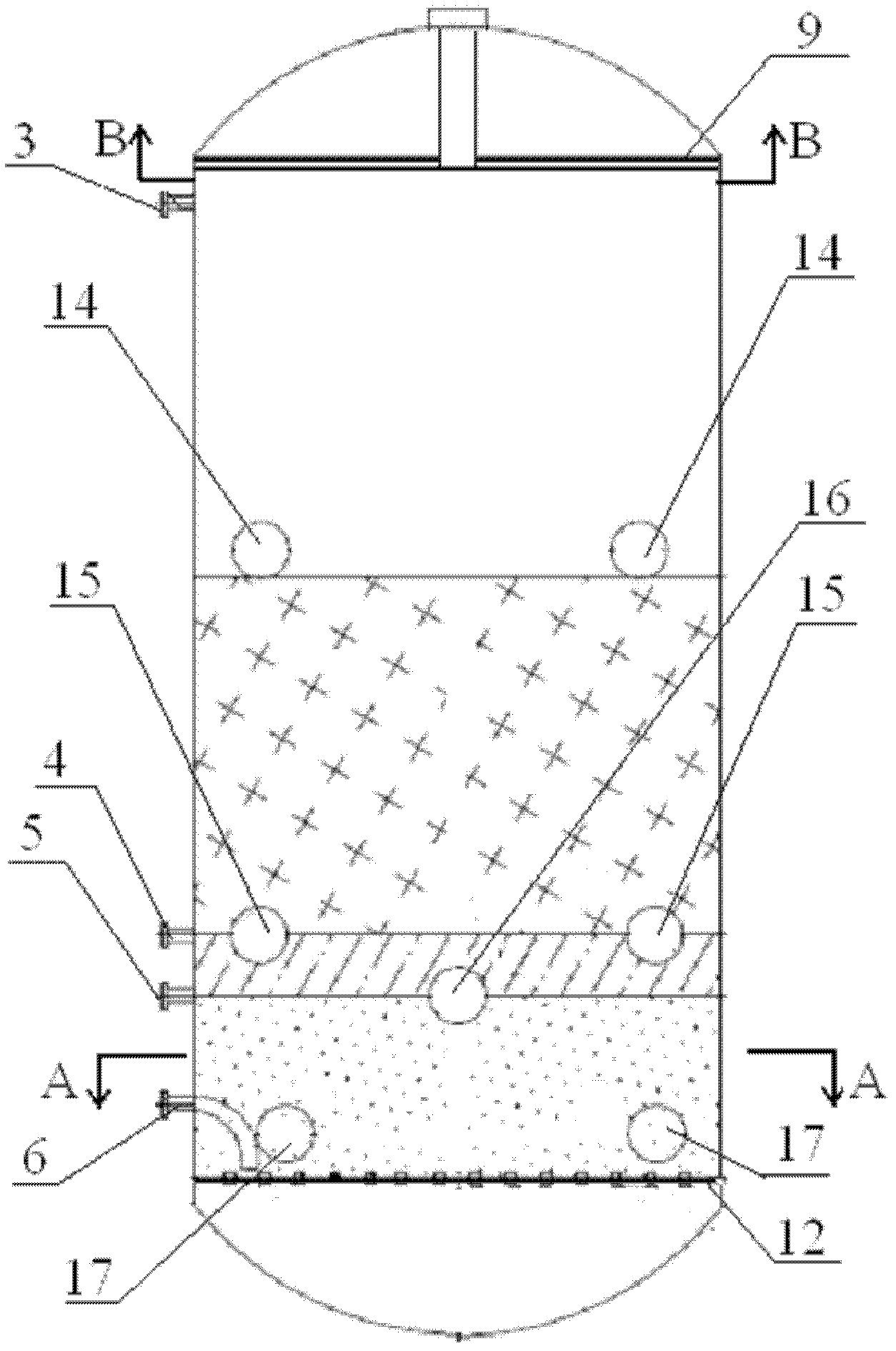

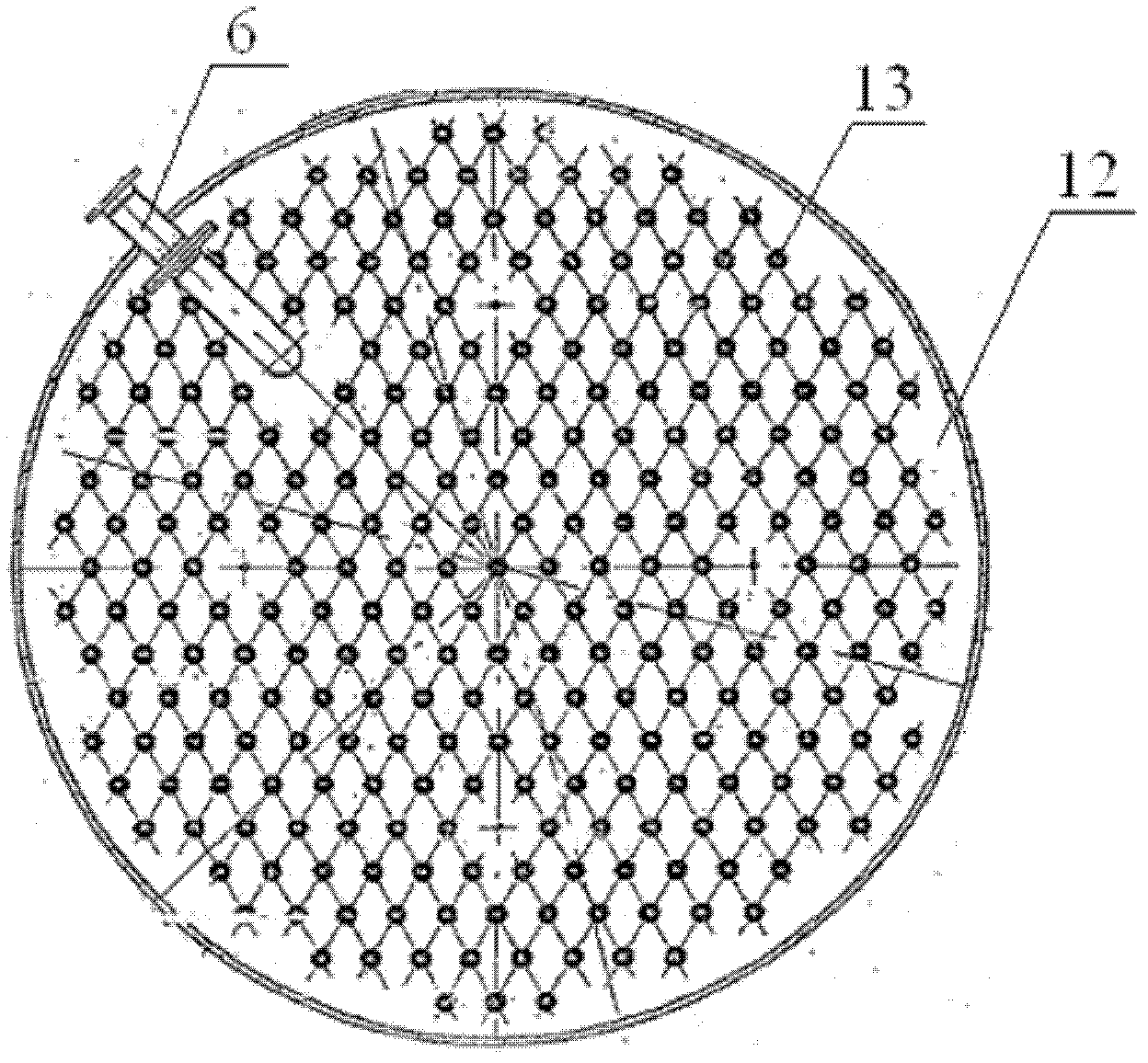

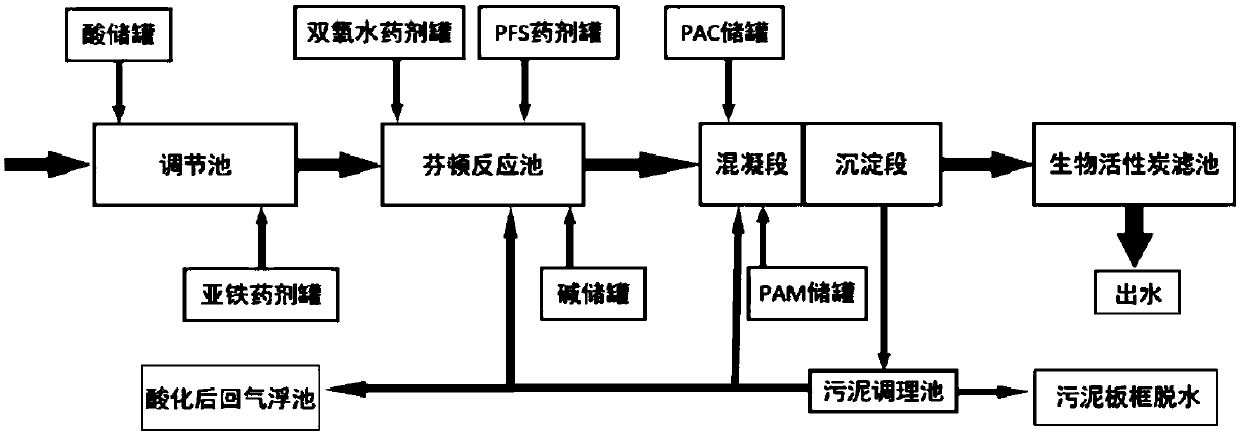

Printing and dyeing wastewater deep treatment method and equipment

PendingCN109592861AReduce adsorption loadExtend the life cycleWater treatment compoundsWater contaminantsFenton reactionBiological activated carbon

The invention provides a printing and dyeing wastewater deep treatment method and equipment. The method comprises the following steps: regulating the pH value in an adjustment tank before a Fenton reaction, and adding a catalyst at the tail end of the adjustment tank; adding hydrogen peroxide in the early stage of a Fenton reaction tank, and adding PFS in the middle-late stage of the Fenton reaction tank according to the water quality condition, and adding an alkaline liquor at the tail end of the Fenton reaction tank to adjust the pH value of effluent; adding PAC at the coagulation section ofa sedimentation tank, and adding PAM accordingly, performing a coagulation reaction, and separating mud and water at the sedimentation section of the sedimentation tank; and performing biodegradationand adsorptive filtration on the effluent of the sedimentation tank in a bio-activated carbon filter tank. The printing and dyeing wastewater deep treatment method and equipment have low cost and efficient treatment.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com