Alkylation reaction method

A technology of alkylation reaction and alkylation reactor, which is applied in chemical instruments and methods, catalysts, organic chemistry, etc., can solve the problems of short catalyst cycle life, reduce energy consumption, prolong overall life, and be easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

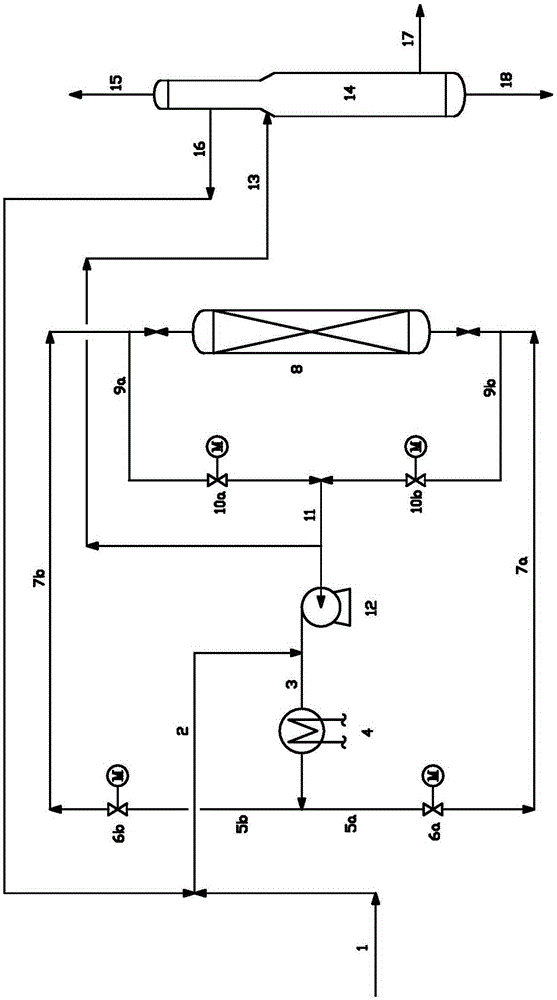

Method used

Image

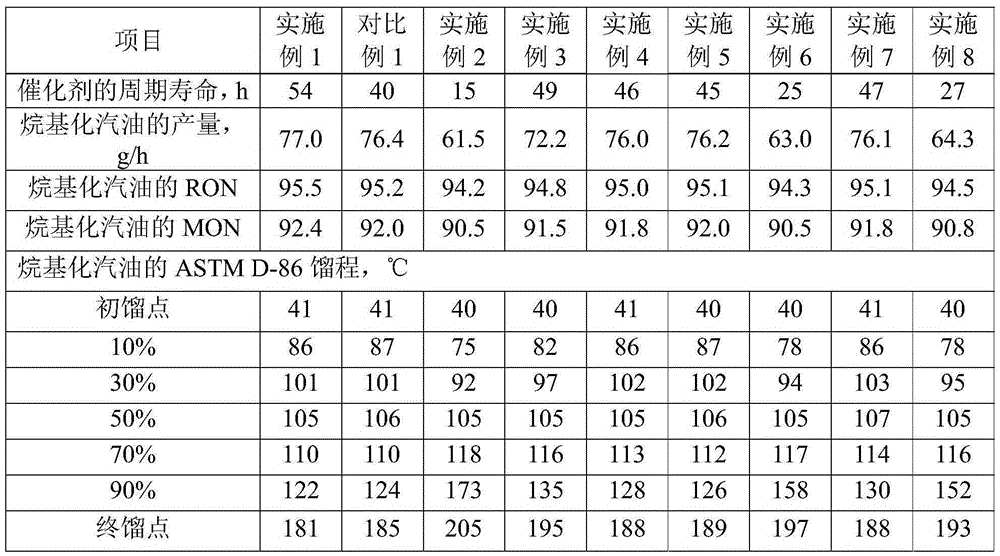

Examples

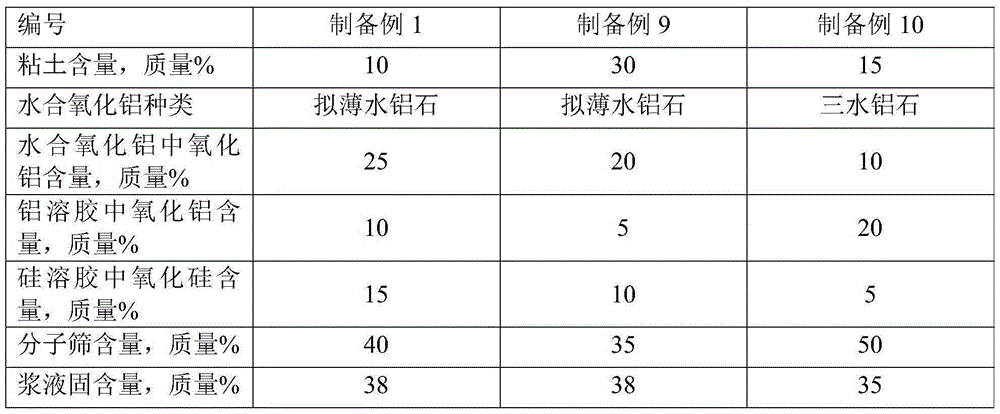

preparation example 1

[0074] With stirring, nitric acid (HNO 3 The concentration is 65% by mass, based on the total amount of slurry, HNO 3 The consumption is 2 mass %), then add clay, beating for 10 minutes, then add Y molecular sieve (purchased from Sinopec Catalyst Branch Company, specific surface area is 638m 2 / g, the pore volume is 0.37mL / g, and the unit cell constant is 2.45nm), finally add aluminum sol, silica sol and water, the slurry obtained is kneaded and extruded, and the extruded wet strip is dried at 120°C for 5 hours, followed by calcining at 450° C. for 4 hours to obtain an alkylation catalyst. The dosage of various raw materials is shown in Table 1.

preparation example 2

[0076] (1) With stirring, add nitric acid (HNO 3 The concentration is 65% by mass, based on the total amount of slurry, HNO 3 The consumption is 2% by mass), then add clay, beating for 10 minutes, then add Y molecular sieve (with preparation example 1), finally add aluminum sol, silica sol and water, the slurry obtained is kneaded and extruded, extruded The wet strip of was dried at 120° C. for 5 hours, followed by firing at 450° C. for 4 hours, thereby obtaining a molded body. The charging amount of various raw materials is the same as that of Preparation Example 1.

[0077] (2) H 2 PtCl 6 ·6H 2 O and Mn(NO 3 ) 2 Dissolve in water, then add hydrochloric acid (the addition of hydrochloric acid makes the Cl produced by HCl -The mass is 3.6 times the mass of Pt), and stirred evenly to obtain the impregnation solution. Using the method of isovolumic impregnation, impregnate the molded body prepared in the step (1) with the above impregnation solution, the impregnation is ...

preparation example 3

[0079] The difference between Preparation Example 3 and Preparation Example 2 is: in step (2), when preparing the impregnating solution, hydrochloric acid is not used, that is, the impregnating solution does not contain Cl - .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com