Method of regenerating molten salt for chemically toughening glass, and production method of toughened glass

A glass strengthening and molten salt technology, which is applied in the field of molten salt regeneration, can solve problems such as high cost, reduced processing efficiency, and increased frequency of molten salt exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

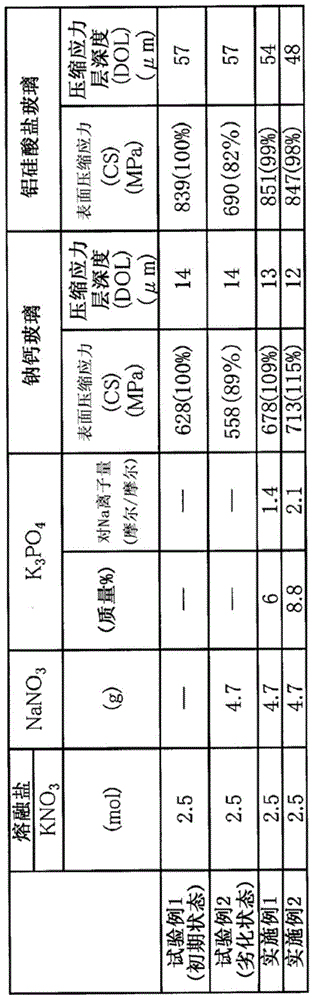

[0108] (Example 1: Preparation and chemical strengthening of molten salt regenerated from a deteriorated state)

[0109] For the molten salt in the deteriorated state simulated in Test Example 2, potassium orthophosphate trihydrate (K 3 PO 4 ·3H 2 O) 20g (K 3 PO 4 6.0% by mass). Then, stir for 2 hours using a stirring motor and 4 helical blades, and let stand for 2 hours.

[0110] Soda lime glass and aluminosilicate glass were immersed in the molten salt thus obtained at 430° C. for 8 hours to perform chemical strengthening treatment. Thereafter, each glass was washed with ion-exchanged water at 100° C., and dried at 60° C. for 2 hours. CS and DOL after this treatment were measured respectively. The results are shown in Table 1.

Embodiment 2

[0111] (Example 2: Preparation and chemical strengthening of molten salt regenerated from a deteriorated state)

[0112] Potassium orthophosphate trihydrate (K 3 PO 4 ·3H 2 O) was changed to 30g (K 3 PO 4 8.8% by mass), except that, a regenerated molten salt was prepared in the same procedure as in Example 1, and CS and DOL of each glass after chemical strengthening using the regenerated molten salt were measured, respectively. The results are shown in Table 1.

[0113] Table 1

[0114]

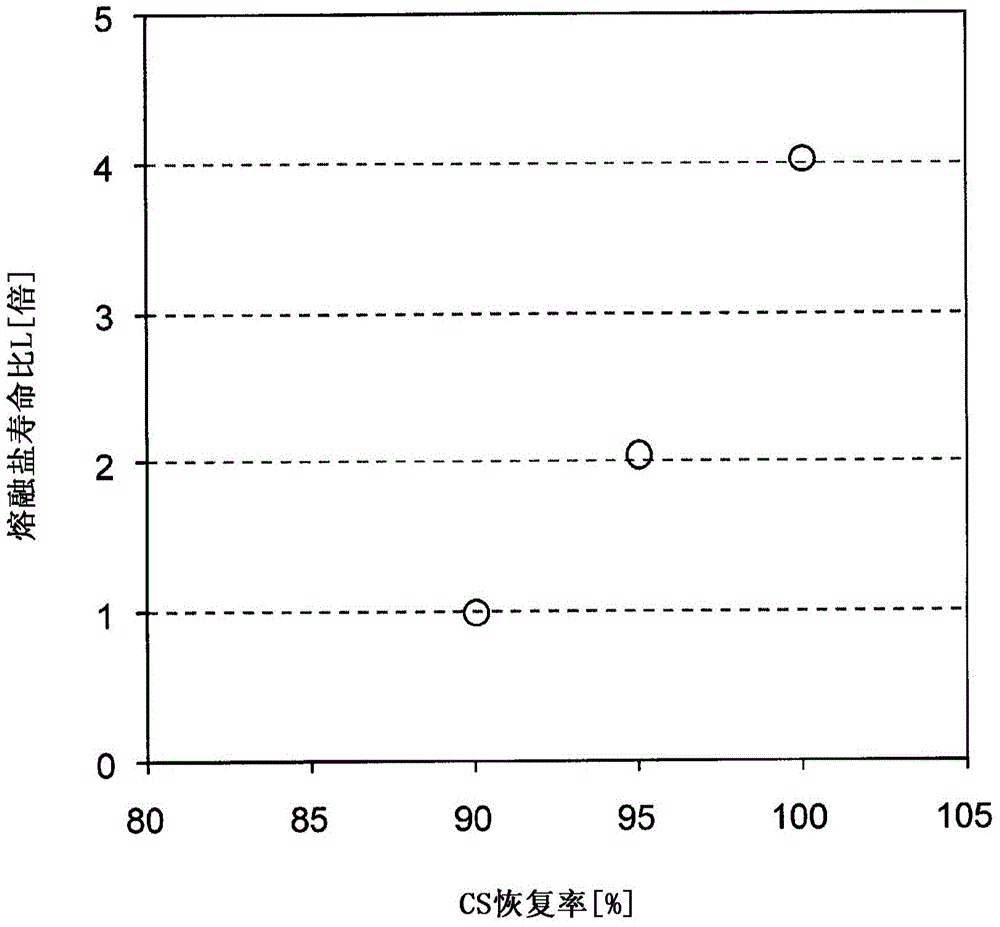

[0115] From these results, it was found that regardless of the type of glass, by adding potassium orthophosphate to molten salt degraded by Na (Test Example 2), the CS value returned to 95% or more of the initial state (Test Example 1). The same CS value can be obtained in silicate glass, and a CS value exceeding the initial state can be obtained in soda lime glass. From this, it can be seen that the molten salt capable of imparting a high CS value to glass is regenerated (recovered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com