Condensate polishing mixed bed anion-cation resin separation filter and control method thereof

A technology for fine treatment of condensate and yin and yang resin, applied in chemical instruments and methods, ion-exchange water/sewage treatment, chemical/physical processes, etc. deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

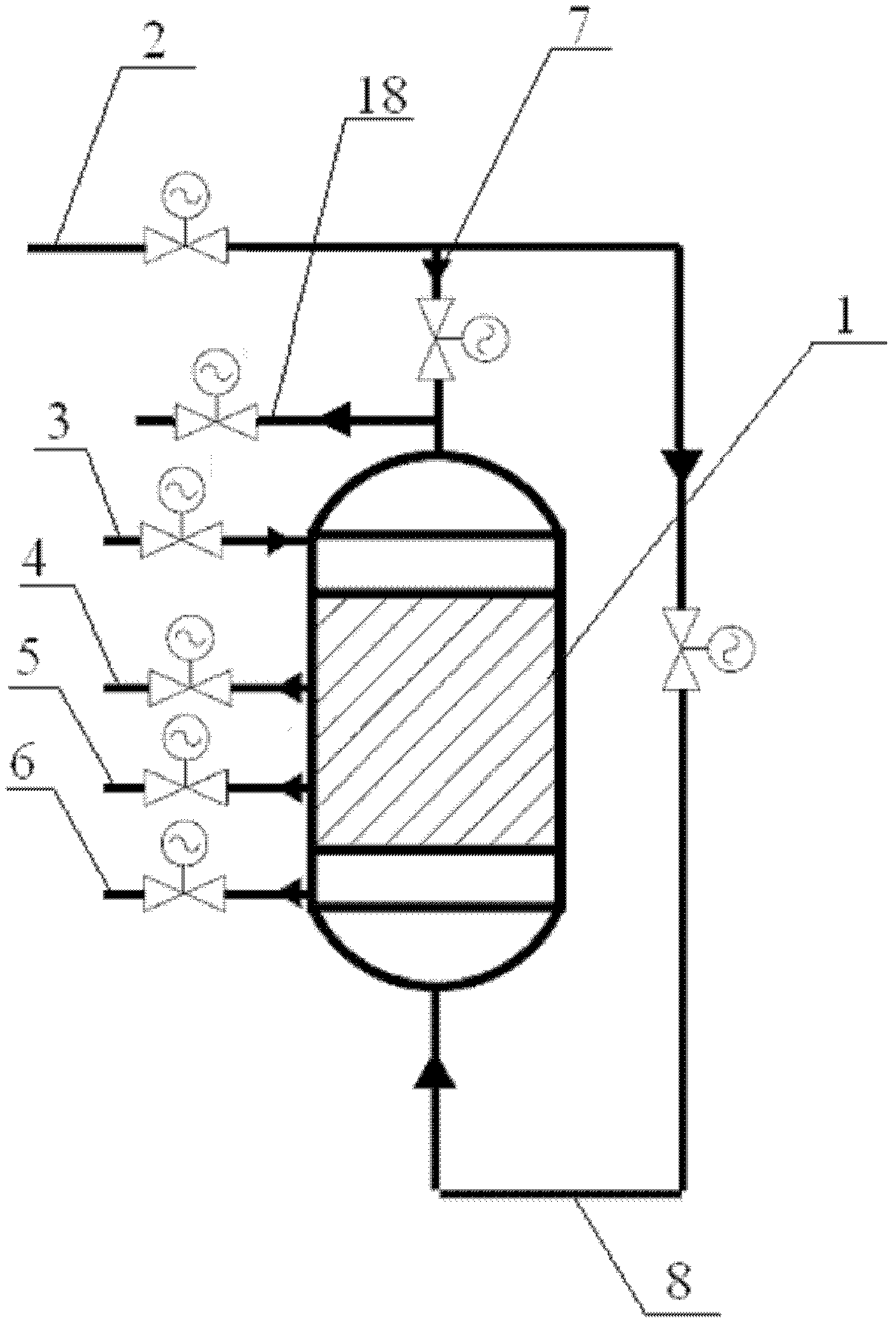

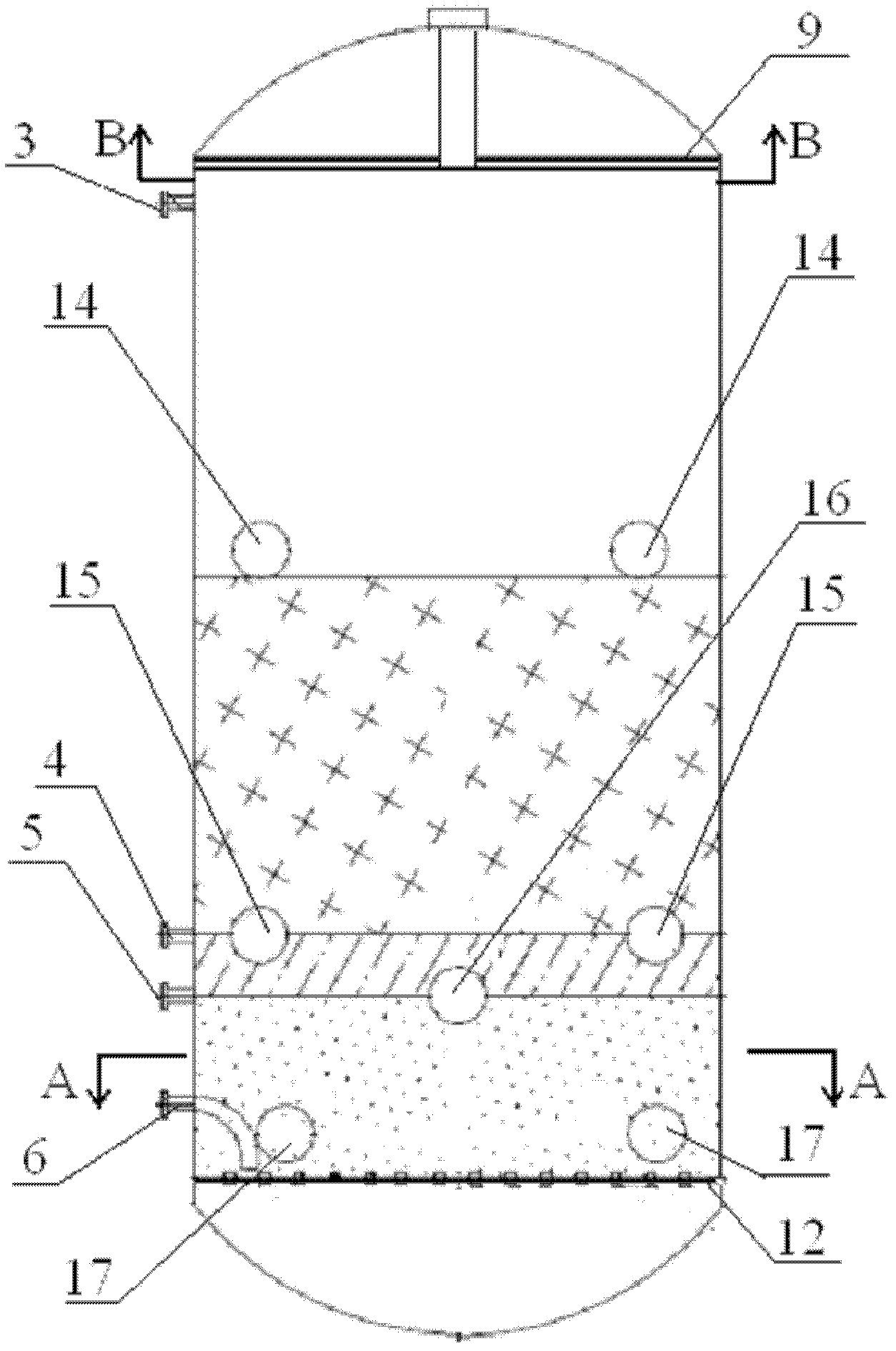

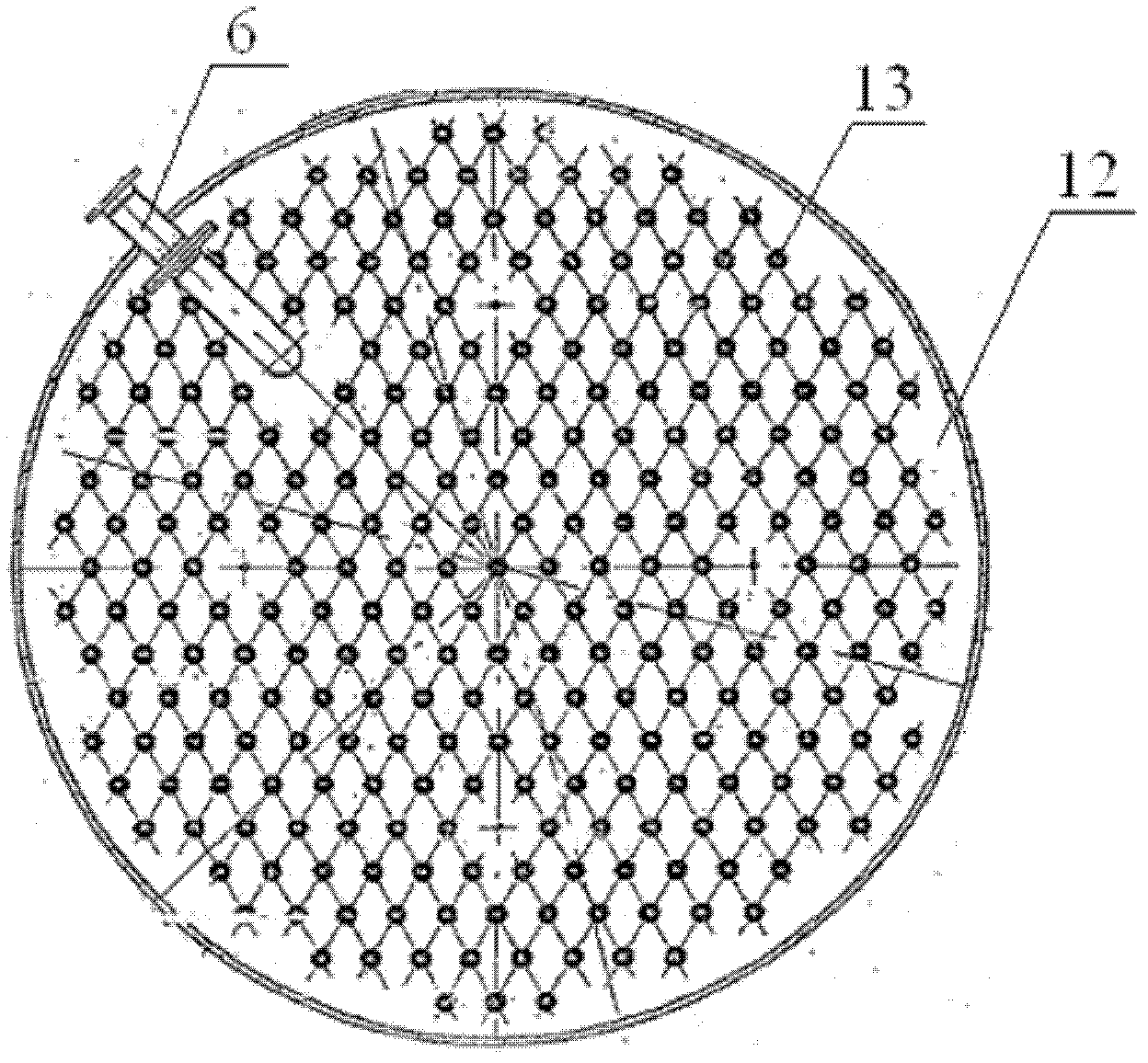

[0039] The following combination Figure 1 to Figure 4 The present invention will be further described with examples.

[0040] Such as figure 1Shown in the present invention is a mixed-bed anion-yang resin filter for condensate polishing, comprising a resin tank 1, a main water inlet pipe 2, a resin inlet pipe 3, a first resin outlet pipe 4, a second resin outlet pipe 5, and a third resin outlet pipe Pipe 6, the main water inlet pipe 2 is branched into a top water inlet pipe 7 and a bottom water inlet pipe 8, the top water inlet pipe 7 is connected to the vertical top of the resin tank 1, and the top water inlet pipe 7 is also connected to a backwash outlet pipe 18. The bottom water inlet pipe 8 is connected to the vertical bottom of the resin tank 1; the resin inlet pipe 3, the first resin outlet pipe 4, the second resin outlet pipe 5, and the third resin outlet pipe 6 are sequentially connected with the resin tank from top to bottom. 1 is connected vertically on one side; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com