Oil separator

A technology of oil-water separation device and separation chamber, which is applied in the direction of liquid separation, separation method, immiscible liquid separation, etc., which can solve the problems of increasing filter resistance, hindering the filtration process of treated water, and clogging, so as to prevent the clogging of meshes , Reduce the blockage of the mesh and reduce the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

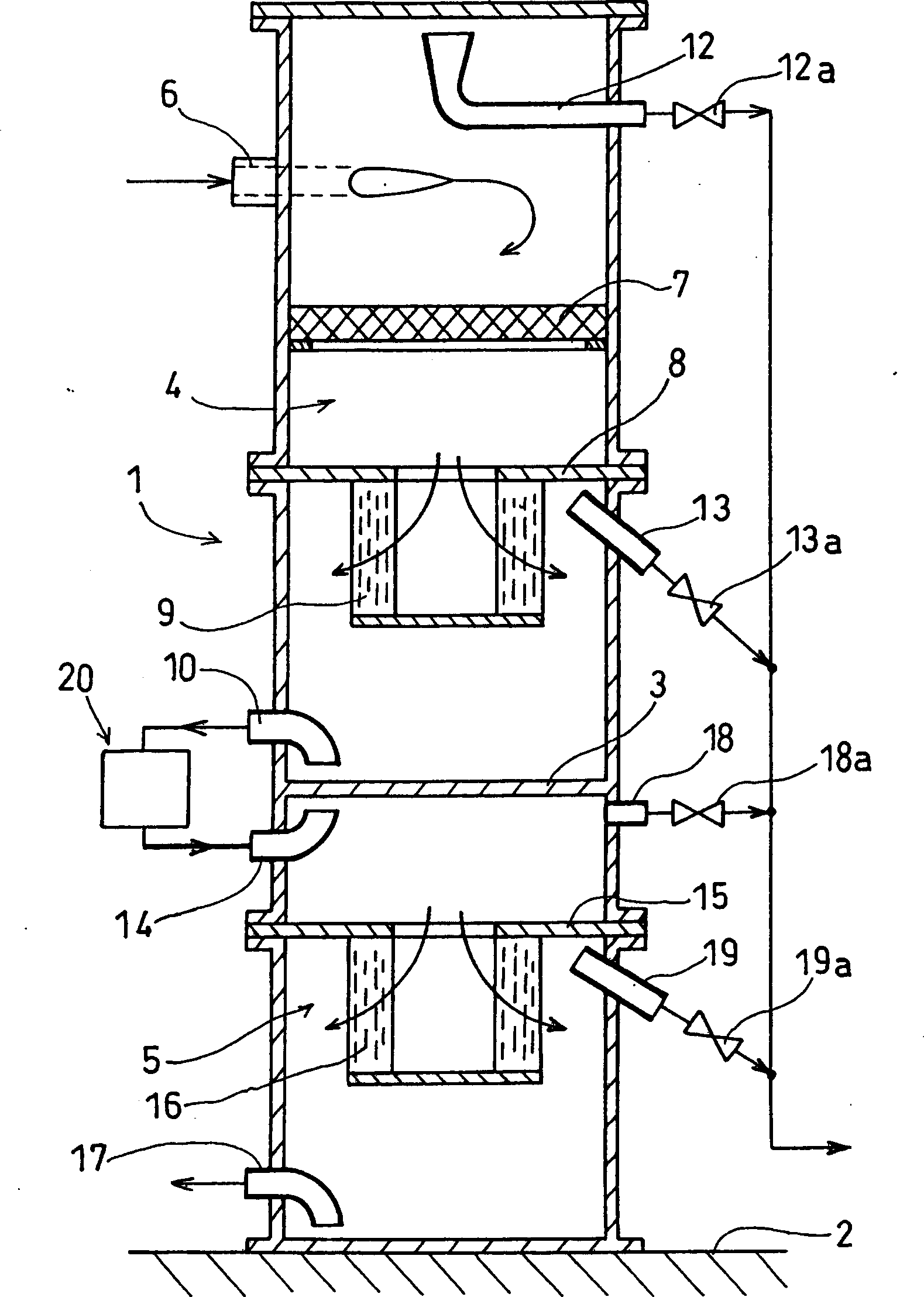

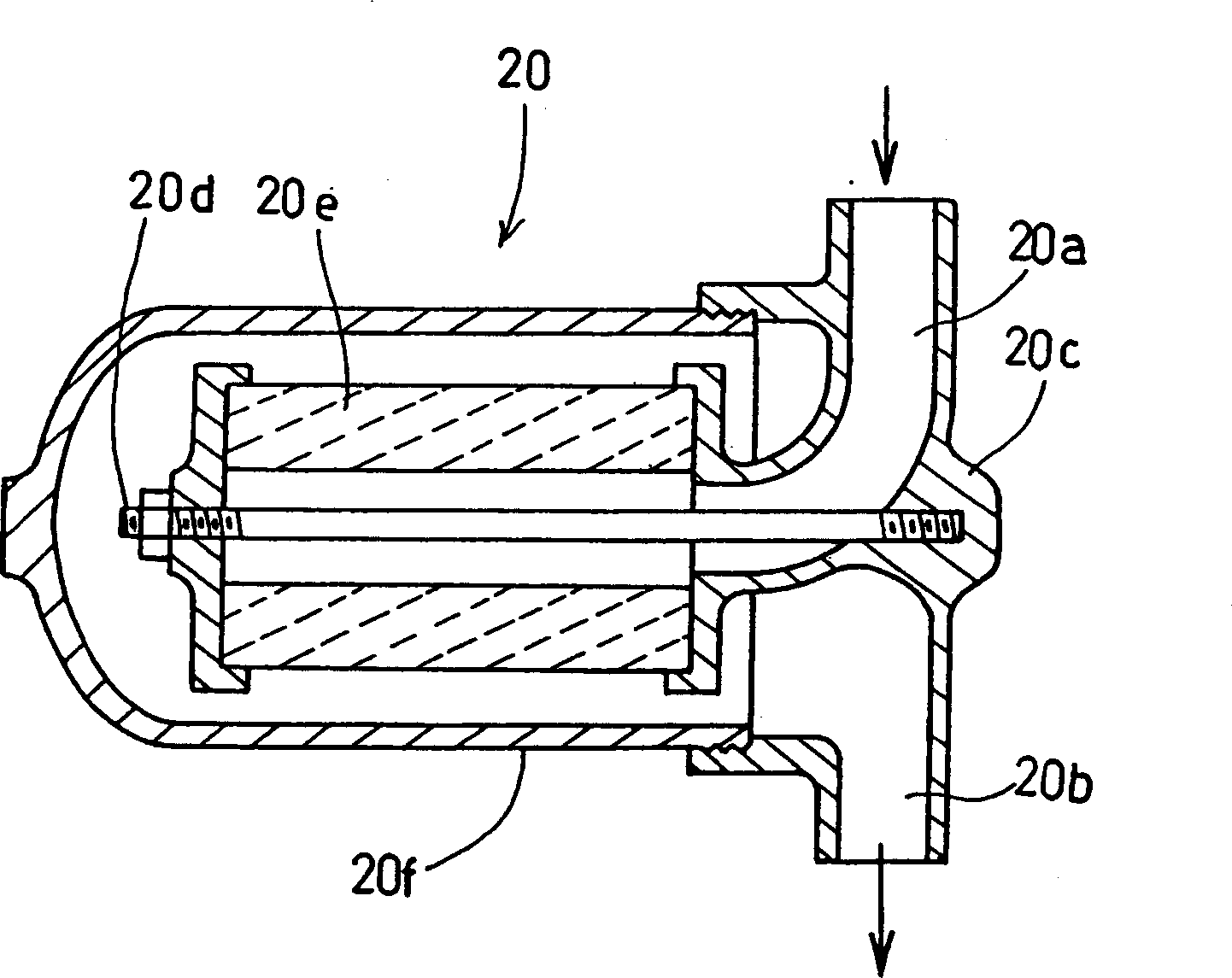

[0031] Below, the embodiment of the present invention is used figure 1 and figure 2 Be explained.

[0032] exist figure 1 In the figure, reference numeral 1 denotes a closed container formed of a vertical cylindrical shape erected on a bottom surface 2 .

[0033] The inside of the airtight container 1 is divided into an upper front-stage separation chamber 4 and a lower rear-stage separation chamber 5 by providing a partition plate 3 .

[0034] On the upper part of the pre-stage separation chamber 4, a supply port 6 for introducing the treated water containing oil and solid particle components into the pre-stage separation chamber 4 is provided. In the tangential direction when viewed in the axial direction of the container 1 , the water to be treated introduced from the supply port 6 can rotate around the axis of the airtight container 1 in the pre-stage separation chamber 4 .

[0035] In addition, a metal mesh layer 7 is provided at a position below the supply port 6 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com