Energy-saving and environment-friendly concrete sandstone separator

A kind of sand and gravel separator, energy saving and environmental protection technology, applied in the field of sand and gravel separator, can solve the problems of screen blockage, affecting the filter efficiency of the screen, difficult to clean the sand and gravel, etc., and achieve the effect of reducing the blockage of the mesh.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

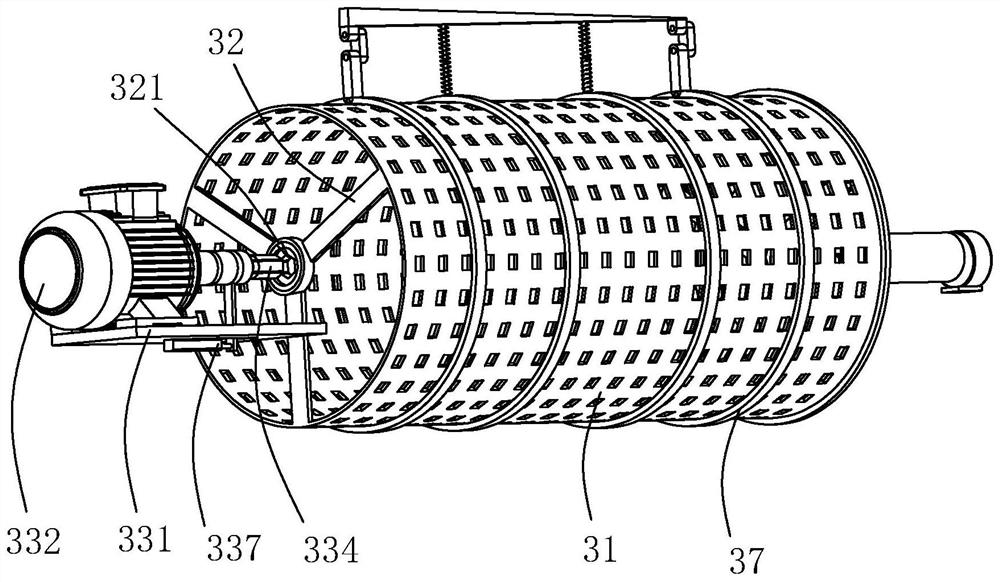

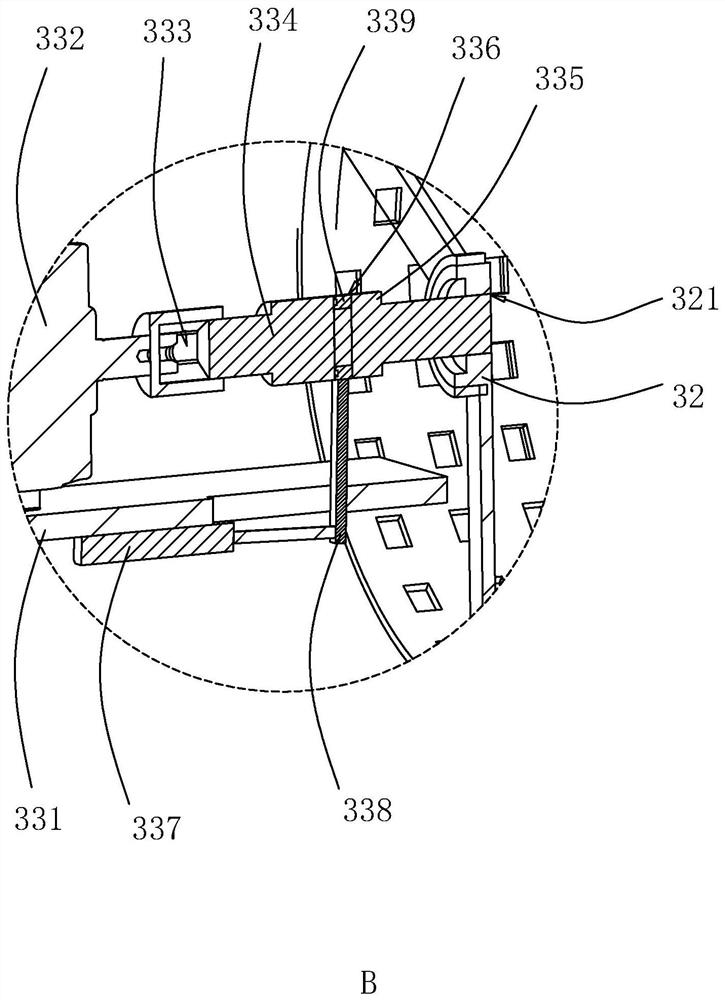

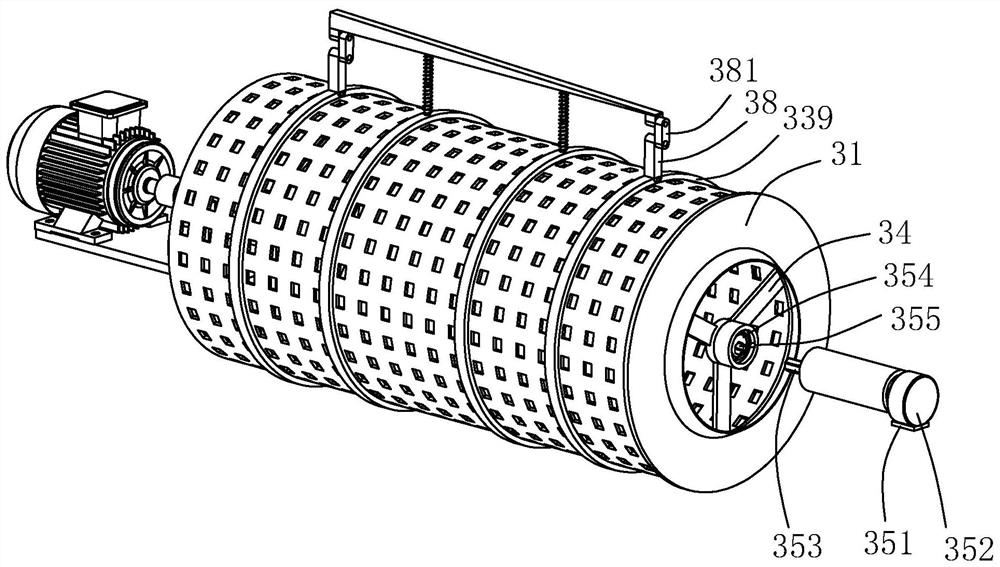

[0035] The following is attached Figure 1-9 The application is described in further detail.

[0036] The embodiment of the application discloses an energy-saving and environment-friendly concrete sand and gravel separator. refer to figure 1 and figure 2 , an energy-saving and environment-friendly concrete sand and gravel separator includes a body 1, an upper hopper 11 is arranged on the top of the body 1, a screening mechanism 3 is arranged inside the body 1, a stone outlet 12 and a sand outlet 13 are provided at one end of the body 1, The rock outlet 12 and the sand outlet 13 are located at the end of the body 1 away from the upper hopper 11 , and the end of the body 1 near the bottom is provided with a sewage pipe 14 , and the sewage pipe 14 is located at the end of the body 1 near the upper hopper 11 . The concrete and sewage for cleaning the concrete truck enter into the screening mechanism 3 through the upper hopper 11, and the screening mechanism 3 filters the sand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com