Matched plastic film residue separation device for cotton picker

A separation device and cotton picker technology, which is used in picking machines, solid separation, and separation of solids from solids by air flow, can solve the problems of increased crushing, increased opening links, time-consuming and laborious, and reduce foreign fibers. content, improve the quality grade, avoid the effect of separation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

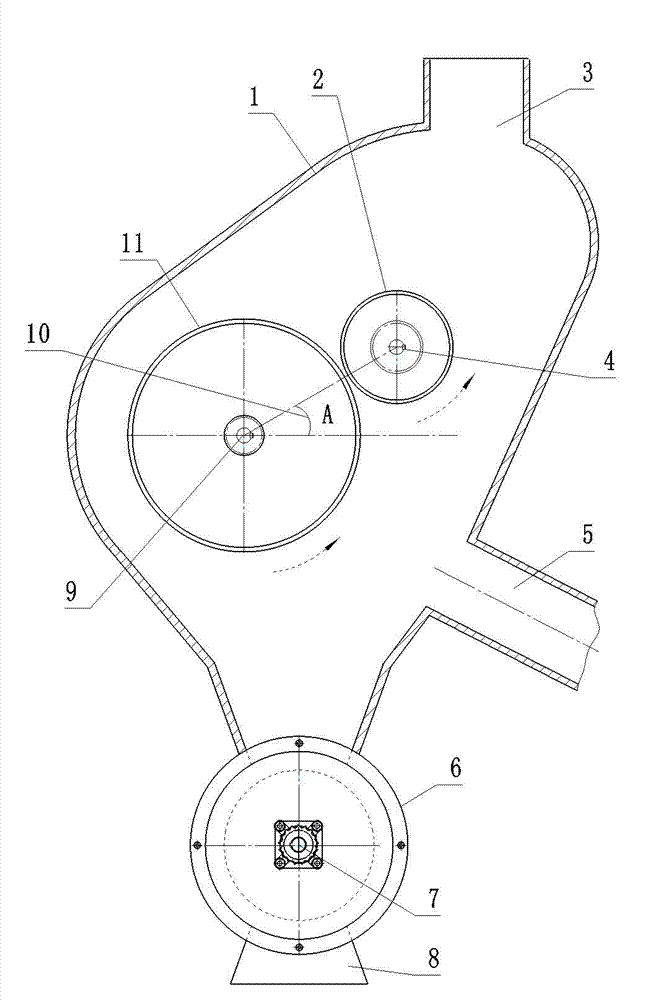

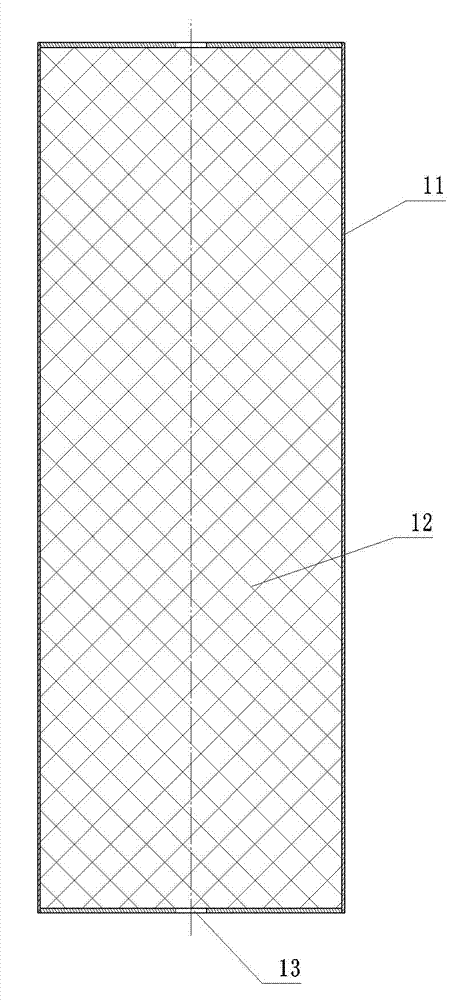

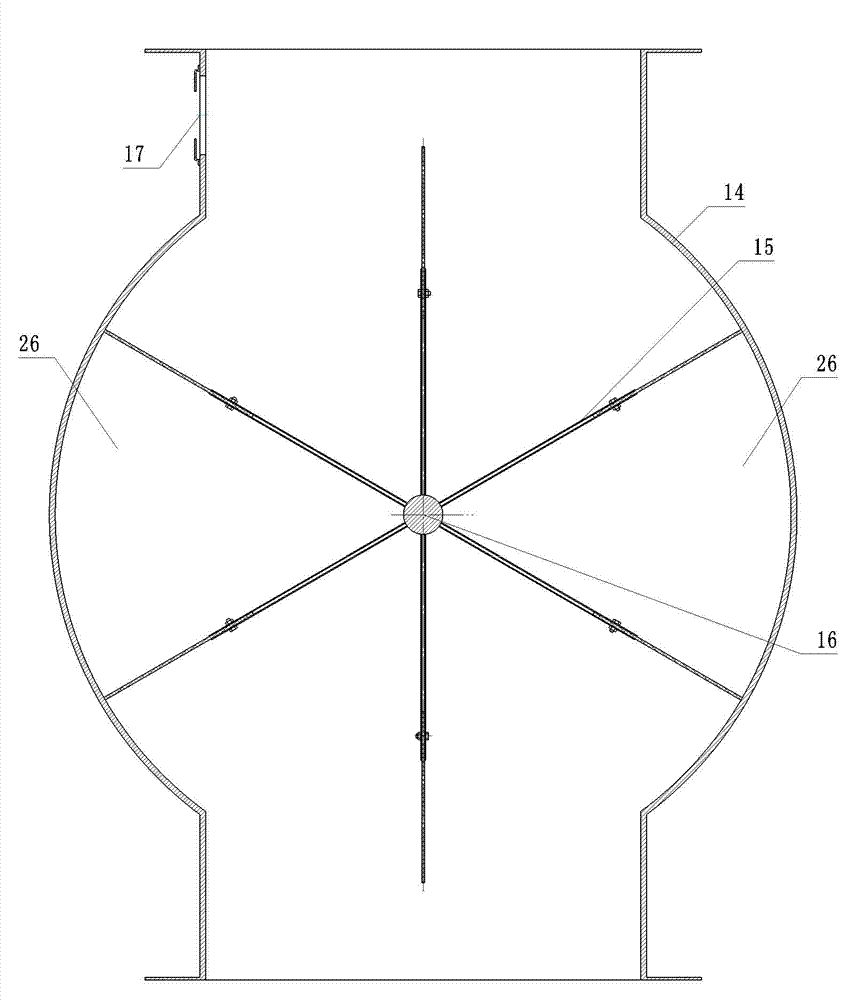

[0023] refer to Figure 1 to Figure 4 , Image 6 , the present embodiment is a supporting residual film separation device for a cotton picker, comprising a separation chamber 1, a large mesh drum 11, a small mesh drum 2, and an air locker 6 are arranged in the separation chamber 1, and the separation chamber 1 Cotton inflow inlet 5, residual film outlet 3 and seed cotton outlet 8 are arranged on the top, the cotton inflow inlet is connected with the cotton conveying pipeline of the cotton picker, and the structure of the large mesh drum 11 and the small mesh drum 2 are internal It is hollow, and the outer layer is a mesh drum of gauze 12. The large mesh drum 11 is adjacent to the small mesh drum 2, and the small mesh drum 2 is placed obliquely above the large mesh drum 11. , and close to the residual film outlet 3, the large mesh drum 11 and the small mesh drum 2 rotate in the same direction during work, and the air lock 6 is located at the seed cotton outlet 8 at the lower e...

Embodiment 2

[0028] Compared with Embodiment 1, the difference of this embodiment is that the housing 14 of the damper is preferably provided with an observation window 17 . The angle A is preferably 28°. The number of fan blades 15 of the air locker 6 is three. The blade 18 that is located on the clamp handle 19 is made of soft rubber material.

Embodiment 3

[0030] refer to Figure 5 , 6 , Compared with Embodiment 1, the difference of this embodiment is that the angle A is preferably 42°. The number of fan blades 15 of the air locker 6 is 8 pieces. The residual film outlet 3 is provided with a residual film collecting device 27, and the residual film collecting device 27 is a mesh collecting bag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com