Patents

Literature

215results about How to "Resolve separation difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for continuously producing epoxy chloropropane

ActiveCN101747297ARealize automatic separationResolve separation difficultiesOrganic chemistryChemical recyclingSolventChemistry

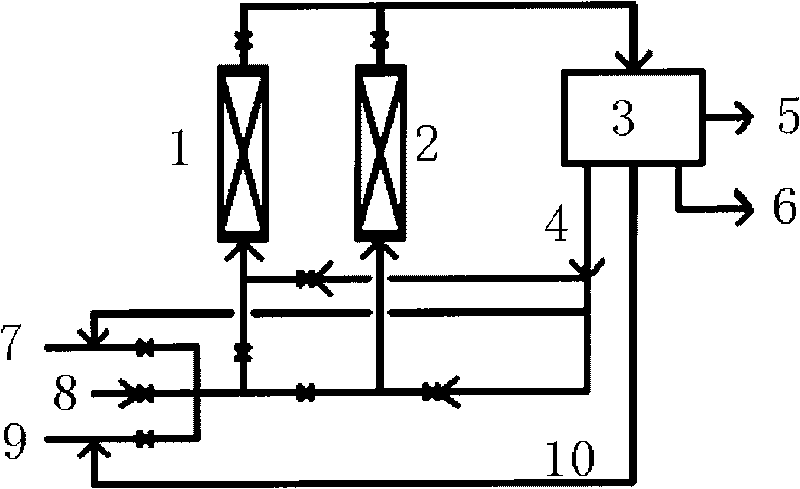

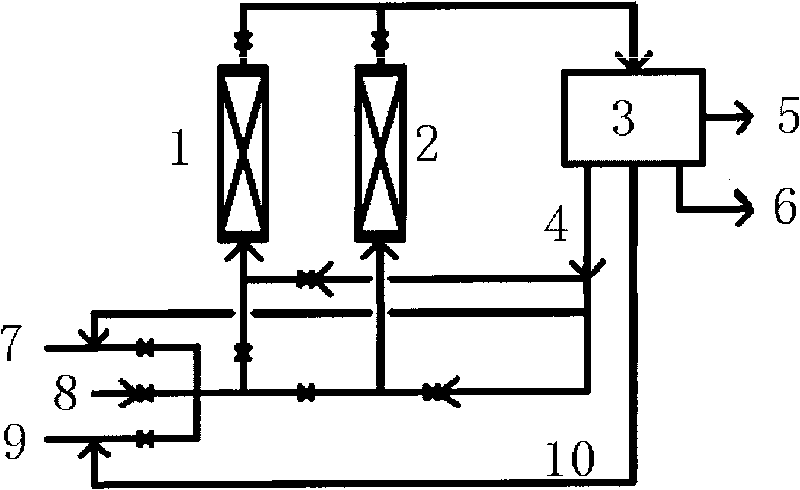

The invention relates to a method for continuously producing epoxy chloropropane, comprising the following steps: leading 3-chloropropene, hydrogen peroxide and solvent in a plurality of fixed bed reactors filled with titanium silicalite catalyst; enabling the 3-chloropropene and the hydrogen peroxide to carry out epoxidation; and stopping epoxidation in at least one fixed bed reactor and regenerating the catalyst therein, wherein when regeneration is carried out in any one of the reactors, at least one reactor in the rest reactors is in epoxidation. The method provided by the invention has the advantages of simplifying the separation process of the catalyst and the reaction products, realizing long-period continuous and stable operation in the production process of epoxy chloropropane, reducing the loss caused by equipment downtime, and having simple technology process and convenient process realization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for nano-cellulose

ActiveCN104047198APromote swellingFacilitate dissociationPulping with organic solventsPlant fibreWastewater

The invention relates to a preparation method for nano-cellulose. The method comprises the steps of: providing a plant fiber pulp; untwining the plant fiber pulp to separate the plant fiber into single fiber; conducting pre-defiberization treatment on the untwined plant fiber pulp, and simultaneously adding a TEMPO catalytic oxidation system to oxidize the fiber; when the freeness of the plant fiber pulp reaches 150-450ml, separating the oxidized fiber and wastewater; conducting defiberization treatment on the oxidized fiber again to freeness of 50ml and below, thus obtaining defiberized oxidized fiber; and carrying out nanocrystallization treatment on the defiberized oxidized fiber so as to obtain a nano-cellulose solution. The method is easier to realize wastewater separation and recovery of chemicals, at the same time can save pulping energy consumption by 20%-82%, and is easier to obtain nano-cellulose with uniform size and low cost.

Owner:GOLD EAST PAPER JIANGSU

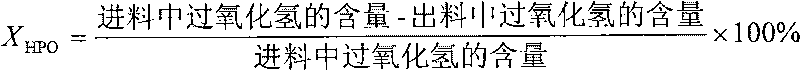

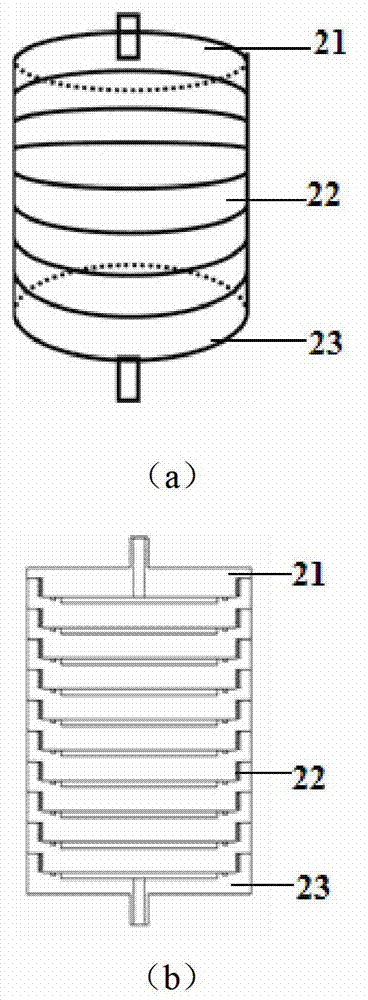

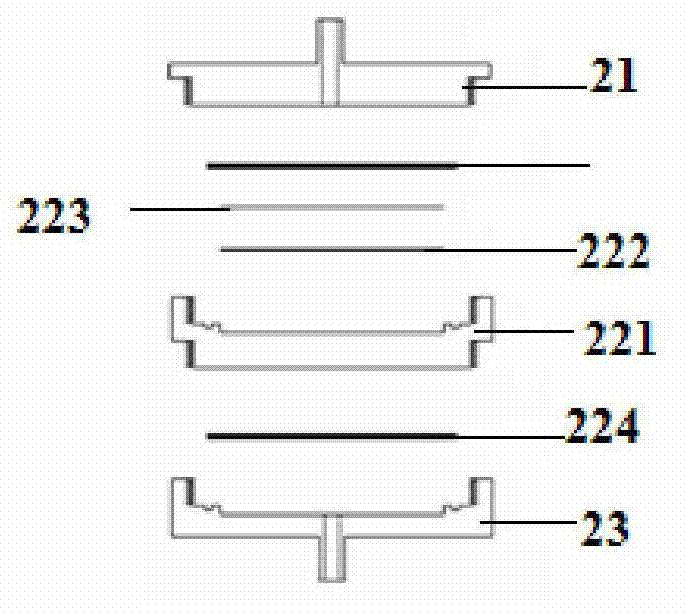

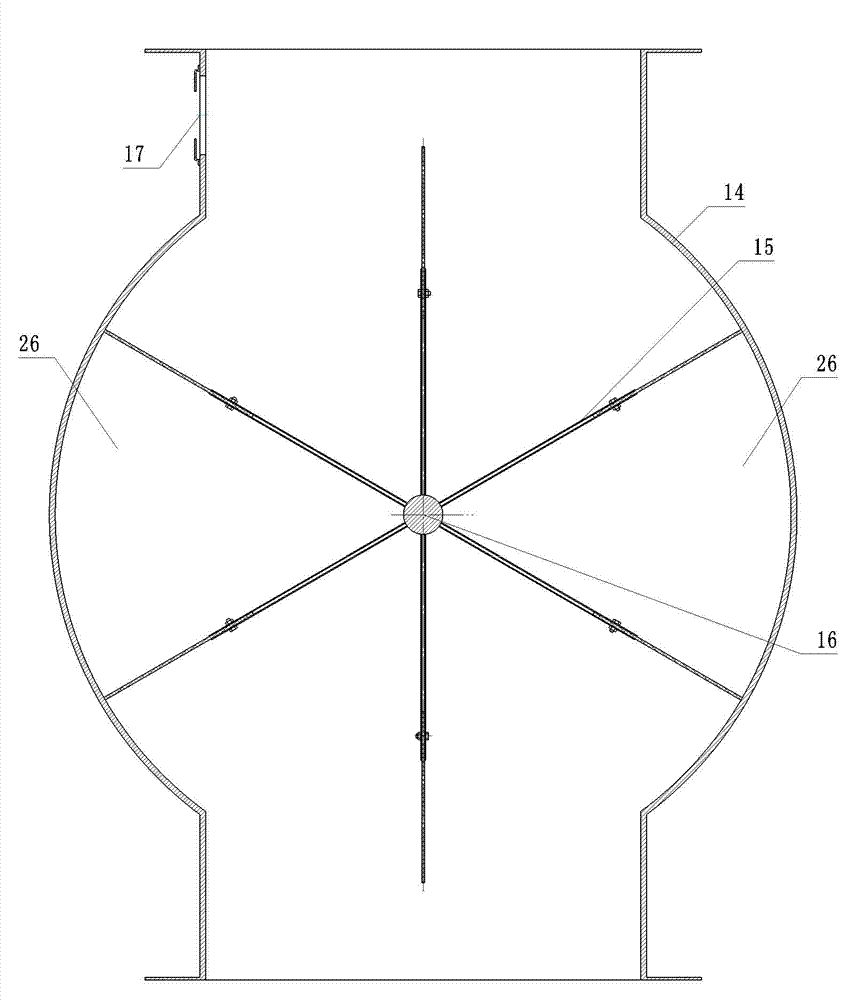

Hierarchical collection device of suspended matters of natural water body, and collection method of hierarchical collection device

InactiveCN102928257AGuaranteed original conditionPrevent coagulationWeighing by removing componentWithdrawing sample devicesEnvironmental engineeringSuspended matter

The invention discloses a hierarchical collection device of suspended matters of a natural water body, and a collection method of the hierarchical collection device. The collection device comprises a filtering combination suite, a control box, a submersible pump and a water pipe, wherein the filtering combination suite further comprises a water inlet element, filtering elements and a water outlet element, and a plurality of filtering elements are overlapped together and are arranged between the water inlet element and the water outlet element. According to the hierarchical collection device, the plurality of filtering elements are overlapped together, the apertures of the filtering elements are gradually reduced from top to bottom, the suspended matters in different particle sizes are separated in a layer-by-layer manner, and the suspended matters in different particle sizes can be separated at one time, so that the operation is simple and quick, and precision is improved. The collection device is easy to use during field sampling, depth and flow instruments can be used for quantitative sampling of the natural water bodies in different depths, the suspended matters are separated in place, and the original state of the suspended matters is ensured; and the difficulty in separation of bio-particles in a sedimentation method is overcome; and the collection device has the advantages of large flux, time saving and very low cost.

Owner:PEKING UNIV

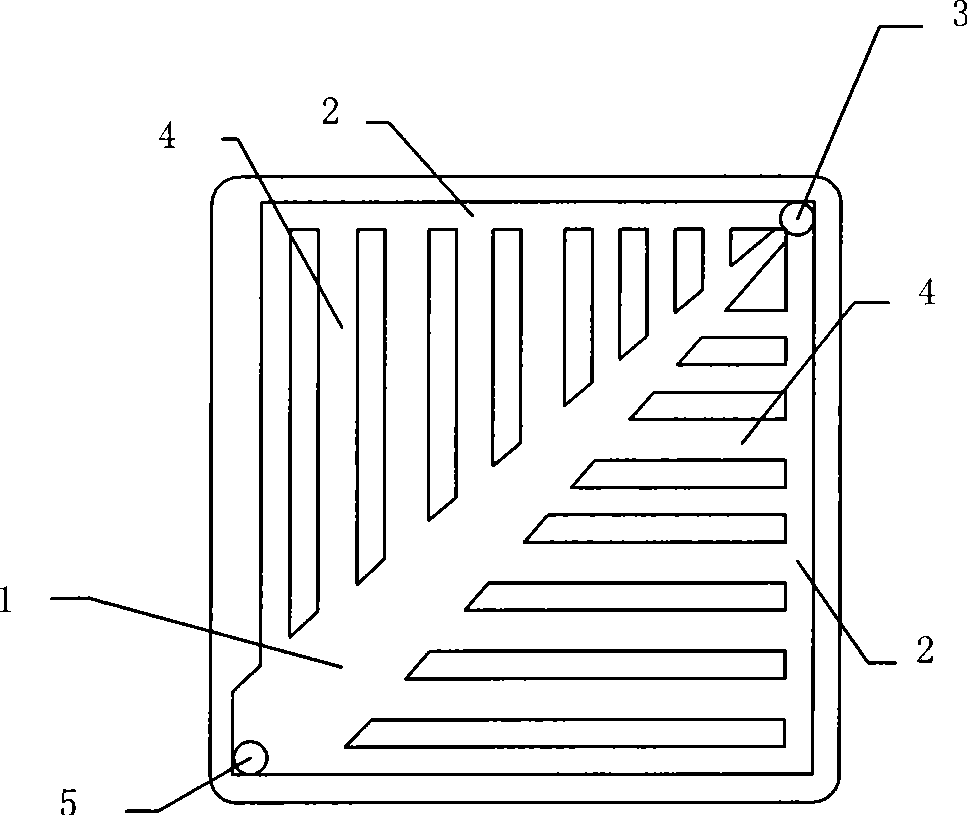

Leaf vein shaped fuel cell flow field plate

A vein-shaped fuel cell flow field plate comprises two flow field plates mutually joined, wherein a approximately square flow field area is arranged on the flow field plate, a sealing gasket is arranged on the periphery of the flow field area, a main vein for liquid flowing in extends along a diagonal line of the square, jointed veins for liquid flowing out are parallel to the edge of the square and are perpendicularly crossed at a liquid outlet, one end of each branch vein is connected with the main vein via a 45-degrees angle and is parallel to the edge of the square, and the other end is connected with the jointed veins via a vertical angle. The invention has the advantages that the flowing resistance of the liquid in the flow field plates can be smaller and more uniformly distributed, and gas generated during reaction can be exhausted via a shortest path.

Owner:ZHEJIANG UNIV OF TECH

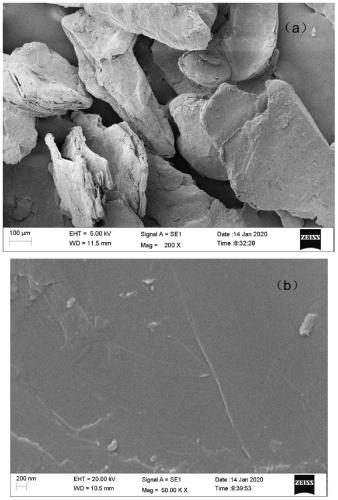

ZSM-5 structure zeolite, preparation and use thereof

InactiveCN1257840CTroubleshooting FiltrationImprove conversion rateMolecular sieve catalystsPentasil aluminosilicate zeoliteHydration reactionPtru catalyst

A ZSM-5 structured zeolite, the molar ratio of silicon oxide to aluminum oxide is 15-200, the primary particle diameter is 0.5-10 μm, and the mesopore surface area with a pore diameter of 2-50 nm measured by BET low-temperature nitrogen adsorption method is 25- 250m 2 / g. The zeolite is prepared from conventionally produced zeolite with larger crystal grains as raw material, treated with alkaline aqueous solution, ammonium ion exchange, dried and roasted. When the zeolite is used as a catalyst for the hydration of cyclohexene to prepare cyclohexanol, a good conversion rate of cyclohexene can be obtained, and it solves the difficulty in separating the catalyst from the liquid phase after the hydration reaction in the prior art and the fine crystal grains during the zeolite synthesis. resulting in difficult filtering problems.

Owner:CHINA PETROLEUM & CHEM CORP +1

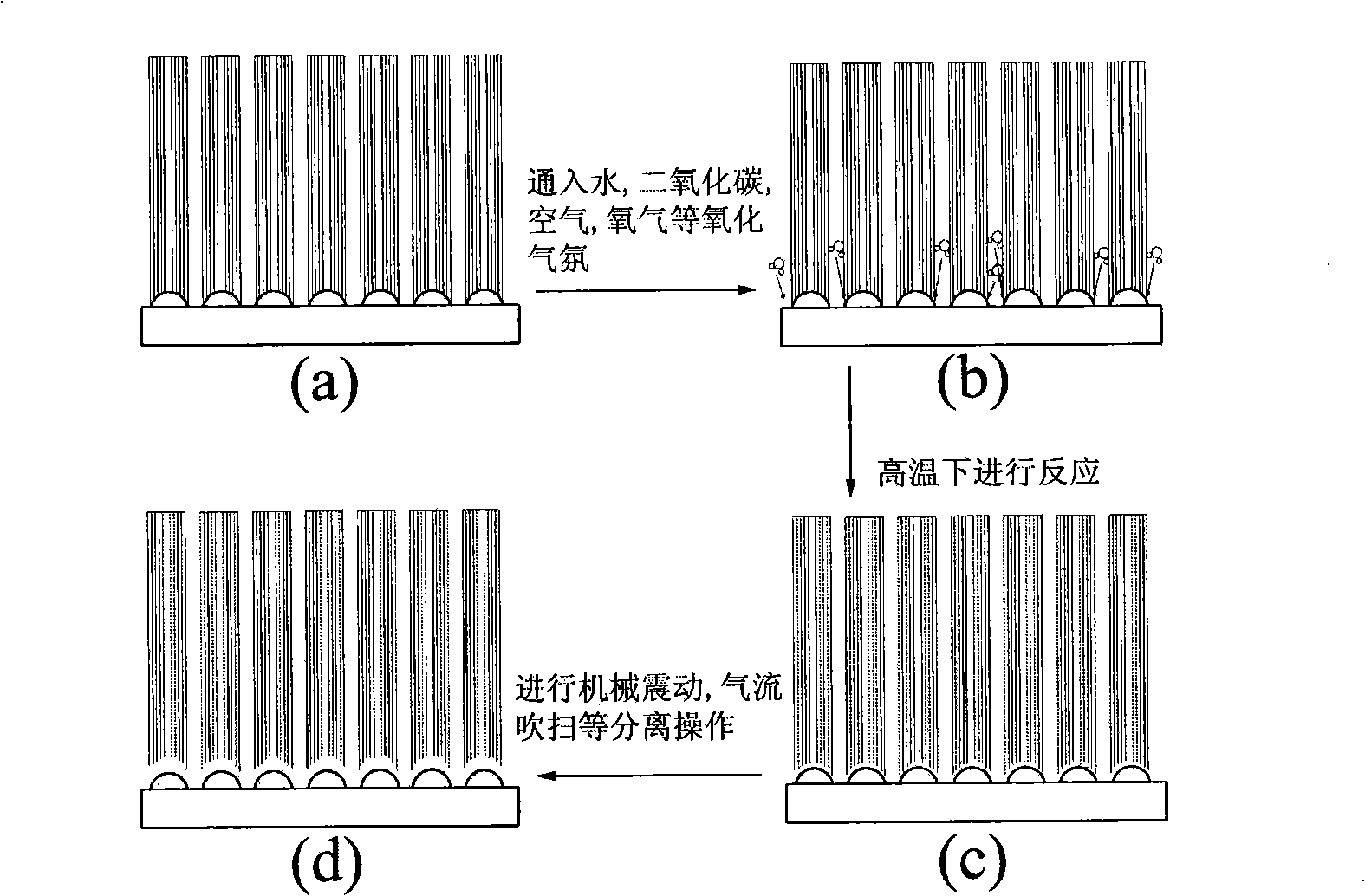

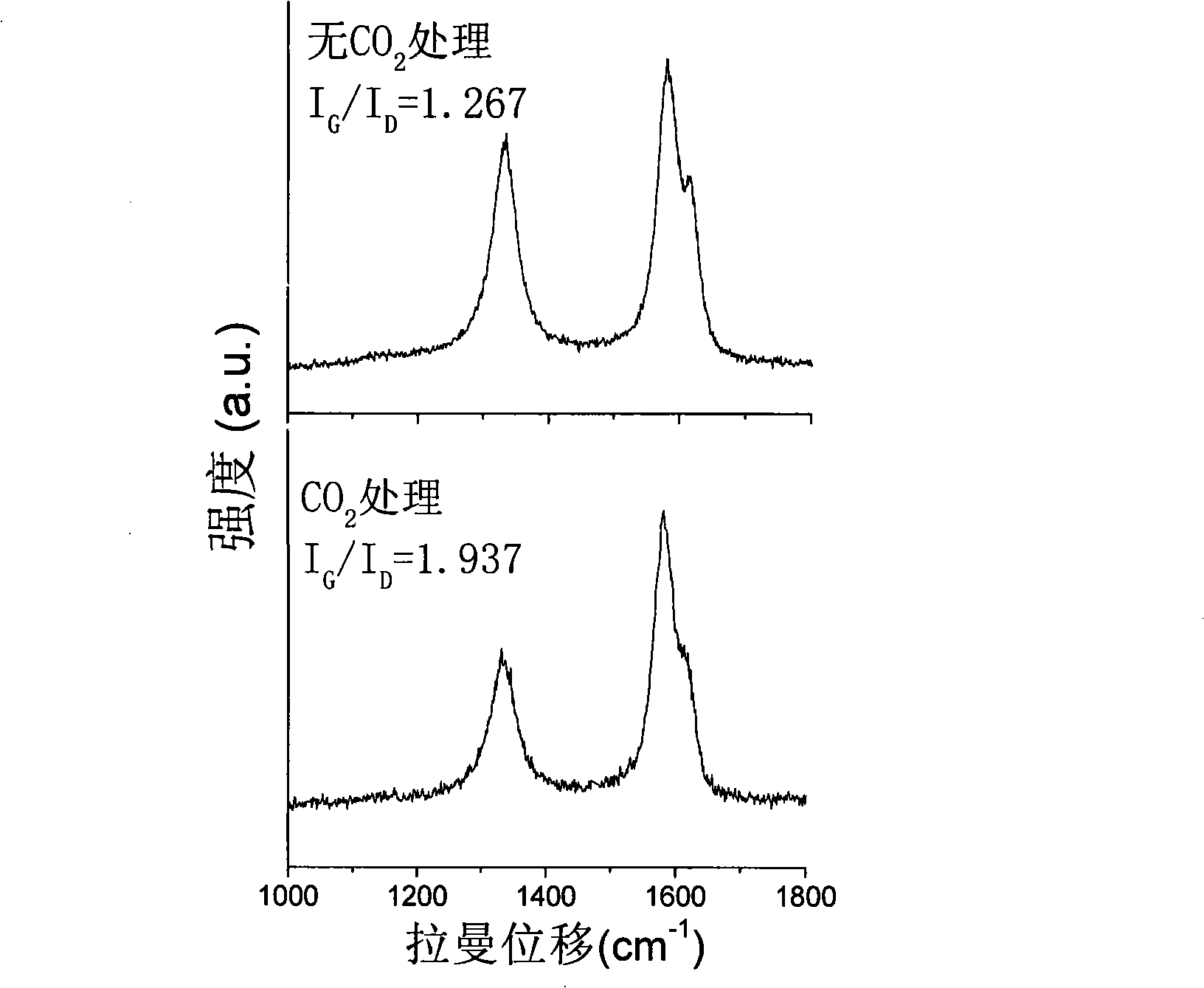

Oxidation treatment based method for separating carbon nano-tube array and substrate

The invention provides an oxidizing treatment-based method for separating carbon nano pipe arrays from the surface of a base plate. In the method, carbon dioxide and water vapor, etc. are taken as weak oxidants, during the growing process of the carbon nano pipe arrays or after the growth of the carbon nano pipe arrays, the carbon nano pipe arrays are subjected to oxidizing treatment and separated from the surface of the base plate by the methods of air flow blowing or mechanical separation. Compared with the conventional chemical vapor deposition preparation method, the carbon nano pipe arrays subjected to weak oxidative atmosphere treatment have weak bonding capability with the base plate, thereby resolving the problem of the separation of the carbon nano pipe arrays from the base plate, not only protecting the arrays from being damaged during separation, but also removing impurities such as unformed carbon, etc. in the arrays by the weak oxidizing treatment and improving the quality of the arrays.

Owner:TSINGHUA UNIV

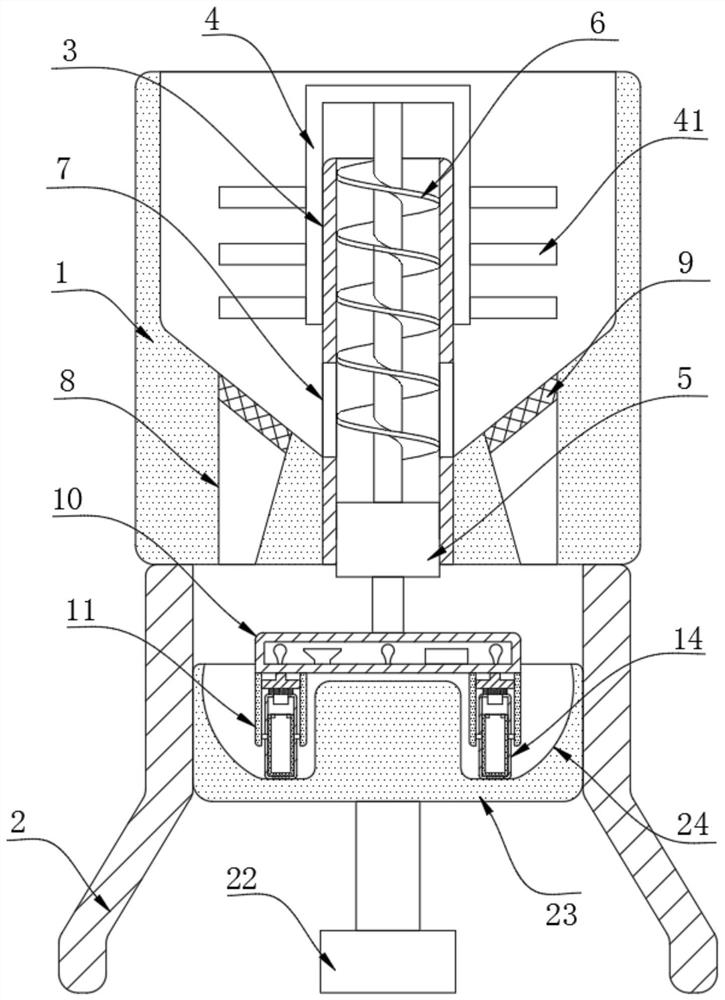

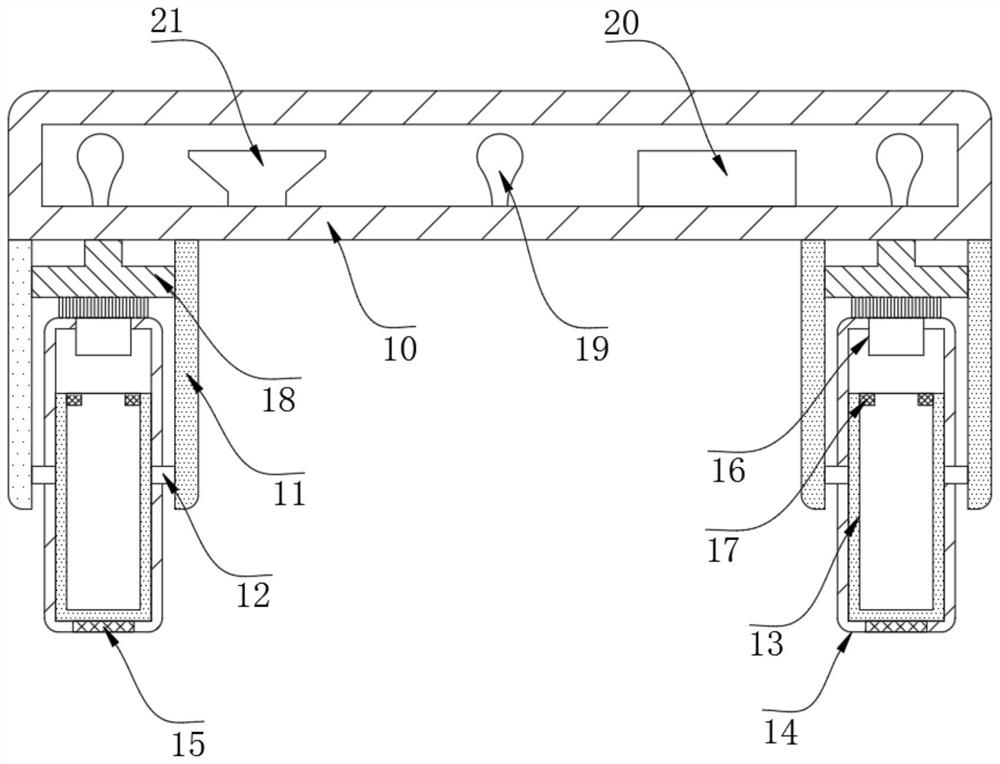

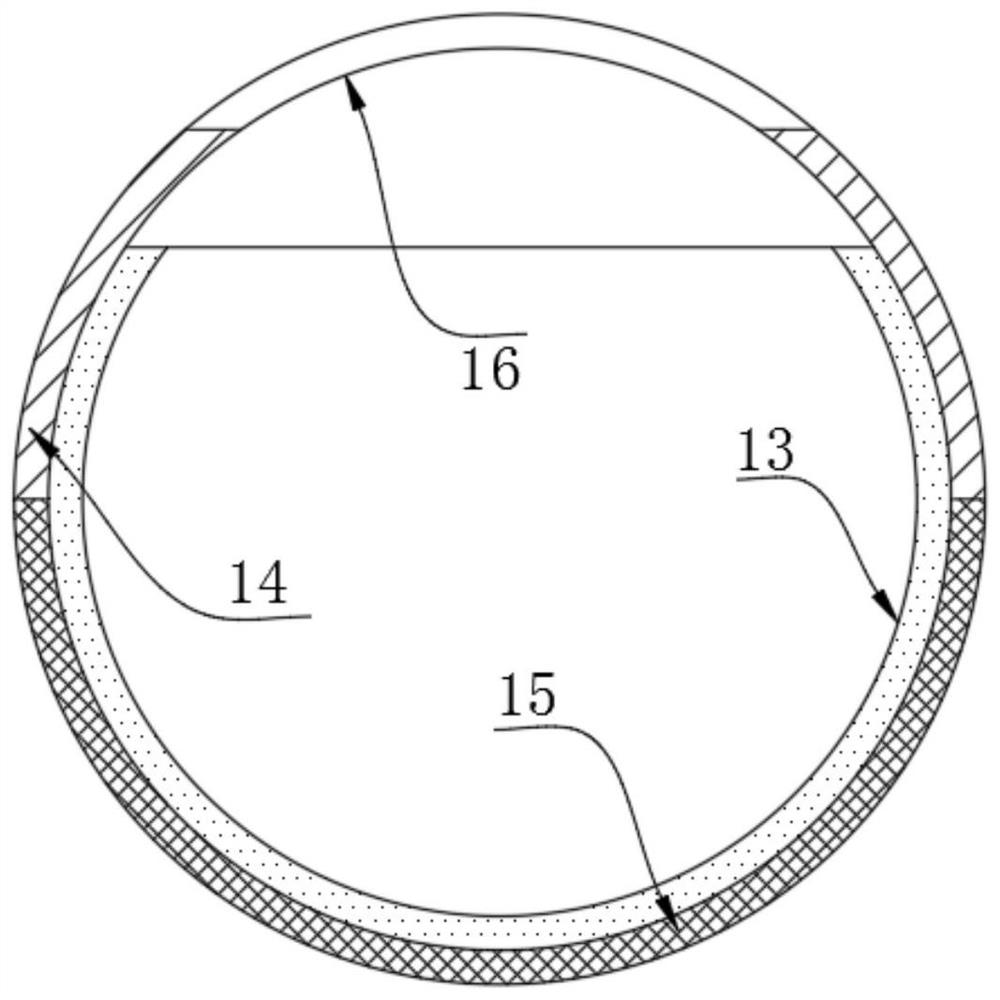

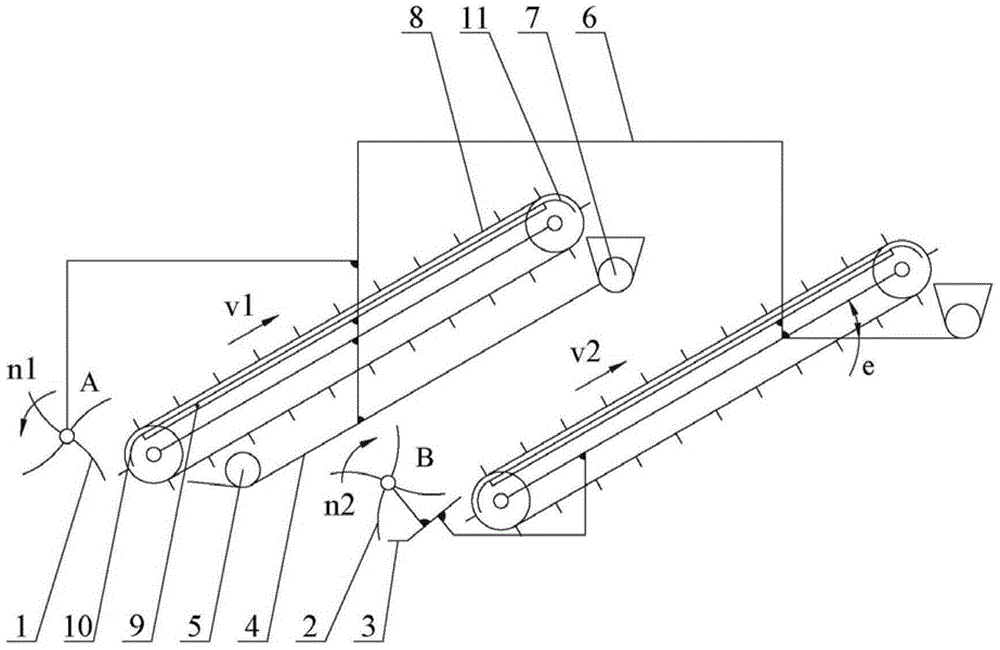

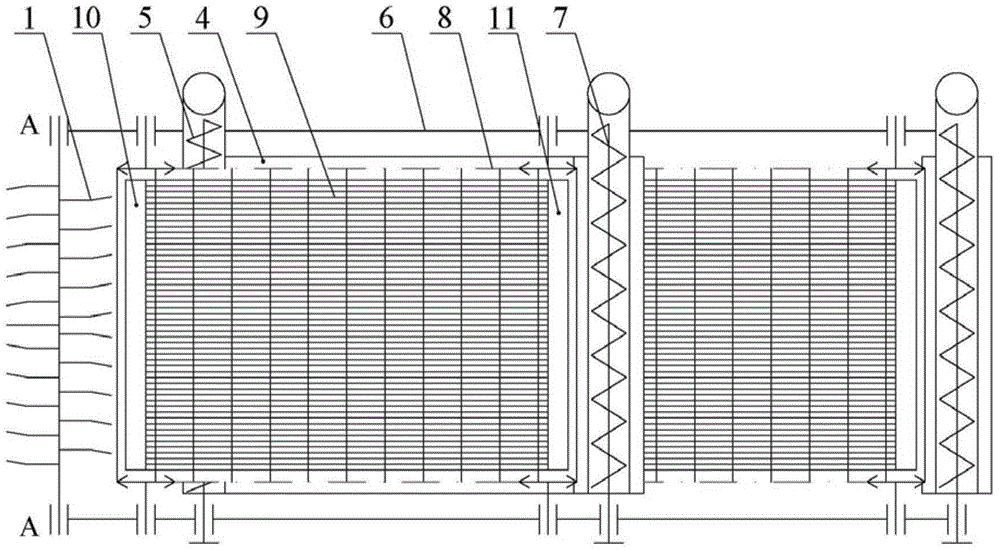

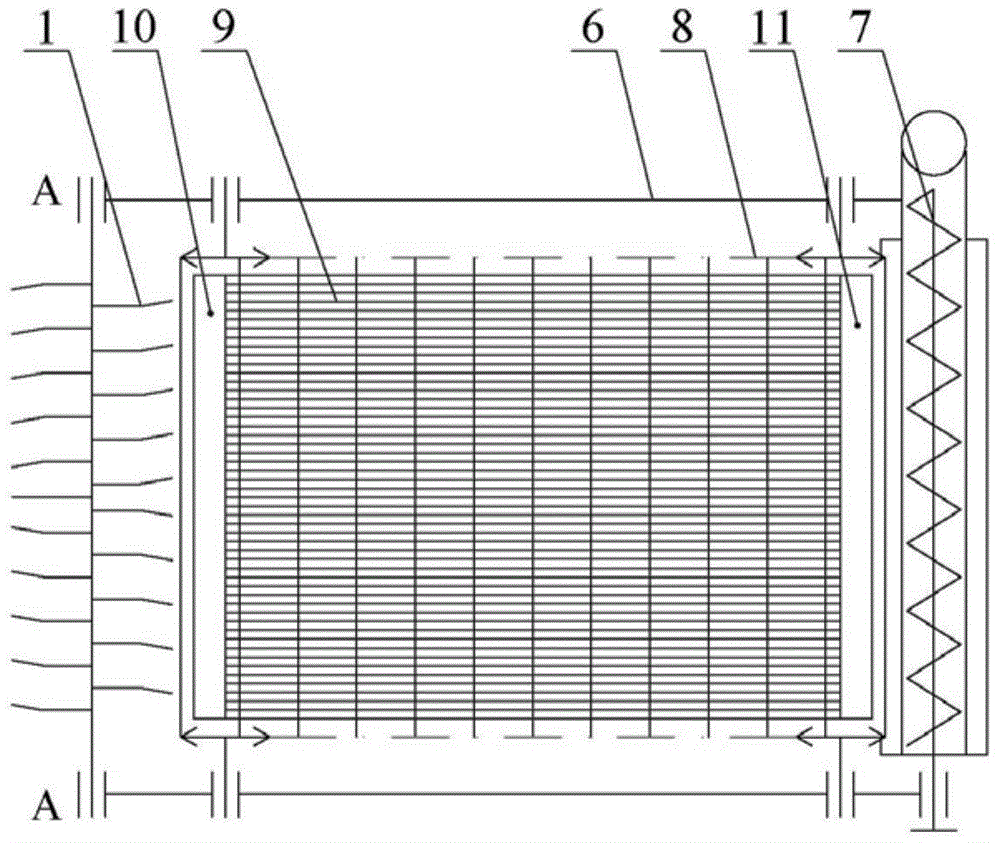

Harvesting device capable of realizing layered collection and soil removal

ActiveCN104855036AIncrease the instantaneous separation areaResolve separation difficultiesDiggersEngineeringCell separation

The invention relates to the technical field of agricultural harvest machinery and discloses a harvesting device capable of realizing layered collection and soil removal. The harvesting device comprises a positive-rotation soil crushing wheel, a reverse-rotation soil crushing wheel, a collecting shovel, a soil collecting plate, a soil discharge helix, a rack, a material collecting helix and a conveying separating part, wherein the positive-rotation soil crushing wheel, the conveying separating part, and the material collecting helix form an upper layer collecting and separation mechanism; the reverse-rotation soil crushing wheel, the collecting shovel, the conveying separating part and the material collecting helix form a lower layer collecting and separation mechanism; according to a layered harvesting method of cyperus beans, soil of a whole soil layer is excavated and collected by two layers, and excavation, collection and soil separation are carried out by the upper layer collecting and separation mechanism and the lower layer collecting and separation mechanism simultaneously, so that an instantaneous separation area of unit soil is increased, the problem of the whole soil layer harvesting method that separation of the cyperus beans and soil is difficult is solved, and cyperus beans layered-collection soil-removal paving sectional type harvesting operation is realized.

Owner:CHINA AGRI UNIV

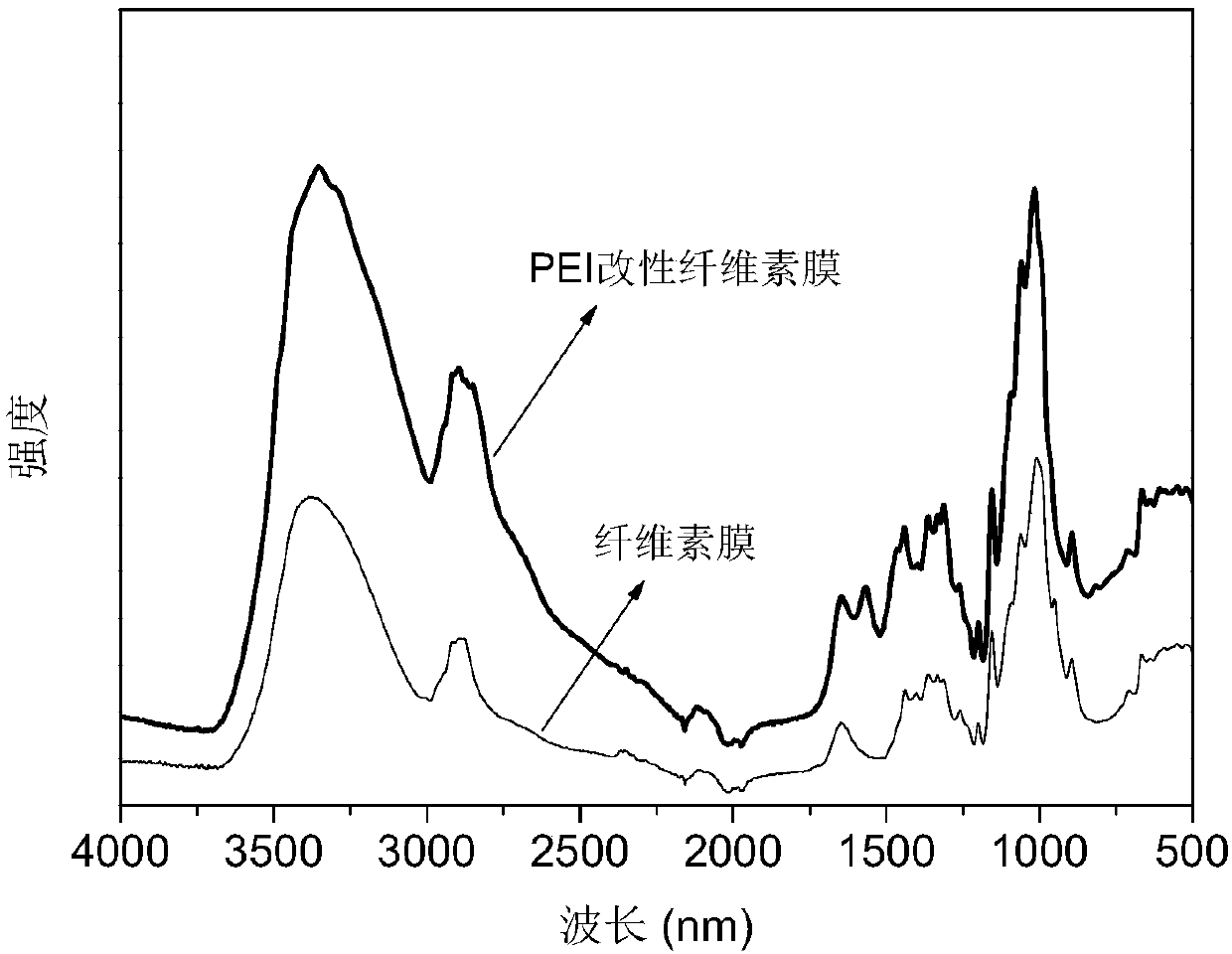

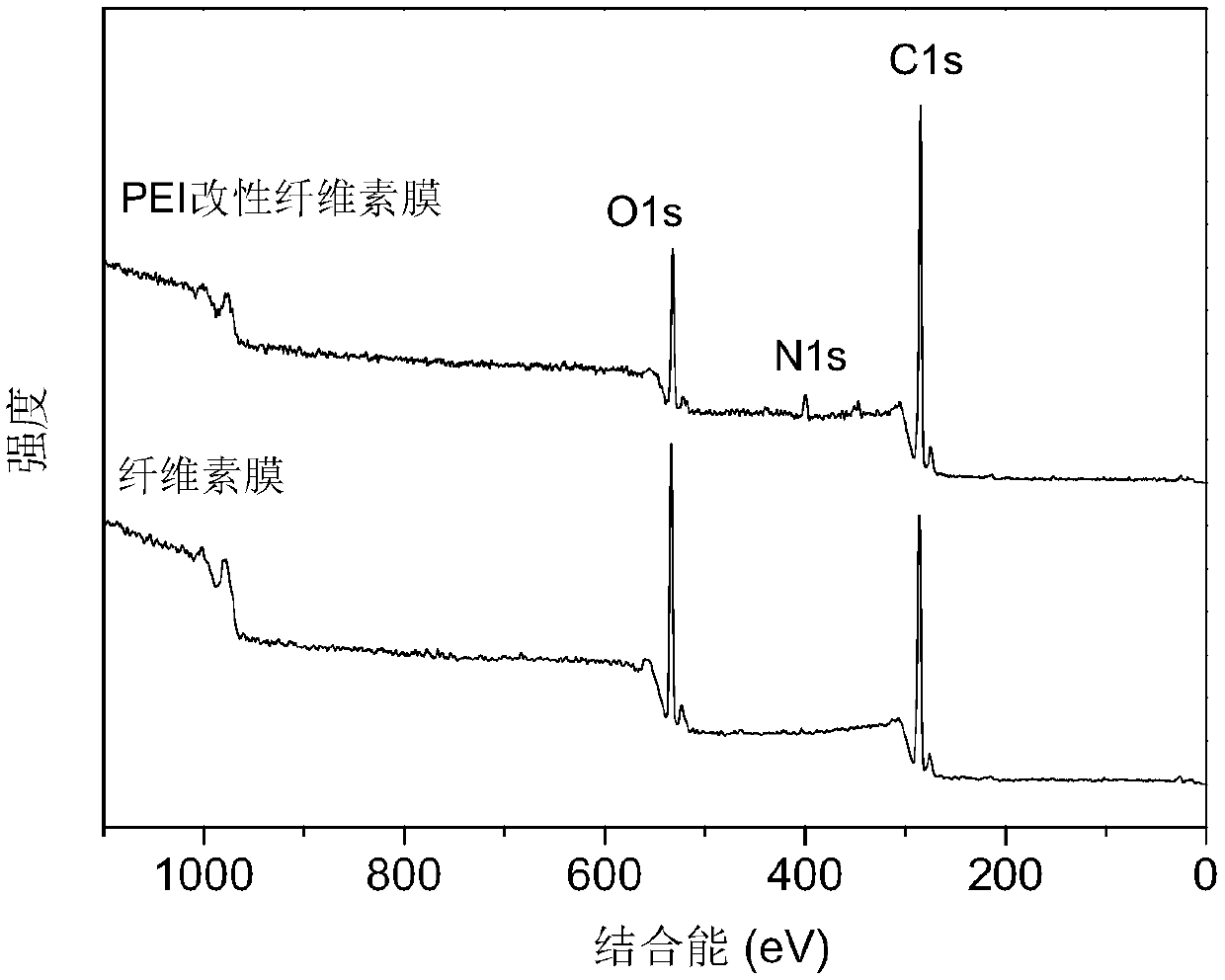

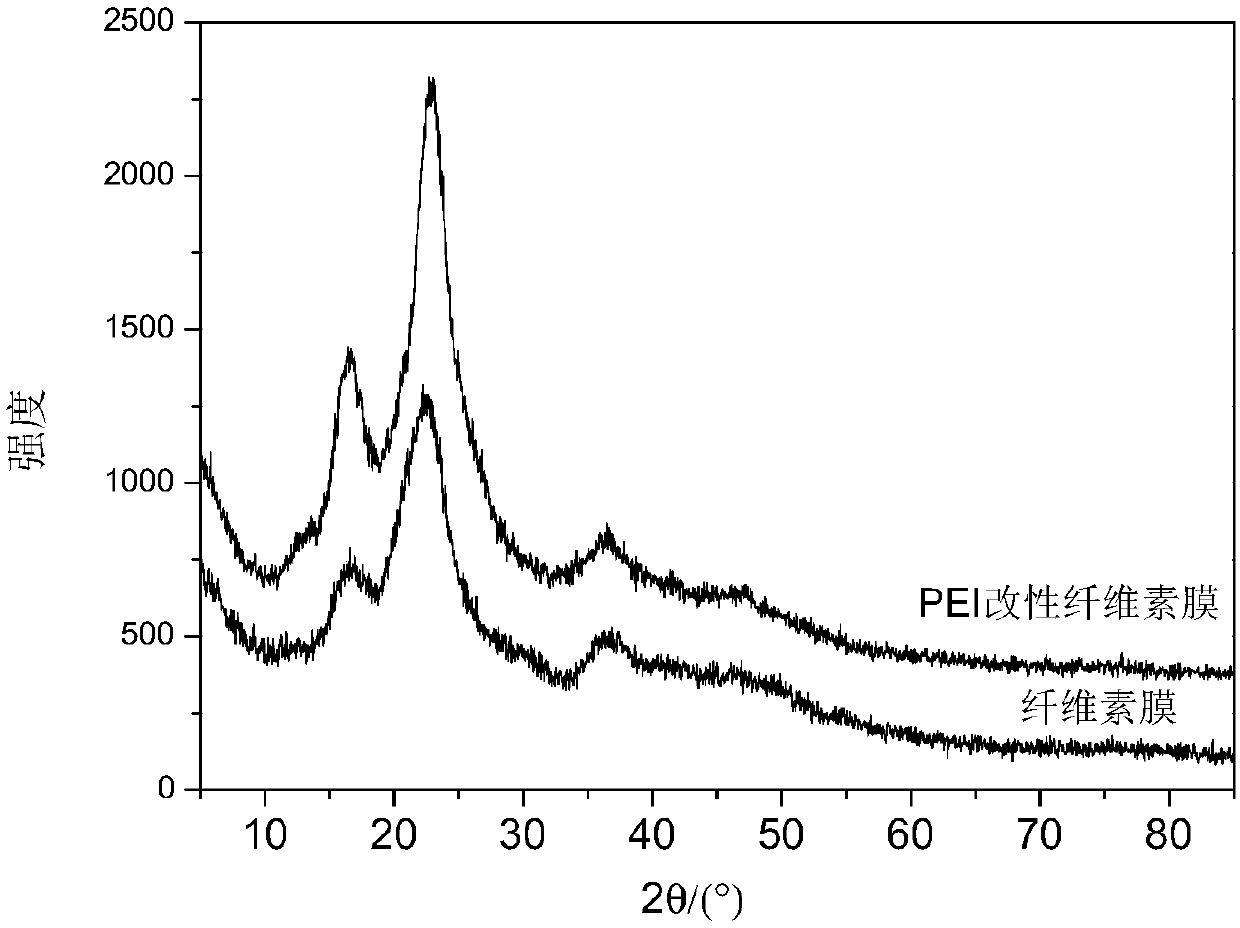

PEI (polyethyleneimine) modified cellulose membrane adsorbent and preparation method thereof

ActiveCN107837791AResolve separation difficultiesMeet the requirements of green chemistryOther chemical processesAlkali metal oxides/hydroxidesCross-linkSorbent

The invention provides a PEI (polyethyleneimine) modified cellulose membrane adsorbent and a preparation method thereof. The preparation method comprises the steps of (1) preparing a cellulose solution; (2) defoaming, knifing, gelatinizing and washing the cellulose solution to prepare a cellulose hydrogel membrane; (3) oxidizing an object obtained in the step (2) into a hydrogen peroxide solutionto obtain an oxidized cellulose hydrogel membrane; (4) soaking an object obtained in the step (3) into a PEI water solution for reacting, and washing with water after finishing reaction to obtain a PEI modified cellulose hydrogel membrane; (5) drying an object obtained in the step (4), and preparing the PEI modified cellulose membrane adsorbent. The preparation method is simple, and no cross-linking agent needs to be used during a preparation process, so that not only is the cost favorably reduced, but also adverse effects brought by additive residues are avoided; meanwhile, the preparation process is environmentally friendly without pollution, and the prepared adsorbent has an excellent adsorption effect on heavy metal ions and is easy to separate and recover after use.

Owner:SOUTHWEST JIAOTONG UNIV

Preparation method of non-binder titaniferous mercerizing molecular sieve catalyst

ActiveCN103252252ASimple methodEasy to manufactureMolecular sieve catalystsOximes preparationMolecular sieveGas phase

The invention discloses a preparation method of a non-binder titaniferous mercerizing molecular sieve catalyst. The preparation method is characterized by comprising the following steps of: mixing sodium mercerizing zeolite raw powder as seed crystal with a silicon source, an aluminum source and an alkali source so as to prepare sial mercerizing zeolite with a dry rubber method; and then exchanging the sial mercerizing zeolite with ammonium, pickling, dealuminizing and reinforcing silicon in a gas-phase manner so as to prepare the non-binder titaniferous mercerizing molecular sieve catalyst, specifically comprising the steps of preparation of a catalyst precursor and mercerizing zeolite and crystallization, calcination, pickling and dealuminizing. Compared with the prior art, the method is simple, and the catalyst is convenient to prepare, so that the problems of separation difficulty, shortening of service life and the like during a ketones ammoximation process are efficiently solved, and effective utilization ratio and activity of the catalyst are greatly improved; and the non-binder titaniferous mercerizing molecular sieve catalyst has certain industrialized popularization and application prospects and obvious economic benefit.

Owner:EAST CHINA NORMAL UNIV

Preparation method of amino-containing magnetic microspheres

InactiveCN106378112AImprove bindingEasy to separateOther chemical processesAlkali metal oxides/hydroxidesEthylenediamineGlycidyl methacrylate

The invention relates to the technical field of function materials, in particular to a preparation method of amino-containing magnetic microspheres. The preparation method of amino-containing magnetic microspheres comprises the following steps of (1) magnetofluid preparation; (2) magnetic microsphere preparation; (3) surface amino-containing magnetic microsphere preparation. The glycidyl methacrylate is used as a functional monomer; ethanediamine is used for modification; the amino functional magnetic polymer microspheres are prepared; the protonated amino groups have strong combination effects with acid orange 7 molecules through the electrostatic adsorption effects; in addition, magnetic adsorbents can be easily separated through external magnetic fields; therefore the problem of separation difficulty of a method through centrifugation or filtration and the like can be effectively solved.

Owner:SHAANXI SHENGMAI PETROLEUM

Preparation method and application of core-shell P-CoFe2O4(at)GCN photocatalyst

InactiveCN110142061AUniform particlesHigh crystallinityPhysical/chemical process catalystsWater/sewage treatment by irradiationPhotocatalytic degradationAir atmosphere

The invention belongs to the technical field of composite materials and relates to a preparation method and application of a core-shell P-CoFe2O4(at)GCN photocatalyst. The preparation method comprisesthe following steps: firstly mixing cobalt salt and ferric salt, dropwise adding alkali lye and precipitating to prepare strongly magnetic nanoparticles CoFe2O4; fully dispersing a graphite-type carbonitride precursor and a phosphorus source in distilled water, carrying out solid-liquid separation, drying a solid at 80-100 DEG C for 12-24 h, and grinding to obtain a powder; and finally placing the powder into a muffle furnace, and heating in the air atmosphere at 500-600 DEG C for 2-5 h so as to obtain the photocatalyst. In the invention, the prepared material is also applied to wastewater soas to remove antibiotics. By compound modification of the graphite-type carbonitride, the photocatalytic performance is greatly improved, and the solid-liquid separation problems are solved. The preparation method is simple to operate, and the sources of the raw materials are wide. The surface of the prepared material has a pore structure, and the specific surface area is increased, thus providing more active sites for a photo-catalytic reaction. The result shows that the tetracycline photocatalytic degradation rate of the product is 3.66 times higher than the tetracycline photocatalytic degradation rate of pure graphite-type carbonitride before modification.

Owner:EAST CHINA JIAOTONG UNIVERSITY

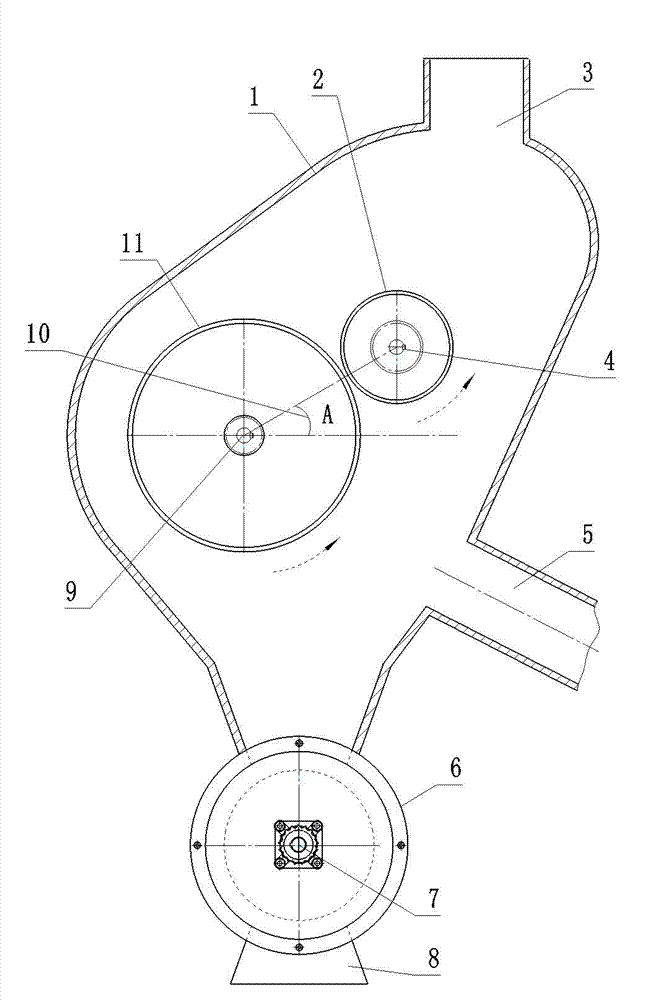

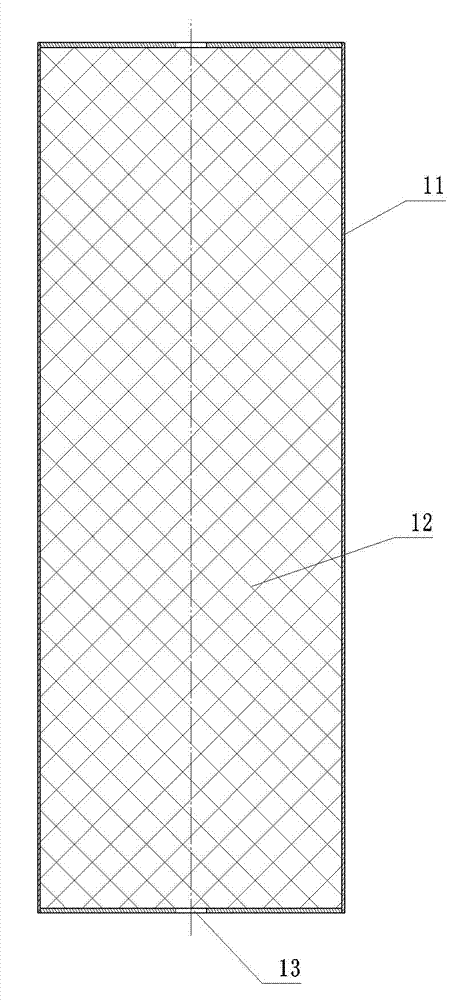

Matched plastic film residue separation device for cotton picker

ActiveCN103111419AAchieve separationEfficient separationGas current separationPicking devicesEngineeringFan blade

The invention relates to a matched plastic film residue separation device for a cotton picker. The matched plastic film residue separation device comprises a separation chamber. A large net-shaped roller, a small net-shaped roller and an air-lock valve area arranged in the separation chamber. A cotton flow inlet, a plastic film residue outlet and a seed cotton outlet are arranged on the separation chamber. The large net-shaped roller and the small net-shaped roller are both of internal hollow structures, gauzes are arranged at the peripheries of outer layers of the net-shaped rollers, and the small net-shaped roller is arranged obliquely above the large net-shaped roller and close to the plastic film residue outlet. When the matched plastic film residue separation device works, the large net-shaped roller and the small net-shaped roller rotate in a counterclockwise mode. The air-lock valve structurally and mainly comprises a casing, an air-lock valve rotating shaft and a fan blade arranged on the air-lock valve rotating shaft. In an initial stage for picking cotton, sundries in seed cotton can be removed, so that a serial of related work procedure links of opening, removing residues and the like can be eliminated after seed cotton is harvested, and energy consumption is reduced. The device can greatly reduce sundry separation difficulty and is simple in structure, economical and practical.

Owner:SHIHEZI UNIVERSITY

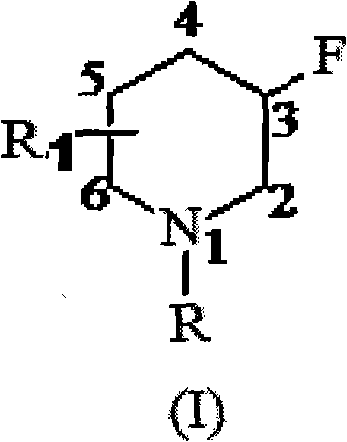

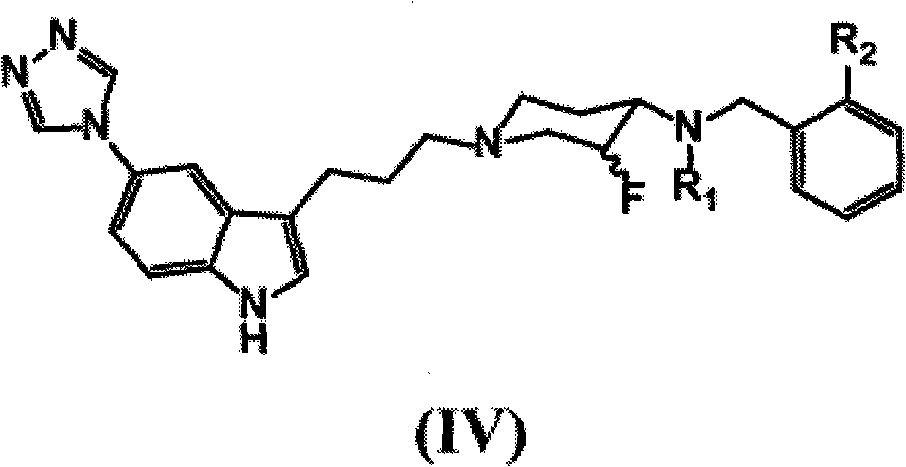

3-droperidol derivative and preparation method thereof

InactiveCN102344407ASolve choice problemsResolve separation difficultiesOrganic chemistryArylHalogen

The invention provides a 3-droperidol derivative represented by a structural formula (I), wherein R is hydrogen, C1-C6 alkyl, aryl, benzyl, or a structure as the formula; R1 is hydrogen, C1-C18 alkyl, aryl, benzyl or hydroxymethyl; R2 is C1-C6 alkyl, aryl, benzyl or alkoxy; substitution positions of R2 on a benzene ring are 2-, 3-, 4-, 5-, 6- sites or a plurality of sites; and the previous groups are not substituted or substituted by one or more substituents selected from alkyl, alkyl halide, hydroxyalkyl, halogen, alkoxy, or hydroxyl. The invention also provides a preparation method of the 3-droperidol derivative. The preparation method is novel, the raw materials and the reagents are cheap, the reaction conditions are mild, and the operations are easy. With the method, produced 1-substituent-3-droperidol can be used as an important intermediate in novel medicine developing.

Owner:SHANGHAI AQ BIOPHARMA CO LTD

Feeder head knock-off core

ActiveCN102328030AResolve separation difficultiesReduce connection strengthFoundry mouldsFoundry coresUltimate tensile strengthMaterials science

The invention relates to the cast field, in particular relates to a knock-off core between a cast cavity and a feeder head. The feeder head knock-off core solves the technical problems that a cast feeder head and a cast main body in the existing feeder head knock-off core have high connection strength, the cast feeder head is hard to separate from the cast main body, and the separation work of the cast feeder head and the cast main body has high strength in the prior art. The invention provides a feeder head knock-off core, wherein the cast feeder head and the cast main body have low connection strength, the cast feeder head is easy to separate from the cast main body, the separation work strength of the cast feeder head and the cast main body is low, and the processing work load after the casting of the cast main body is low. The feeder head knock-off core provided by the invention comprises a knock-off core main body on which a liquid communicating hole for communicating upper and lower surfaces of the knock-off core is arranged; the liquid communicating hole comprises an upper liquid communicating hole and a lower communicating hole; and cross section outlines of the upper and lower communicating holes are in four-pointed star shape or five-pointed star shape or six-pointed star shape, and a lower opening of the upper liquid communicating hole is congruent to a small opening of the lower communicating hole.

Owner:ZHEJIANG WUJING MACHINE MFG +1

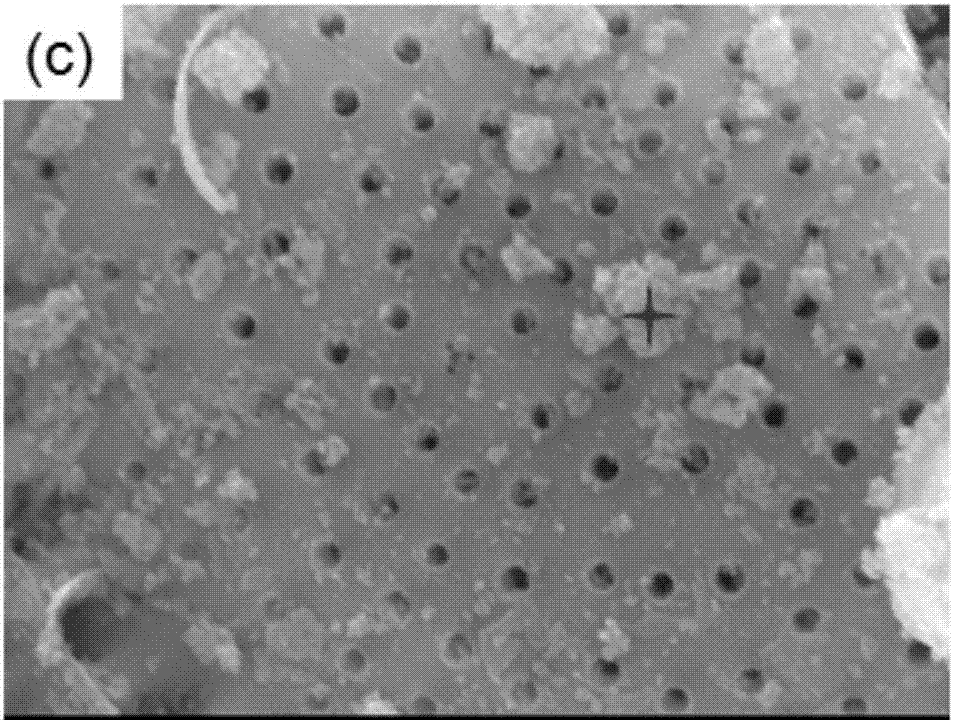

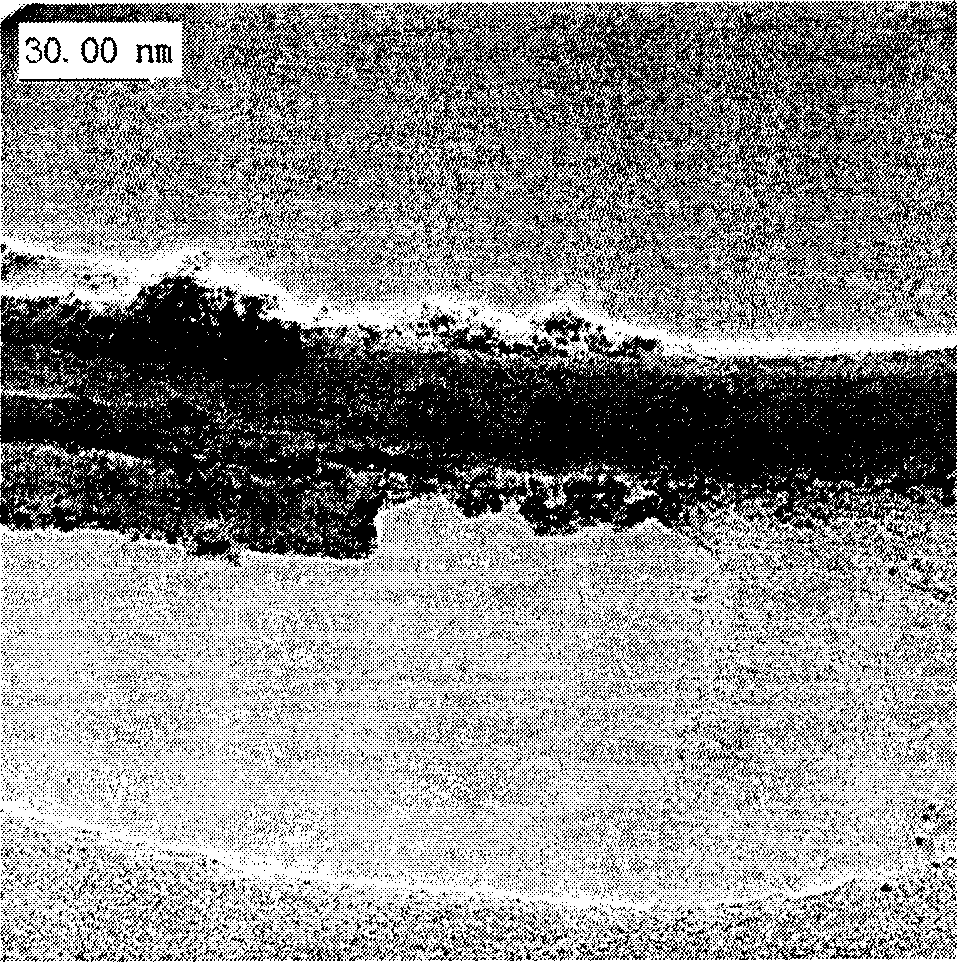

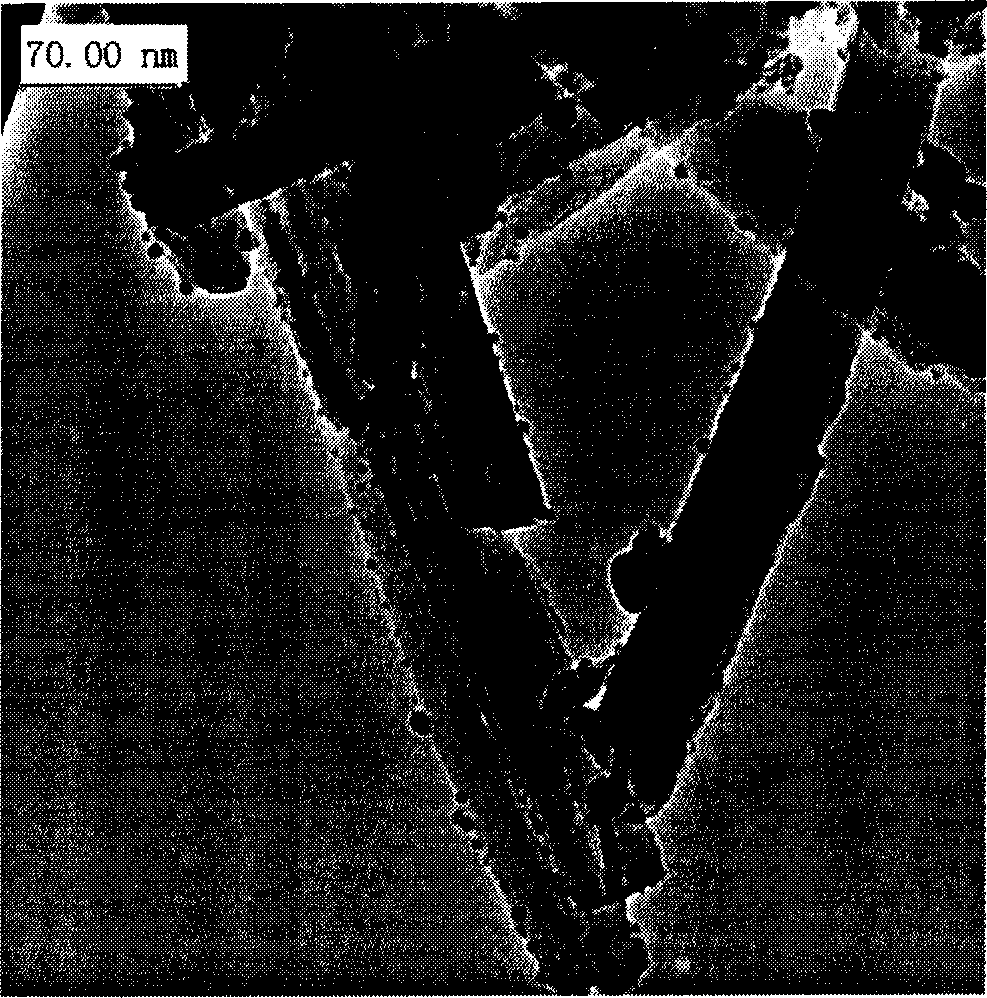

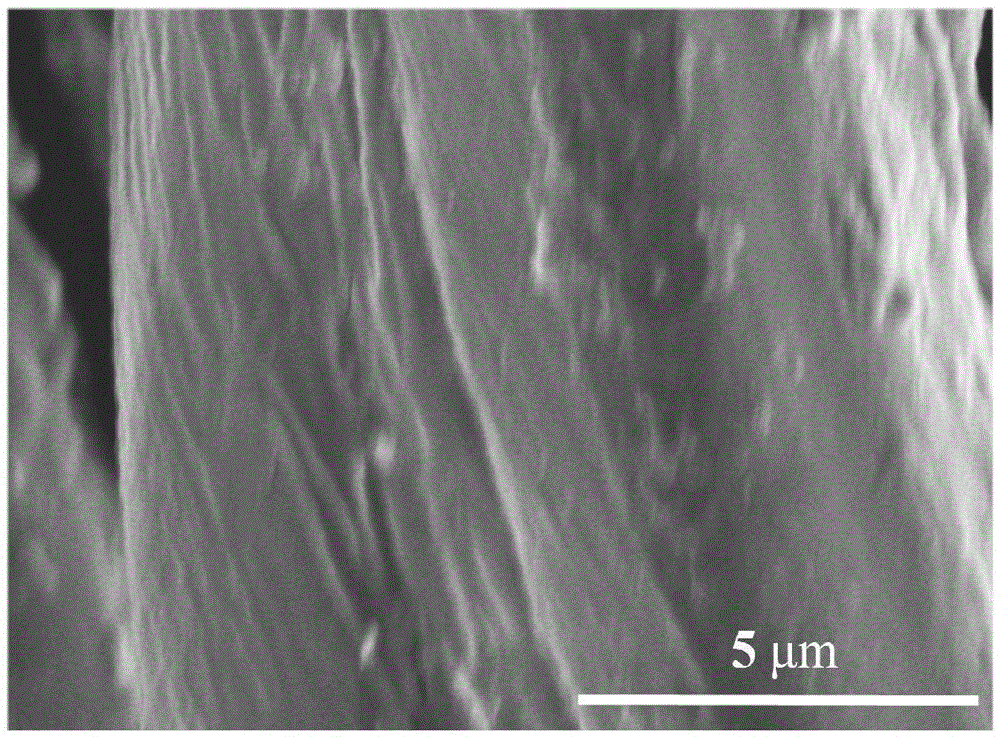

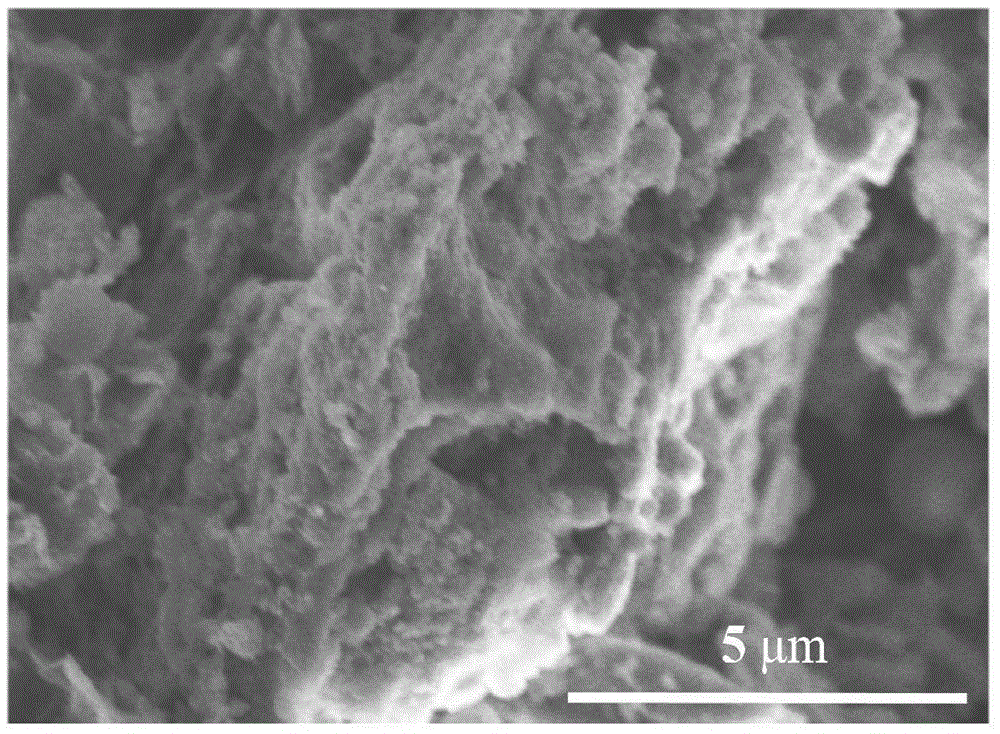

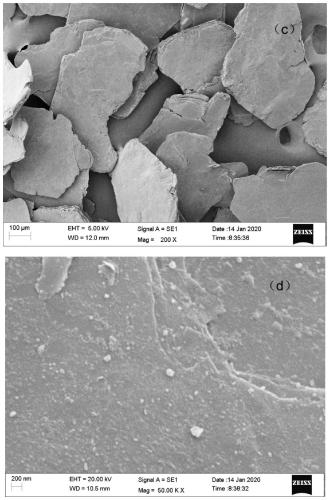

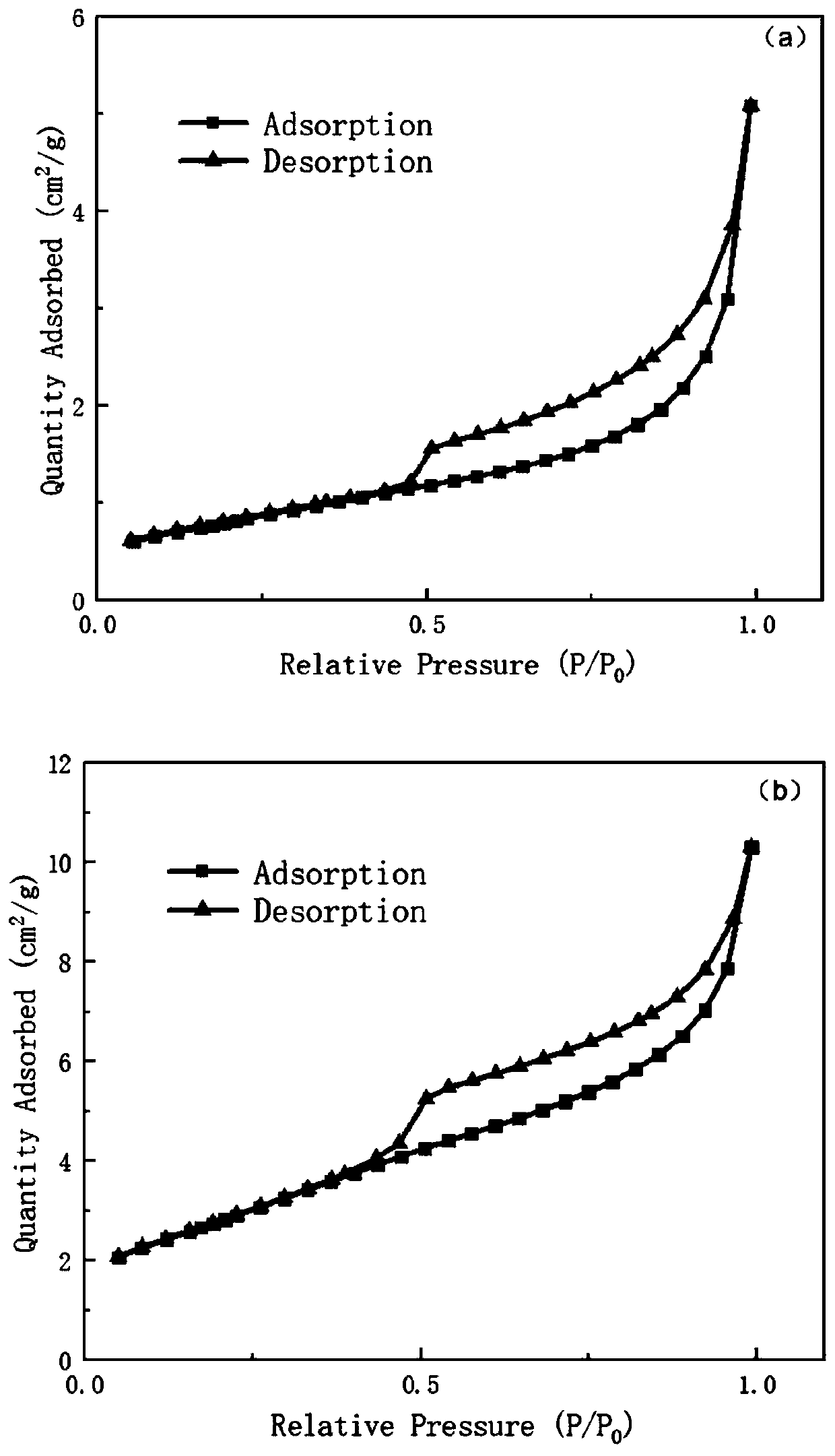

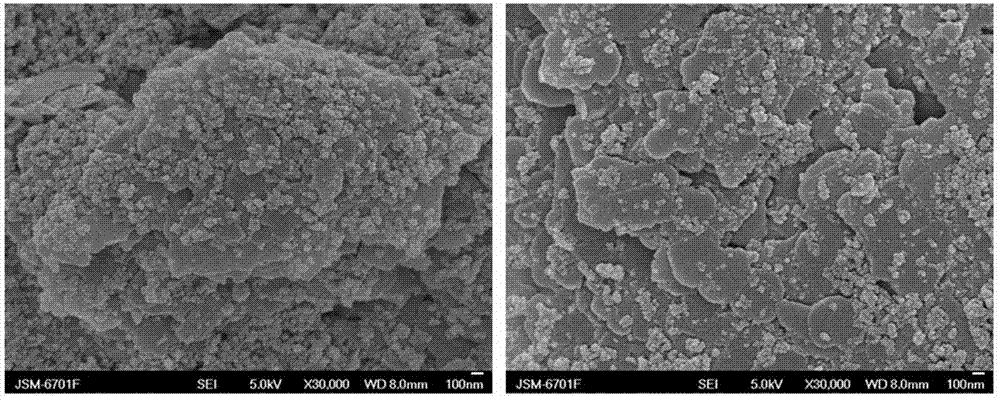

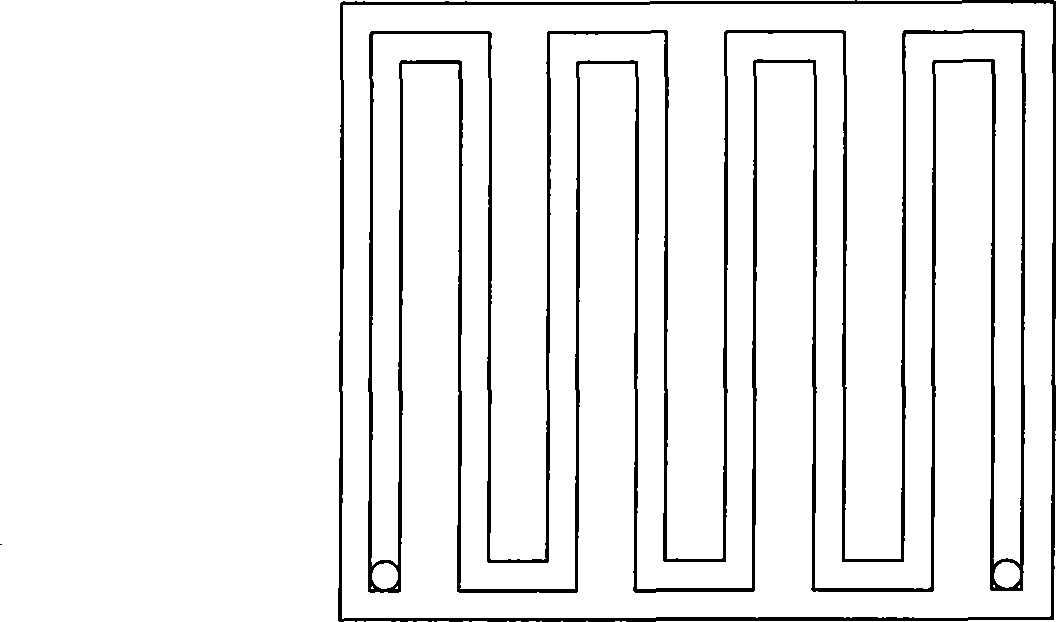

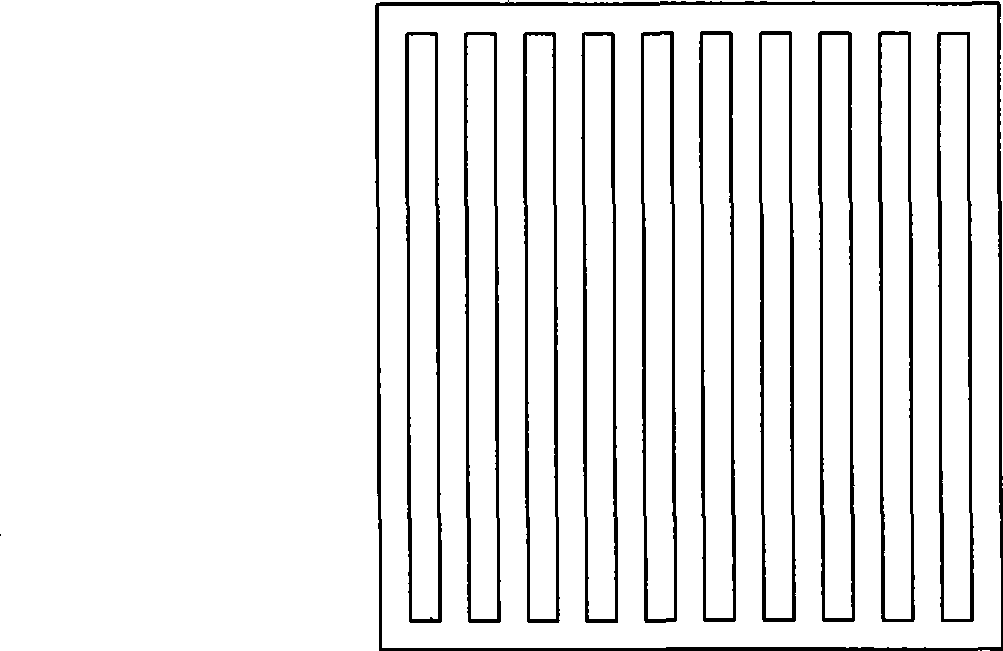

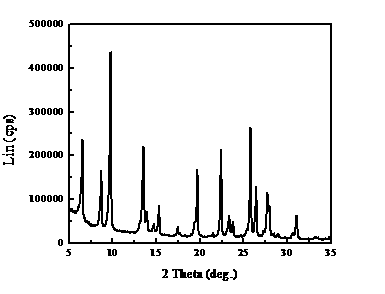

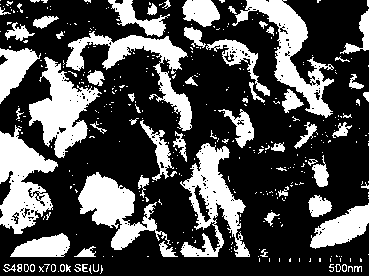

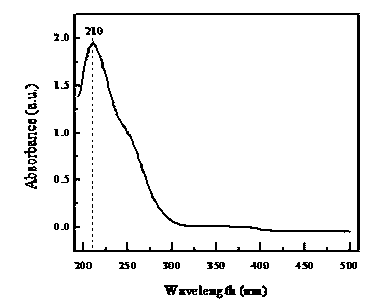

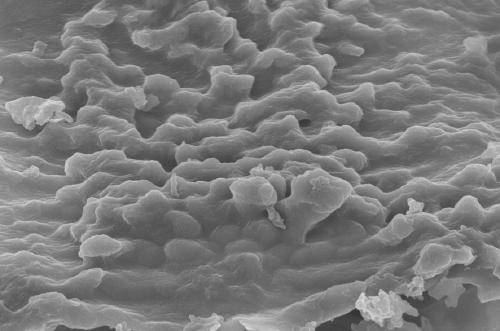

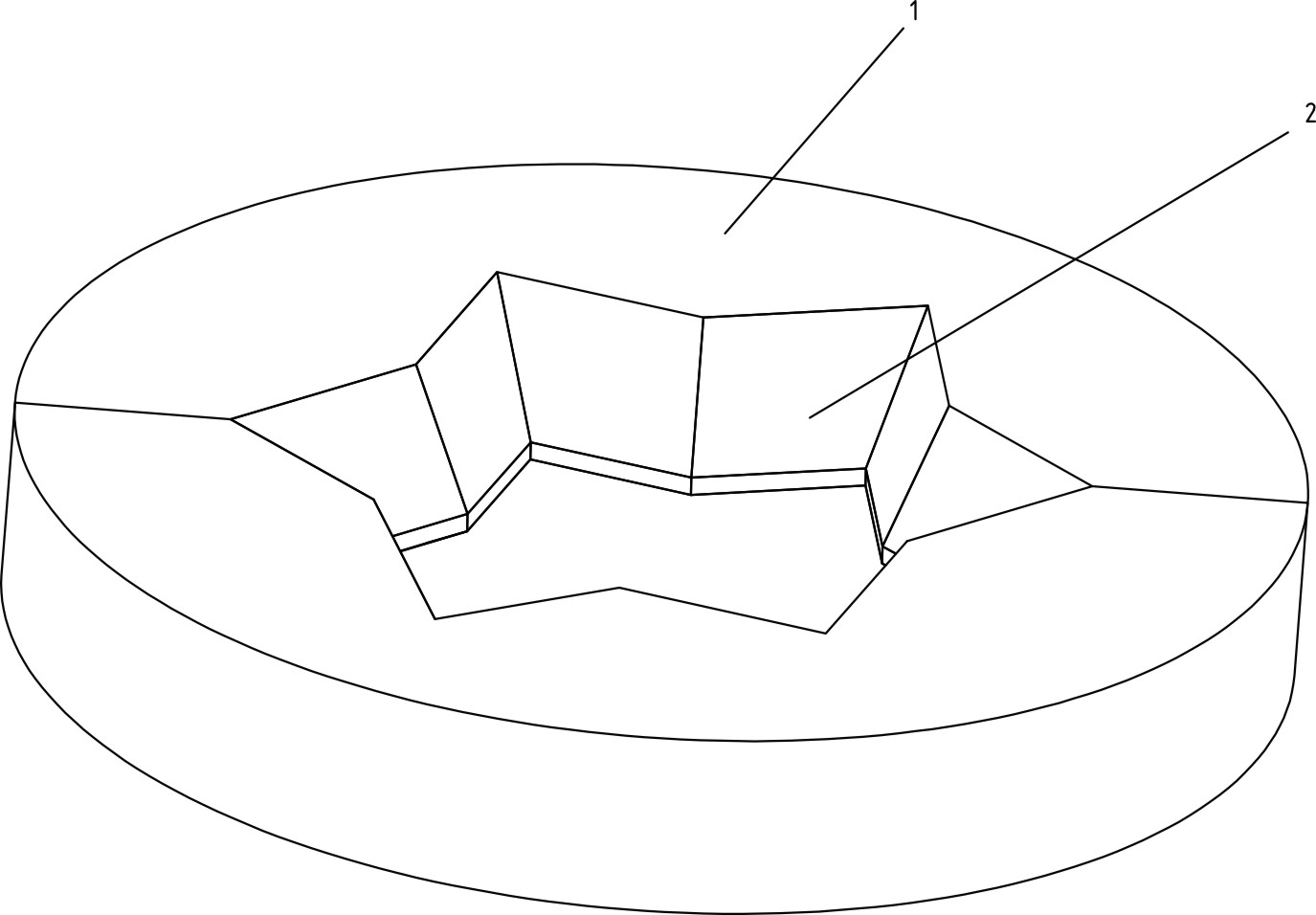

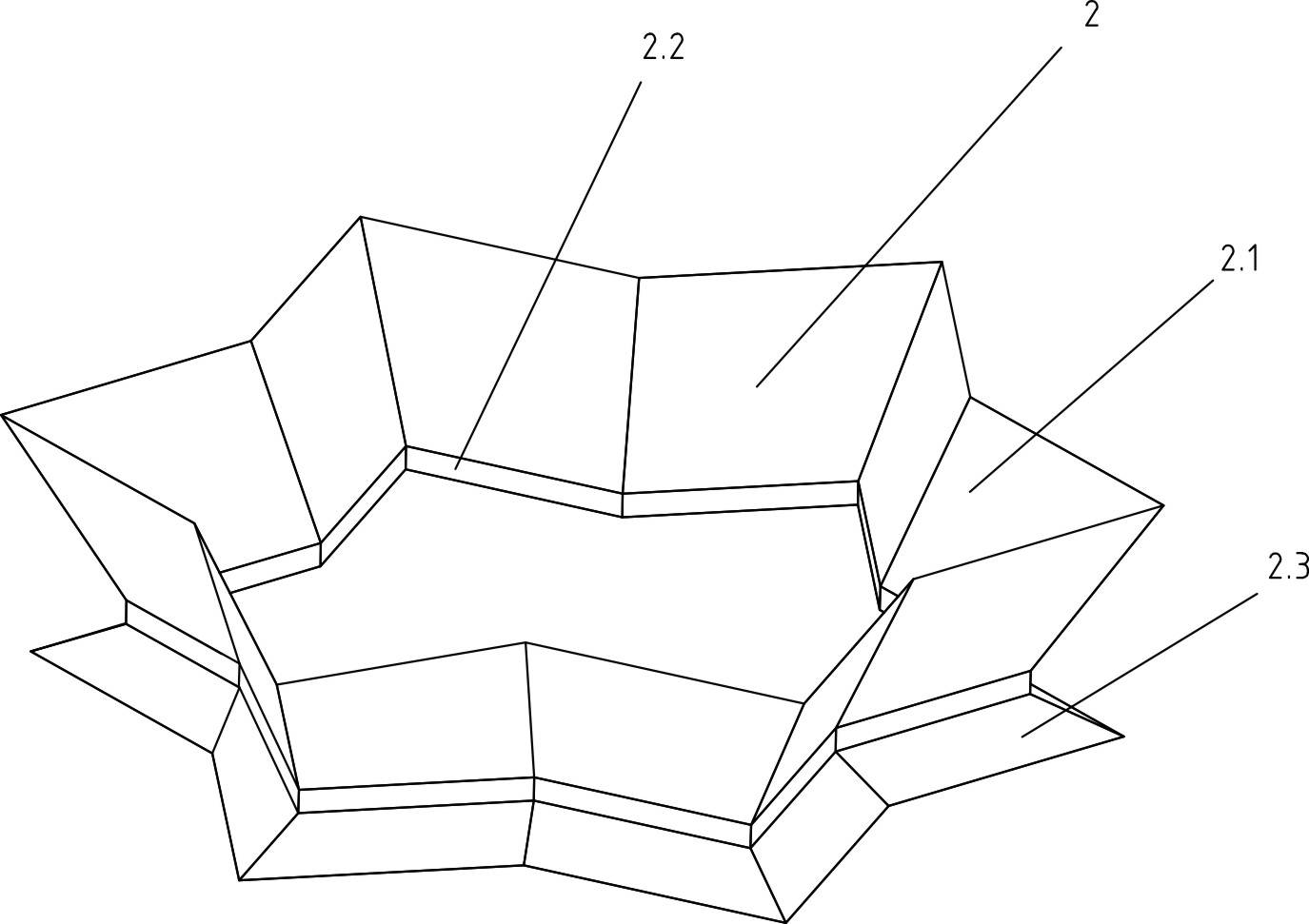

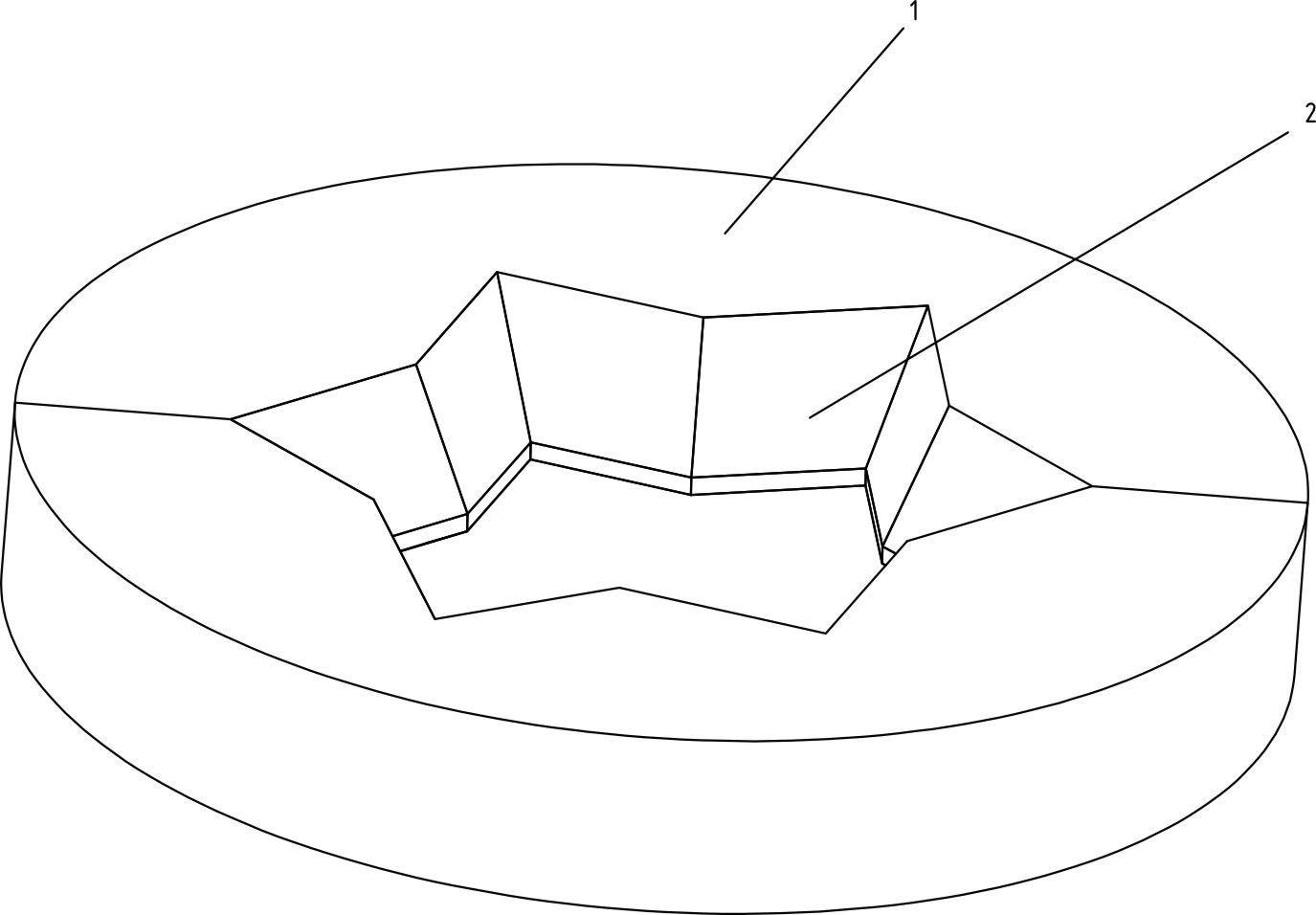

Porous [beta]-cyclodextrin cross-linked polymer nanofiber and preparation method thereof and application thereof in removing bisphenol organic pollutants in water body

ActiveCN111203199ALarge specific surface areaStrong adsorption affinityOther chemical processesWater contaminantsMetal-organic frameworkNanofiber

The invention relates to a porous [beta]-cyclodextrin cross-linked polymer nanofiber and a preparation method thereof and application thereof in removing bisphenol organic pollutants in a water body,and relates to the technical field of nano materials. The technical problems that an existing [beta]-cyclodextrin polymer adsorbent is low in adsorption binding capacity and low in removal efficiencyof low-concentration pollutants in the process of efficiently adsorbing and removing bisphenol organic pollutants in a water body are solved. The porous [beta]-cyclodextrin cross-linked polymer nanofiber disclosed by the invention is a porous [beta]-cyclodextrin cross-linked polymer prepared by taking a [beta]-cyclodextrin-copper metal organic framework nano material as a template; the obtained polymer has a large specific surface area; [beta]-cyclodextrin molecules in the metal organic framework material reserve the dimer ordered tubular arrangement mode of the [beta]-cyclodextrin molecules in the metal organic framework material; the dimer structure can form a stable host-guest inclusion compound with bisphenol pollutant molecules through a synergistic effect, so that the cross-linked polymer shows strong adsorption affinity and good adsorption performance on bisphenol pollutants in water.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

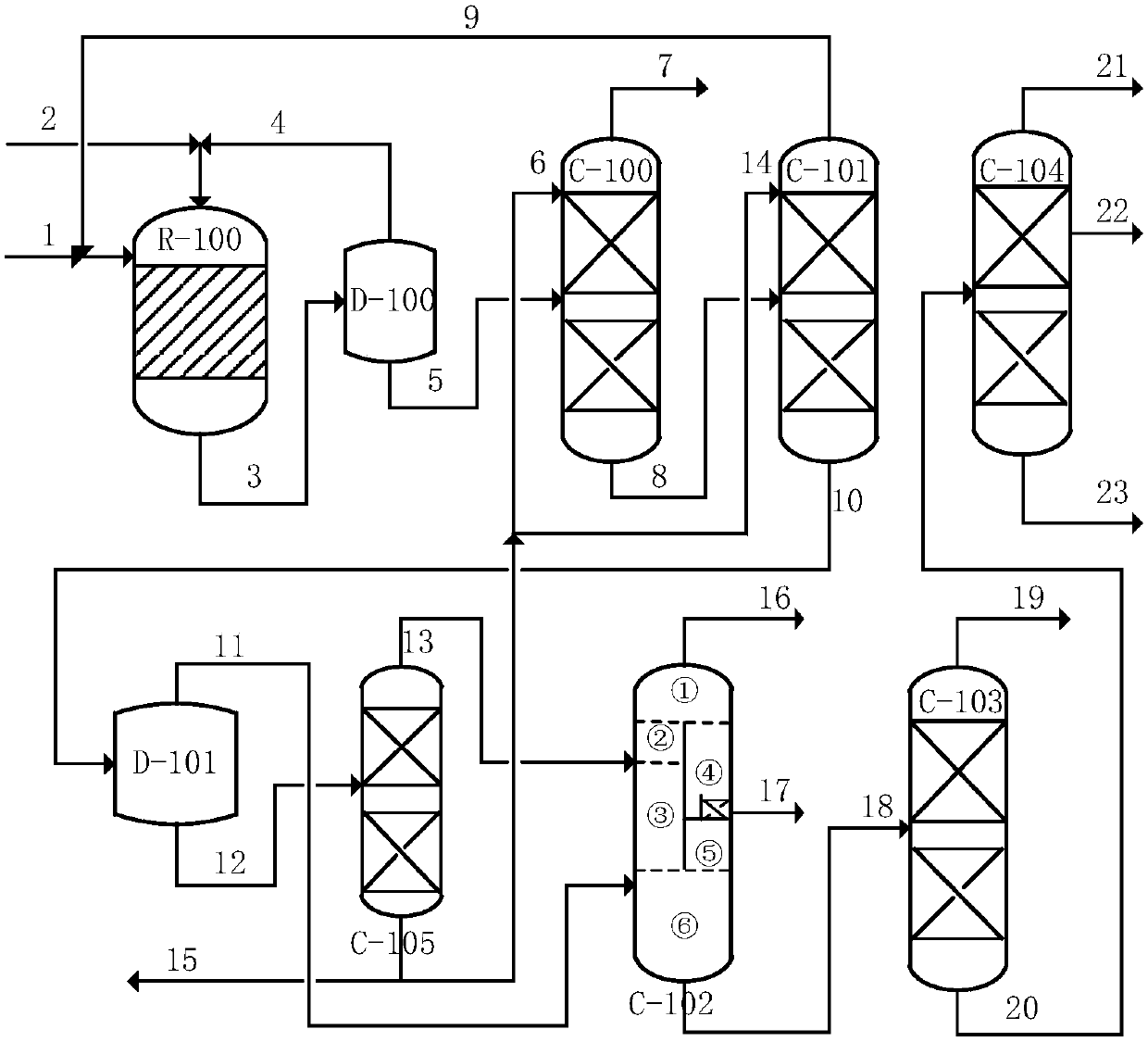

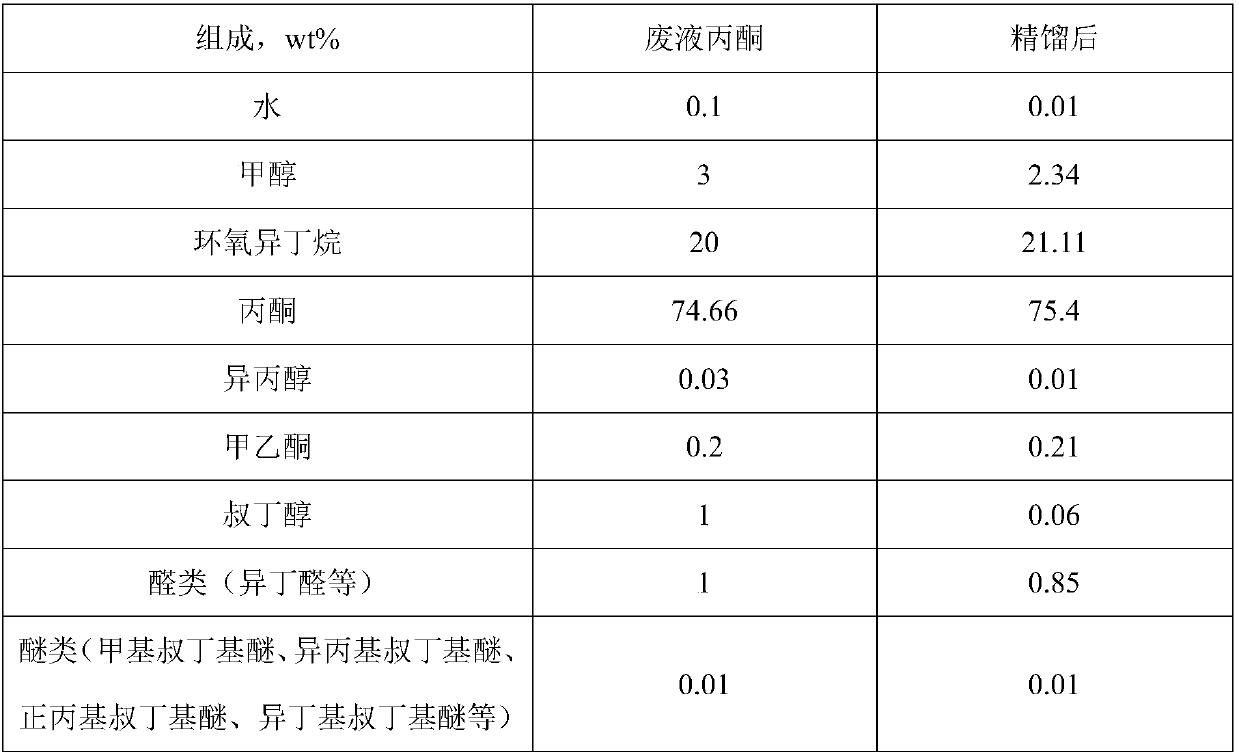

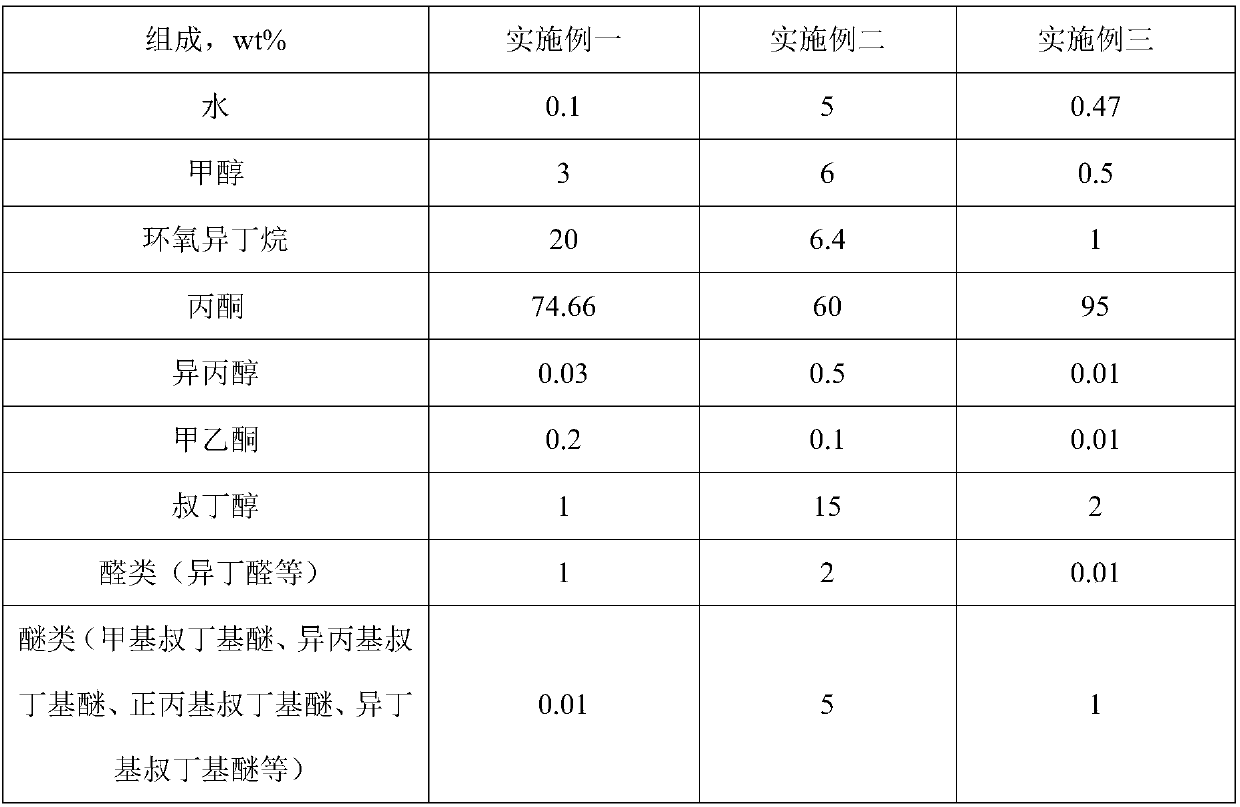

Method for preparing purified MIBK (methyl isobutyl ketone) from industrial byproduct waste acetone liquor

ActiveCN107915612AEfficient use ofResolve separation difficultiesOrganic compound preparationCarbonyl compound separation/purificationAlcoholMethyl isobutyl ketone

The invention discloses a technological process for preparing high-purity MIBK (methyl isobutyl ketone) from industrial byproduct waste acetone liquor. The method comprises the steps as follows: a reaction liquid of MIBK is synthesized from waste acetone liquor, a light component with the boiling point lower than that of acetone is obtained at the top of a light component removal tower, and unreacted acetone is obtained at the top of an acetone recovery tower; an organic matter with the boiling point lower than that of an MIBK / water azeotrope and the MIBK / water azeotrope are obtained at the top of a process water tower; low-boiling-point organic matter such as acetone, methanol and the like coming from raw materials are obtained at the top of a dehydrating tower; an alcohol / water distillate is obtained at the top of an alcohol removal tower and a crude MIBK distillate is obtained from the tower; a light component with the boiling point lower than that of MIBK is obtained at the top ofan MIBK refining tower and an MIBK product with the purity larger than or equal to 99.5% is obtained on the side. The technology is simple, low in energy consumption and low in production cost, the high-purity MIBK product can be obtained from high-impurity waste acetone liquor, and the economic benefits are significant.

Owner:WANHUA CHEM GRP CO LTD

Preparation method of diatomite/(GR+TiO2) composite photocatalyst

ActiveCN107321341AResolve separation difficultiesHigh affinityPhysical/chemical process catalystsOther chemical processesDoped graphenePhotocatalytic degradation

The invention discloses a preparation method of a diatomite / (GR+TiO2) composite photocatalyst. Diatomite subjected to fine purification and pore structure improvement as a carrier and tetrabutyl titanate as a titanium source are doped with graphene so that the diatomite / (GR+TiO2) composite photocatalyst is obtained. The diatomite / (GR+TiO2) composite photocatalyst can effectively improve the affinity between the particles and the organic substance, the adsorption efficiency and the photocatalytic degradation rate under the visible light condition, and can effectively solve the problem that the catalyst is difficult to separate from the water. The method does not generate pollution in the production process and is suitable for industrial production.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Magnetic particle-attapulgite composite nano material and preparation method by directly dissolving attapulgite in acid

InactiveCN1844032AWith characteristicsResolve separation difficultiesWater/sewage treatment by sorptionClaywaresIonMagnetism

The invention relates to a direct acid-soluble process for preparing magnetism grain concavo-convex baculine stone nanometer composite material and concavo-convex baculine stone, which direct uses acid for dissolution, wherein composite material is loading nanometer magnetism grain on the surface of concavo-convex baculine stone. Selecting sedimentary concavo-convex baculine stone clay as raw materials, dissolving the clay with acidm and dissolving iron ion of the concavo-convex baculine stone crystal structure out, adding alkali for neutralization reaction, making the iron ion dissolved hydrolyze and forming iron hydroxide; dewatering and washing suspending liquid, reduced calcining the solid obtained to make iron hydroxide change into nanometer magnetism grain and load on the crystal surface, to get the magnetism grain concavo-convex baculine stone nanometer composite material. The composite material can be operated with electromagnetic field, to carry out magnetic flocculation, recovery, filtration and target controlling of the concavo-convex baculine stone adsorbent.

Owner:HEFEI UNIV OF TECH

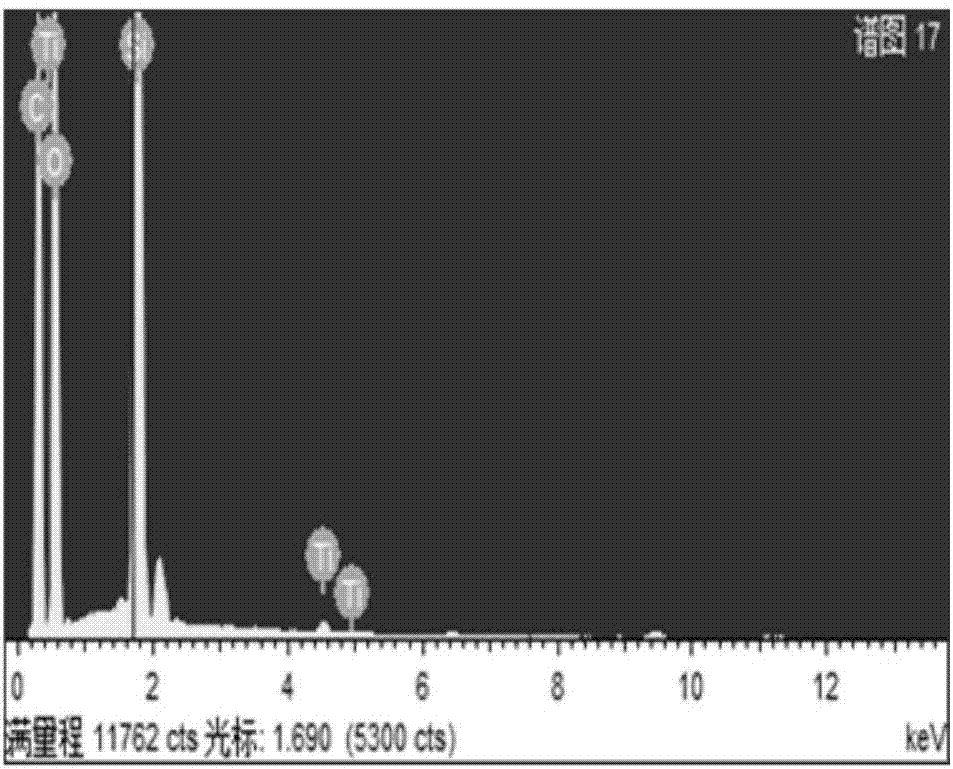

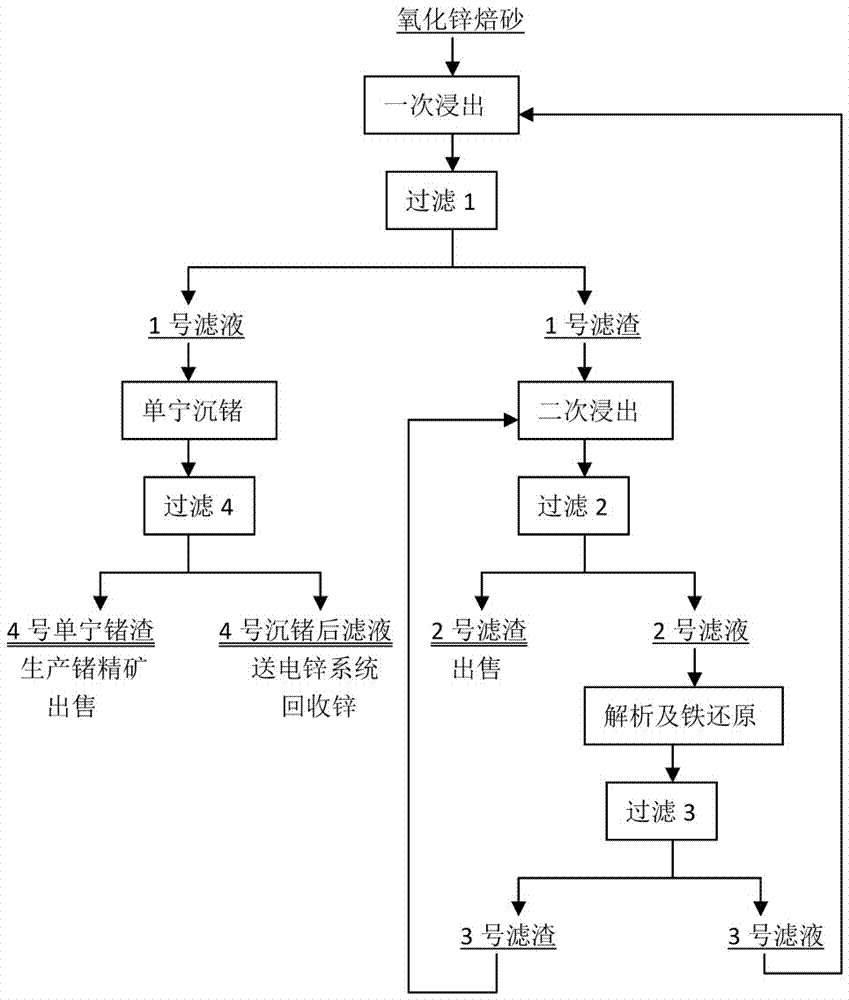

Method for recovering valuable metals by comprehensively treating high-iron and low-germanium zinc oxide calcine and zinc sulfite

ActiveCN106916945AAvoid poisoning risks and environmental risksSolve the difficulty of liquid-solid separationProcess efficiency improvementOxideZinc

The invention discloses a method for recovering valuable metals by comprehensively treating high-iron and low-germanium zinc oxide calcine and zinc sulfite. The method comprises the following steps: 1) primary leaching of zinc oxide calcine; 2) secondary leaching of zinc oxide calcine; 3) zinc sulfite analysis and ferric reduction; and 4) tannin germanium precipitation. In the process of recovering valuable metals by comprehensive treatment, the zinc sulfite analysis and the reduction of ferric ions, namely ferric sulfate in a solution into ferrous ions, namely ferrous sulfate are completed at one step by using a simple and convenient method, so that resources are sufficiently recycled, and the production cost is reduced; and the problems that zinc and germanium are recovered by analyzing zinc sulfite into a zinc sulfate solution and the ferric ions in a system for recovering zinc and germanium from the zinc oxide calcine cannot form an open path because of being enriched are simultaneously solved, meanwhile, the filtering performance for liquid-solid separation of the whole production system is also improved to ensure that the solution is clear and has no suspended matters, and consumption of tannic acid can be reduced and the grade of a germanium concentrate can be improved in the tannin germanium precipitation process.

Owner:YUNNAN LUOPING ZINC & ELECTRICITY

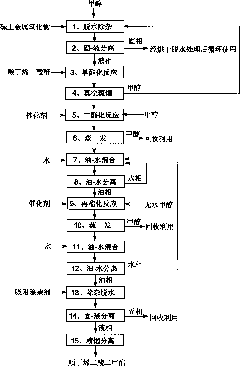

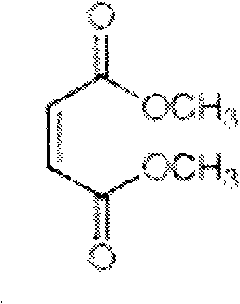

Method for preparing dimethyl maleate

ActiveCN101823962AThorough responseReduce generationOrganic compound preparationCarboxylic acid esters preparationEvaporationCis-Butenedioic Acid

The invention relates to a method for preparing dimethyl maleate, which comprises the following steps of : (1) dehydration and impurity removal: methanol is mixed with alkaline-earth metal oxide to be dehydrated and removed impurity; (2) separation of solid and liquid; (3) monoesterification reaction: maleic anhydride is added in liquid-phase material which is obtained in the previous step; (4) vacuum distillation; (5) two-esterification reaction: acid catalyst and methanol are added in the material after the vacuum distillation in the previous step; (6) evaporation; (7) mixing of oil and water; (8) separation of oil and water; (9) re-esterification reaction; (10) evaporation; (11) mixing of oil and water; (12) separation of oil and water; (13) impurity removal and dehydration; (14) separation of solid and liquid: liquid-phase material enters the next step; (15) rectification separation: the product dimethyl maleate is obtained. The method is simple and has reasonable process, low preparation cost, high product purity and good product quality.

Owner:河北彩客新材料科技股份有限公司

Oil-water separation material as well as preparation method and application thereof

ActiveCN107175063ARealize high-value utilizationEasy to makeFatty/oily/floating substances removal devicesOther chemical processesBiological adhesionSurface modification

The invention discloses a preparation method of a fly ash modification material with an oil-water separation function. The preparation method is characterized in that solid waste fly ash is used as a surface modification material and imitates a biological adhesion effect and a lotus leaf effect of marine mussel foot silk protein; the oil-water separation material with a special wetting property is prepared through dopamine self-polymerization, fly ash adhesion and hydrophobic modification. The separation efficiency of the oil-water separation material prepared by the preparation method on various oil / water mixtures can reach 95 percent or above. The preparation method has the advantages that raw materials of a technology are cheap and easy to obtain, a process is simple and easy to operate and the preparation is carried out at room temperature; a product has a good oil-water separation function, tolerance and recyclability and can be applied in the fields including water-surface oil pollution, chemical engineering, food production and the like.

Owner:BEIFANG UNIV OF NATITIES

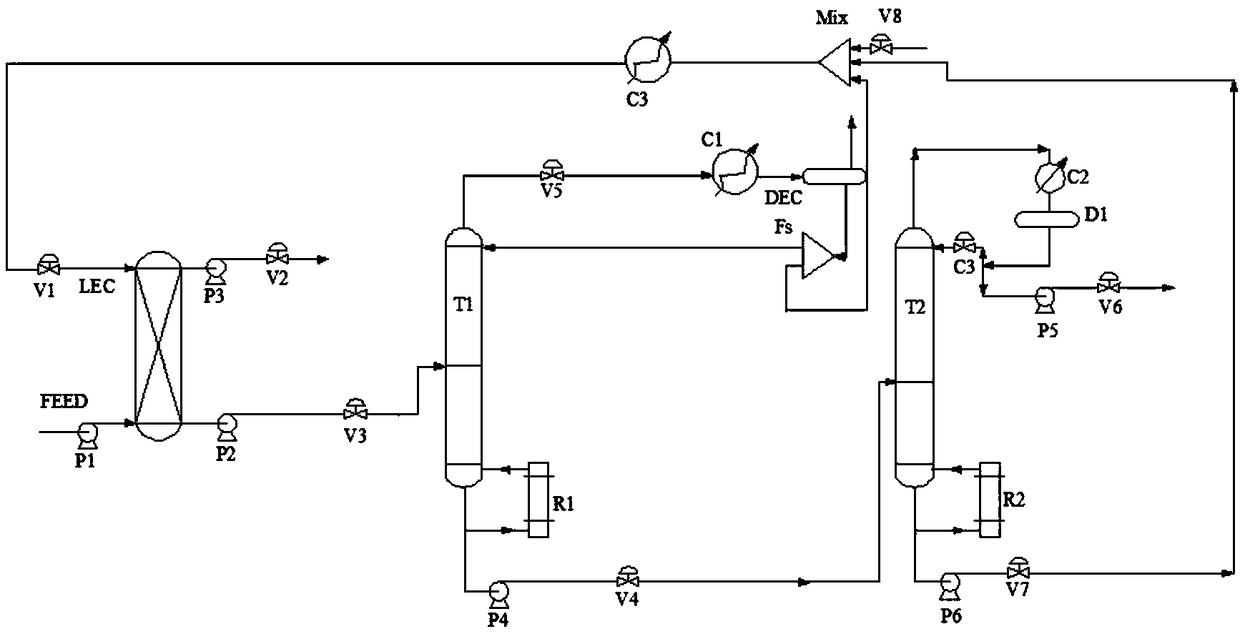

Liquid-liquid extraction-azeotropic rectification mixing process for separating propylene glycol monomethyl ether and water

InactiveCN109251133AResolve separation difficultiesEasy to separateEther separation/purificationPropylene glycolChemistry

The invention relates to a liquid-liquid extraction-azeotropic rectification mixing process for separating propylene glycol monomethyl ether and water. Firstly, a mixed extracting agent IS prepared byusing extracting agents 2-ethylhexoic acid and chloroform according to a certain ratio liquid-liquid extraction is performed on a propylene glycol methyl ether water solution, wherein the purity of the water in a raffinate phase at the top of a liquid-liquid extraction tower can reach more than 99.9 mol %, and an extraction phase is conveyed to an azeotropic rectification tower for azeotropic rectification. A phase separator is added to the upper part of the azeotropic rectification tower, water is collected from the upper part of the phase separator, chloroform is collected from the lower part of the phase separator for recycling the extracting agent, and a 2-ethylhexoic acid and propylene glycol monomethyl ether mixed solution at the bottom of the azeotropic rectification tower is conveyed to a recovery tower for separation. The product propylene glycol monomethyl ether is extracted from the top of the recovery tower, and the purity of the propylene glycol monomethyl ether is more than 99.9 mol %, and the extraction agent 2-ethylhexoic acid at the bottom of the tower is recycled. Devices mainly comprise the liquid-liquid extraction tower (LEC), the extraction rectifying tower (T1), the recovery tower (T2), a condenser (C1), a condenser (C2), a condenser (C3), a reflux tank (D1), a reboiler (R1), a reboiler (R2), a mixer (Mix), a flow divider (Fs) and a phase separator (DEC).

Owner:QINGDAO UNIV OF SCI & TECH

Preparation of high purity and high optical rotation mixing vitamin E

ActiveCN101475557AReduce contentResolve separation difficultiesOrganic chemistryDistillationIon-exchange resin

The invention discloses a method for preparing a high-purity and high-optical rotation mixed vitamin E, which comprises the following steps: dissolving a low-content mixed vitamin E into ethanol water; carrying out absorptive separation of anion exchange resin; adding ethanol water into the mixed solution till an effluent is colorless; passing an acidic gas through the mixed solution for analysis; eluting with the ethanol water and concentrating an eluate; adding first-grade edible oil into a concentrate of the eluate with mixing; and subjecting the mixture to three-stage molecular distillation and obtaining the high-purity and high-optical rotation vitamin E. The method overcomes the separation difficulty caused by a plurality of solvents adopted, reduces production cost, simplifies operation, tremendously enhances the color and luster of products, greatly reduces the content of sterol in the raw material, and improves the product purity, optical rotation fluidity and transparency. The products have almost no residual solvent and can be used more safely in food industry and other industries.

Owner:COFCO GROUP +1

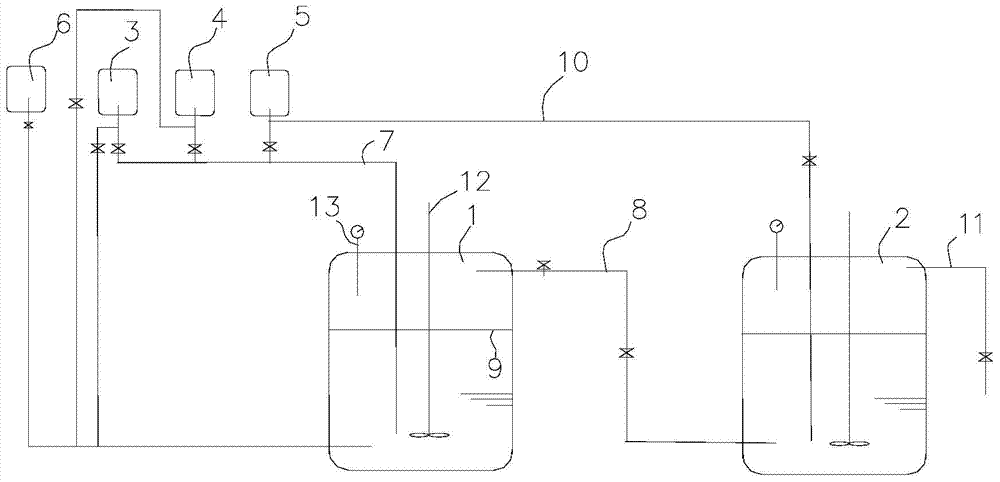

Production equipment and preparation technology for o-chlorotoluene Grignard reagent

ActiveCN104497026AHigh yieldSolve problemsChemical/physical/physico-chemical stationary reactorsMagnesium organic compoundsGrignard reagentO-chlorotoluene

The invention discloses production equipment and a preparation technology for an o-chlorotoluene Grignard reagent. The equipment comprises a first-stage reaction kettle, a second-stage reaction kettle, a tetrahydrofuran storage tank, an o-chlorotoluene storage tank, a magnesium chip storage tank and a toluene storage tank; the center parts of the first-stage reaction kettle and the second-stage reaction kettle are both provided with a separation net for obstructing magnesium chips; and pipelines are employed for connection of the reaction kettles and the storage tanks. Combination of the continuous production equipment and the corresponding preparation technology for the o-chlorotoluene Grignard reagent solves the problems that initiation is difficult and magnesium chips are difficult to separate in a conventional industrial preparation process of the o-chlorotoluene Grignard reagent, and helps to improve the yield of the o-chlorotoluene Grignard reagent.

Owner:SHANGYU HUALUN CHEM

Preparation method and application of iron oxyhydroxide modified vermiculite composite adsorbing material for removing Mn from underground water

ActiveCN111266081AEfficient removalEnhance manganese removal functionOther chemical processesWater contaminantsManganesePhysical chemistry

The invention relates to a preparation method and an application of an iron oxyhydroxide modified vermiculite composite adsorbing material for removing Mn from underground water. The preparation method comprises the following steps: washing vermiculite with water for many times, carrying out acid treatment, carrying out solid-liquid separation, washing the vermiculite subjected to acid treatment with water until the washing waste liquid is neutral, and drying the obtained vermiculite for later use; placing the vermiculite in a water-soluble ferric iron salt solution, and performing ultrasonicoscillation for 30-60 min to obtain a mixed solution; dropwise adding an alkali liquor into the mixed solution while stirring until the pH value of the mixed solution is 10-12, then continuing to stirfor 30-120 min, and then carrying out constant-temperature aging, cooling and solid-liquid separation to obtain an initial product of the composite adsorbing material; and washing, drying and coolingthe initial product of the composite adsorbing material to obtain the iron oxyhydroxide modified vermiculite composite adsorbing material. The composite adsorbing material is good in stability and easy to recover, can simultaneously exert the activity of iron oxyhydroxide for enhancing catalytic adsorption of manganese ions and the excellent adsorption performance of vermiculite, and has higher adsorption capacity than single vermiculite, and the Mn adsorption capacity at low concentration is 2.94 mg / g.

Owner:HUNAN UNIV

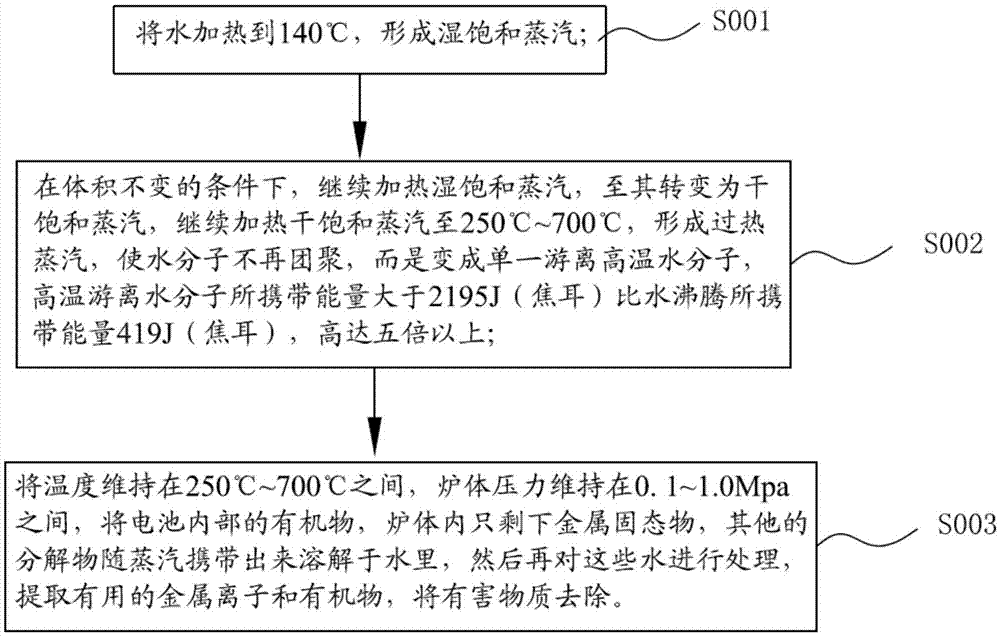

Treatment method of used battery

ActiveCN105449306AReduce separation costsResolve separation difficultiesReclaiming serviceable partsWaste accumulators reclaimingDecomposerEngineering

The invention discloses a treatment method of a used battery. The treatment method comprises the steps that superheated steam is used for treating the used battery, only metal solid is left in the used battery, and other decomposer of the used battery enters steam. According to the treatment method of the used battery, the superheated steam is used for treating the used battery, splitting separation is performed to the used battery by thehydrone characteristics, separation of organic matters and the metal solid is simply and efficiently realized, and at the same time the treatment method of the used battery has the advantages that the separation cost is low.

Owner:GUANGZHOU BAOSHI WIRELESS POWER SUPPLYING TECH CO LTD

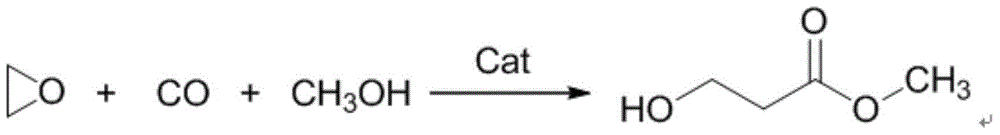

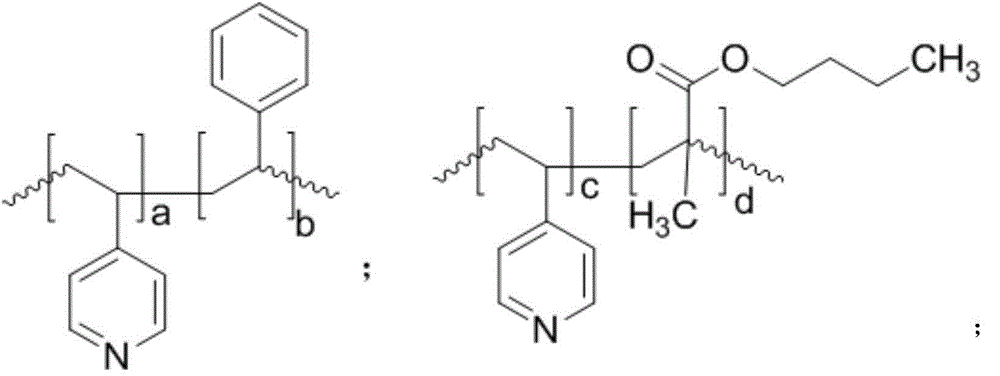

Method for synthesizing 3-hydracrylic acid ester

ActiveCN106431926AAvoid easy separationEasy to separateOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reaction3-Hydroxypropionic acidAlcohol

The invention relates to a method for synthesizing 3-hydracrylic acid ester. The method mainly solves the problem that in the prior art, catalysts in a homogeneous system are difficult to separate. The method for synthesizing 3-hydracrylic acid ester includes the following steps that firstly, a ligand and cobalt carbonyl are subjected to a coordination reaction in an alcohol solvent to obtain turbid liquid of a catalyst; secondly, ethylene oxide and carbon monoxide are added, and a reaction is conducted to obtain 3-hydracrylic acid ester. According to the technical scheme, the ligand is selected from 4-vinylpyddine homopolymers or copolymers containing 4-vinylpyddine monomeric units, the technical problem is well solved, and the method can be used in industrial production of 3-hydracrylic acid ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

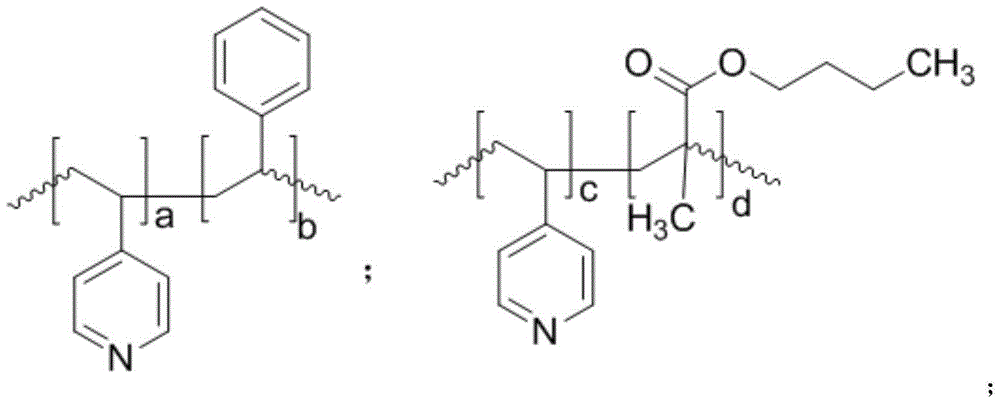

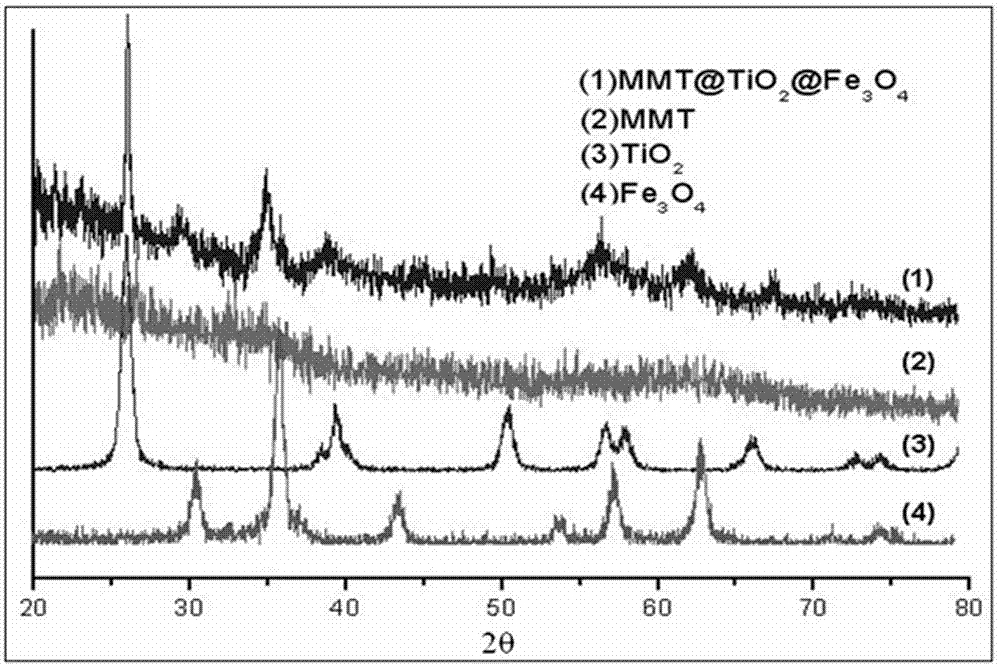

Photocatalytic nano composite material having magnetic response property and preparation method thereof

InactiveCN103111295AResolve separation difficultiesSimple preparation procedureMetal/metal-oxides/metal-hydroxide catalystsAnhydrous ethanolEmulsion

The invention provides a photocatalytic nano composite material having magnetic response property, belonging to the technical field of photocatalysts. The preparation method of the photocatalytic nano composite material comprises the following steps: by using alcohol as a dispersion medium and organic montmorillonite as a template, intercalating a mixed microemulsion of magnetic particles and a titanium source into lamellae of the organic montmorillonite under ultrasonic conditions, thus forming a thermodynamically stable system; then, adding an acid solution to initiate hydrolysis so as to generate TiO2, and ensuring that the magnetic particles and the TiO2 are simultaneously intercalated into the lamellae of the montmorillonite; and finally, attracting the product with a magnet, washing with anhydrous ethanol, and drying to obtain the photocatalytic nano composite material having magnetic response property. Thus, the invention solves the problem that solid-liquid separation is difficult in the photocatalyst, and has good application prospects in the photocatalytic degradation of organic waste water. Besides, in the preparation process provided by the invention, the intercalation and hydrolysis of the emulsion of the magnetic particles and the photocatalytic particles are synchronously performed, thereby effectively simplifying the composite material preparation procedure, shortening the process period, lowering the cost and being beneficial to industrial production.

Owner:NORTHWEST NORMAL UNIVERSITY

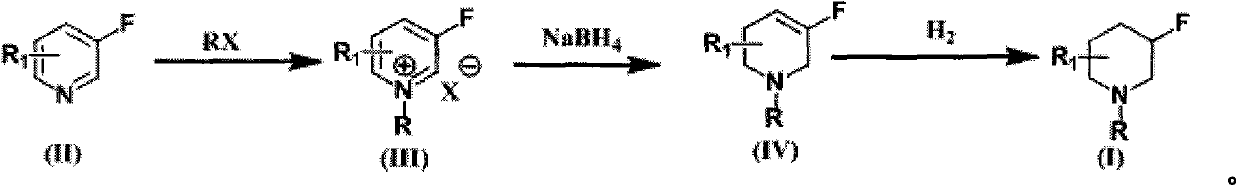

Preparation method of 5,5-difluoro-3-substituted piperidine derivative

ActiveCN102731368AResolve separation difficultiesMild reaction conditionsOrganic chemistryArylHalogen

The invention relates to a preparation method of a 5,5-difluoro-3-substituted piperidine derivative. The method comprises the following steps: (1) by taking a compound 2 as a starting material, reducing the compound 2 at 0-80 DEG C to generate a compound 3; (2) dehydrating the compound 3 to generate a compound 4; (3) carrying out Pd-C catalysis and H2 reduction on the compound 4 at the temperature of 0-70 DEG C to generate a compound 5; and (4) further reacting the compound 5 to generate the 5,5-difluoro-3-substituted piperidine derivative 1, and the reaction formula of the derivative 1 is as shown in the specification, wherein R1 is ester group, carboxyl, hydroxymethyl, amino, acetyl amino, trifluoro acetyl amino, benzylamine or R3 is C1-C9 alkyl, aryl or benzyl; R2 is hydrogen, C1-C9 alkyl, aryl, hydroxymethyl, benzyl or R4 is C1-C9 alkyl, aryl or benzyl, and the groups are not substituted or substituted by one or a plurality of substituents consisting of selected free alkyl, halide alkyl, hydroxy alkyl, halogen, alkoxy or hydroxy.

Owner:SHANGHAI AQ BIOPHARMA CO LTD

Graphite crushing and grinding equipment

The invention discloses graphite crushing and grinding equipment. The equipment comprises a crushing box, wherein a support is fixed to the bottom of the crushing box, a conveying cylinder is insertedinto the inner bottom of the crushing box in a penetrating manner, a motor is fixed to the inner wall of the conveying cylinder, an output shaft of the upper end of the motor is connected with a rotating shaft of a spiral conveyor through a one-way bearing, a driving rod is fixed to the top of the rotating shaft of the spiral conveyor, and a plurality of stirring blades are fixed to the side wallof the driving rod. The equipment has the advantages that the rotating shaft of the spiral conveyor is driven by the motor to rotate, the stirring blades rotate under the driving of the driving rod,raw material in the crushing box is continuously preliminarily crushed under the collision with the stirring blades, and the preliminarily crushed raw material enters the conveying cylinder and is conveyed upwards through the rotating shaft of the spiral conveyor to be further extruded and crushed in the conveying process so that the raw material falling from the top of the conveying cylinder canbetter collide with the stirring blades to complete the crushing treatment.

Owner:石门楚晶新材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Porous [beta]-cyclodextrin cross-linked polymer nanofiber and preparation method thereof and application thereof in removing bisphenol organic pollutants in water body Porous [beta]-cyclodextrin cross-linked polymer nanofiber and preparation method thereof and application thereof in removing bisphenol organic pollutants in water body](https://images-eureka.patsnap.com/patent_img/925fd517-4475-46b9-8a03-9a842da62a93/HDA0002392490350000011.png)

![Porous [beta]-cyclodextrin cross-linked polymer nanofiber and preparation method thereof and application thereof in removing bisphenol organic pollutants in water body Porous [beta]-cyclodextrin cross-linked polymer nanofiber and preparation method thereof and application thereof in removing bisphenol organic pollutants in water body](https://images-eureka.patsnap.com/patent_img/925fd517-4475-46b9-8a03-9a842da62a93/HDA0002392490350000012.png)

![Porous [beta]-cyclodextrin cross-linked polymer nanofiber and preparation method thereof and application thereof in removing bisphenol organic pollutants in water body Porous [beta]-cyclodextrin cross-linked polymer nanofiber and preparation method thereof and application thereof in removing bisphenol organic pollutants in water body](https://images-eureka.patsnap.com/patent_img/925fd517-4475-46b9-8a03-9a842da62a93/HDA0002392490350000013.png)