Method for continuously producing epoxy chloropropane

A technology of epichlorohydrin and chloropropene, applied in chemical recovery, organic chemistry, etc., can solve the problems of difficult separation catalysts, achieve the effect of solving separation difficulties, realizing automatic separation, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

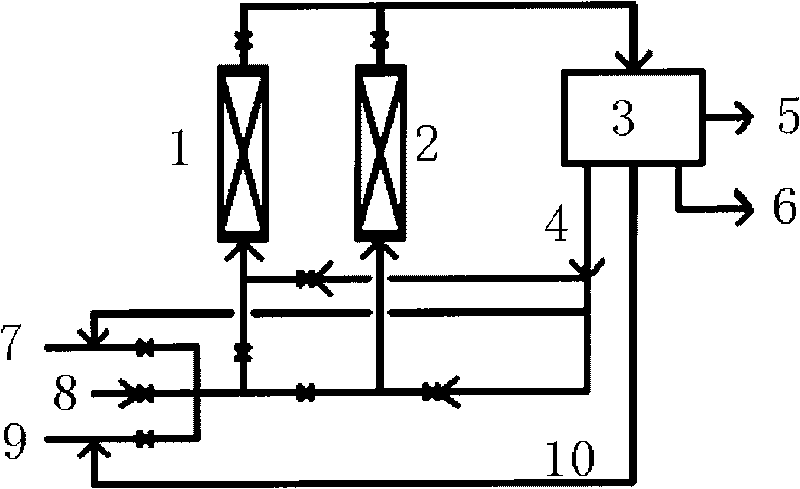

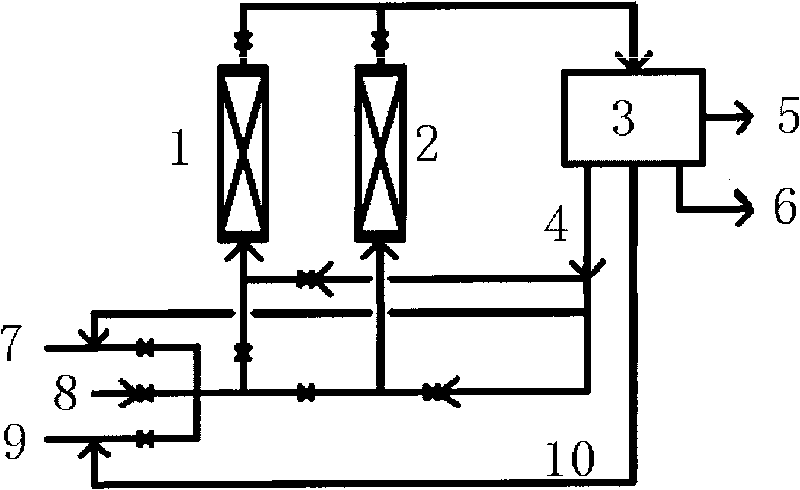

Method used

Image

Examples

Embodiment 1

[0058] In the embodiment, the titanium-silicon molecular sieve catalyst used is extruded TS-1 catalyst, shaped according to the method disclosed in CN200710120615.8, and the mass fraction of TS-1 in the shaped catalyst is 60%. TS-1 is produced by Hunan Jianchang Petrochemical Co., Ltd., the brand is HTS; chloropropene is industrial chloropropene, the mass content of 3-chloropropene is greater than 97%, and it is produced by Baling Petrochemical Co., Ltd.; hydrogen peroxide is As an analytically pure reagent, the mass content of hydrogen peroxide is 30%; methanol is an analytically pure reagent, and the mass content of methanol is greater than 99.5%.

[0059] The epoxidation reaction of 3-chloropropene and hydrogen peroxide was carried out in a jacketed tubular fixed-bed reactor, and the loading amount of the catalyst was 100 mL. The temperature of the reactor was regulated by an automatic thermostatic oil bath flowing through the reactor jacket. The pressure of the reactor wa...

Embodiment 2

[0076] Epichlorohydrin was produced in the same manner as in Example 1, except that ammonia was not added to the reaction raw materials, the temperature of the reactor jacket oil bath was kept constant at 60°C, and the reaction temperature rise did not exceed 10°C. The process and results of the continuous epoxidation reaction are shown in Table 3, and the accumulated continuous epoxidation reaction results are shown in Table 4.

[0077] table 3

[0078] Catalyst status

reactor

Reaction time / h

Regeneration time / h

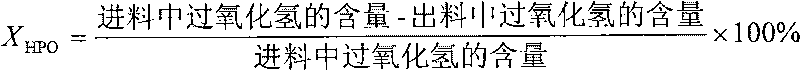

X HPO / %

S ECH / %

fresh

1

165

0

98.6

94.4

fresh

2

173

0

98.8

94.1

first wash regenerated

1

115

16

98.2

94.6

first wash regenerated

2

119

16

98.2

93.9

second wash regenerated

1

102

16

97.9

94.2

second wash regenerated

2

90

16

98.1

94.6

third wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com