Preparation method of diatomite/(GR+TiO2) composite photocatalyst

A technology of diatomite and composite light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and other chemical processes. The effect of improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Select raw materials according to the following requirements:

[0030] 1) Diatomite: finely purified diatomite, fineness 80 mesh, silicon dioxide content 80%;

[0031] 2) tetrabutyl titanate: technically pure;

[0032] 3) Graphene: graphene oxide;

[0033] 4) absolute ethanol: industrial pure;

[0034] 5) Acetic acid: industrial grade.

[0035] The method comprises the steps of:

[0036] 1) Measure 15mL of tetrabutyl titanate, 75mL of absolute ethanol, 7.5mL of distilled water and 1.5mL of acetic acid. TiO 2 Precursor gel, set aside;

[0037] 2) Weigh 30g of purified diatomite powder, 0.8g of graphene, and weigh TiO 2 Precursor gel, converted into 8g of titanium dioxide, add appropriate amount of water to stir and mix the three, put it in a high-pressure reactor, and react at 150°C for 12 hours under magnetic stirring;

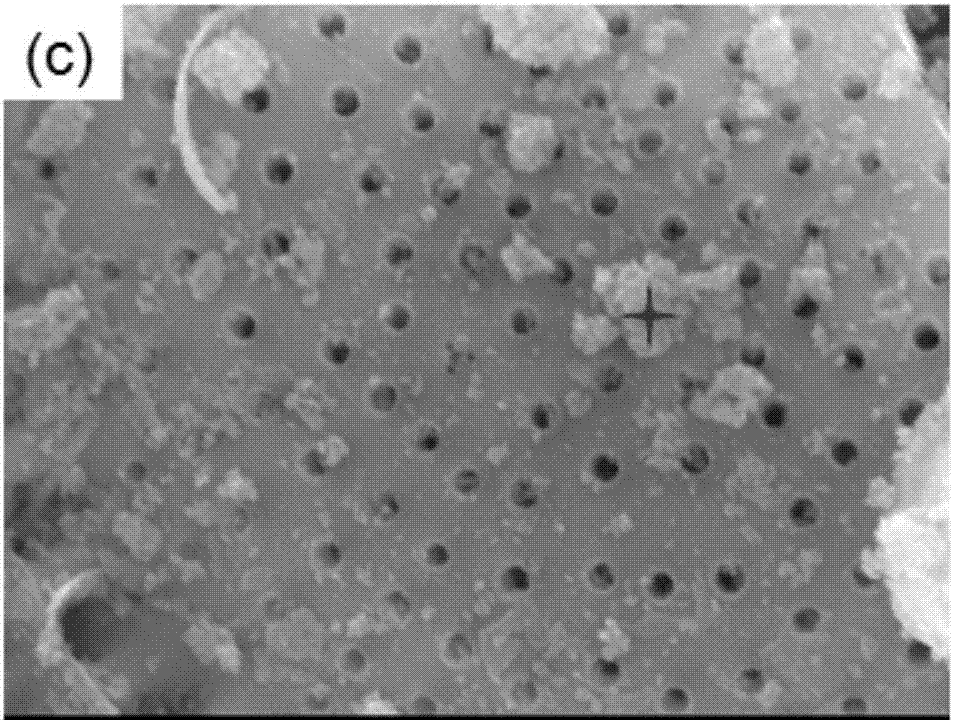

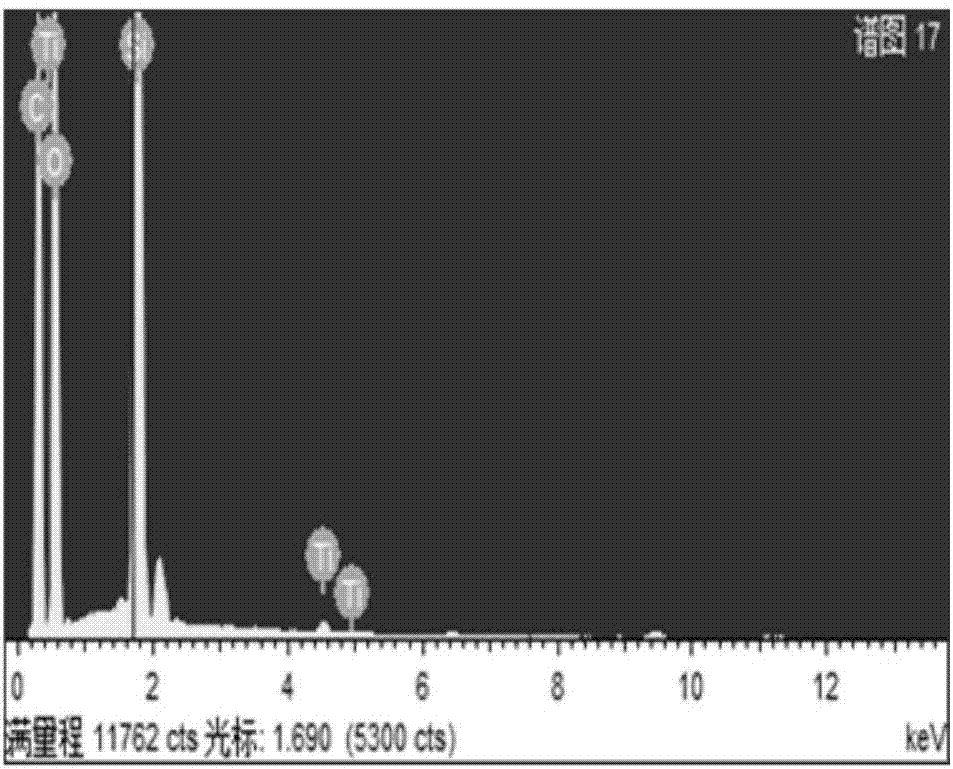

[0038] 3) After drying the mixed solution at 60°C, place it in a nitrogen atmosphere furnace, and keep it at 650°C for 2 hours to obtain diatom...

Embodiment 2

[0041] Select raw materials according to the following requirements:

[0042] 1) Diatomite: finely purified diatomite with a fineness of 800 mesh and a silicon dioxide content of 86%;

[0043] 2) tetrabutyl titanate: technically pure;

[0044] 3) Graphene: graphene oxide;

[0045] 4) absolute ethanol: industrial pure;

[0046] 5) Acetic acid: industrial grade.

[0047] The method comprises the steps of:

[0048] 1) Measure 5mL of tetrabutyl titanate, 65mL of absolute ethanol, 6mL of distilled water and 1mL of acetic acid. 2 Precursor gel, set aside;

[0049] 2) Weigh 85g of purified diatomite powder, 1.5g of graphene, and weigh TiO 2 Precursor gel, converted into 5g of titanium dioxide, add appropriate amount of water to stir and mix the three, put it in a high-pressure reactor, and react at 20°C for 1 hour under magnetic stirring;

[0050] 3) After drying the mixed solution at 80°C, place it in a nitrogen atmosphere furnace, and keep it at 300°C for 1 hour to obtain di...

Embodiment 3

[0052] Select raw materials according to the following requirements:

[0053]1) Diatomite: Finely purified diatomite with a fineness of 1250 mesh and a silicon dioxide content of 92%;

[0054] 2) tetrabutyl titanate: technically pure;

[0055] 3) Graphene: graphene oxide;

[0056] 4) absolute ethanol: industrial pure;

[0057] 5) Acetic acid: industrial grade.

[0058] The method comprises the steps of:

[0059] 1) Measure 10mL of tetrabutyl titanate, 70mL of absolute ethanol, 10mL of distilled water and 5mL of acetic acid. 2 Precursor gel, set aside;

[0060] 2) Weigh 95g of purified diatomite powder, 2.5g of graphene, and weigh TiO 2 Precursor gel, converted into 2.5g of titanium dioxide, add appropriate amount of water to stir and mix the three, put it in a high-pressure reactor, and react at 200°C for 30h under magnetic stirring;

[0061] 3) After the mixed solution was dried at 70°C, it was placed in a nitrogen atmosphere furnace, and kept at 800°C for 100 hours to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com