Feeder head knock-off core

A technology of easy-cut pieces and risers, applied in casting molding equipment, casting molds, cores, etc., can solve the problems of low separation work strength, high connection strength, low connection strength, etc., and achieve low separation work strength and reduce connection. Strength, easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

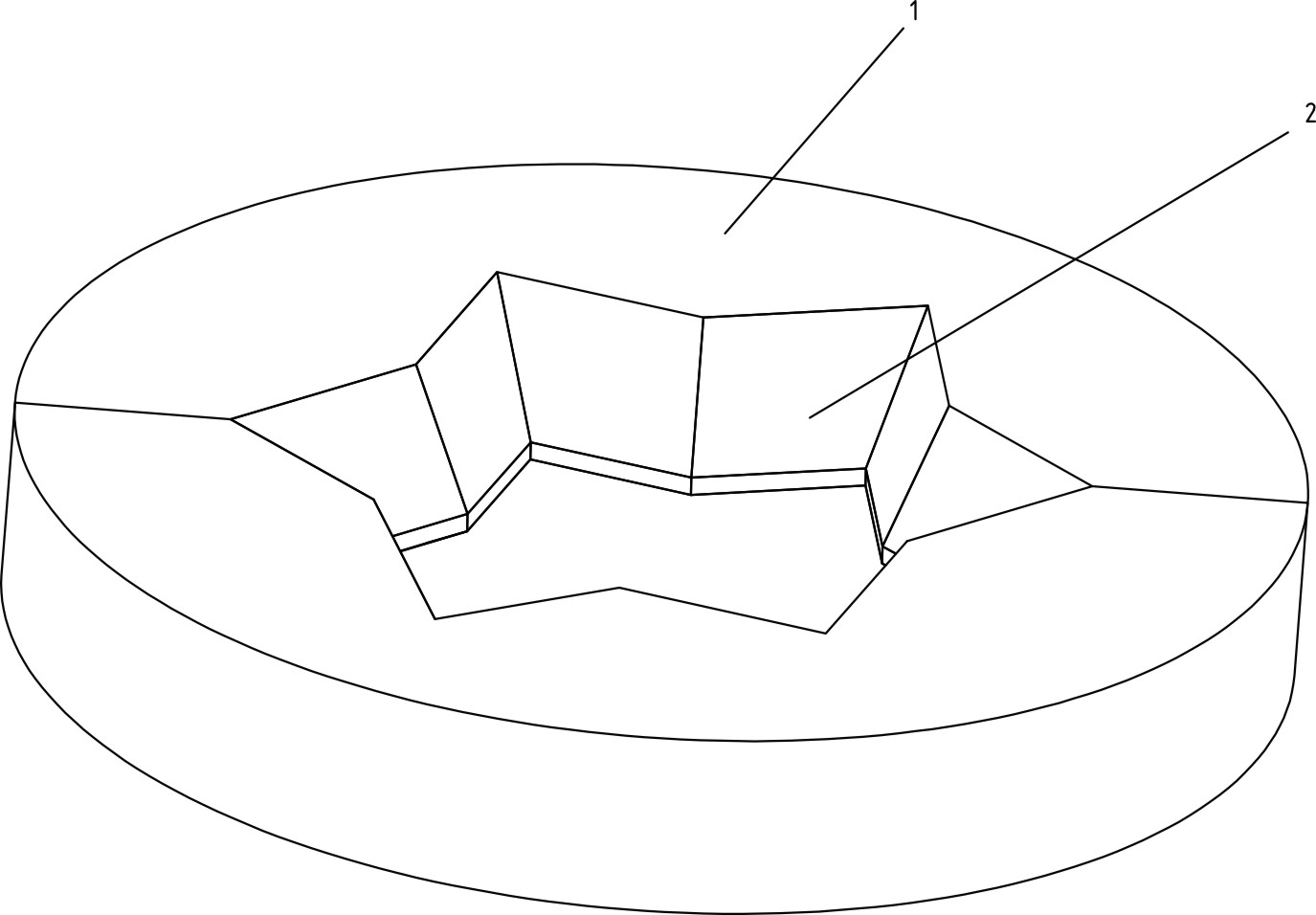

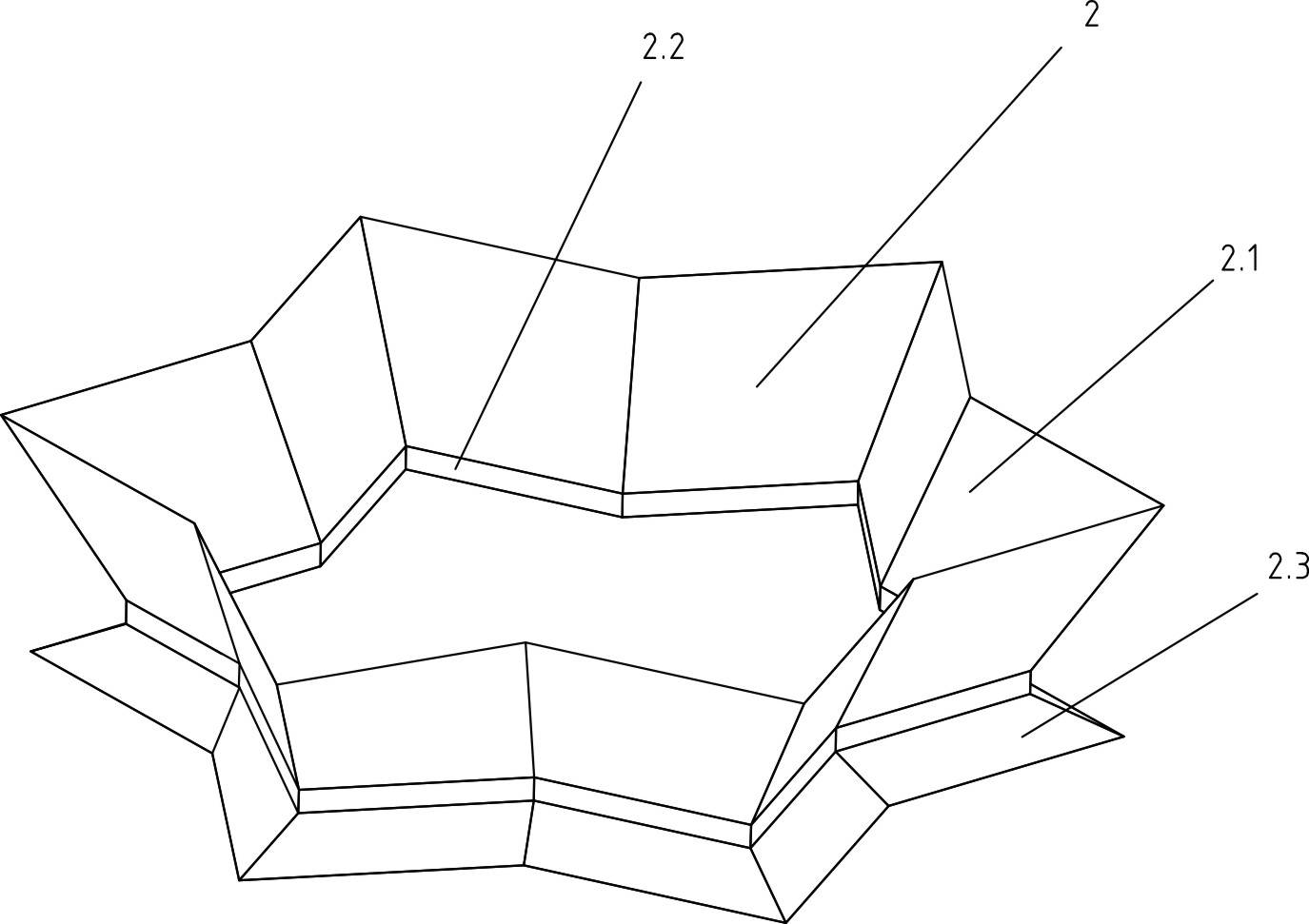

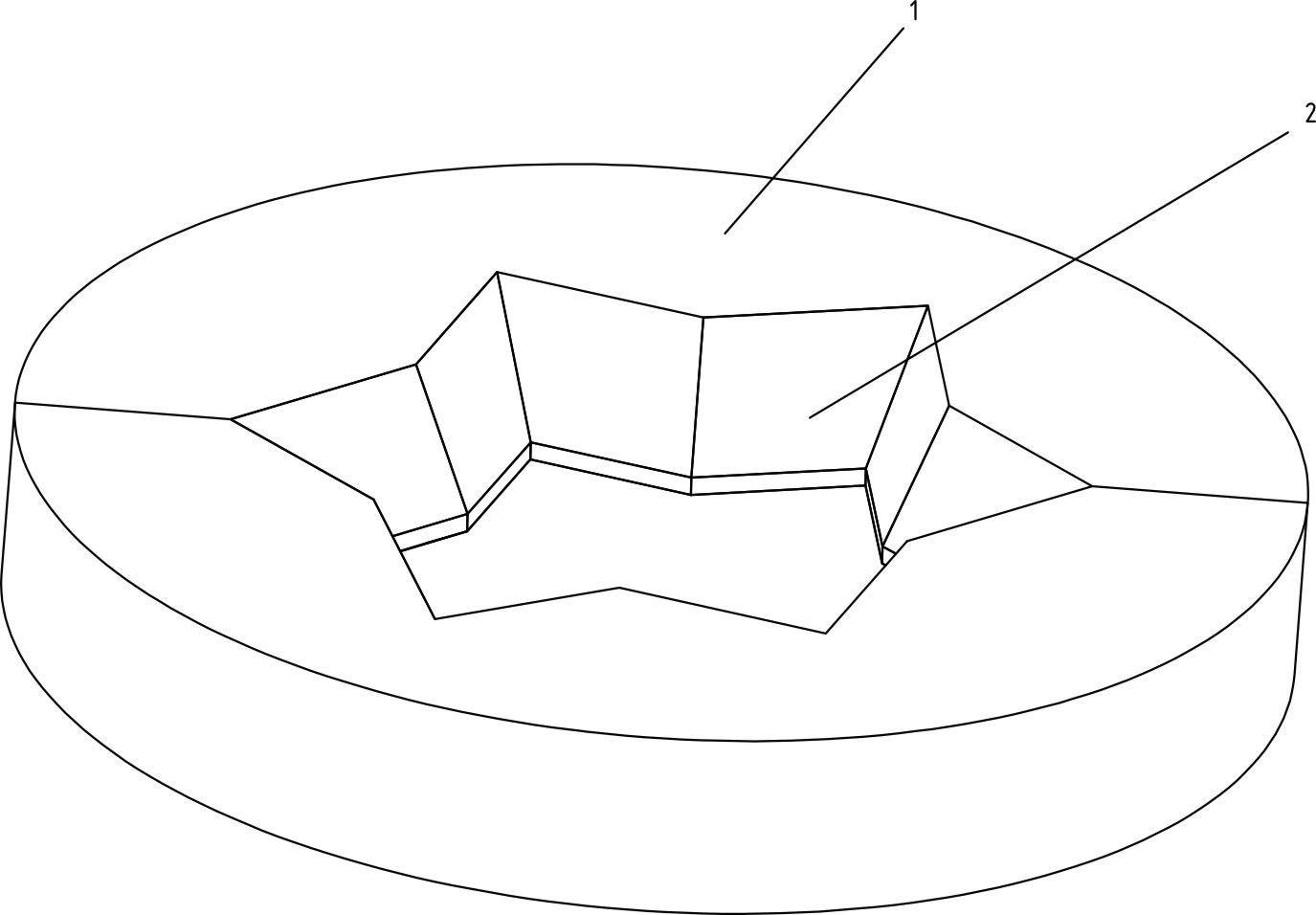

[0016] Such as figure 1 with figure 2 Shown, the present invention comprises cylindrical easy-cut piece body 1, and easy-cut piece body 1 is made of mutually symmetrical two petals, and the center of easy-cut piece body 1 is the liquid-through hole 2 that conducts easy-cut piece body 1 upper and lower surfaces; The liquid hole 2 includes the upper liquid hole 2.1, the lower liquid hole 2.3 and the middle transition hole 2.2; the cross-sectional profiles of the upper liquid hole 2.1, the middle transition hole 2.2 and the lower liquid hole 2.3 are all hexagonal star-shaped, that is, the upper hole The cross-sectional profiles of the liquid hole 2.1, the intermediate transition hole 2.2 and the lower liquid hole 2.3 are all composed of 12 equal-length straight line segments connected head to tail in tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com