Method for preparing purified MIBK (methyl isobutyl ketone) from industrial byproduct waste acetone liquor

An industrial by-product and acetone technology, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of increased separation difficulty, no literature reports, complex product composition, etc., and achieve the effect of promoting stratification , the effect of reducing the amount of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

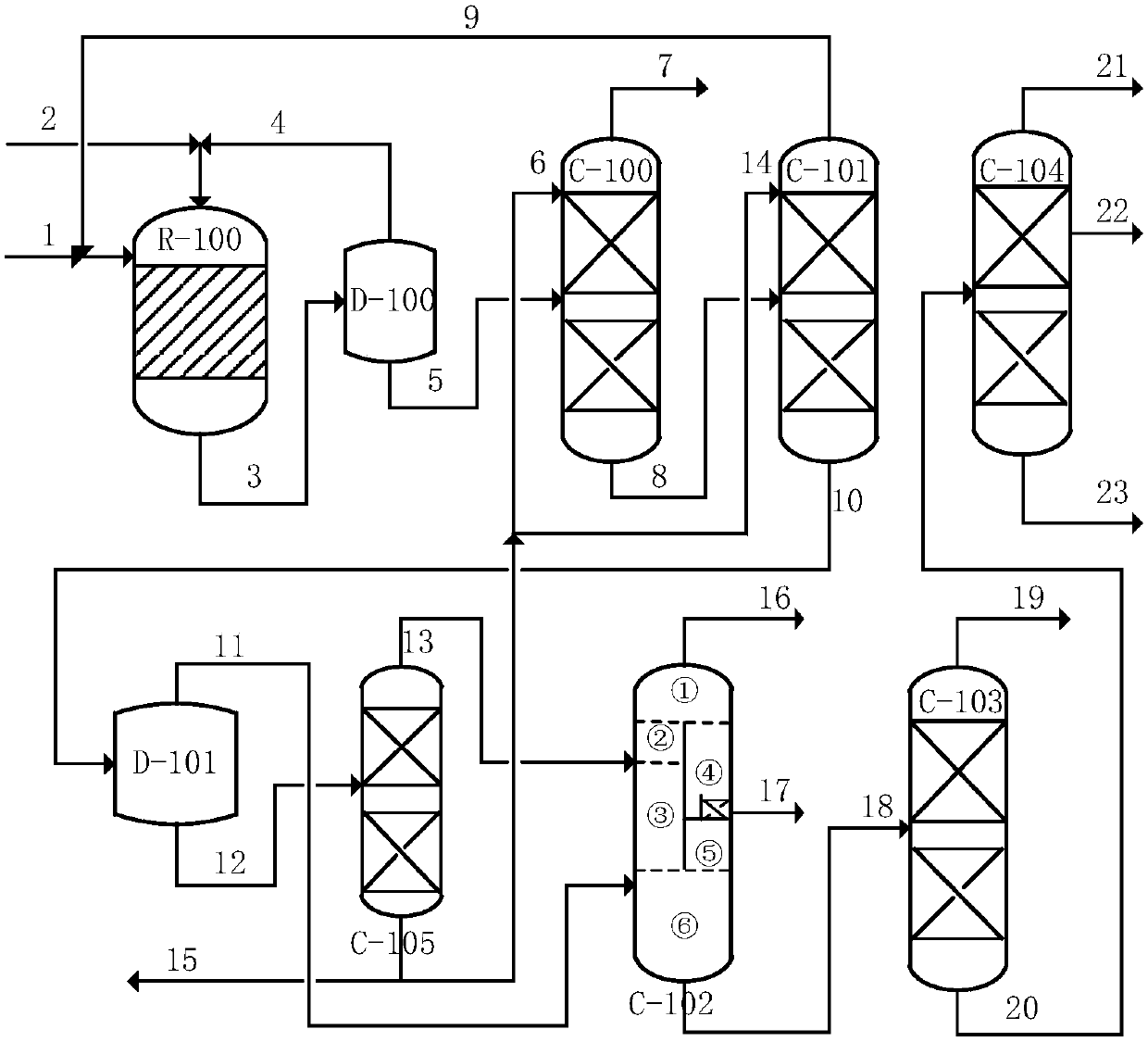

[0062] As shown in the flow process of accompanying drawing, carry out rectification by the rectification condition of table 4 and table 5 after the dehydrogenation of reaction synthesis liquid, wherein the extractant of delight component tower is water, and the mass ratio of consumption and feed liquid is 3:1, added in the second theoretical plate, wherein the height ratio of packing A and packing B in the liquid-liquid stratifier on one side of the dehydration tower is 1:4, and the results are shown in Table 6. It can be seen from Table 6 that the mass fraction of MIBK product finally obtained is 99.56% through the rectification of each rectification column.

[0063] The preparation method of filler A and filler B is as follows: the stainless steel filler is put into potassium permanganate sulfuric acid solution for 18 hours, and then washed with deionized water until neutral to obtain filler A. Spray polytetrafluoroethylene emulsion and sulfonated polyimide emulsion on the ...

Embodiment 2

[0072] As shown in the flow process of accompanying drawing, carry out rectification by the rectification condition of table 7 and table 8 after the dehydrogenation of reaction synthesis liquid, wherein the extractant of delight component tower is water, and the mass ratio of consumption and feed liquid is 2:1, added in the fifth theoretical plate, wherein the height ratio of packing A and packing B in the liquid-liquid stratifier on one side of the dehydration tower is 1:1, and the results are shown in Table 9. It can be seen from Table 9 that the mass fraction of MIBK product finally obtained is 99.67% through the rectification of each rectification column. The preparation method of filler A and filler B is shown in Example 1.

[0073] The rectification condition of table 7 rectification column

[0074] Distillation column

C-100

C-101

C-103

C-104

C-105

Theoretical number of boards

30

100

55

20

5

Feed position

20

40...

Embodiment 3

[0082] As shown in the flow process of accompanying drawing, carry out rectification by the rectification condition of table 10 and table 11 after the dehydrogenation of reaction synthesis liquid, wherein the extractant of delight component tower is water, and the mass ratio of consumption and feed liquid is 0.1, added on the 20th theoretical plate, the extractant of the acetone recovery tower is water, the mass ratio of the dosage to the feed liquid is 0.3, added on the second theoretical plate, wherein the liquid-liquid separation on the plate on one side of the dehydration tower The height ratio of packing A and packing B in the stratifier is 1:4, and the results are shown in Table 12. It can be seen from Table 12 that the mass fraction of the MIBK product finally obtained through the rectification of each rectification column is 99.72%.

[0083] The rectification condition of table 10 rectification column

[0084] Distillation column

C-100

C-101

C-103

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com