Magnetic particle-attapulgite composite nano material and preparation method by directly dissolving attapulgite in acid

A nano-composite material and attapulgite technology, applied in the field of magnetic particle-attapulgite clay composite materials, can solve the problems of high cost, increased cost of flocculants, restrictions, etc., achieve low raw material consumption, reduce sludge volume, and excellent The effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

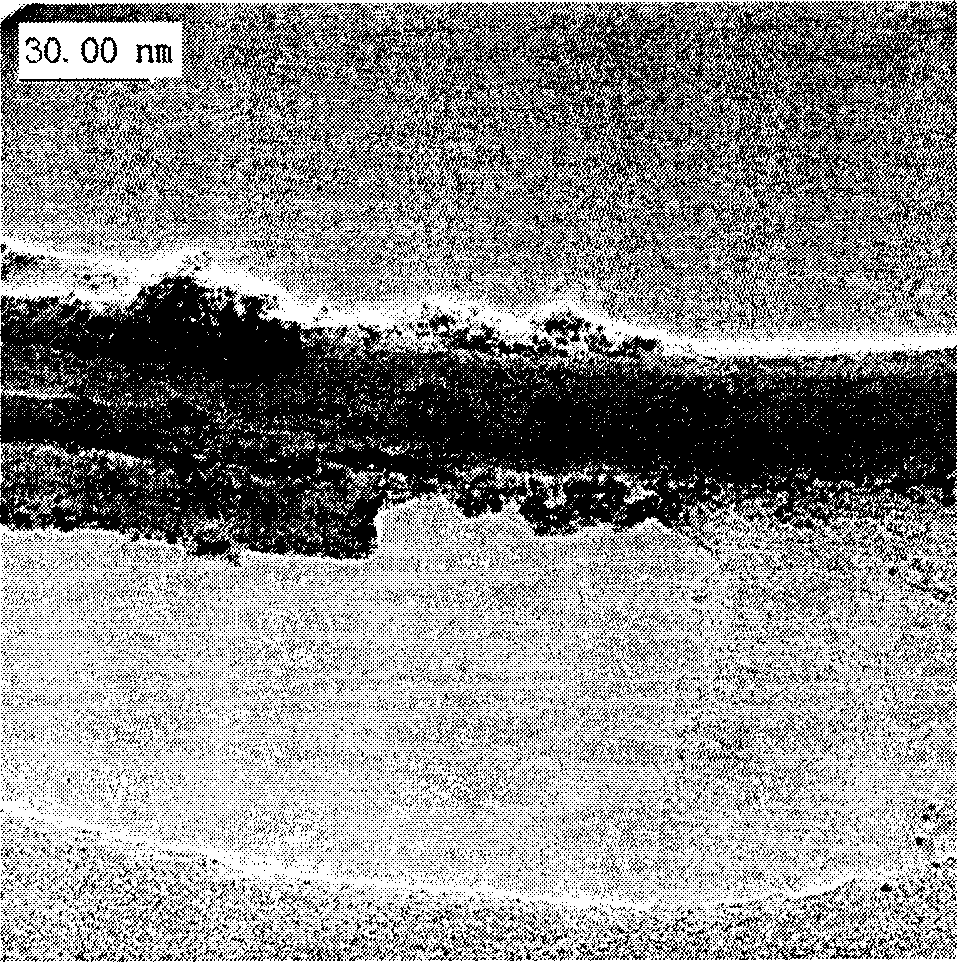

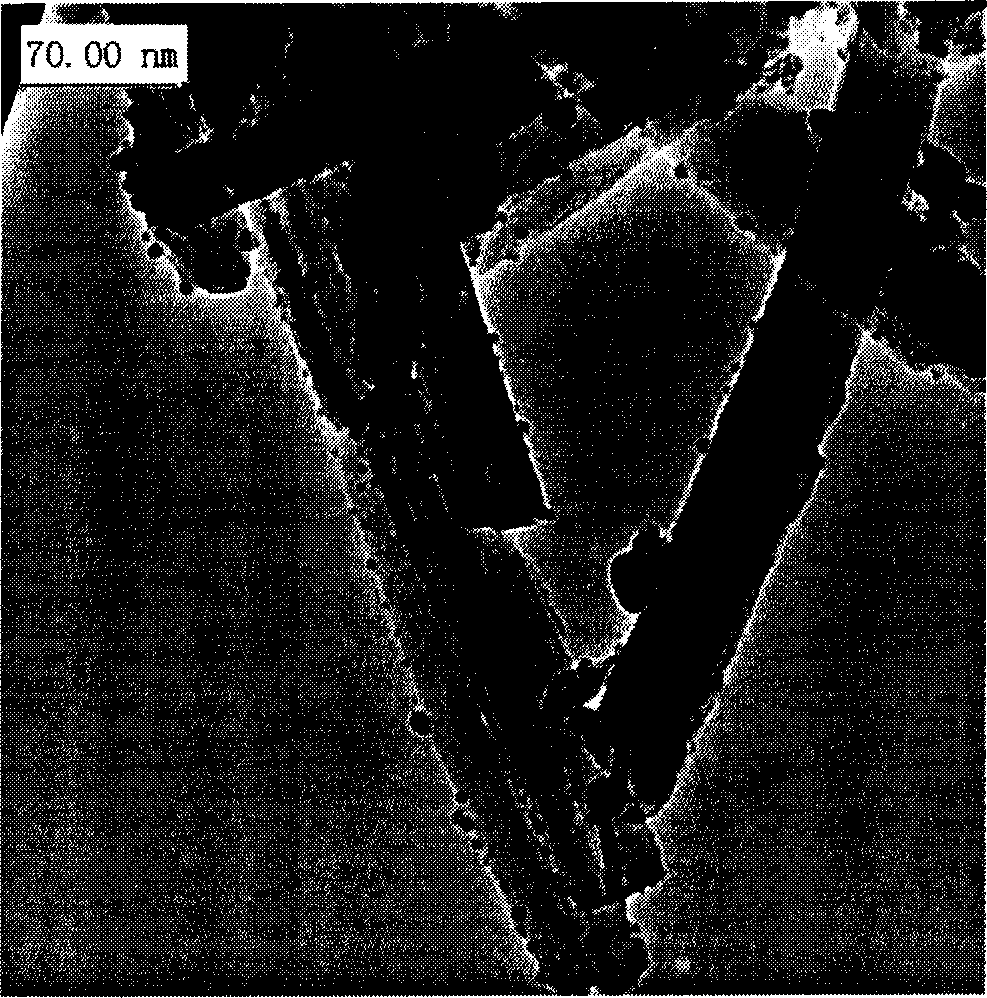

[0026] Attapulgite clay is selected, the content of attapulgite in attapulgite clay is not less than 60%, the content of minerals such as quartz and feldspar is not higher than 5%, and the content of dolomite is not higher than 10%.

[0027] When the water content of the ore is too high, it needs to be dried first, and crushed on the premise that the water content meets the crushing requirements, so that the attapulgite clay passes through a 100-mesh sieve, and the sieve residue is less than 0.5%.

[0028] Attapulgite clay powder reacts with acid. The acid concentration used is 5%-35%, preferably 10%. The acid referred to is sulfuric acid, or hydrochloric acid, or nitric acid, or phosphoric acid or their mixed acids, the reaction time is 30 minutes to 10 hours, preferably 2 hours; the reaction temperature is from room temperature to 100°C, preferably 70°C; attapulgite The mass-volume ratio of the clay to the acid solution is 1:100-1:3, preferably 1:4; the reaction pressure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com