Production equipment and preparation technology for o-chlorotoluene Grignard reagent

A technology of o-chlorotoluene and Grignard reagent, which is applied in the field of production equipment and preparation technology of o-chlorotoluene Grignard reagent, can solve problems such as difficult and difficult separation of magnesium chips, and achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

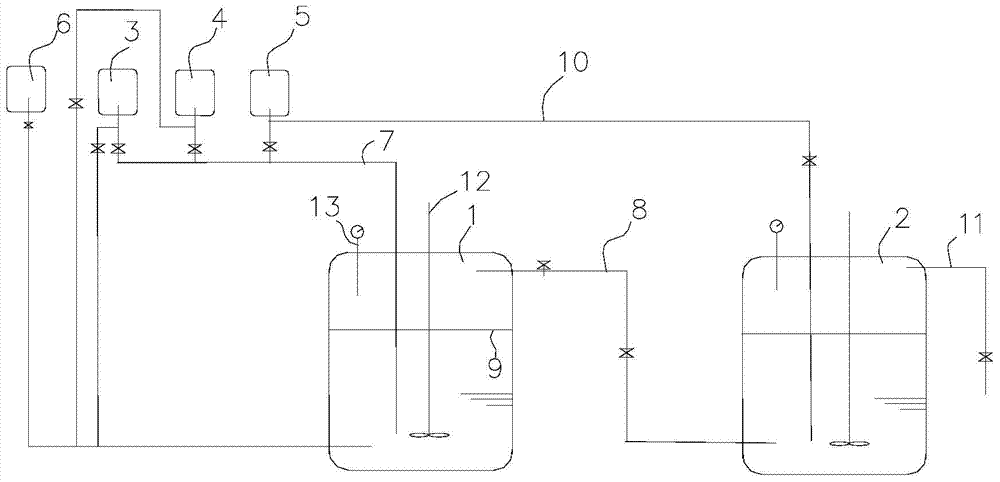

[0037] Utilize production equipment among the present invention to prepare o-chlorotoluene Grignard reagent, step is as follows:

[0038] (1) Anhydrous tetrahydrofuran (THF) with a flow rate of 10kg / h, ortho-chlorotoluene and magnesium chips with a flow rate of 5kg / h are passed into the first-level reaction kettle together through the first dip tube, and anhydrous tetrahydrofuran (THF), ortho-chlorotoluene and magnesium Chips are heated up to 65°C while flowing through the first dipping pipe;

[0039] (2) flow is that the anhydrous tetrahydrofuran of 20kg / h, the ortho-chlorotoluene that flow is 10kg / h and the toluene that flow is 10kg / h are passed in the first-level reactor by feed pipe, and step (1) in The mixed liquids are mixed and heated to 80°C to obtain a reaction mixture;

[0040](3) The reaction mixture enters the secondary reaction kettle through the overflow guide pipe of the primary reaction kettle, and is mixed with the incoming magnesium chips, heated to 80°C, an...

Embodiment 2

[0043] Utilize production equipment among the present invention to prepare o-chlorotoluene Grignard reagent, step is as follows:

[0044] (1) Be that the anhydrous tetrahydrofuran of 25kg / h, the ortho-chlorotoluene and the magnesium chips that the flow is 5kg / h are passed into the primary reaction kettle together through the first dipping pipe, anhydrous tetrahydrofuran, ortho-chlorotoluene and magnesium Chips are heated to 70°C while flowing through the first dipping pipe;

[0045] (2) flow is that the anhydrous tetrahydrofuran of 40kg / h, the ortho-chlorotoluene that flow is 10kg / h and the toluene that flow is 15kg / h are passed in the first-level reaction still by feeding pipe, with step (1) The mixed liquids are mixed and heated to 85°C to obtain a reaction mixture;

[0046] (3) The reaction mixture enters the secondary reaction kettle through the overflow guide pipe of the primary reaction kettle, and is mixed with the incoming magnesium chips, heated to 85°C, and the Grig...

Embodiment 3

[0049] Utilize production equipment among the present invention to prepare o-chlorotoluene Grignard reagent, step is as follows:

[0050] (1) Anhydrous tetrahydrofuran (THF) with a flow rate of 20kg / h, ortho-chlorotoluene and magnesium chips with a flow rate of 5kg / h are passed into the first-level reaction kettle together through the first dip tube, and anhydrous tetrahydrofuran (THF), ortho-chlorotoluene and magnesium Chips are heated up to 65°C while flowing through the first dipping pipe;

[0051] (2) flow is that the anhydrous tetrahydrofuran of 30kg / h, the ortho-chlorotoluene that flow is 10kg / h and the toluene that flow is 12kg / h are passed in the first-level reactor by feeding pipe, and step (1) in The mixed liquids are mixed and heated to 85°C to obtain a reaction mixture;

[0052] (3) The reaction mixture enters the secondary reaction kettle through the overflow guide pipe of the primary reaction kettle, and is mixed with the incoming magnesium chips, heated to 85°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com