Preparation method of non-binder titaniferous mercerizing molecular sieve catalyst

A technology without binder and catalyst, applied in the field of chemical catalytic materials and chemical applications, can solve the problems of easy blockage of molecular sieve channels, difficult separation, shortening, etc., and achieves the effects of obvious industrialization promotion and application prospects, solving separation difficulties, and convenient preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] a. Preparation of catalyst precursor particles

[0039]Mix 100g of fumed silica gel and 120g of sodium mordenite raw powder evenly, then dissolve 20g of sodium metaaluminate and 2g of sodium hydroxide in an appropriate amount of water and add to the above materials, mix and stir, extrude and shape into a clover-shaped catalyst Precursor, the shaped catalyst precursor is dried at 80°C for 10 hours to obtain catalyst precursor particles with a particle size of 0.1mm~1cm.

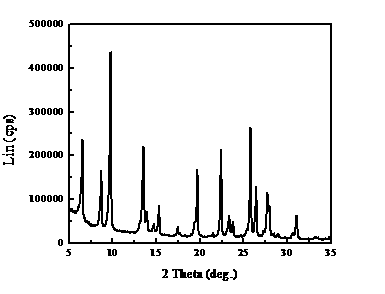

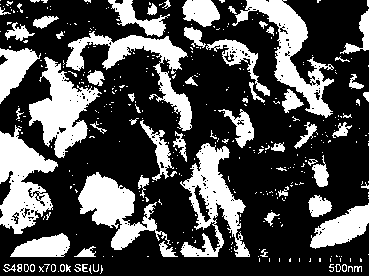

[0040] b, the preparation of mordenite

[0041] The catalyst precursor particles prepared by the above dry glue method were statically crystallized under water vapor at 170°C for 72 hours, and binder-free mordenite was synthesized in situ by an amine-free method.

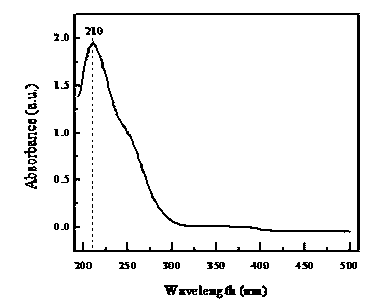

[0042] c. Ammonium exchange of mordenite

[0043] The mordenite prepared above without binder was washed twice with water and mixed with NH at a concentration of 1mol / L 4 The Cl aqueous solution is mixed at a weight ratio of 1:30, heated i...

Embodiment 2

[0053] a. Preparation of catalyst precursor particles

[0054] Mix 160g of alkaline silica sol and 120g of sodium mordenite raw powder evenly, then dissolve 18g of aluminum chloride and 9g of potassium hydroxide in an appropriate amount of water and add to the above materials, mix and stir, extrude and shape into a clover-shaped catalyst Precursor, the shaped catalyst precursor is dried at 80°C for 10 hours to obtain catalyst precursor particles with a particle size of 0.1mm~1cm.

[0055] b, the preparation of mordenite

[0056] The catalyst precursor particles prepared by the dry glue method were statically crystallized under water vapor at 140° C. for 120 hours, and binder-free mordenite was synthesized in situ by an amine-free method.

[0057] c. Ammonium exchange of mordenite

[0058] The mordenite prepared above without binder was washed twice with water and mixed with NH at a concentration of 1mol / L 4 The Cl aqueous solution is mixed at a weight ratio of 1:30, heated ...

Embodiment 3

[0068] a. Preparation of catalyst precursor particles

[0069] Mix 70g of water glass and 120g of sodium-type mordenite raw powder evenly, then dissolve 33g of aluminum sulfate and 40g of potassium carbonate in an appropriate amount of water and add them to the above materials, mix and stir, extrude and shape into cylindrical catalyst precursors, and form The catalyst precursor was dried at 80° C. for 10 h to prepare the catalyst precursor particles with a particle size of 0.1 mm to 1 cm.

[0070] b, the preparation of mordenite

[0071] The catalyst precursor particles prepared by the dry glue method were statically crystallized under water vapor at 150° C. for 96 hours, and binder-free mordenite was synthesized in situ by an amine-free method.

[0072] c. Ammonium exchange of mordenite

[0073] The mordenite prepared above without binder was washed twice with water and mixed with NH at a concentration of 1mol / L 4 The Cl aqueous solution is mixed at a weight ratio of 1:30,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com