Method for preparing dimethyl maleate

A technology of dimethyl maleate and maleic anhydride, which is applied in the field of preparing dimethyl maleate, can solve the problem of dimethyl maleate selectivity and yield reduction, material Difficult to separate and refine, difficult to remove water, etc., to achieve high selectivity and yield, reasonable process, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

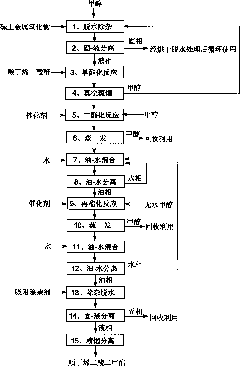

Image

Examples

Embodiment 1

[0050] Main process equipment The chemical reactor for monomethyl ester reaction, diesterification reaction and re-esterification reaction is a tank-type stirred chemical reactor, the solid-liquid separation device is a sedimentation type solid-liquid separation device, and the oil-water separation device is a sedimentation oil-water separator.

[0051] As shown in the figure, a method for preparing dimethyl maleate is to prepare dimethyl maleate with maleic anhydride and methanol as raw materials, and the method steps are as follows:

[0052] (1) Dehydration and impurity removal: methanol is added to the dehydration and impurity removal equipment, and alkaline earth metal oxides are added to mix evenly for dehydration and impurity removal operations. The alkaline earth metal oxides are calcium oxide, and the amount of calcium oxide is 1% of the methanol mass;

[0053] (2) Solid-liquid separation: The material obtained in the previous step is subjected to solid-liquid separati...

Embodiment 2

[0068] Main process equipment The chemical reactor for monomethyl ester reaction, diesterification reaction and re-esterification reaction is a tubular chemical reactor, the solid-liquid separation device is a filter type solid-liquid separation device, and the oil-water separation device is a centrifugal type Water separator.

[0069] As shown in the figure, a method for preparing dimethyl maleate is to prepare dimethyl maleate with maleic anhydride and methanol as raw materials, and the method steps are as follows:

[0070] (1) Dehydration and impurity removal: methanol is added to the dehydration and impurity removal equipment, and alkaline earth metal oxides are added to mix evenly for dehydration and impurity removal operations. The alkaline earth metal oxides are magnesium oxide, and the amount of magnesium oxide is 3% of the methanol mass;

[0071] (2) Solid-liquid separation: The material obtained in the previous step is subjected to solid-liquid separation in a filter...

Embodiment 3

[0086] Main process equipment The chemical reactor for monomethyl esterification reaction, diesterification reaction and re-esterification reaction is a static mixer, the solid-liquid separation device is a centrifugal solid-liquid separation device, and the oil-water separation device is a high-efficiency oil-water Splitter.

[0087] As shown in the figure, a method for preparing dimethyl maleate is to prepare dimethyl maleate with maleic anhydride and methanol as raw materials, and the method steps are as follows:

[0088] (1) Dehydration and impurity removal: Add methanol to the dehydration and impurity removal equipment, add alkaline earth metal oxides and mix evenly to perform dehydration and impurity removal operations. The alkaline earth metal oxides are barium oxide, and the amount of barium oxide is 4% of the methanol mass;

[0089] (2) Solid-liquid separation: The material obtained in the previous step is subjected to solid-liquid separation in a centrifugal solid-liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com