Jet combustion device and method for super-critical water oxidization of organic matter

A supercritical water oxidation and combustion device technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of easy corrosion and blockage of the reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A specific embodiment of the present invention is given below in conjunction with each accompanying drawing.

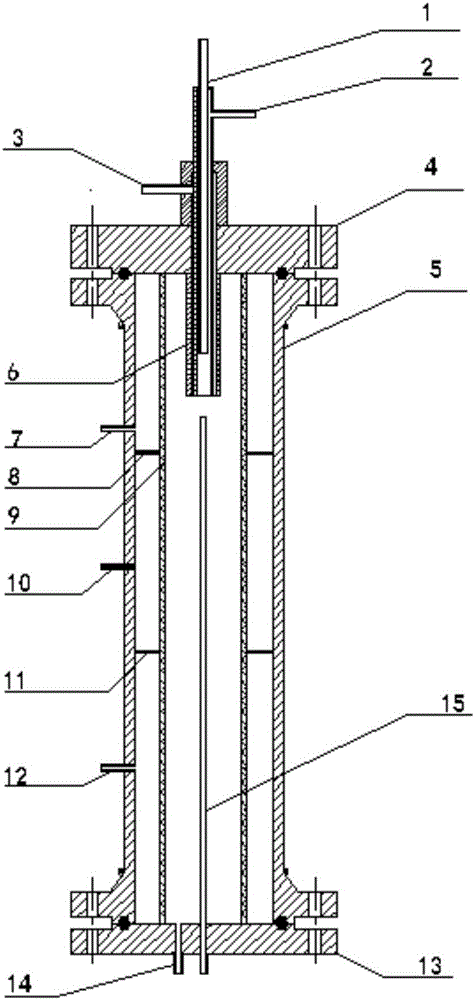

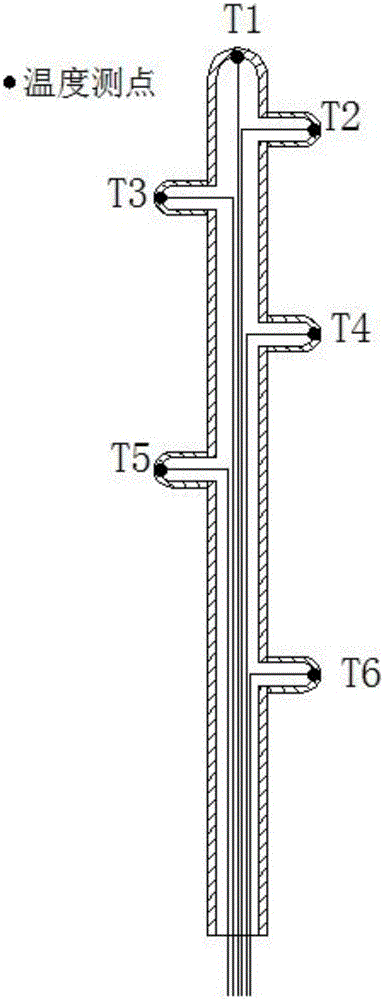

[0038] figure 1 The jet combustion device for the supercritical water oxidation of organic matter is composed of a reactor outer cylinder 5, a reactor inner cylinder 9, an upper flange end cover 4, a lower flange end cover 13, a coaxial jet burner 6, and a multi-point temperature measurement The envelope is composed of 15, and the reactor outer cylinder 5 and the upper and lower flange end covers 4, 13 are fastened by bolts, which is convenient for disassembly and assembly. The coaxial jet burner 6 is welded on the center line of the upper flange end cover 4 .

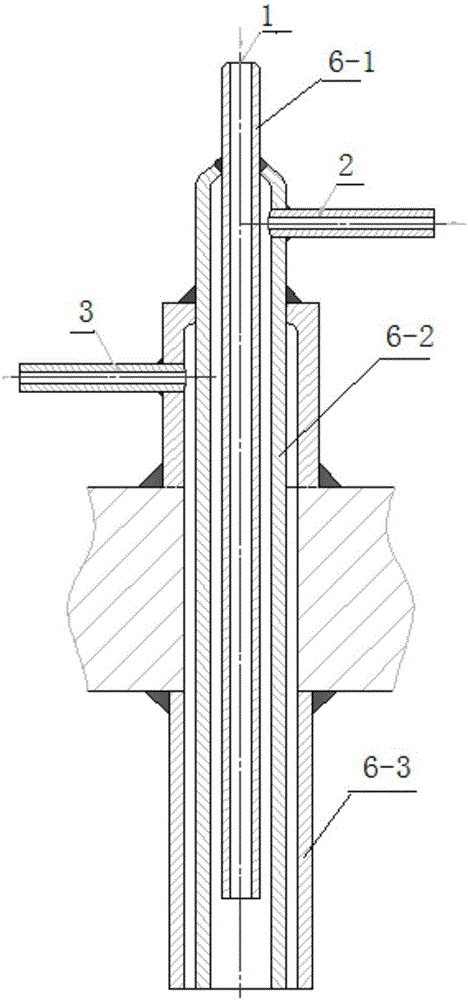

[0039] The coaxial jet burner 6 is a three-layer coaxial sleeve structure, including a central tube 6-1, an inner tube 6-2, and an outer tube 6-3; the central channel is formed by the central tube 6-1, and the central channel The inside is an auxiliary heat source; the middle annular channel is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com