Pressure sintering furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

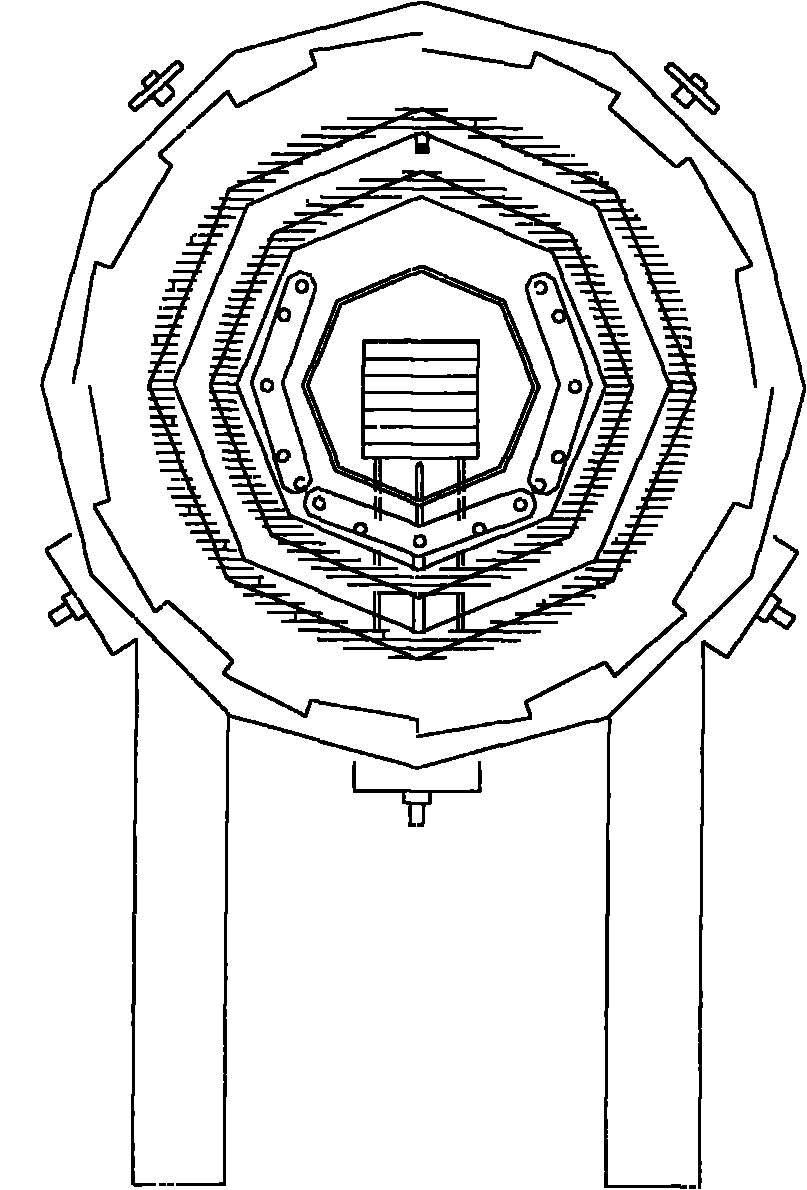

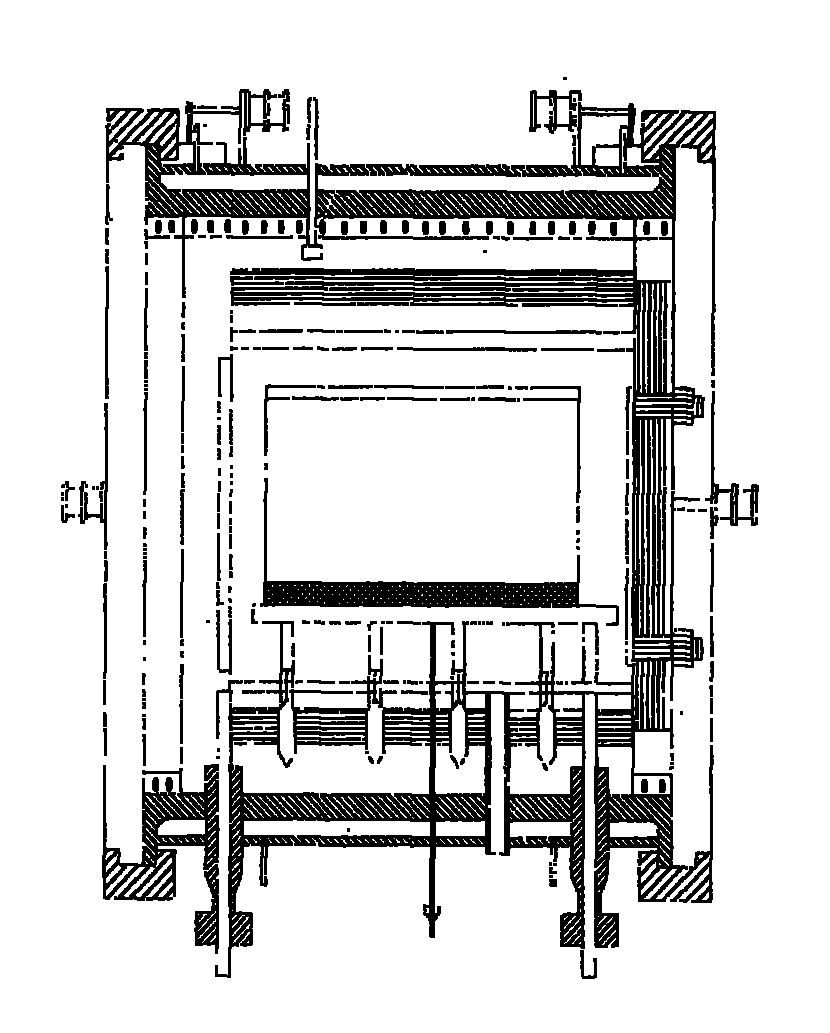

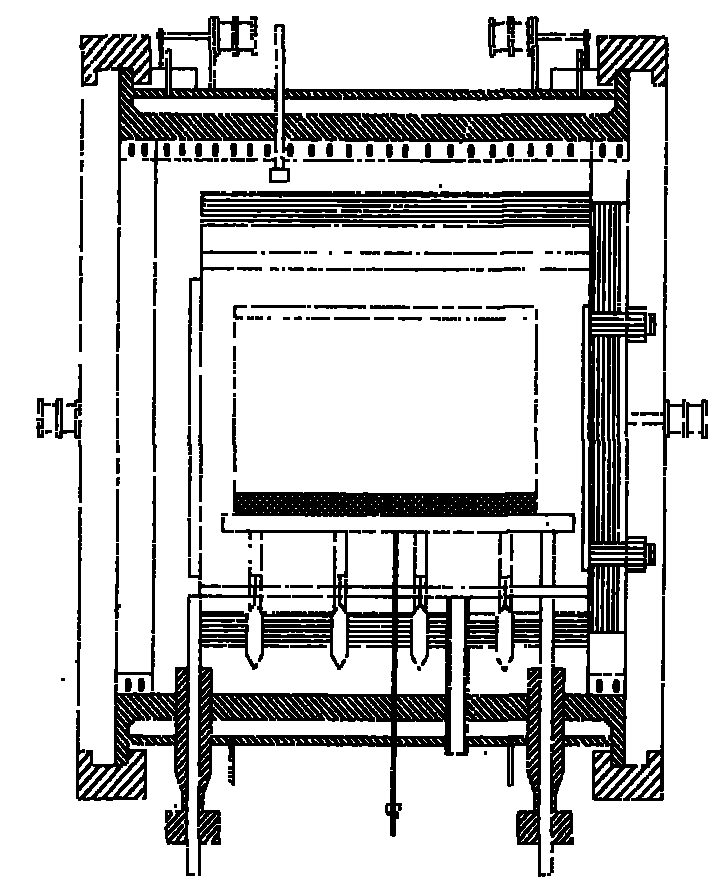

[0042] A pressure sintering furnace, such as figure 1 , figure 2 As shown, it includes a furnace shell, a vacuum system, a gas distribution system, a heating and heat preservation device, a pressurization system, a cooling system, and a pressure relief device. The furnace body is its core component, mainly including heat exchanger 1, safety plug 2, air inlet 3, insulation layer 4, furnace door 5, charging track 6, exhaust port 7, thermocouple 8, furnace shell 9, inlet Parts such as the electric column 10 and the heating element 11 are connected with the external pipe network through the interface on the furnace body. The distribution of the external pipe network system can be adjusted according to the user's installation site conditions.

[0043]The furnace shell 9 is a horizontal cylinder provided with a double-walled water jacket. The furnace door 5 on the furnace shell 9 is a quick-opening hydraulic side-rotating structure. The furnace door 5 of the furnace shell 9 inclu...

Embodiment 2

[0048] A pressure sintering furnace, such as figure 1 , figure 2 As shown, it includes a furnace shell, a vacuum system, a gas distribution system, a heating and heat preservation device, a pressurization system, a cooling system, and a pressure relief device. The furnace body is its core component, mainly including heat exchanger 1, safety plug 2, air inlet 3, insulation layer 4, furnace door 5, charging track 6, exhaust port 7, thermocouple 8, furnace shell 9, inlet Parts such as the electric column 10 and the heating element 11 are connected with the external pipe network through the interface on the furnace body. The distribution of the external pipe network system can be adjusted according to the user's installation site conditions.

[0049] The furnace shell 9 is a horizontal cylinder provided with a double-walled water jacket. The furnace door 5 on the furnace shell 9 is a quick-opening hydraulic side-rotating structure. The furnace door 5 of the furnace shell 9 incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com