Combined carton based on in-built reinforcement technology

A technology and a built-in technology, applied in the field of combined cartons, can solve the problems of inconvenient purchase of daily necessities, inability to classify and package food materials, and affect the taste of food materials, so as to avoid shaking, improve convenience, and ensure logistics hygiene and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

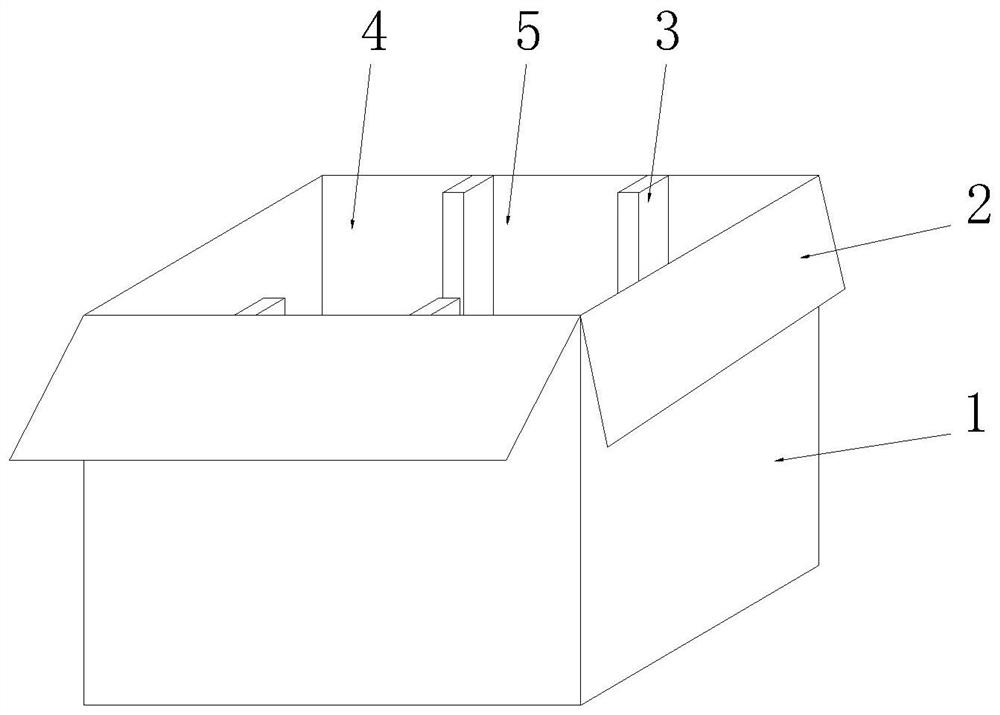

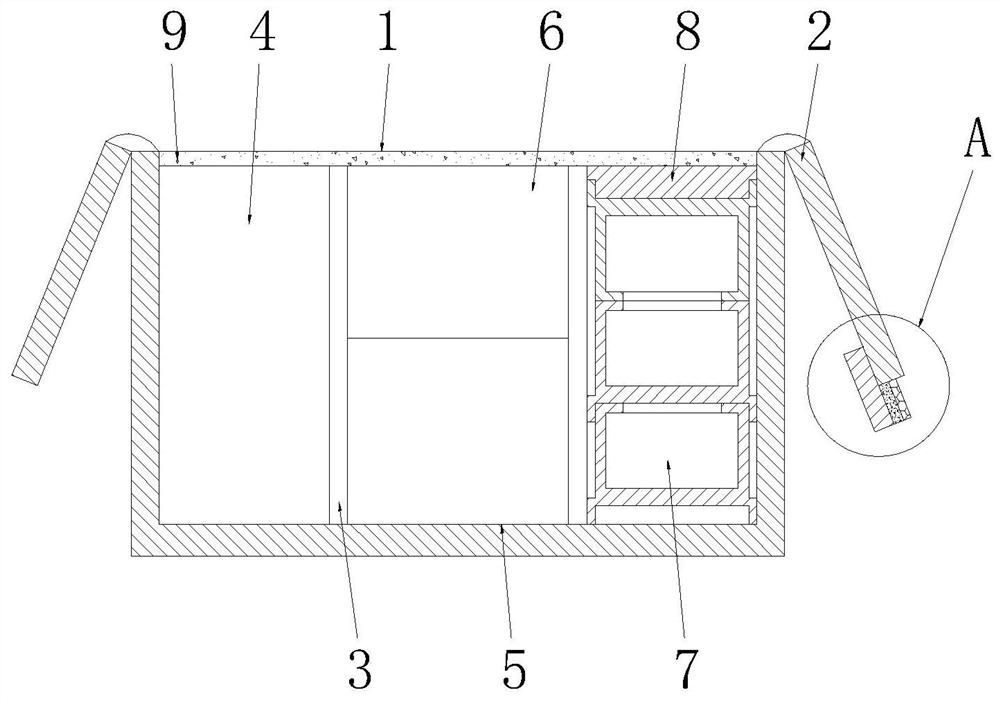

[0037] See Figure 1-3 , a combined carton based on internal reinforcement technology, including a box body 1, the box body 1 is a box-type structure with an open top, the opening end of the box body 1 is evenly hinged with a number of sealing plates 2, and the inside of the box body 1 The front and rear walls of the cavity are symmetrically provided with two pairs of vertical plates 3, the vertical plates 3 divide the inner cavity of the box body 1 into a main chamber 5 and two side chambers 4, and the main chamber 5 is arranged between the two pairs of vertical plates 3 Between, the two side chambers 4 are symmetrically arranged on the left and right sides of the main chamber 5, one of the side chambers 4 is evenly provided with a number of partition boxes 7, and the top opening of the side chamber 4 is provided with The auxiliary pressure box plate 8 matched with the partition box 7, several built-in boxes 6 are uniformly arranged in the main chamber 5, and the top opening ...

Embodiment 2

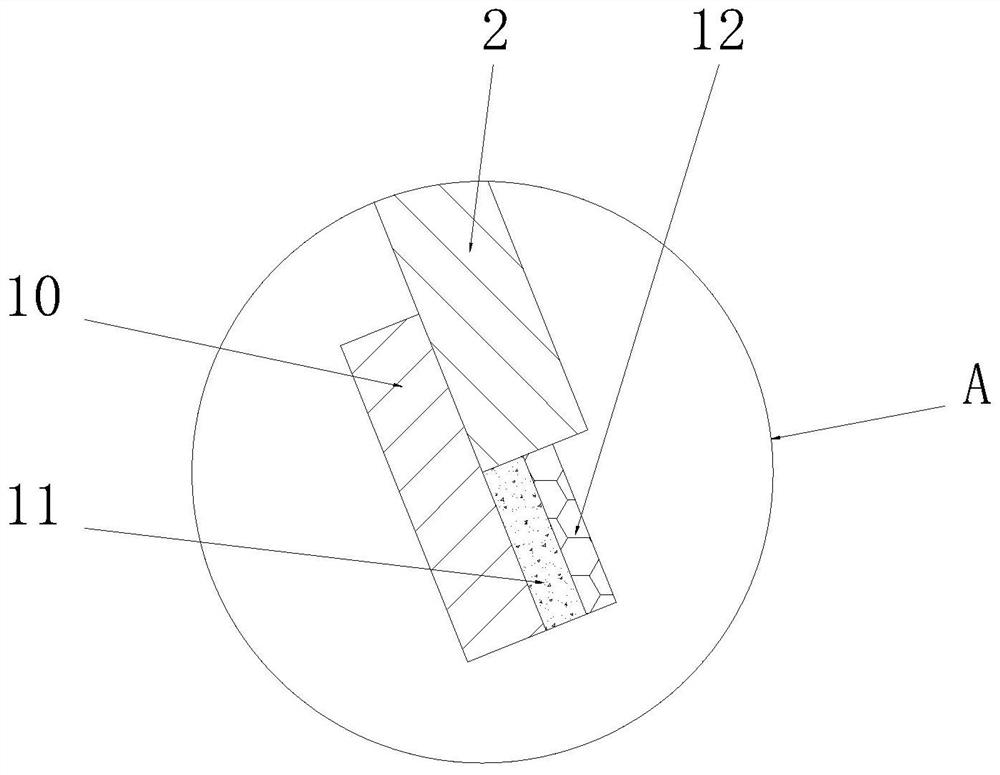

[0040] See Figure 4 The difference from Embodiment 1 is that the main pressure box board 9 includes a first base plate 91, which is a corrugated cardboard, and the bottom end of the first base plate 91 is provided with the built-in box 6 and the auxiliary pressure box. The first elastic layer 92 matched with the plate 8, the first elastic layer 92 is made of sponge, the top of the first substrate 91 is provided with a waterproof layer 93, and the waterproof layer 93 is made of rubber material As a result, the main pressure box plate 9 compresses the top openings of the side chamber 4 and the main chamber 5 through the first elastic layer 92, which can minimize the shaking of the ingredients in the box body 1, the built-in box 6 and the partition box 7, thereby It effectively avoids shaking and bumping of the ingredients during transportation; at the same time, the waterproof layer 93 cooperates with the sealing plate 2, which can greatly reduce the erosion of the ingredients ...

Embodiment 3

[0042] See Figure 5-6 , the difference from Embodiment 1 is that the partition box 7 includes a seat box 71 and a storage box 72, and the bottom end of the seat box 71 is provided with a card cavity 73 matched with the storage box 72, and the storage box 72 It is a box-type structure with an open top. The storage box 72 is fixedly connected to the top of the seat box 71. The storage box 72 and the seat box 71 are integrally formed. The opening end of the storage box 72 is provided with a card cavity 73 The matching support plate 74, the support plate 74 is an annular plate structure, the storage box 72 and the support plate 74 are integrally formed, the entire partition box 7 stores food materials through the storage box 72, and uses the card cavity 73 and the supporting plate 74 cooperate with each other to realize the vertical stacking of a plurality of partition boxes 7, thereby ensuring the stability of the stacking of the partition boxes 7 in the side chamber 4, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com