Hydraulic fixed fixture for ultra-thin fan metal piece machining

A technology for fixing fixtures and metal parts, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of inconvenient operation, high labor intensity, and excessive pressing, so as to reduce the use of labor and improve the The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

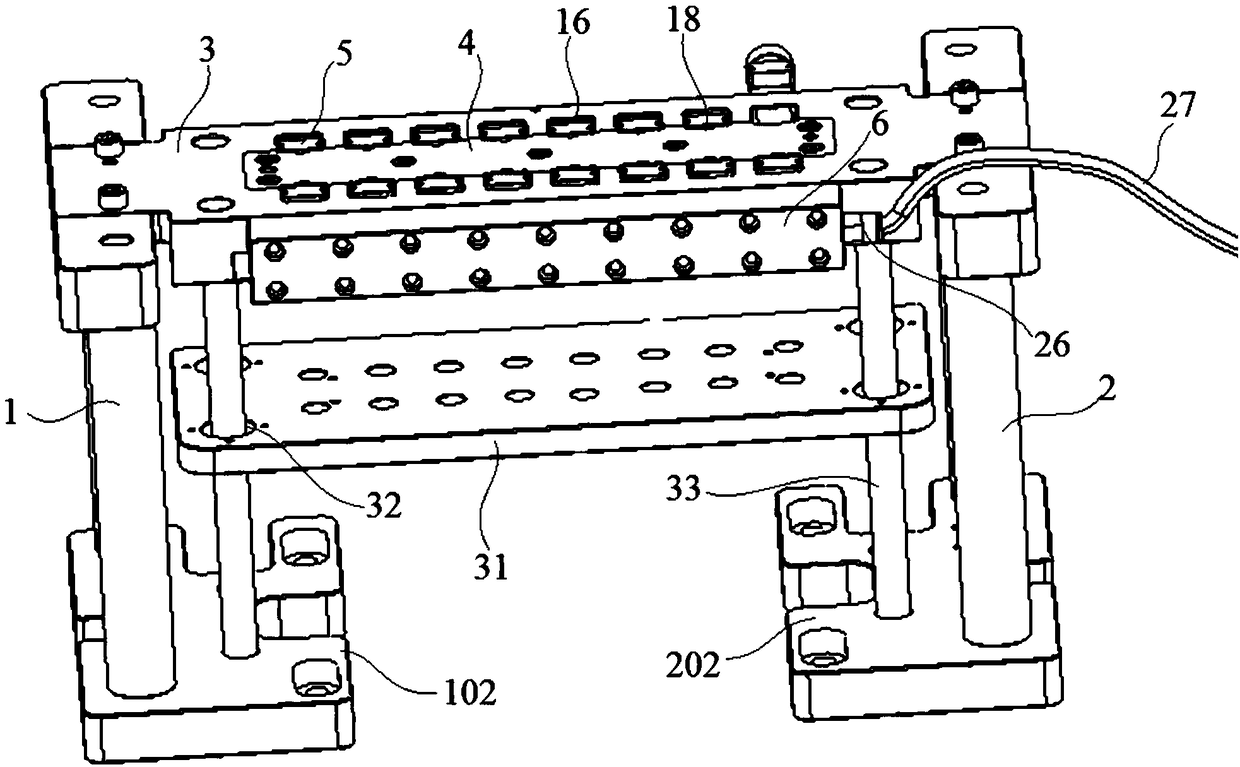

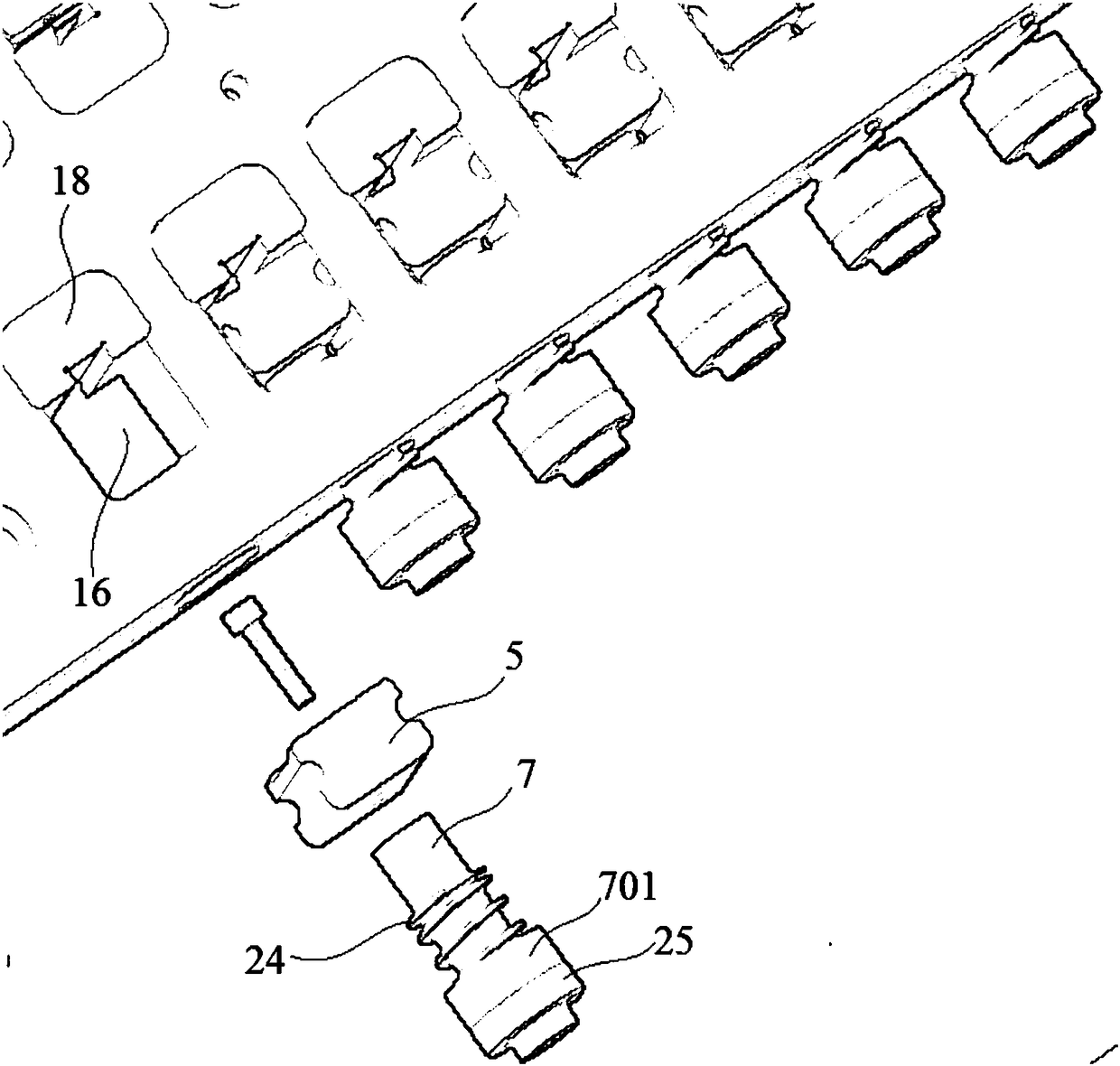

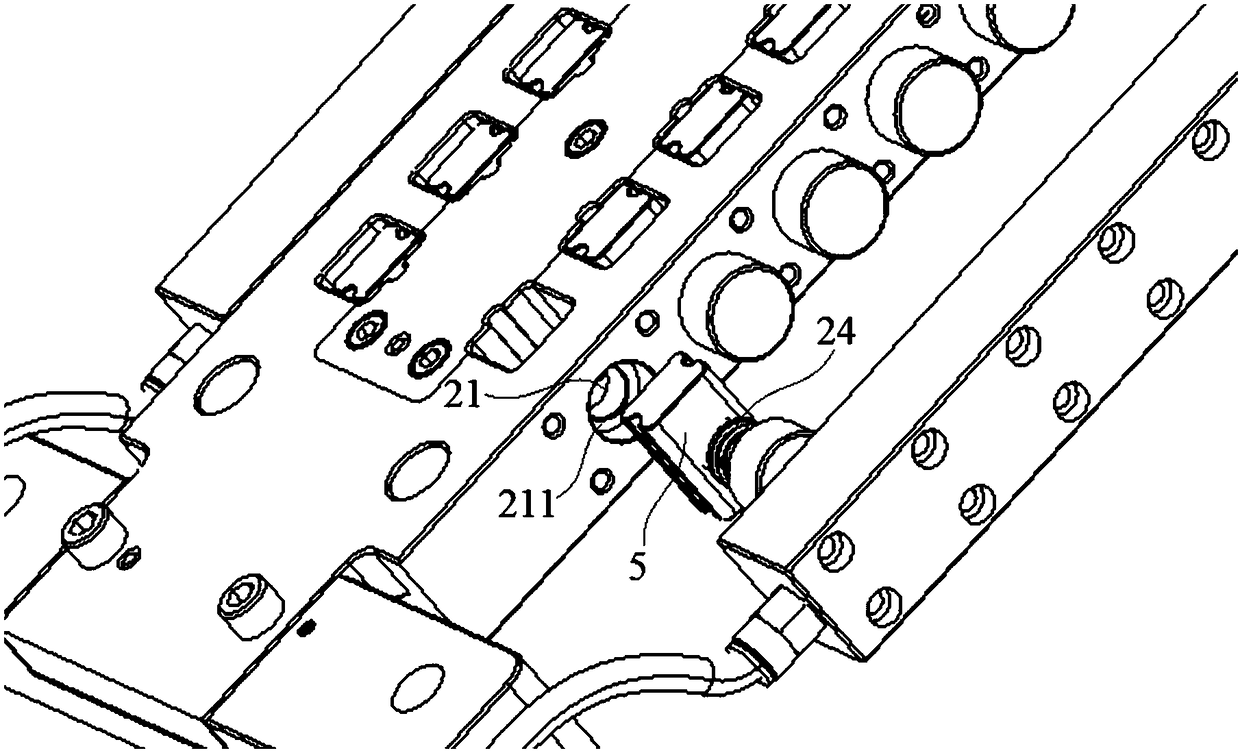

[0027]Embodiment 1: A hydraulic fixing fixture for ultra-thin fan metal parts processing, including left support 1, right support 2, fixed plate 3, positioning plate 4, chuck 5 and pressure mechanism 6, the fixed The two ends of the plate 3 are fixedly connected with the left support 1 and the right support 2 respectively, the positioning plate 4 is fixedly connected with the fixed plate 3, and the pressure mechanism 6 is symmetrically installed on both sides of the fixed plate 3 respectively. The head 5 is respectively installed on the end of the piston rod 7 of the pressure mechanism 6;

[0028] Both sides of the upper surface of the fixing plate 3 are symmetrically opened with a number of uniformly arranged relief through holes 16, and the positioning protrusions 18 and chucks 5 of the positioning plate 4 are located in the relief through holes 16, wherein the positioning protrusions 18 Located on the side close to the center, the chuck 5 is located on the side away from th...

Embodiment 2

[0033] Embodiment 2: A hydraulic fixing jig for processing ultra-thin fan metal parts, including a left support 1, a right support 2, a fixed plate 3, a positioning plate 4, a chuck 5 and a pressure mechanism 6, the fixed The two ends of the plate 3 are fixedly connected with the left support 1 and the right support 2 respectively, the positioning plate 4 is fixedly connected with the fixed plate 3, and the pressure mechanism 6 is symmetrically installed on both sides of the fixed plate 3 respectively. The head 5 is respectively installed on the end of the piston rod 7 of the pressure mechanism 6;

[0034] Both sides of the upper surface of the fixing plate 3 are symmetrically opened with a number of uniformly arranged relief through holes 16, and the positioning protrusions 18 and chucks 5 of the positioning plate 4 are located in the relief through holes 16, wherein the positioning protrusions 18 Located on the side close to the center, the chuck 5 is located on the side awa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com