Patents

Literature

41results about How to "Eliminate pressure loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

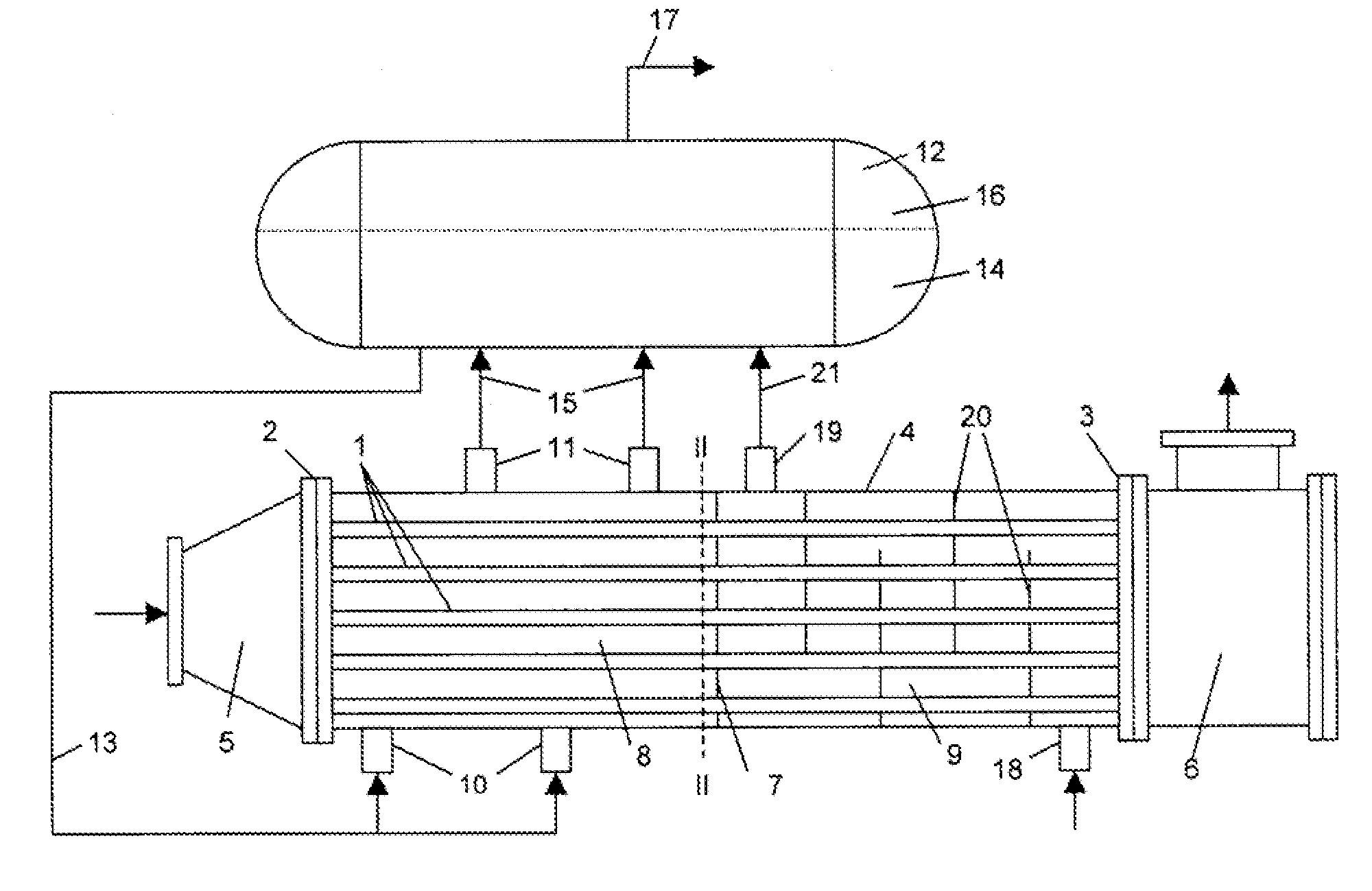

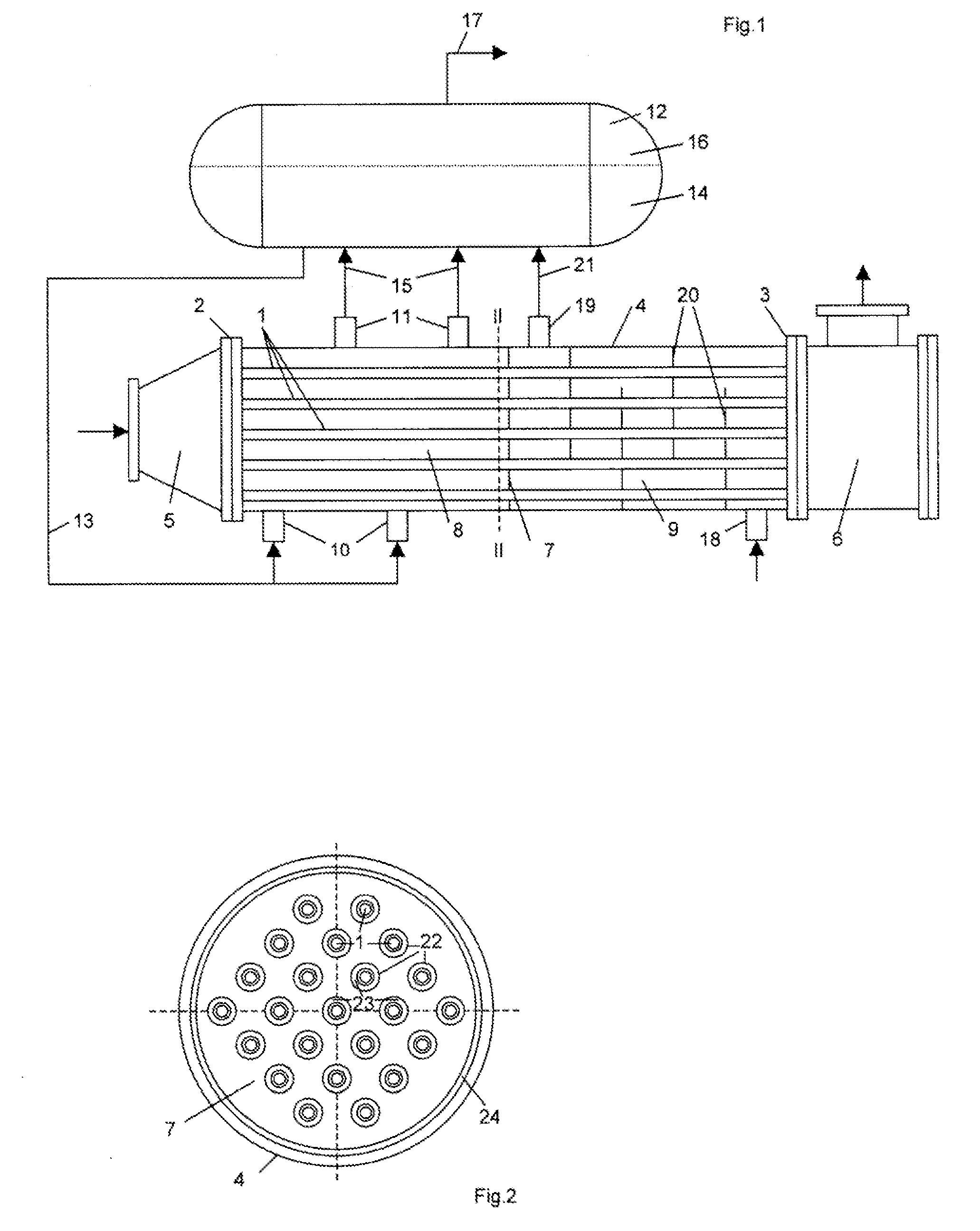

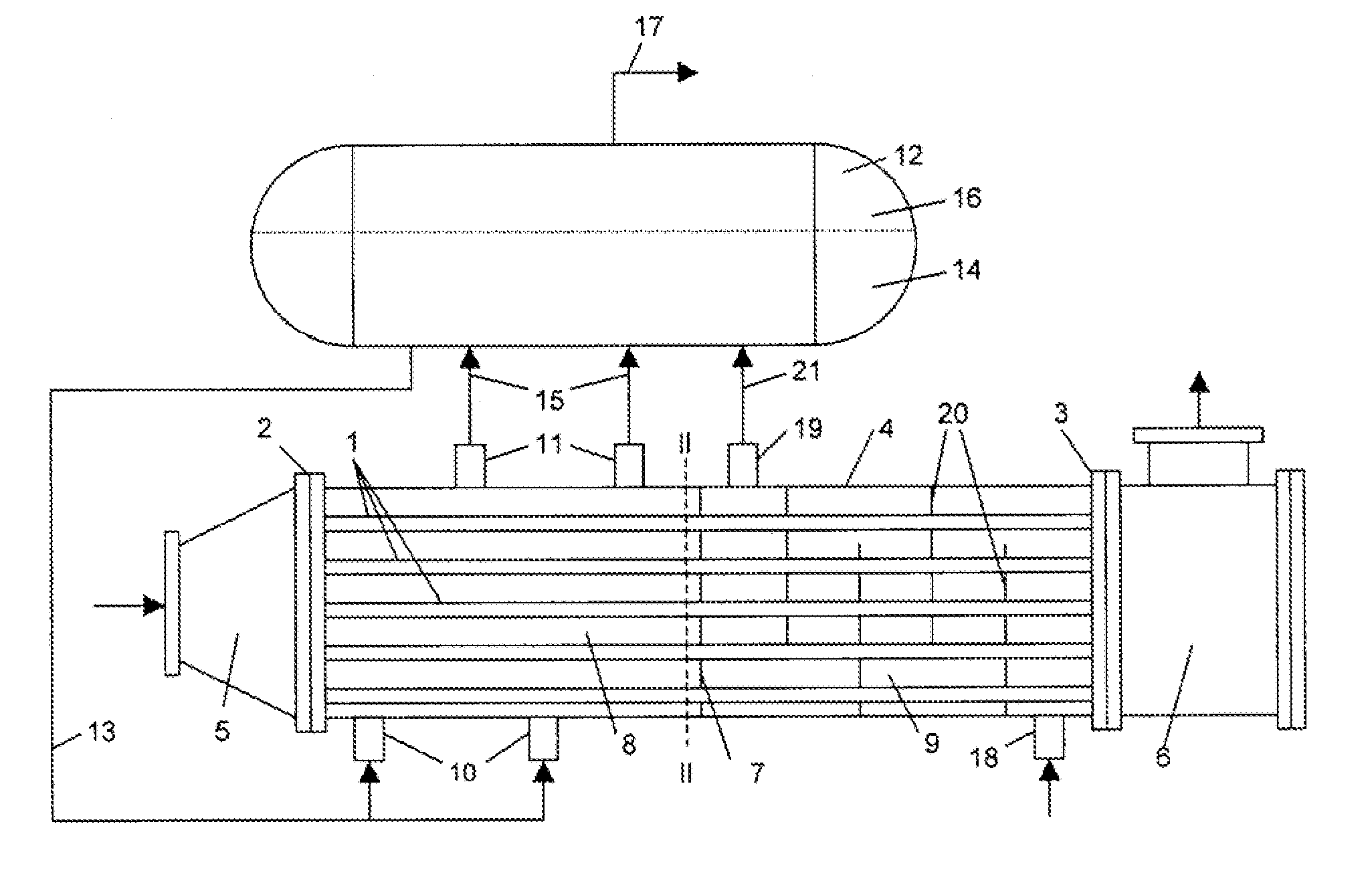

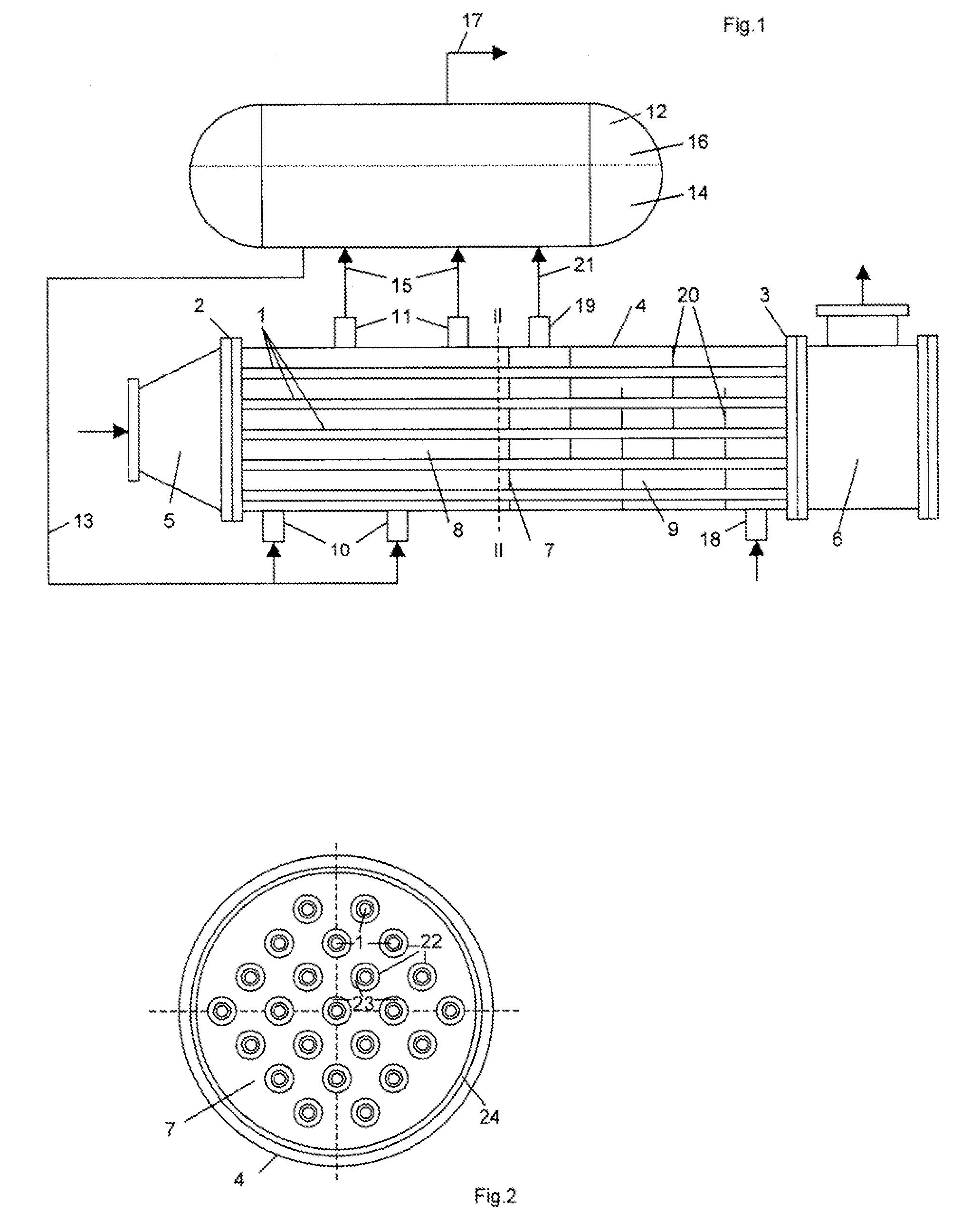

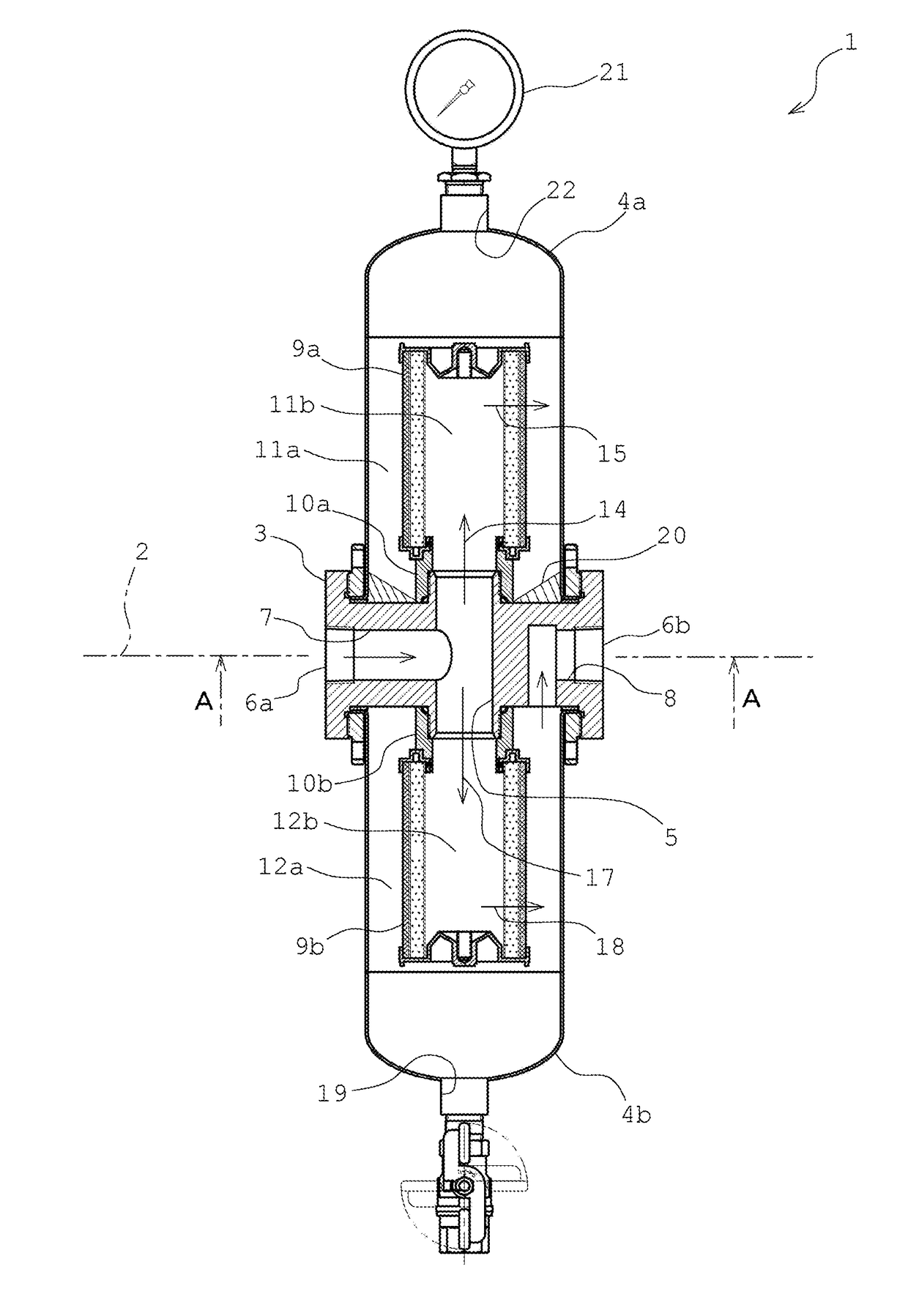

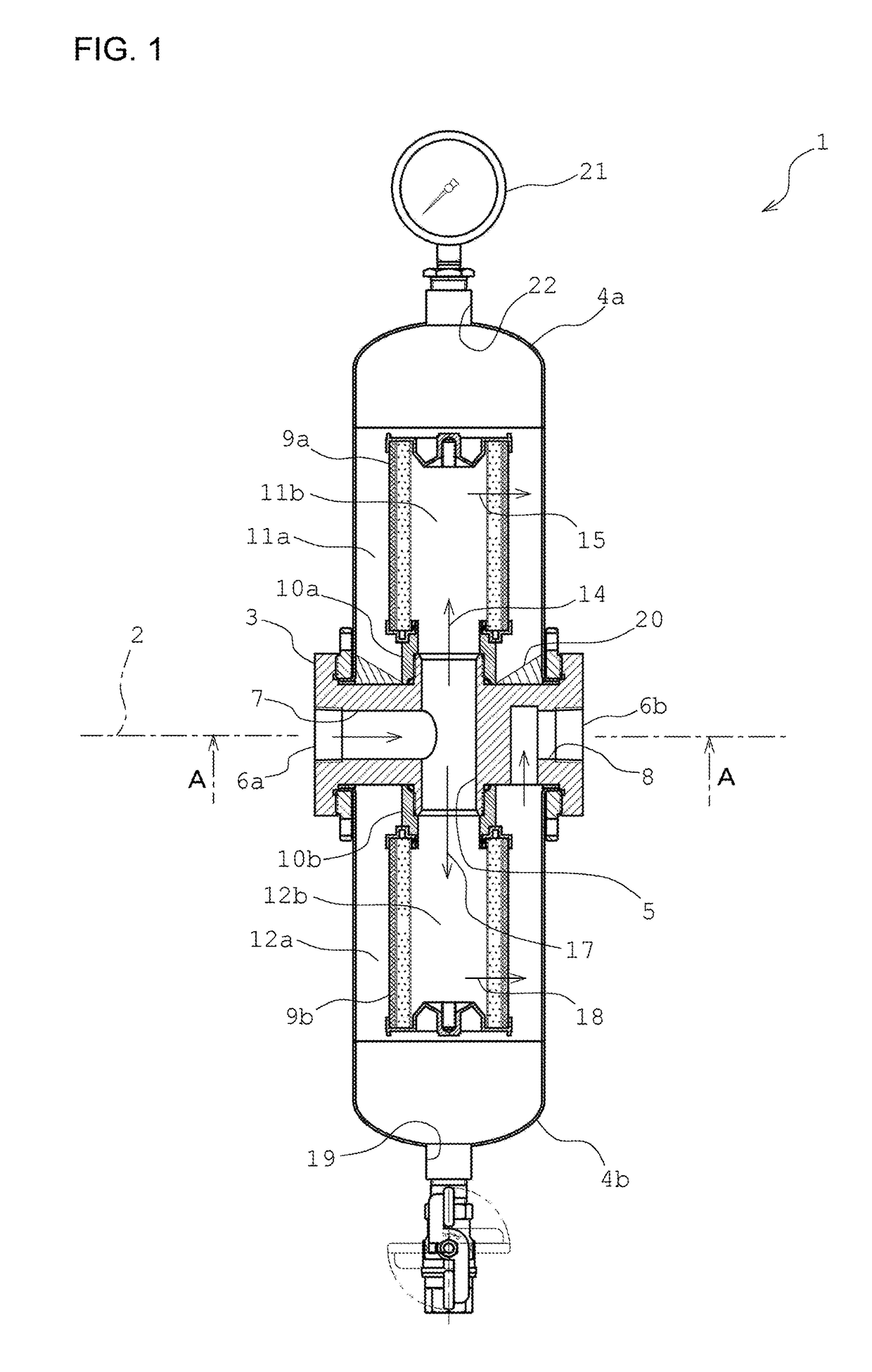

Heat exchanger for cooling reaction gas

ActiveUS20080121383A1Improve cooling effectSimple structureSteam generation heating methodsHeat exchanger casingsPlate heat exchangerNuclear engineering

A heat exchanger for cooling reaction gas, wherein the respective ends of heat exchanger tubes, through which the reaction gas flows, are inserted in a respective tube plate and are surrounded by a jacket, at the two ends of which are provided a respective end chamber that is partially delimited by one of the tube plates and serves for the supply and withdrawal of the reaction gas; water, as cooling agent, flows through the inner chamber of the heat exchanger that is surrounded by the jacket and that is divided by a partition, extending perpendicular to the heat exchanger tubes, which extend through it, into two partial chambers disposed one after the other in the direction of flow of the reaction gas, each partial chamber being provided with its own supply connectors and outlet connectors for the cooling agent; boiling water flows through the partial chamber that is disposed on the inlet side for reaction gas and that is connected via a supply line and withdrawal lines with a water / steam drum; feed water flows through the partial chamber that is disposed on the outlet side for the reaction gas and that is connected via a withdrawal line with the water / steam drum. The partition between the two partial chambers permits the passage of the cooling agent that flows in the inner chamber of the heat exchanger.

Owner:BORSIG AG

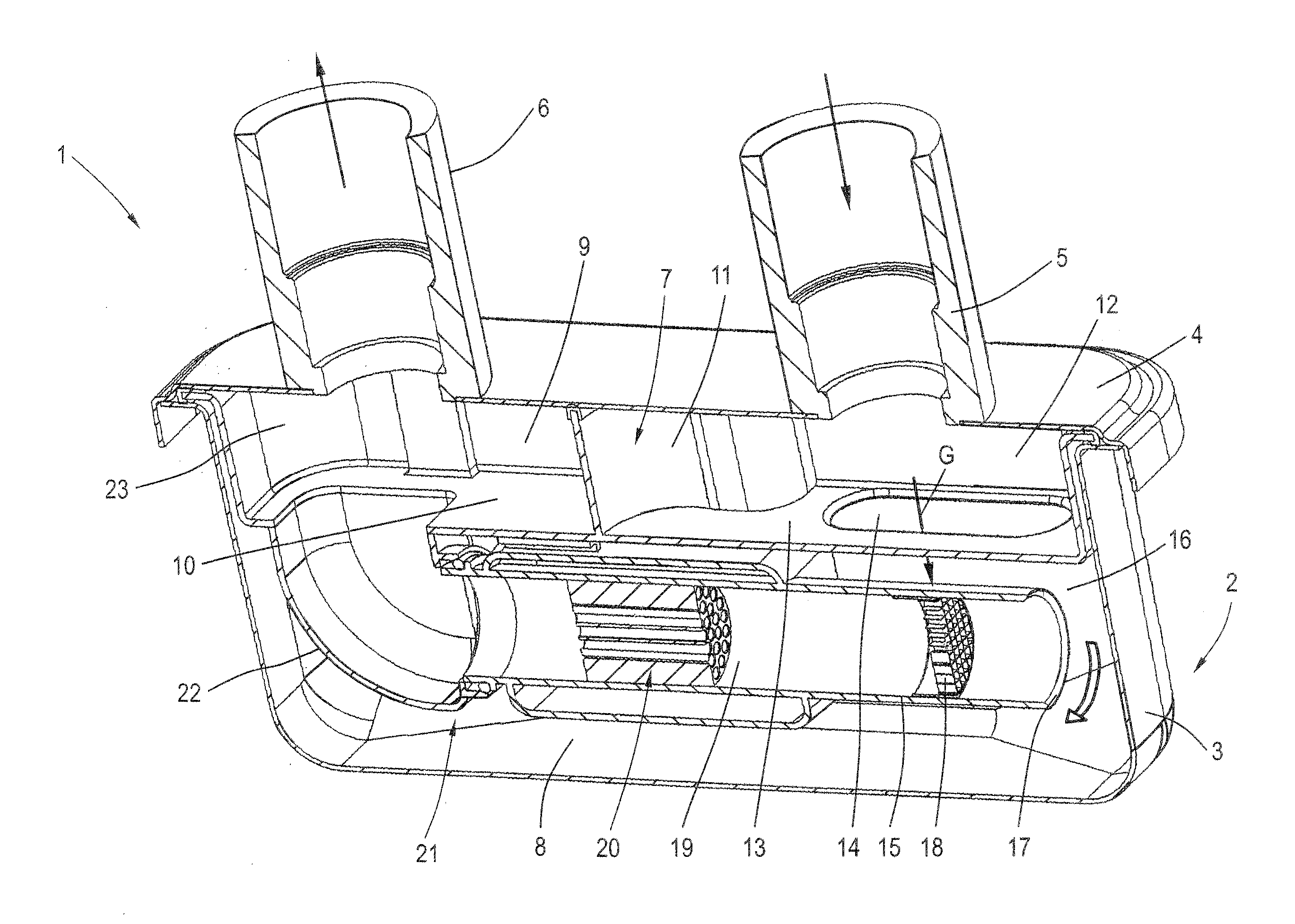

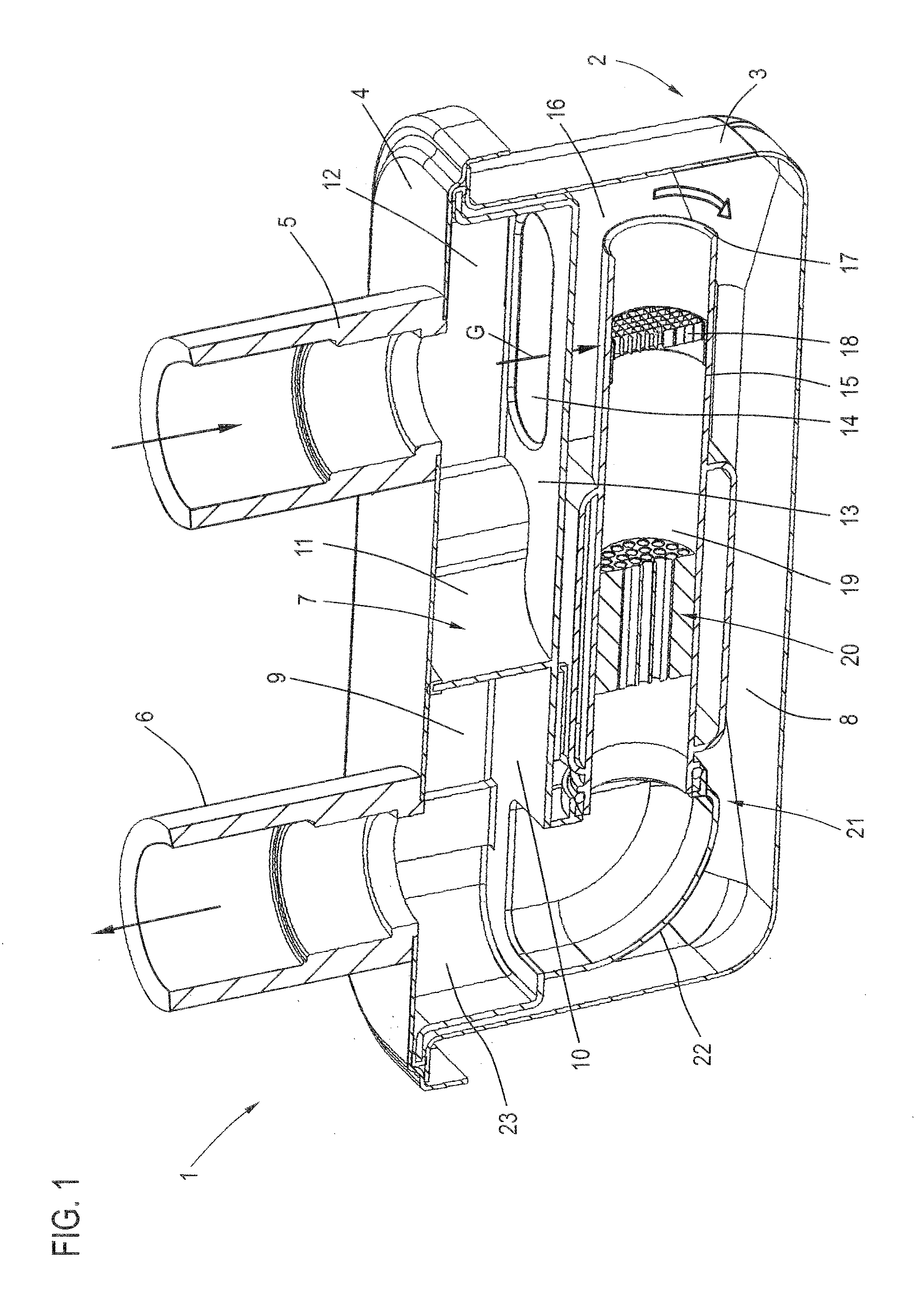

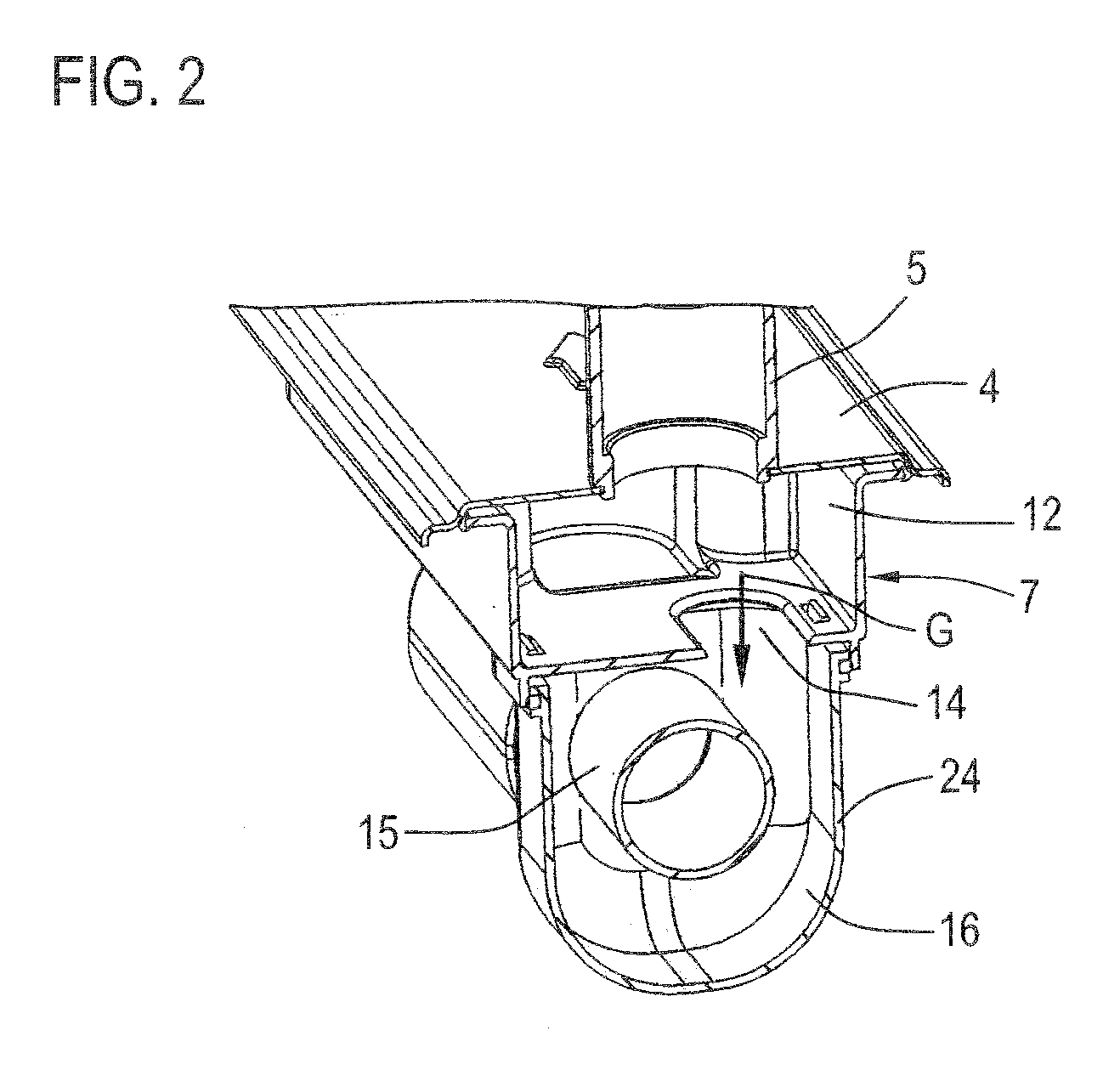

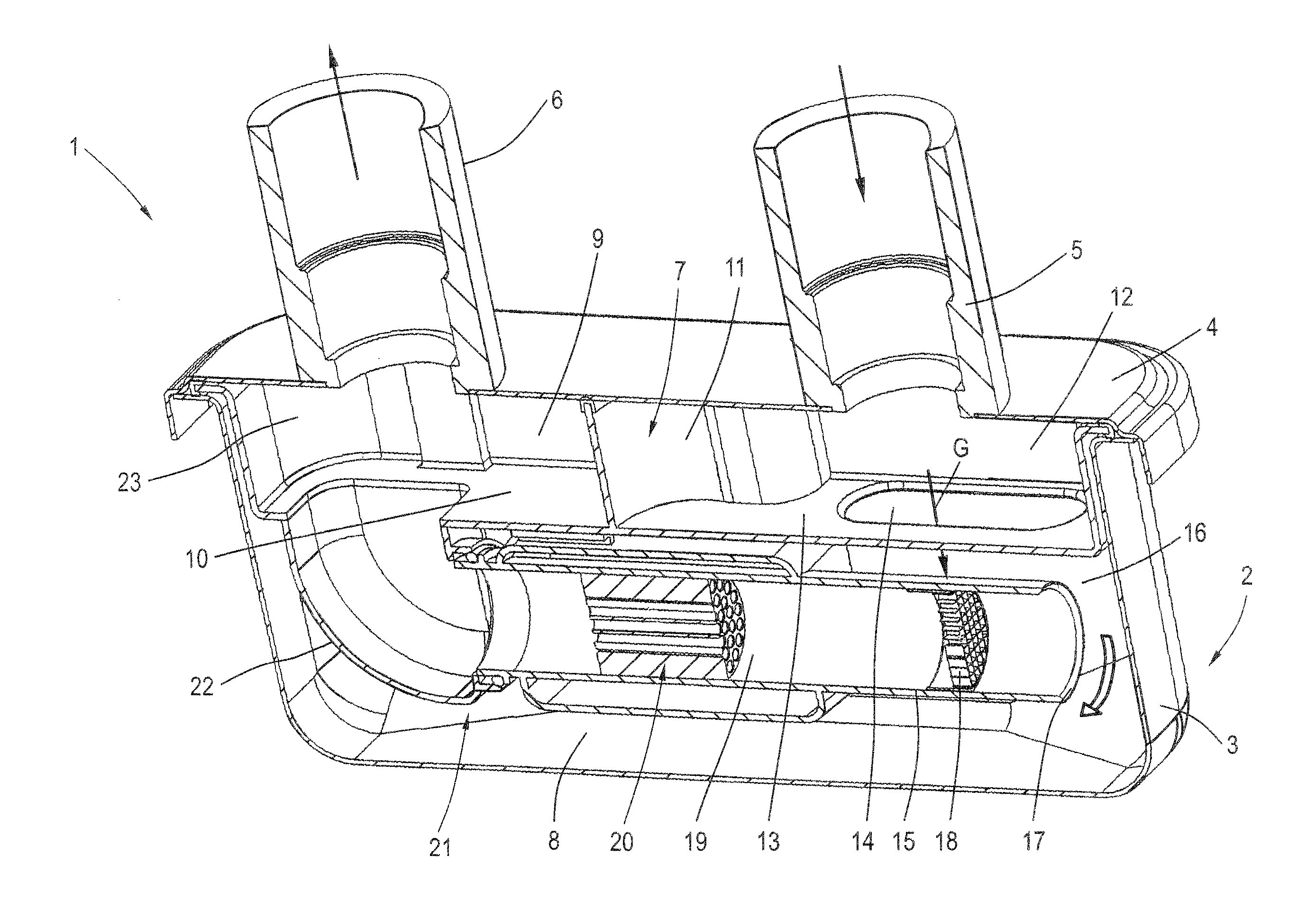

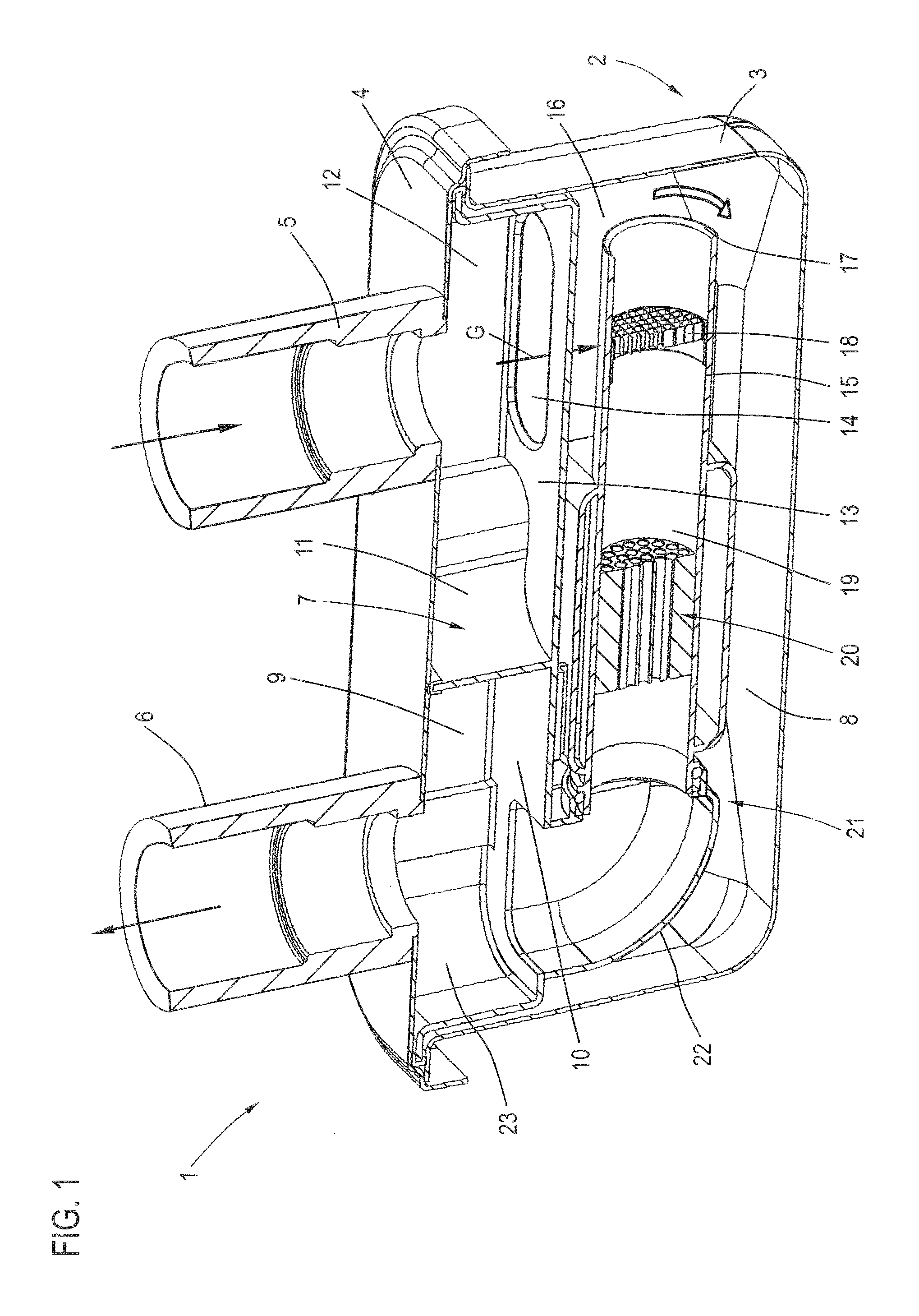

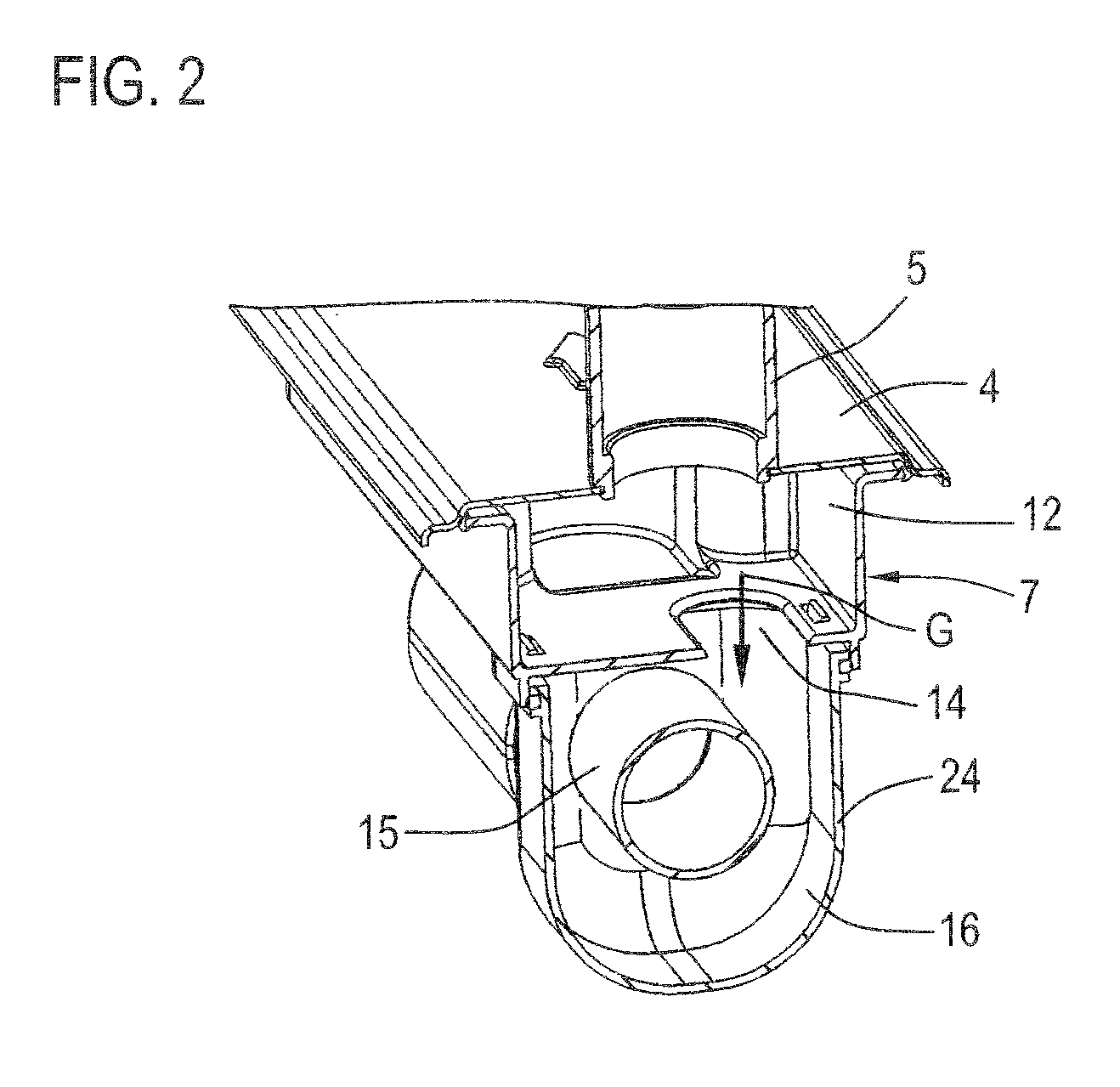

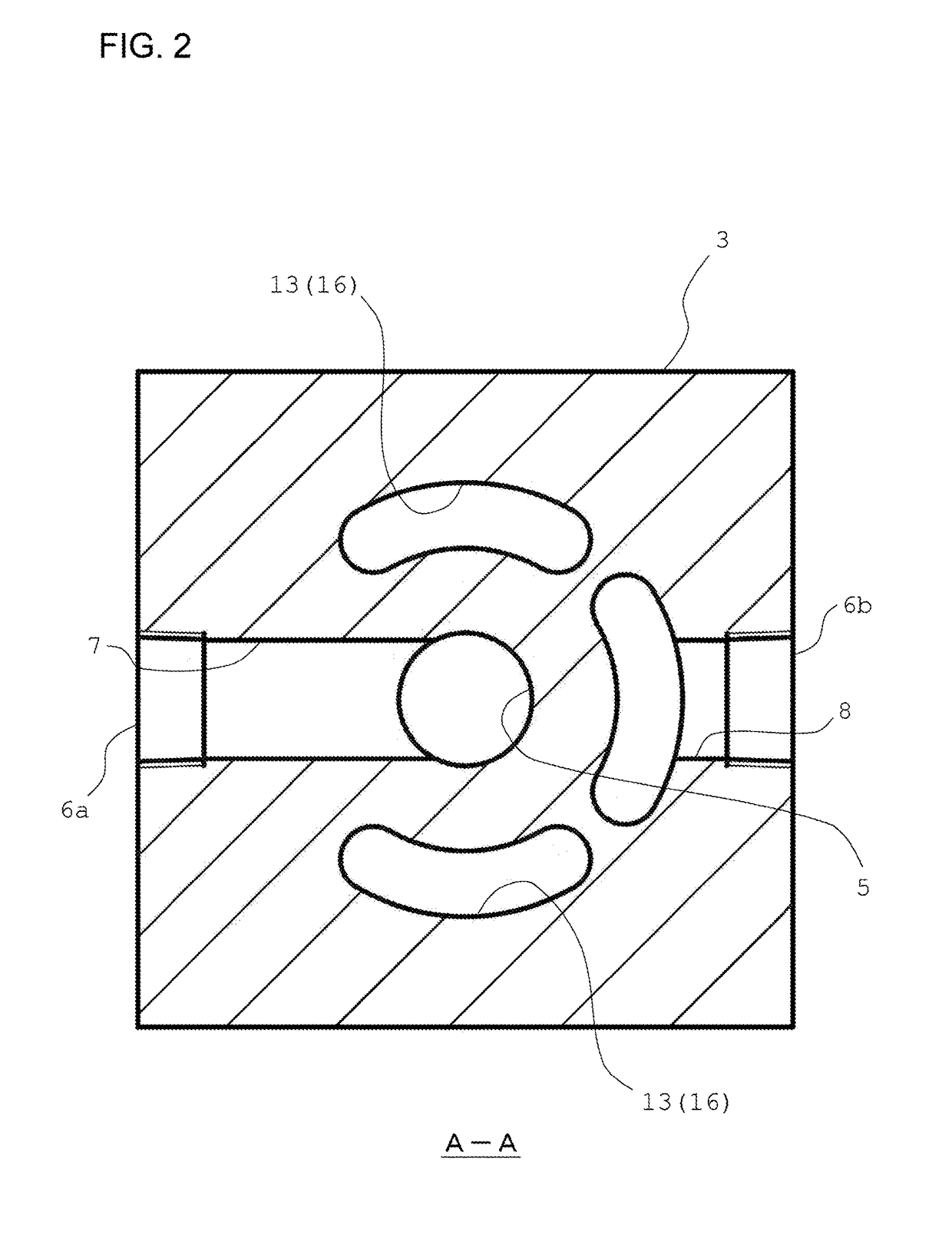

Gas meter

InactiveUS20120118407A1Negatively uniformity of flowEliminate pressure lossValve arrangementsVolume/mass flow by thermal effectsGas passingGas meter

A gas meter comprising a housing (2) with a gas inlet connection (5) and an inflow chamber (16) which is arranged downstream of the latter and into which gas flows via an inflow opening (14), arranged downstream of which inflow chamber (16) is a measuring section (19) arranged upstream of a gas outlet connection (6) and having a measuring device (20), in which the gas flow is measured, wherein projecting into the inflow chamber (16) there is a tube (15) which merges into the measuring section (19) or forms the latter and runs substantially perpendicularly to the gas flow direction through the inflow opening (14) and overlaps the inflow opening (14), at least in a certain section.

Owner:HYDROMETER GMBH

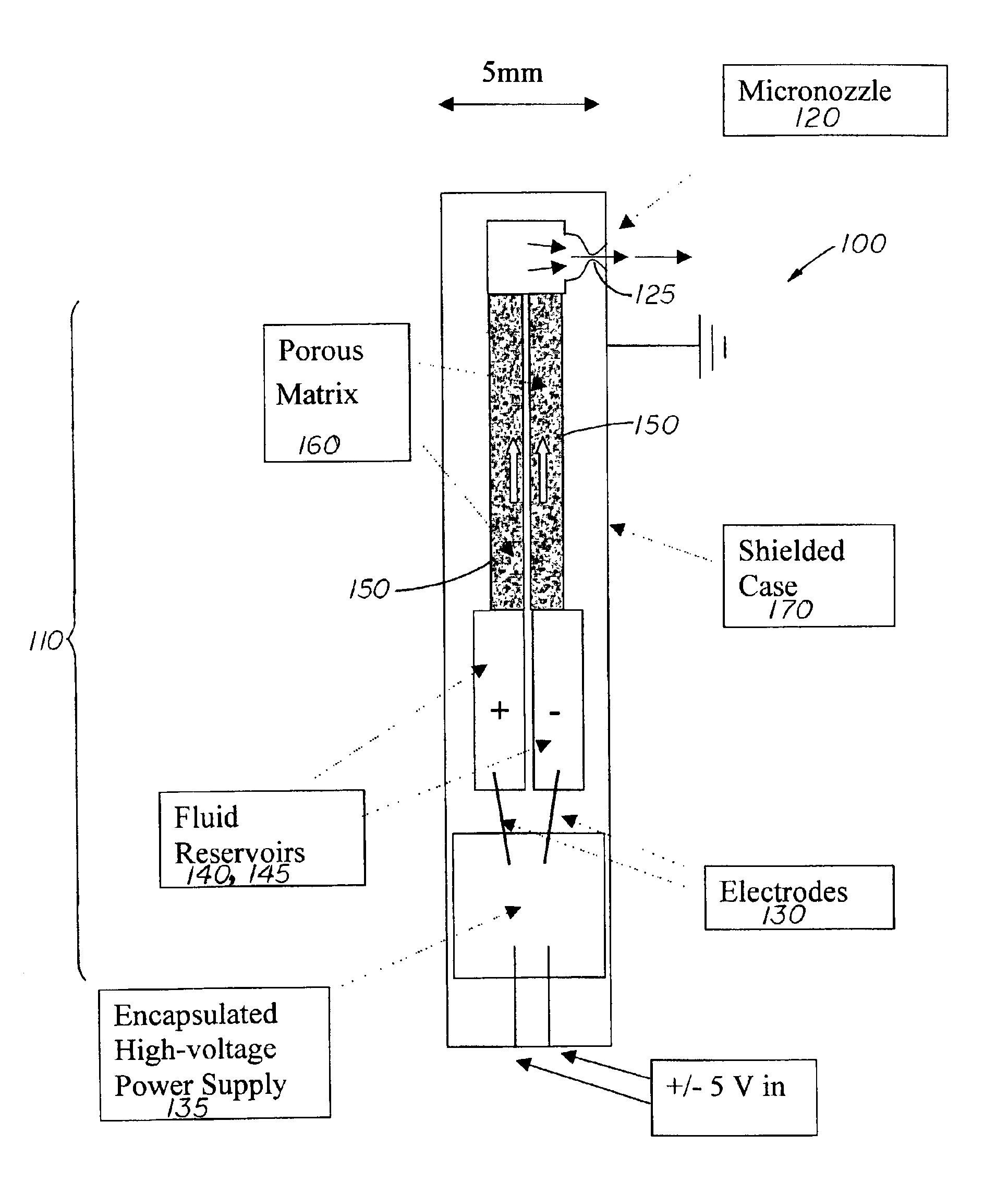

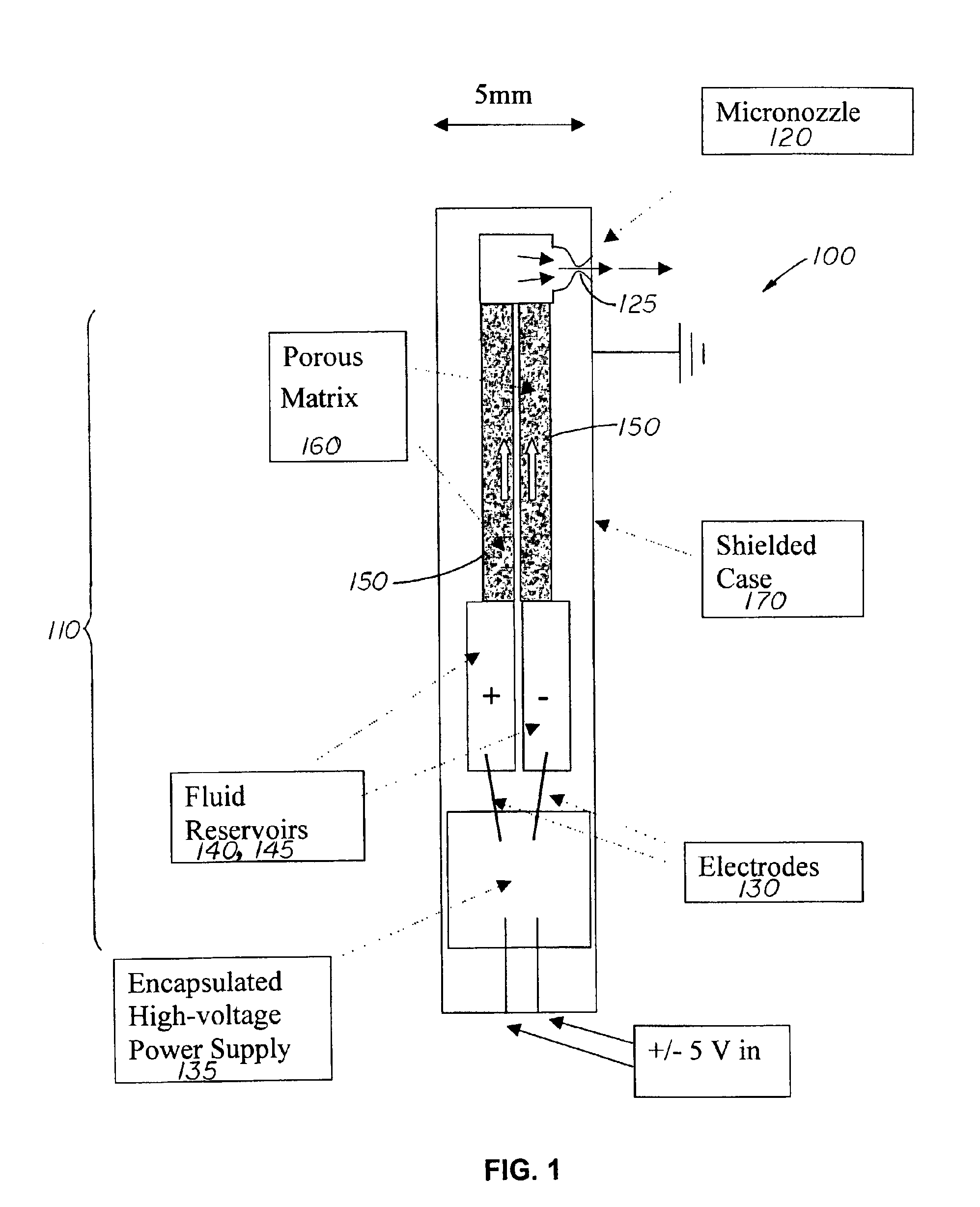

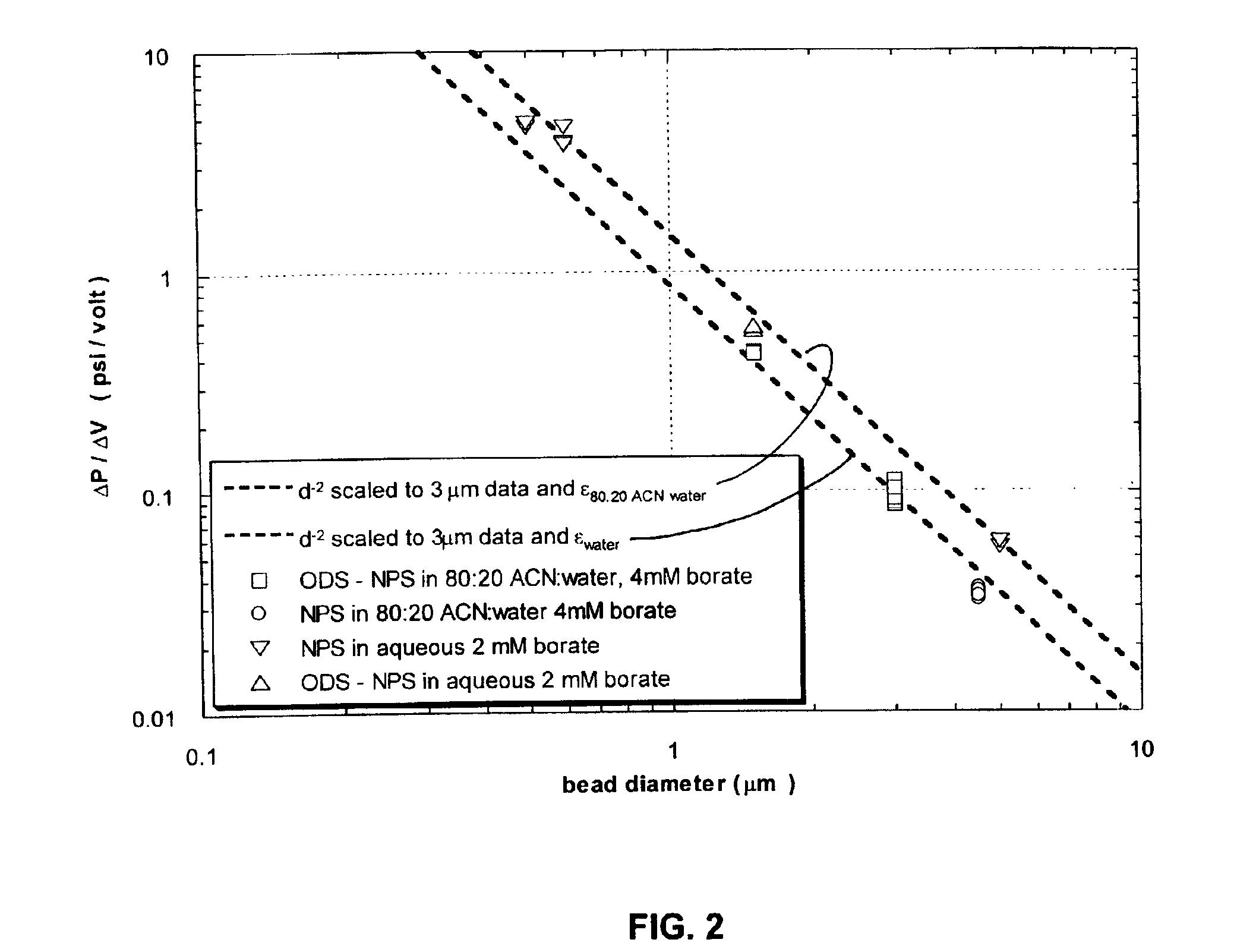

Electrokinetically pumped high pressure sprays

InactiveUS6960285B2Improve abilitiesInexpensive mass productionSludge treatmentVolume/mass flow measurementEngineeringHigh pressure

An electrokinetic pump capable of producing high pressure is combined with a nozzle having a submicron orifice to provide a high pressure spray device. Because of its small size, the device can be contained within medical devices such as an endoscope for delivering biological materials such as DNA, chemo therapeutic agents, or vaccines to tissues and cells.

Owner:SANDIA NAT LAB

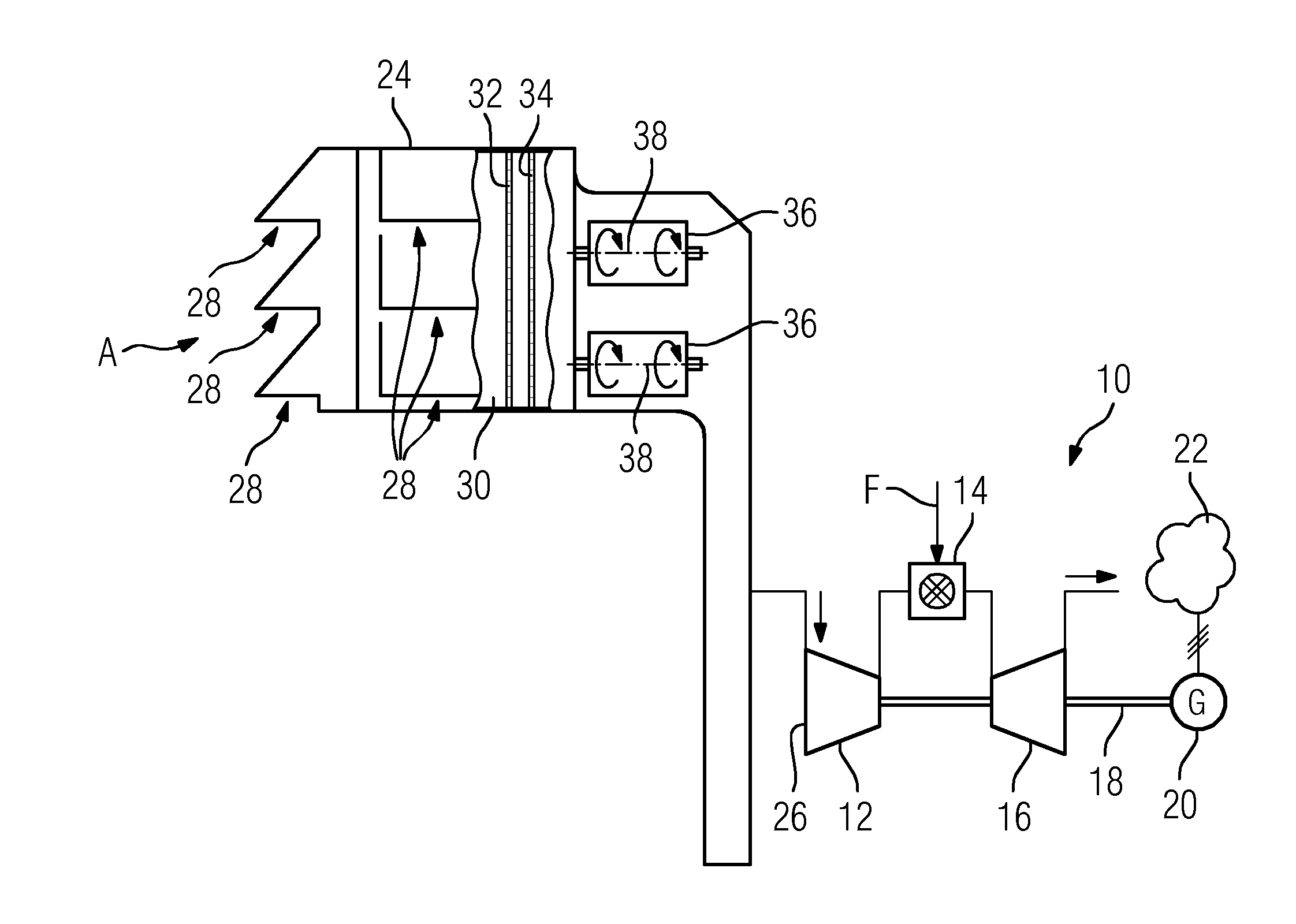

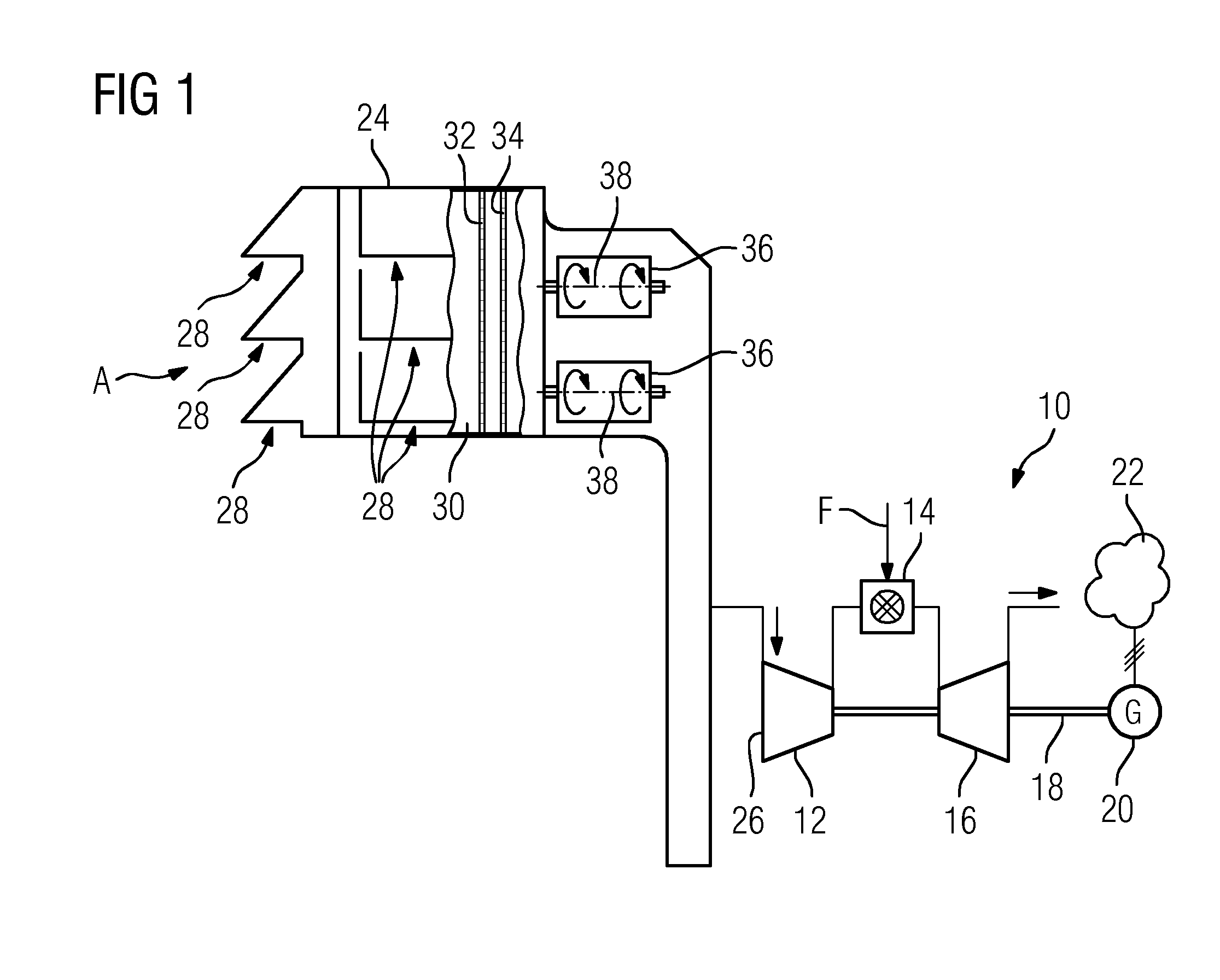

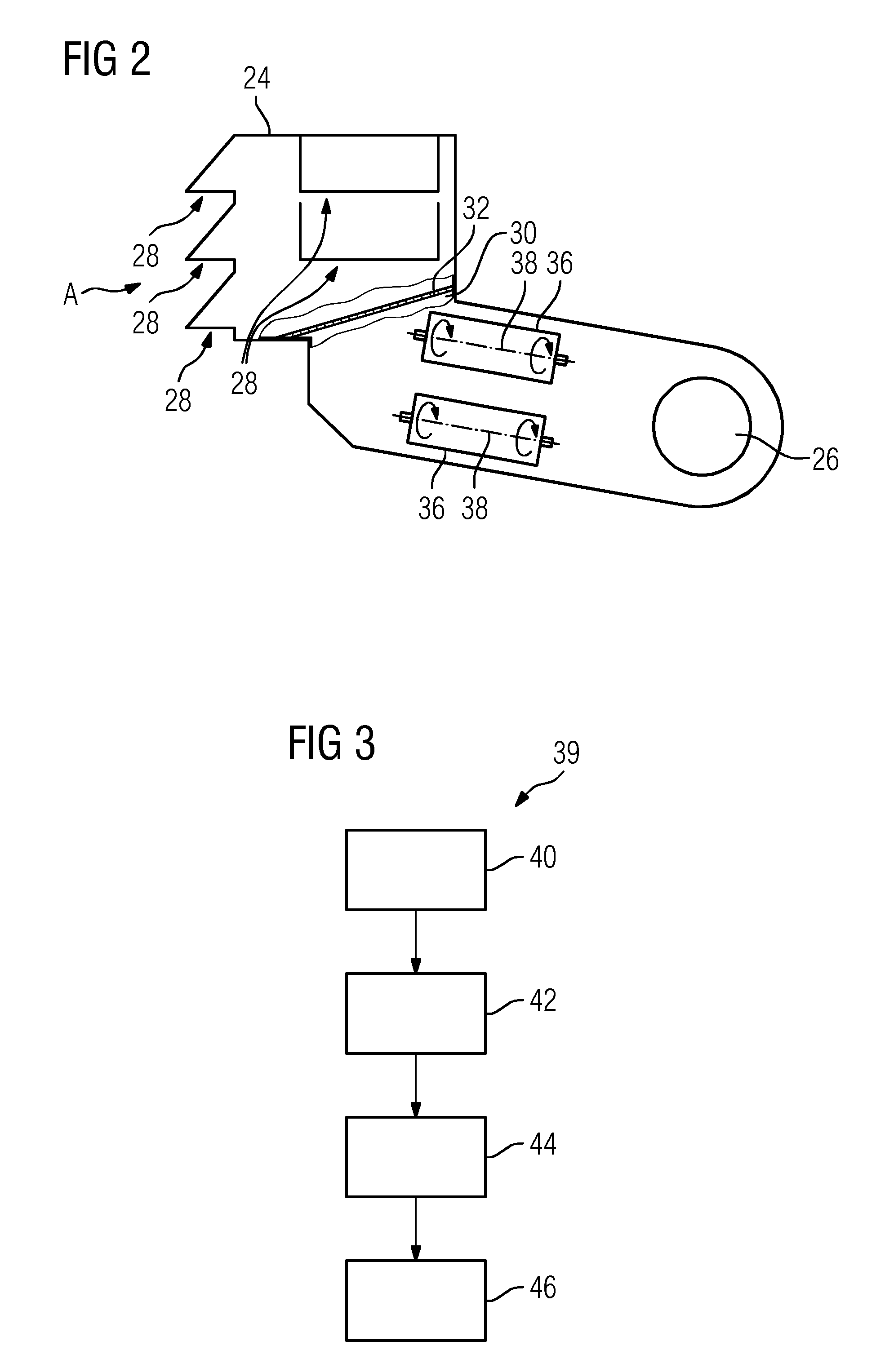

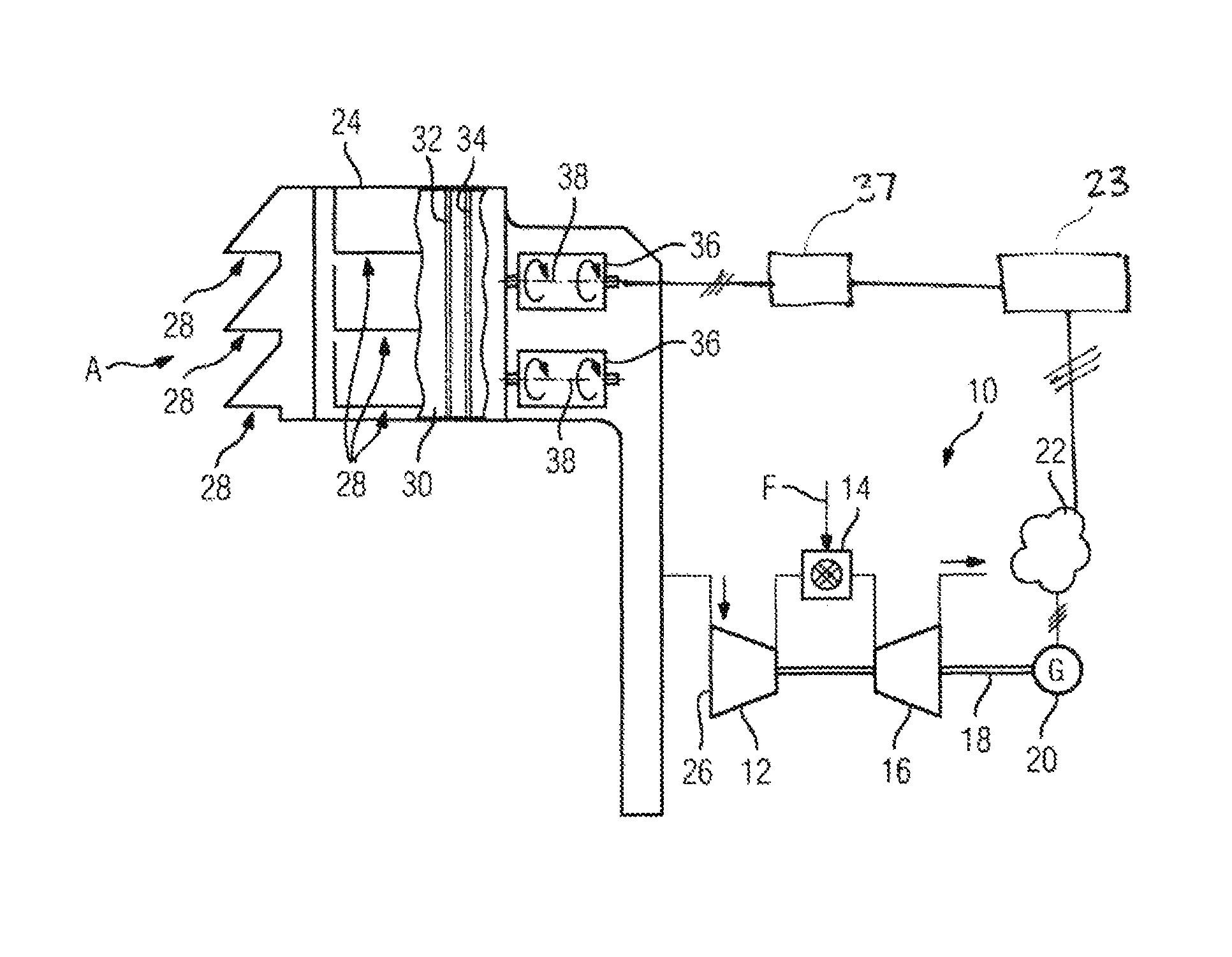

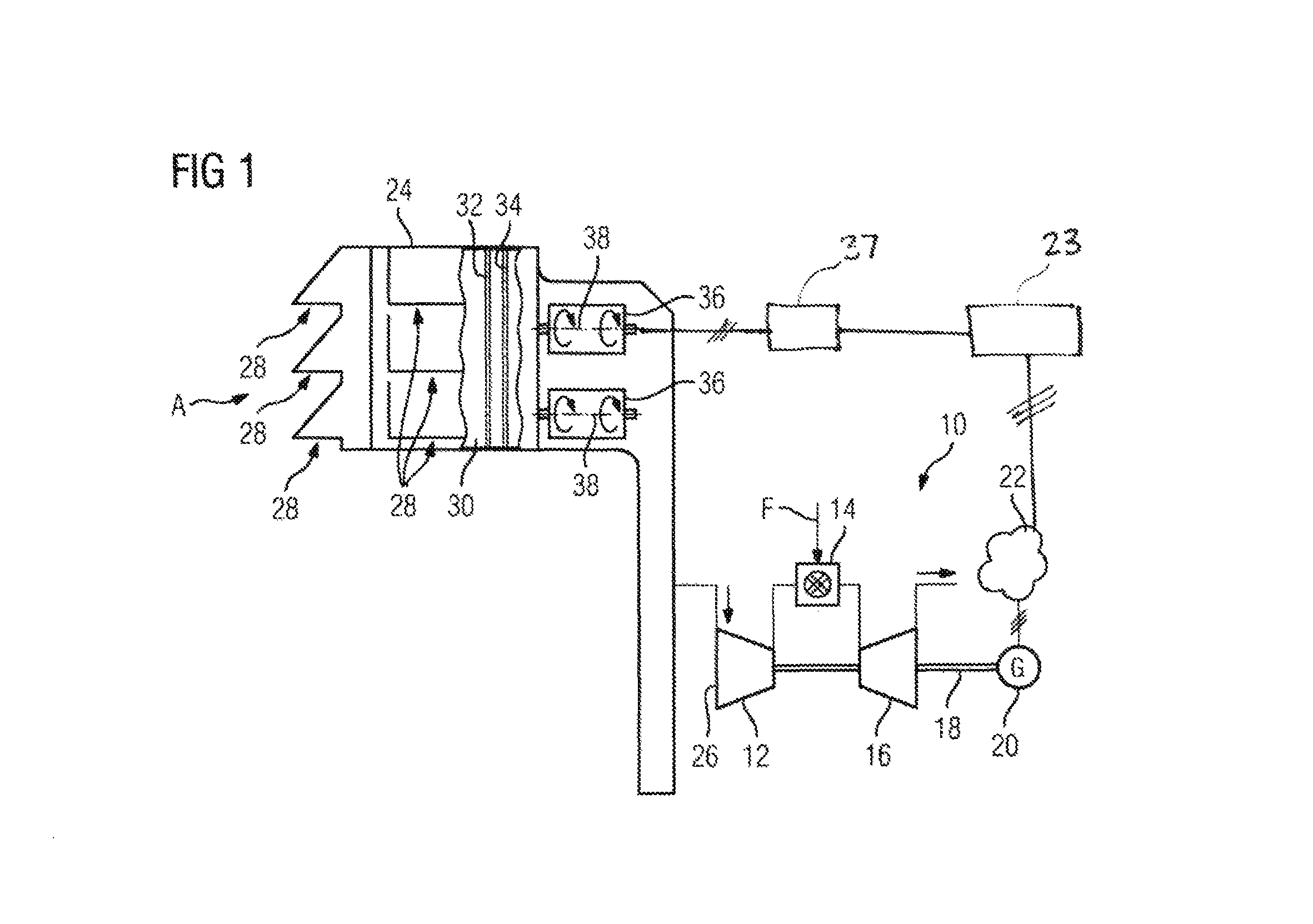

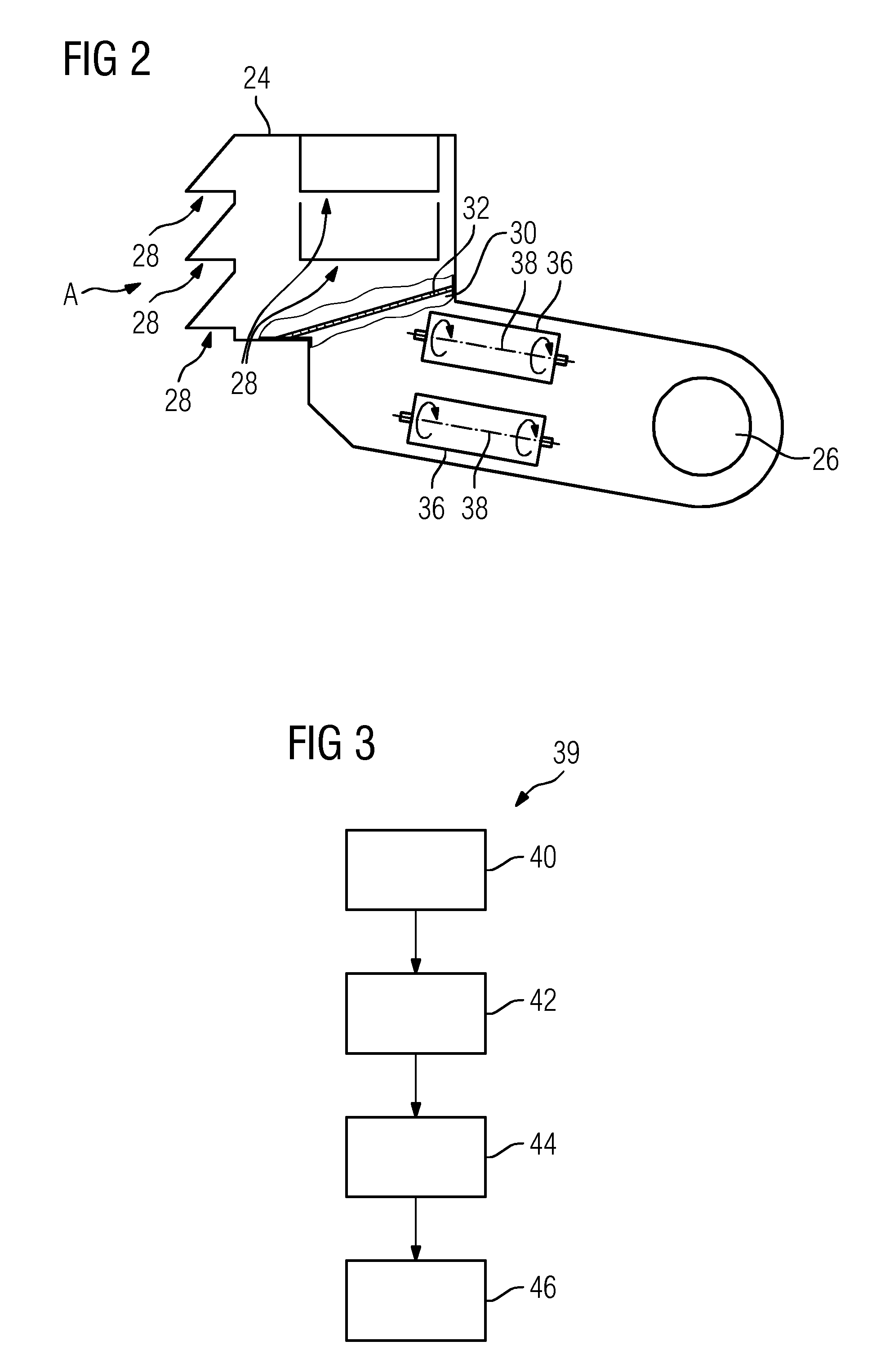

Method for operating a static gas turbine, and intake duct for intake air of a gas turbine

ActiveUS20140196437A1Reduce the required powerLow efficiencyExhaust apparatusSilencing apparatusAmbient airGas turbines

An ambient air intake duct of a static gas turbine is provided, having at least one filter, which is arranged in the intake duct, for cleaning the ambient air (A) that can flow through the intake duct. A method for operating a static gas turbine which is equipped with a filter for cleaning the ambient air (A) is also provided. To rapidly provide a higher level of gas turbine power to a generator, it is provided that, by means of a bypass or by means of flaps arranged downstream of the filter, partially to completely unfiltered ambient air (A) can temporarily flow into the compressor inlet.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Heat exchanger for cooling reaction gas

ActiveUS7784433B2Improve cooling effectSimple structureSteam generation heating methodsHeat exchanger casingsPlate heat exchangerNuclear engineering

A heat exchanger for cooling reaction gas, wherein the respective ends of heat exchanger tubes, through which the reaction gas flows, are inserted in a respective tube plate and are surrounded by a jacket, at the two ends of which are provided a respective end chamber that is partially delimited by one of the tube plates and serves for the supply and withdrawal of the reaction gas; water, as cooling agent, flows through the inner chamber of the heat exchanger that is surrounded by the jacket and that is divided by a partition, extending perpendicular to the heat exchanger tubes, which extend through it, into two partial chambers disposed one after the other in the direction of flow of the reaction gas, each partial chamber being provided with its own supply connectors and outlet connectors for the cooling agent; boiling water flows through the partial chamber that is disposed on the inlet side for reaction gas and that is connected via a supply line and withdrawal lines with a water / steam drum; feed water flows through the partial chamber that is disposed on the outlet side for the reaction gas and that is connected via a withdrawal line with the water / steam drum. The partition between the two partial chambers permits the passage of the cooling agent that flows in the inner chamber of the heat exchanger.

Owner:BORSIG AG

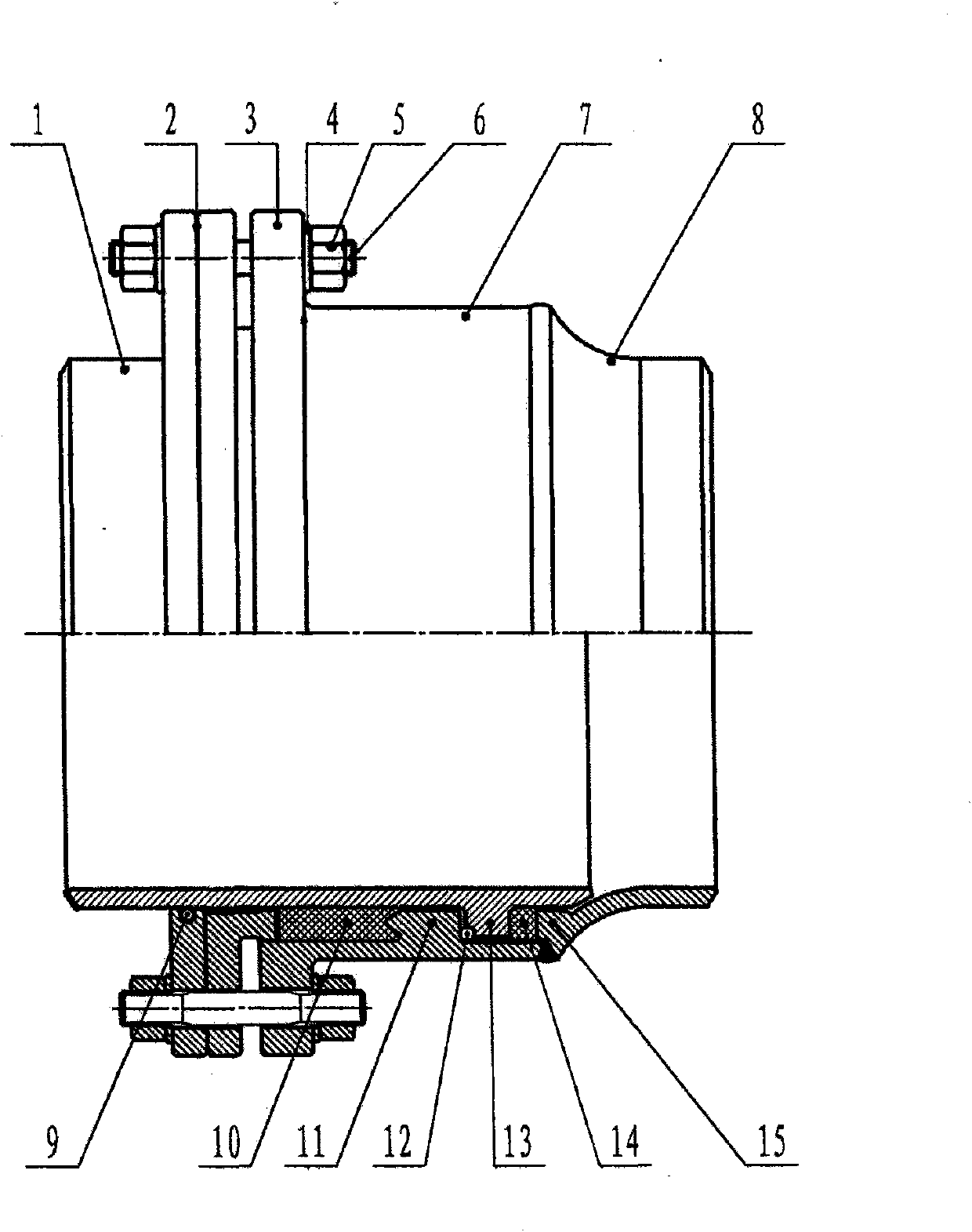

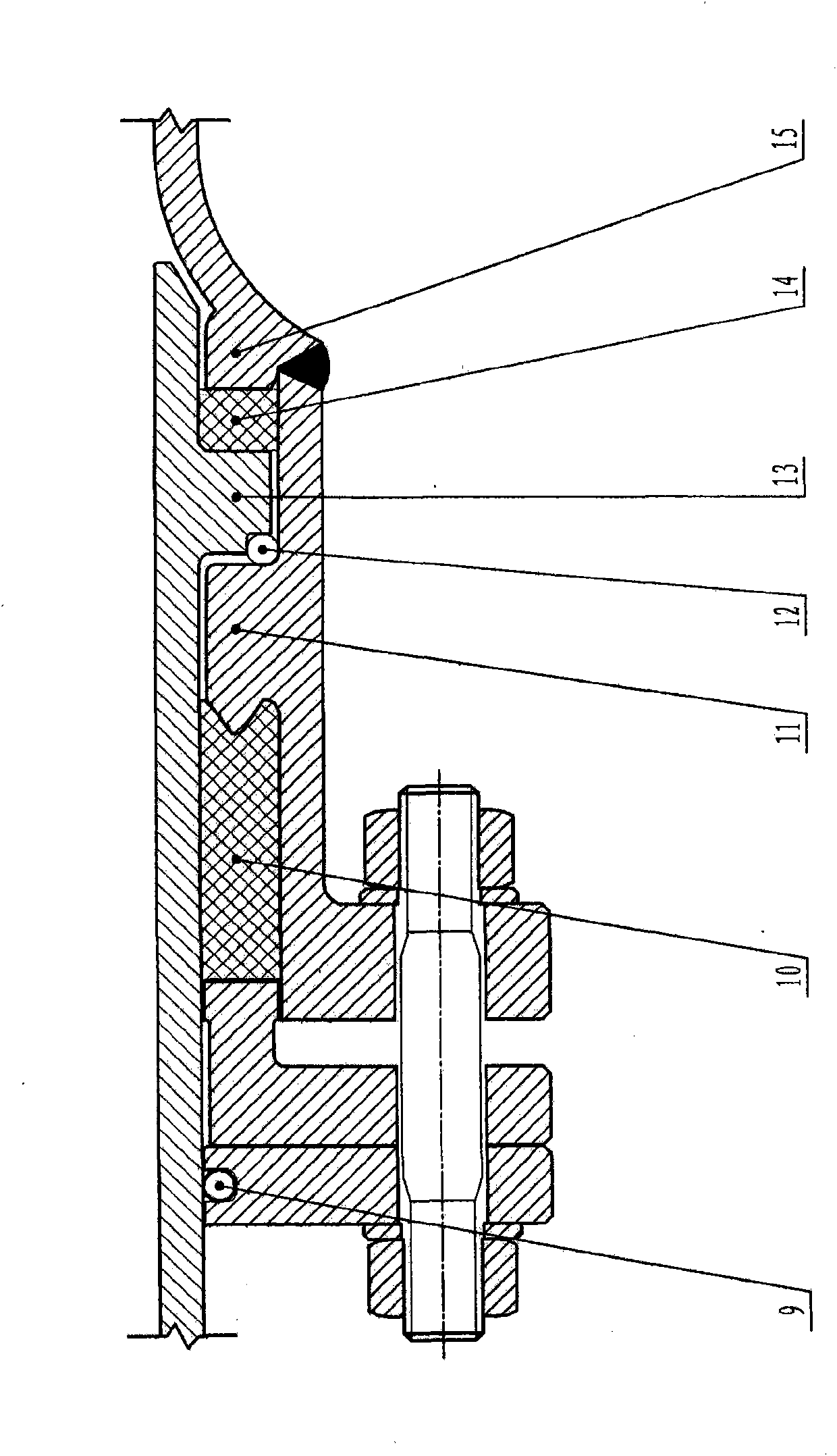

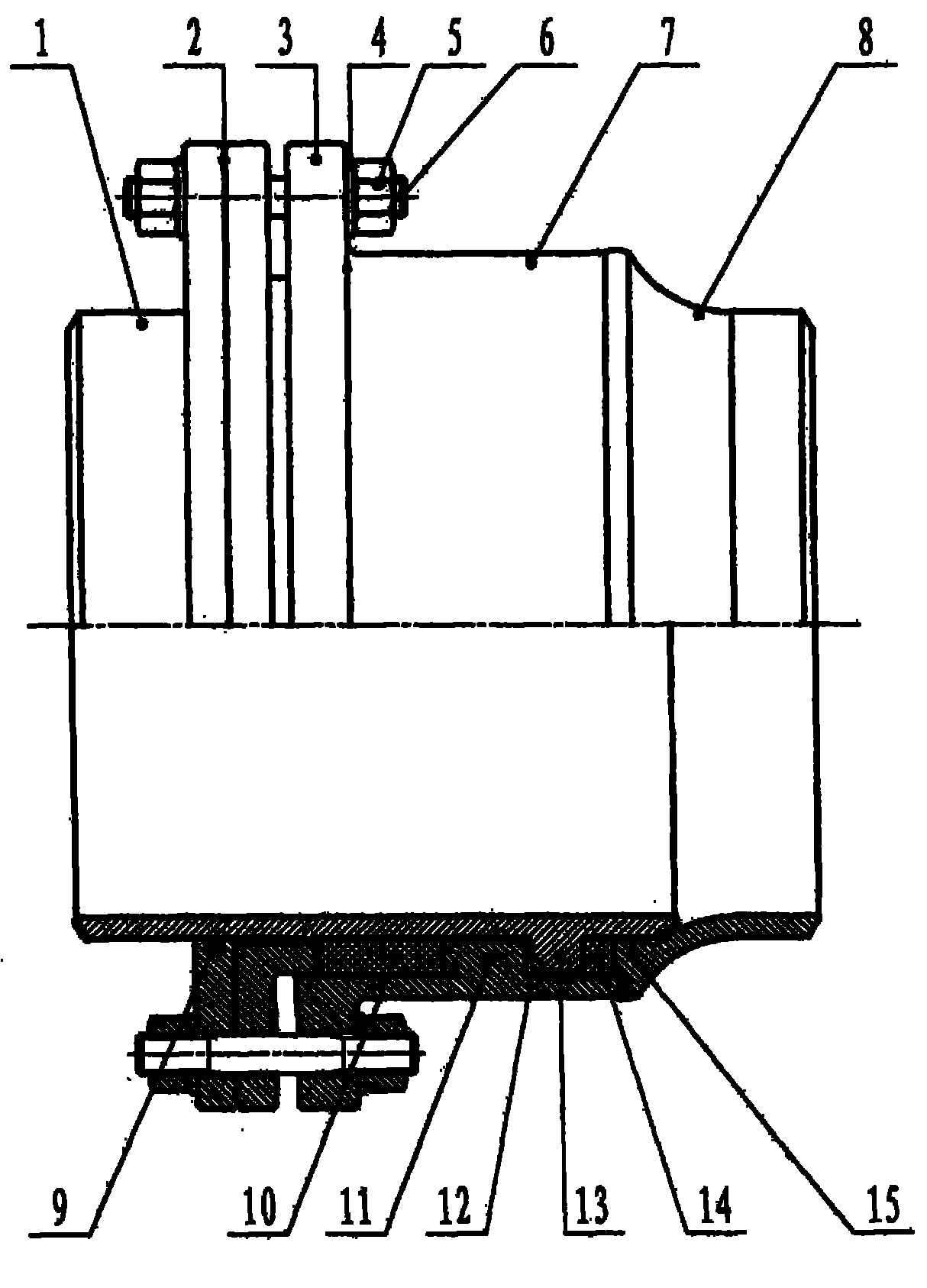

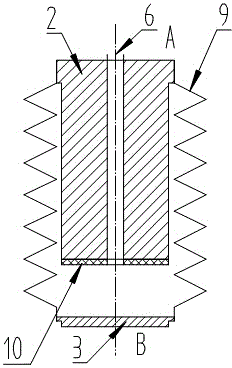

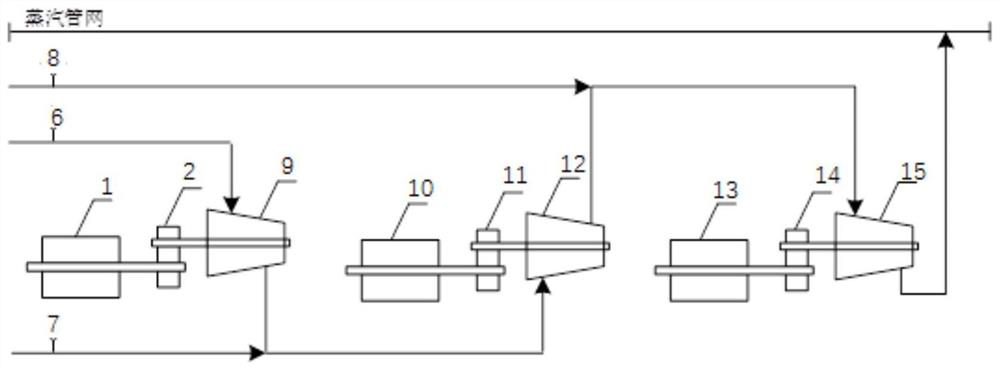

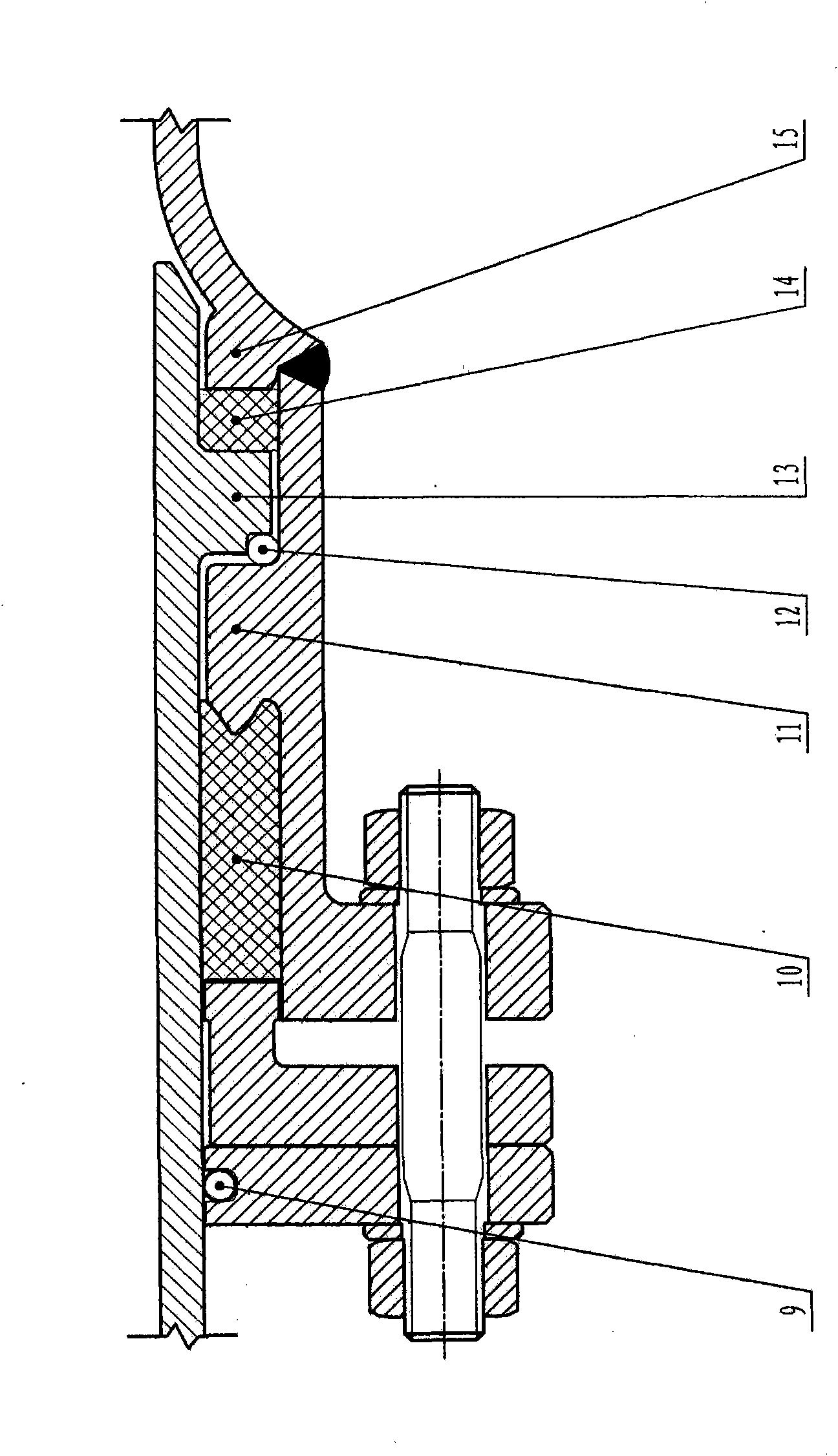

Novel double-gland high-pressure pipeline displacement compensator

ActiveCN102003592AReduce gapGuaranteed uptimePipeline expansion-compensationChemical industryHigh pressure

The invention discloses a novel double-gland high-pressure pipeline displacement compensator, which belongs to the technical field of heat distribution pipeline compensating device structures used in petroleum, chemical industry, light industry, heating power, metallurgy and other industries. The compensator comprises an inner tube, a follower flange, an outer sleeve, a reducing extension pipe, asealing filler, an outer sleeve internal bearing platform, an inner tube convex outer ring, a composite sealing ring, a reducing tube bearing platform and the like, wherein the inner tube convex outer ring is integrally arranged on the inner tube; one end of the inner tube is inserted into the outer sleeve; the inner tube convex outer ring is positioned between the outer sleeve internal bearing platform and the reducing tube bearing platform; the composite sealing ring is pressed against between the inner tube convex outer ring and the reducing tube bearing platform; and a convex end face of the outer sleeve internal bearing platform is pressed against the other end of the inner tube so as to press the sealing filler of the follower flange. By the structure, the novel double-gland high-pressure pipeline displacement compensator has the characteristics of high precision, lower friction coefficient, smaller torque, lower pressure loss, higher bending resistance and bearing capacity, unlimited medium flow direction, reliable sealing, high performance and convenience of pipeline maintenance.

Owner:陈墅庚

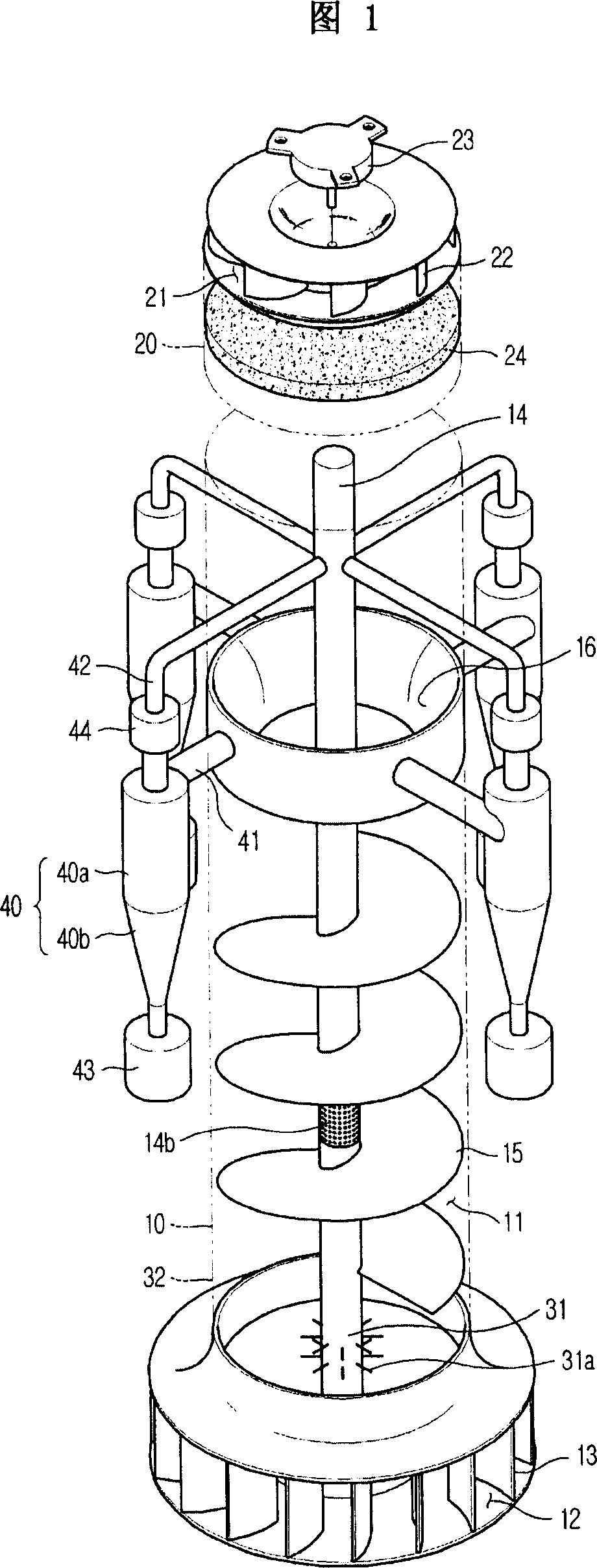

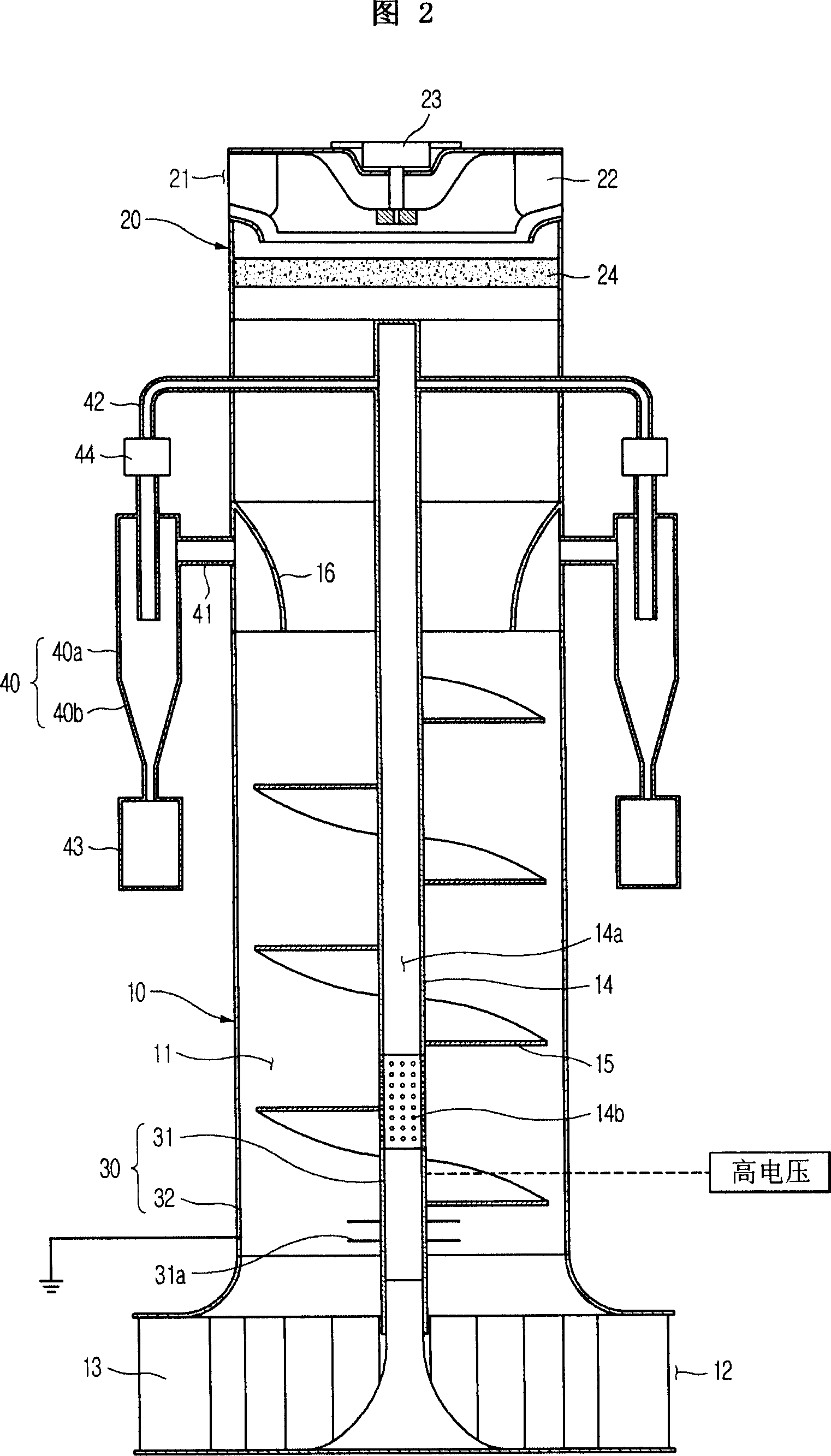

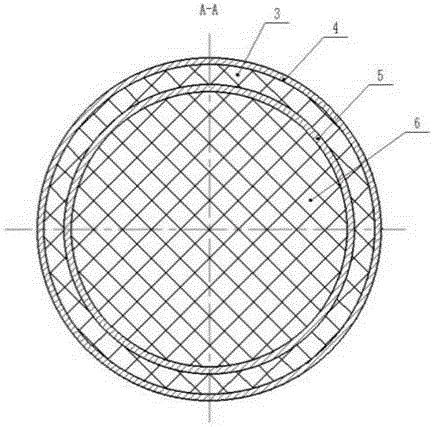

Cyclone air purifier

InactiveCN1990114AEliminate pressure lossCancel noiseReversed direction vortexDispersed particle separationCycloneGravitational force

The invention discloses a cyclone air purifier, capable of effectively separating dust even without the second cyclone body. The cyclone air purifier provided according to the invention includes a cylinder-shaped body with an inflow port provided in the lower and an air channel for rotationally flowing the air inflowing from the inflow port; a plurality of cyclone bodies provided outside of the body for filtering dust in the air intaking from the air channel; a circulation tube provided inside of the body for guiding air discharging from each cyclone body to the air channel; an ionization device with a high voltage electrode part forming outside surface of the circulation tube and a ground electrode part forming inside surface of the body, for guiding the dust to inflow to the each cyclone body by using centrifugal force and electric gravitational force at the same time. And, a plurality of through holes for discharging compression air are formed in the side of the circulation tube to make dust in the air circulating along the air channel cleave to inside surface of the body.

Owner:SAMSUNG ELECTRONICS CO LTD

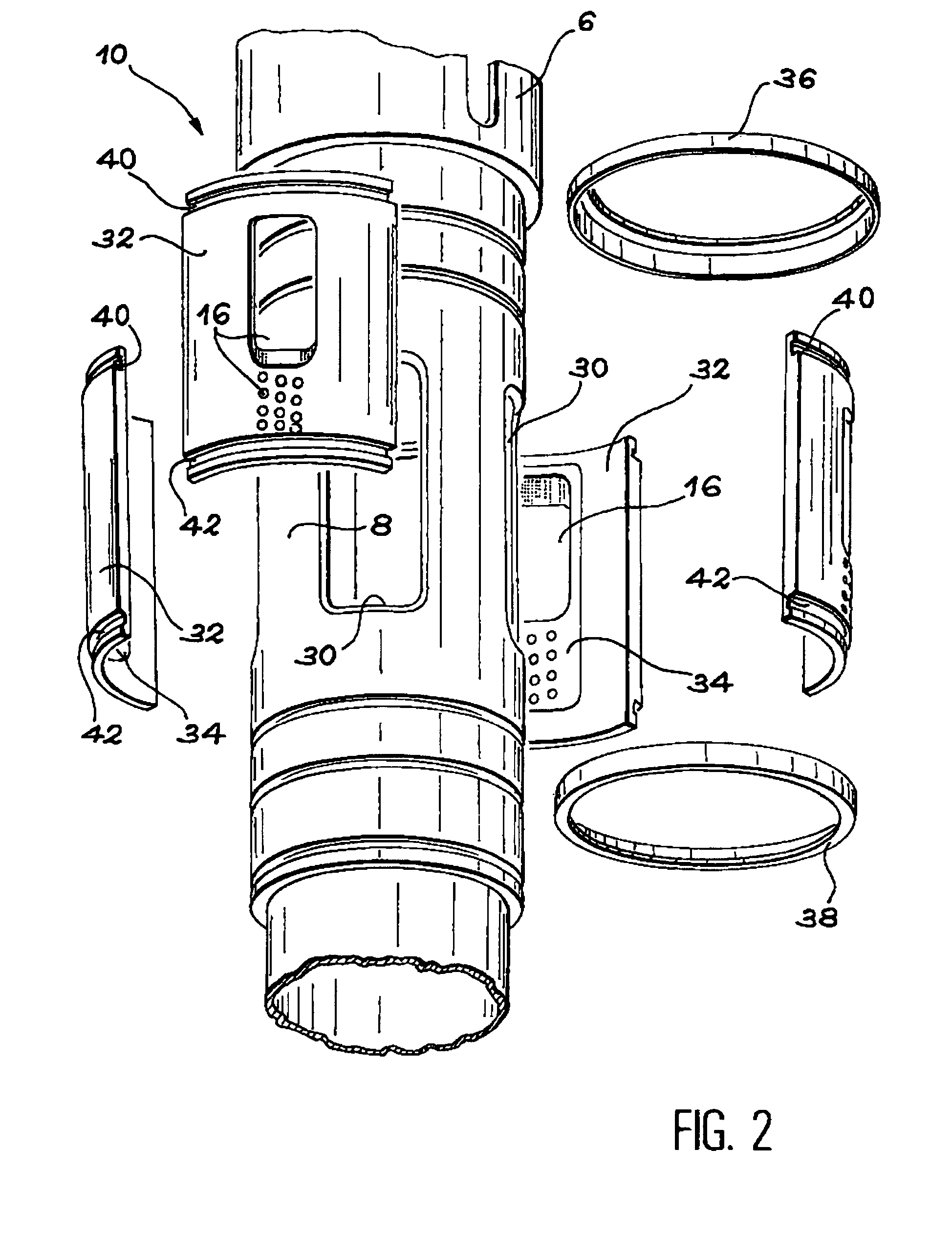

Flow control device

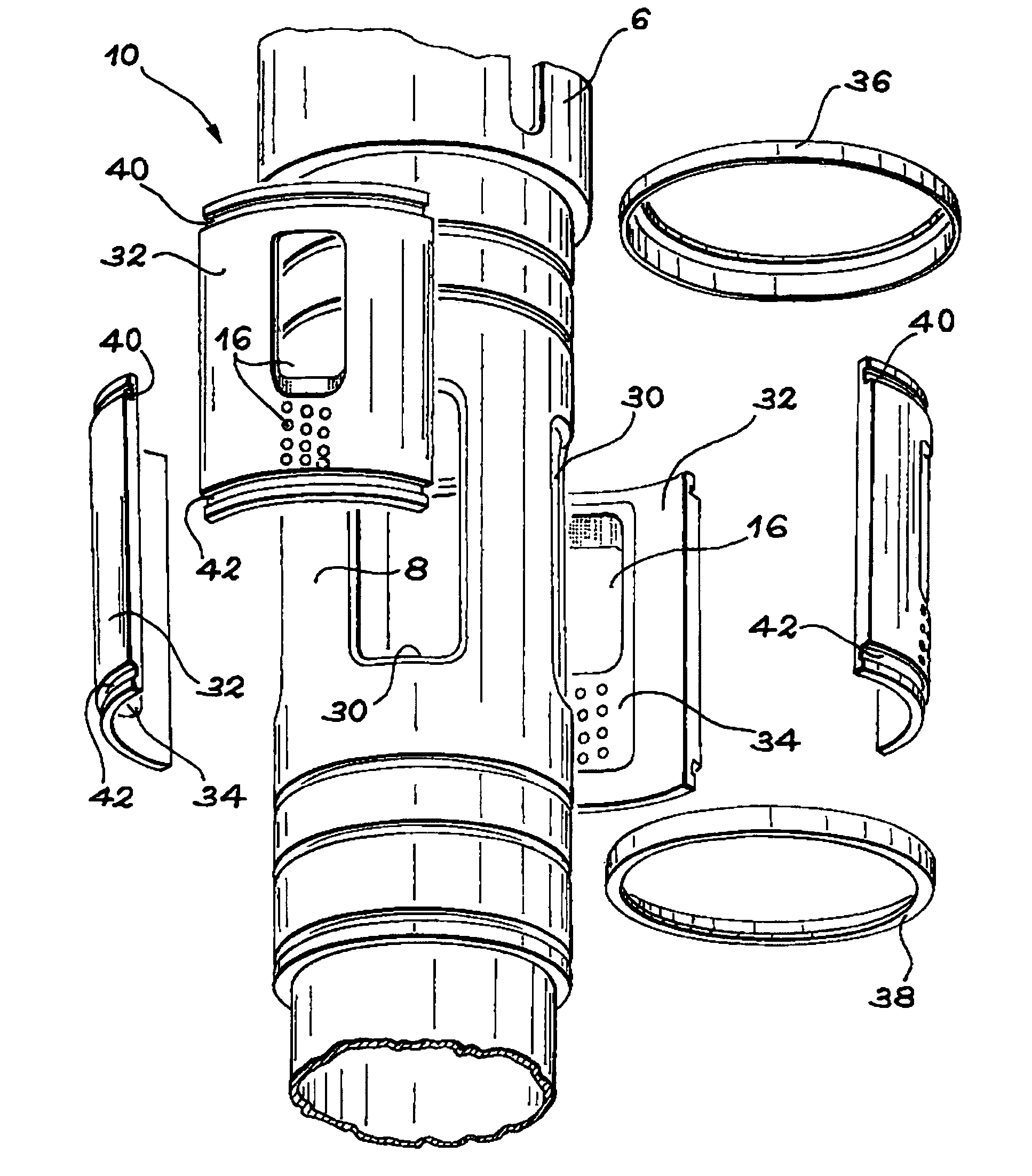

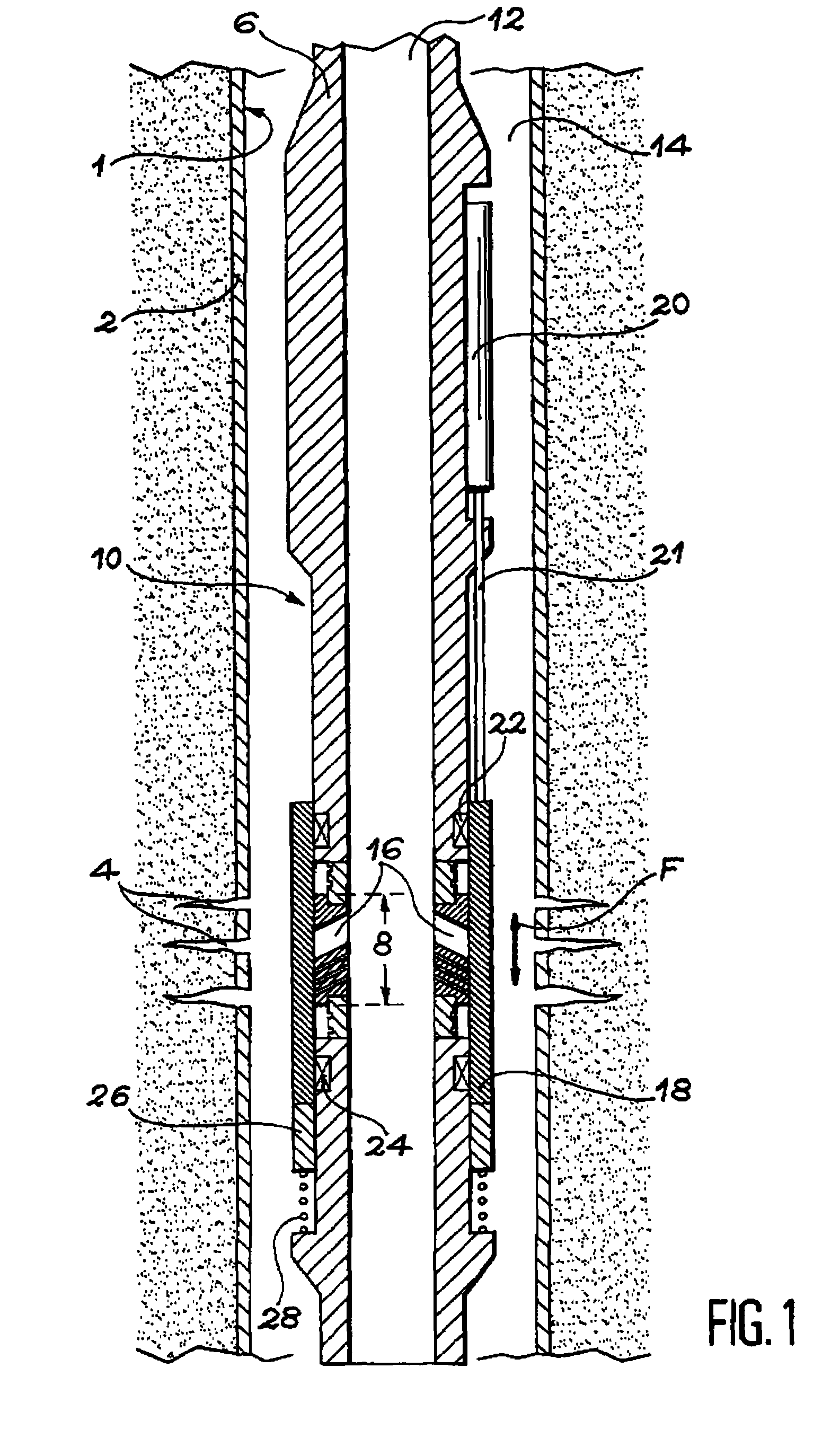

InactiveUS7546879B2Simply and quickly modifyingEffective protectionDrilling rodsFluid removalOil wellBiomedical engineering

The invention relates to a device for control of the flow through a production tube placed in an oil well. The device comprising a portion of the production tube provided with through orifices and protection equipment for providing resistance to wear by erosion. The protection equipment comprises several add-on sectors assembled around the portion of the tube. Each add-on sector provided with an associated inner stiffener penetrating into the portion of the production tube through at least one through orifice. At least one of the add-on sectors provided with at least one opening extending through the sector and its associated inner stiffener.

Owner:SCHLUMBERGER TECH CORP

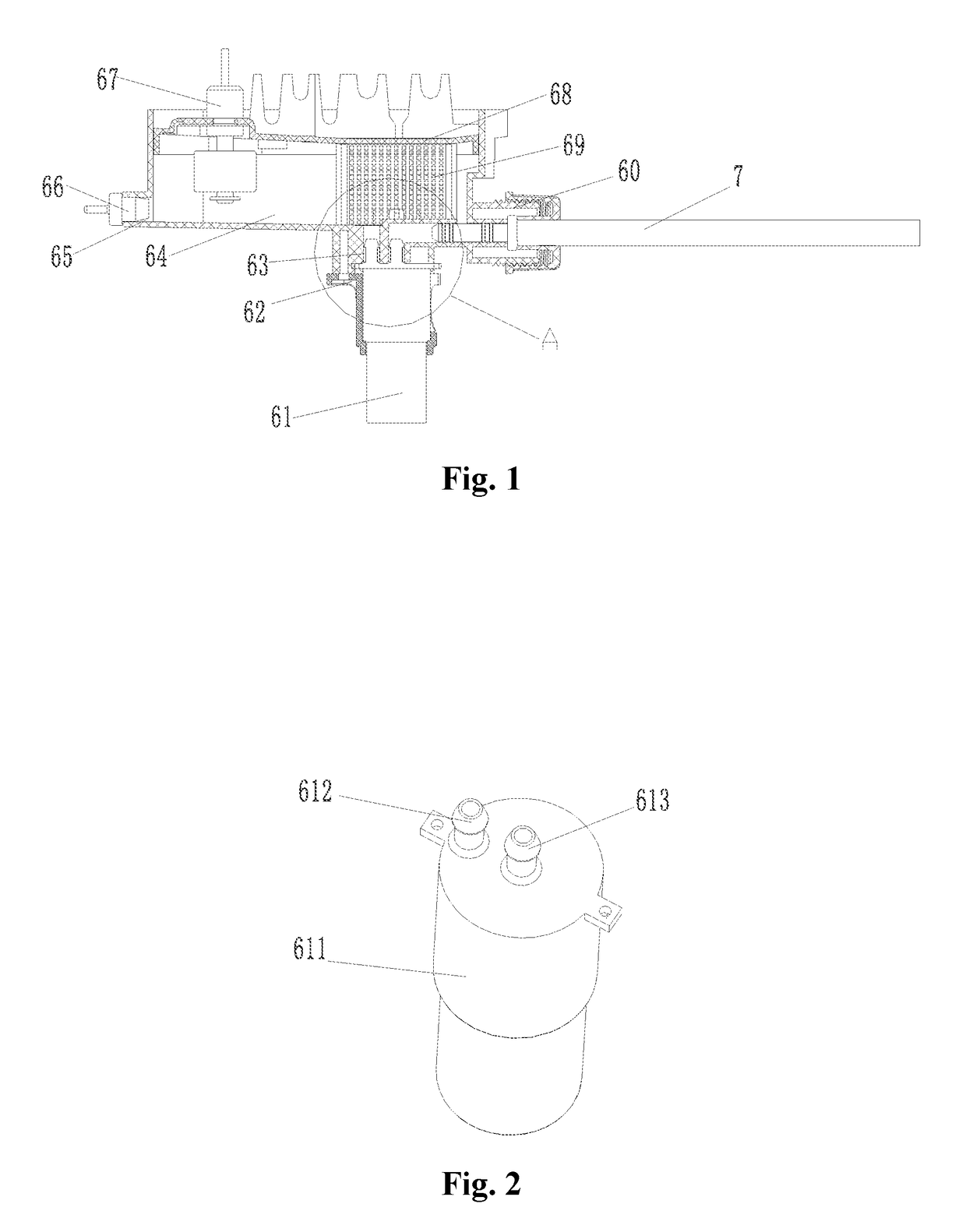

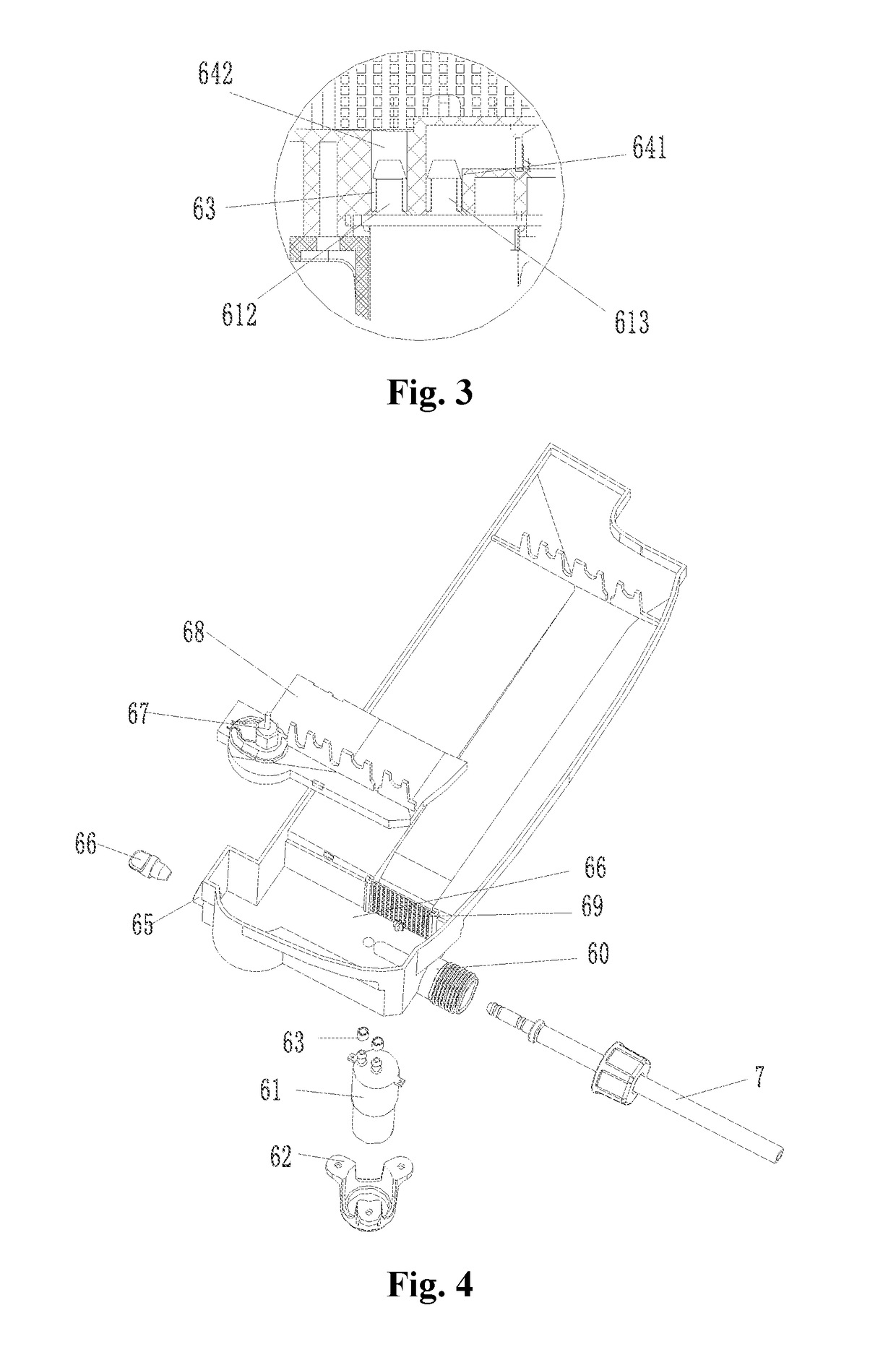

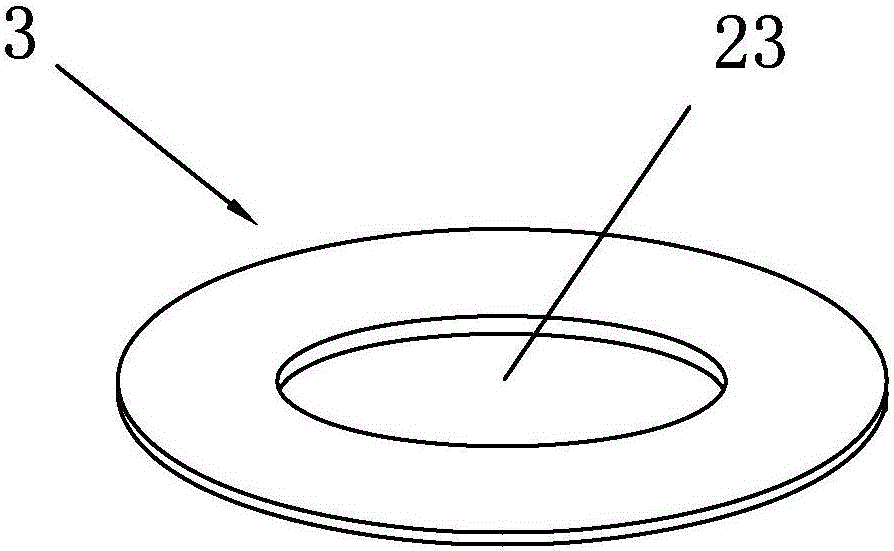

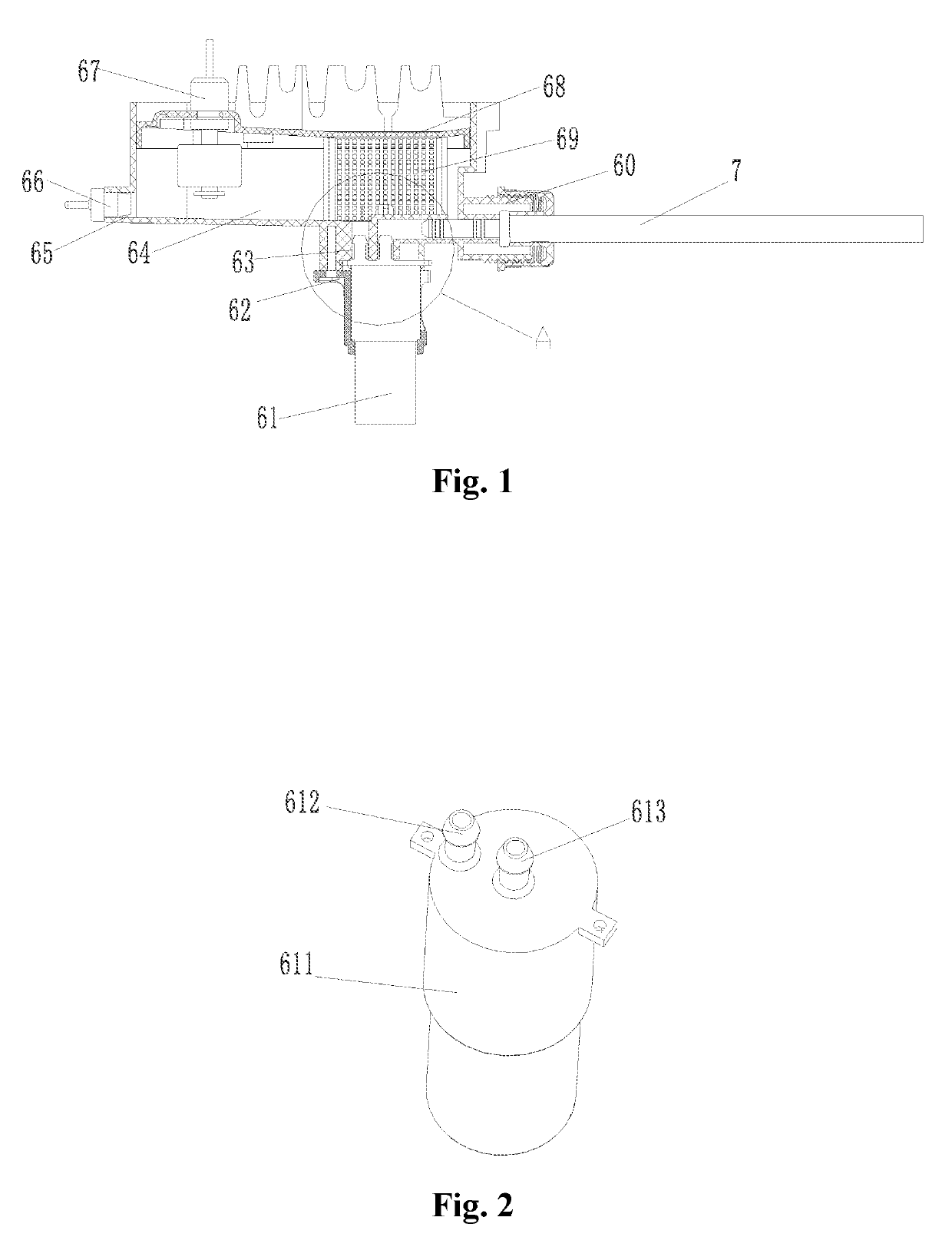

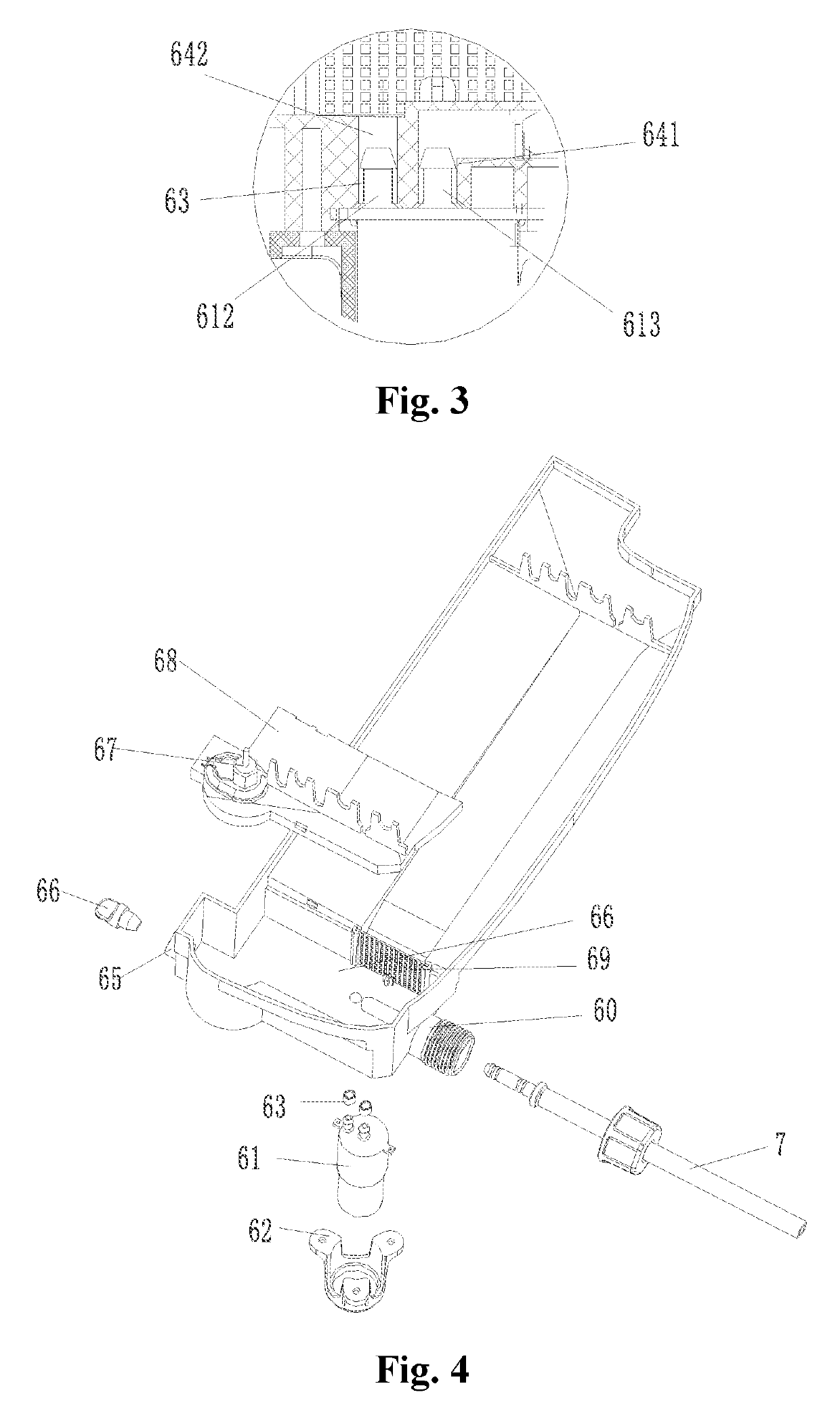

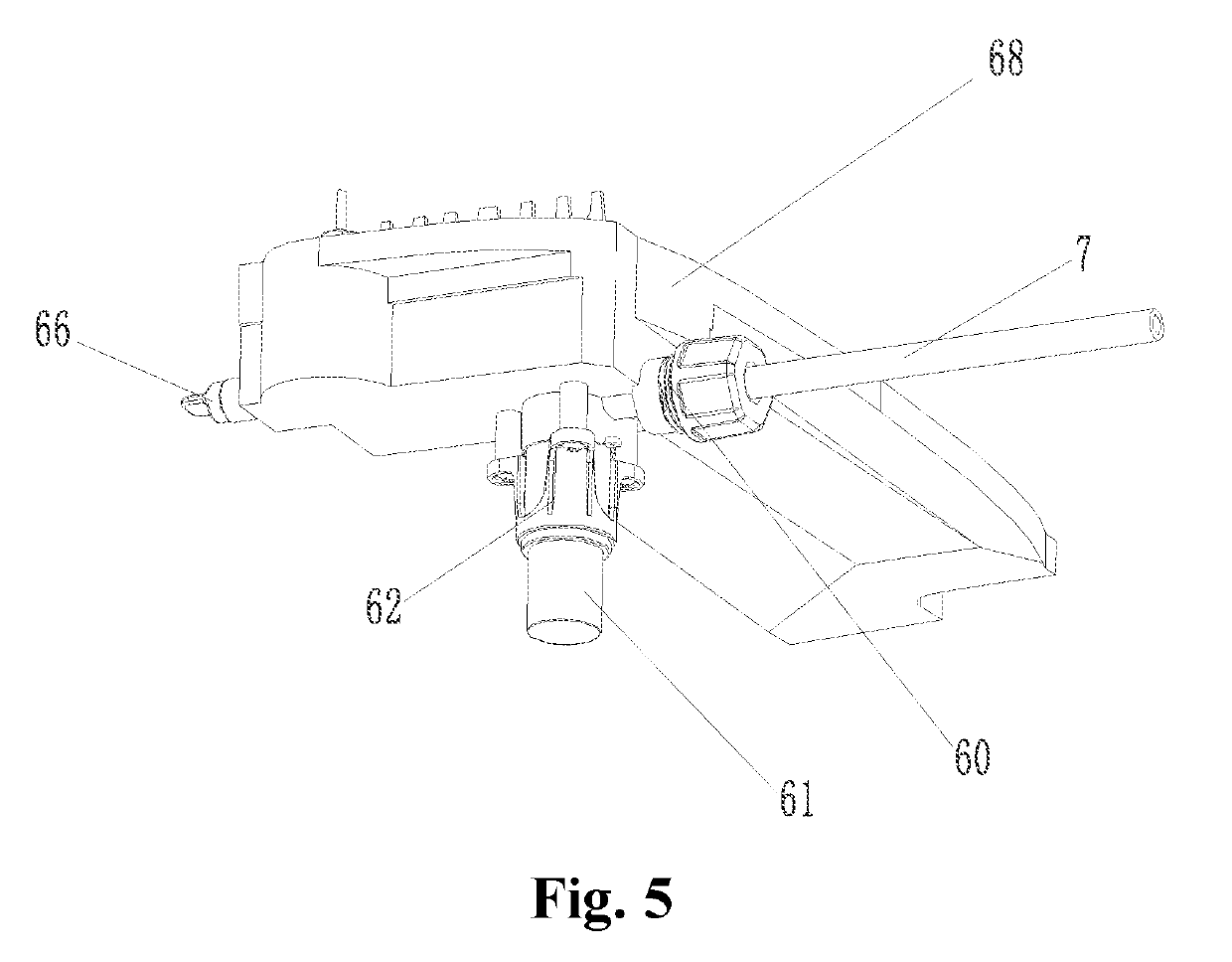

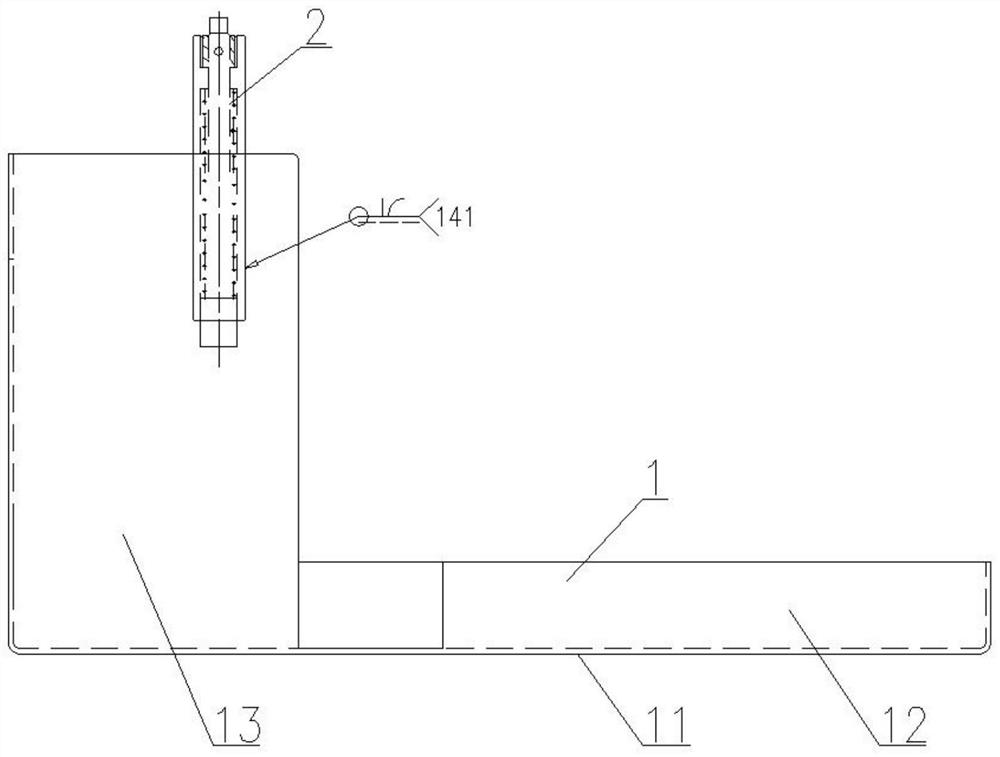

Water Draining Structure of Dehumidifier And Dehumidifier

ActiveUS20180195758A1Reduce riskEliminate pressure lossCondensate preventionFlexible member pumpsOutfallWater leak

A dehumidifier has a water receiving tray receiving condensed water of the dehumidifier. The water receiving tray comprises a water tank outlet, a main water outlet arranged outside the casing of the dehumidifier as a whole, the main water outlet being arranged opposite the water tank outlet; a pump used for draining is provided on the bottom of the outside of the water receiving tray, the pump being directly connected with the water receiving tray, eliminating the need of providing a pipe to connect with the dehumidifier pump, therefore reducing the risk of leaking. By connecting the pump with the water receiving tray directly, the pressure loss due to the connection of pipe is eliminated; the drainage capacity of the pump is utilized fully. Without installing or detaching additional pipes during installment or maintenance, operation is easier.

Owner:JIANGSU YOAU ELECTRIC CO LTD

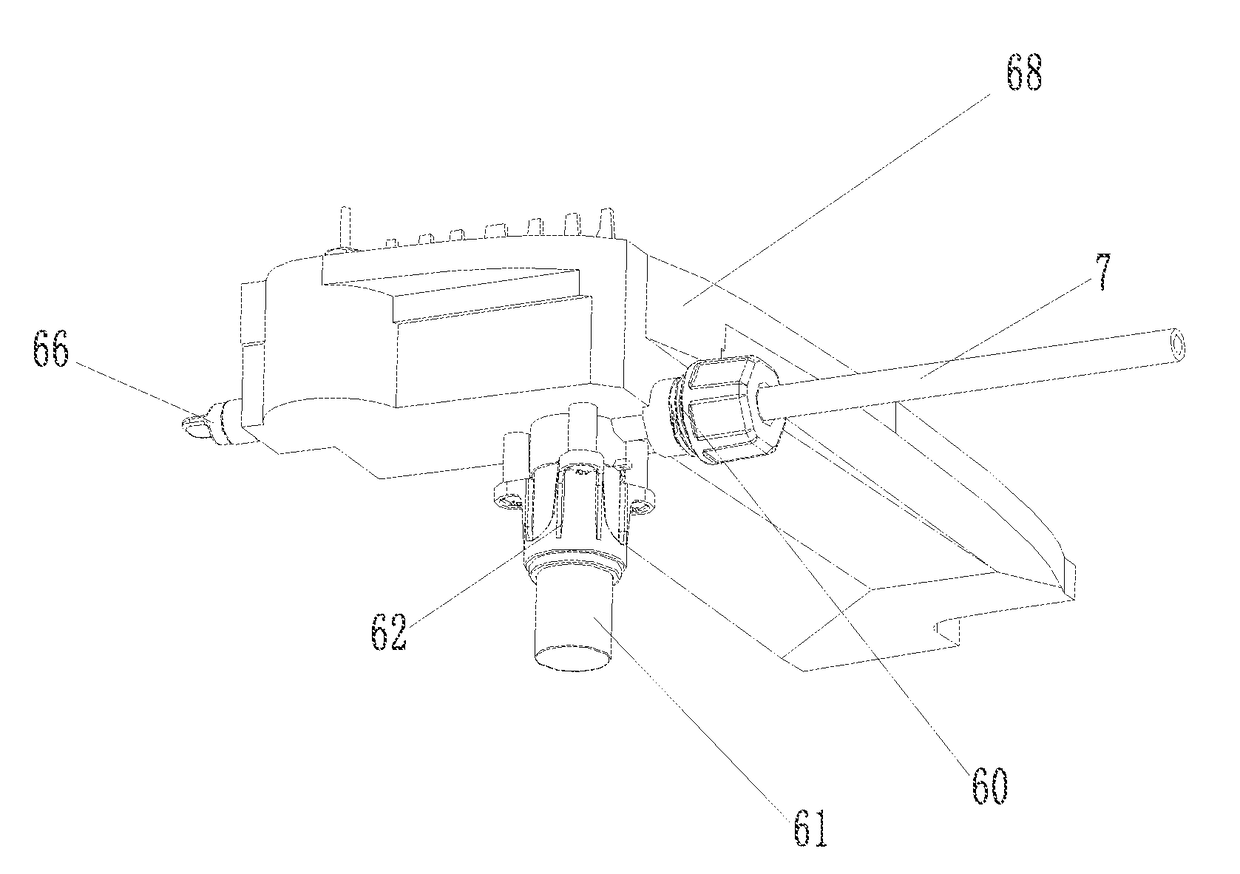

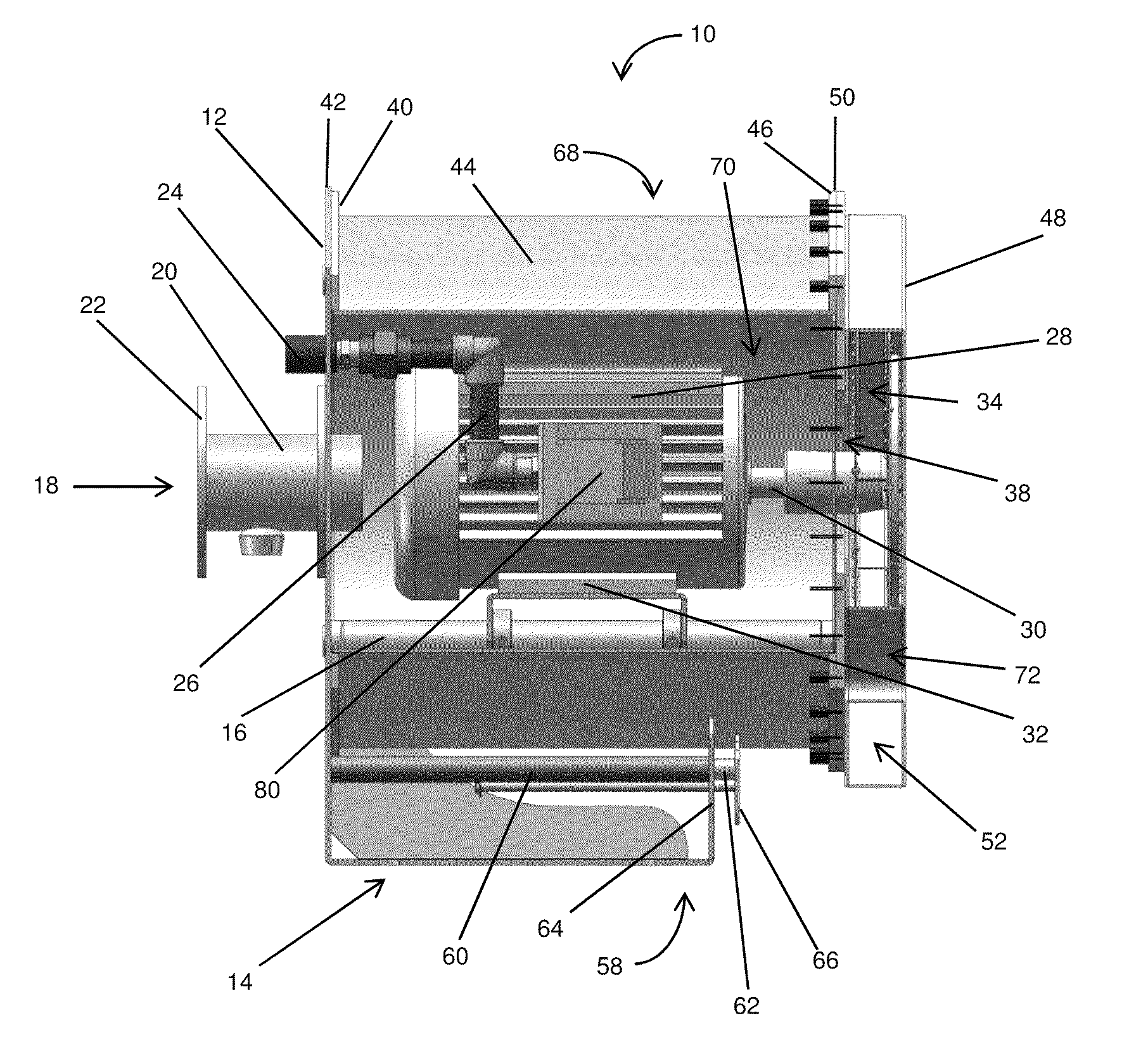

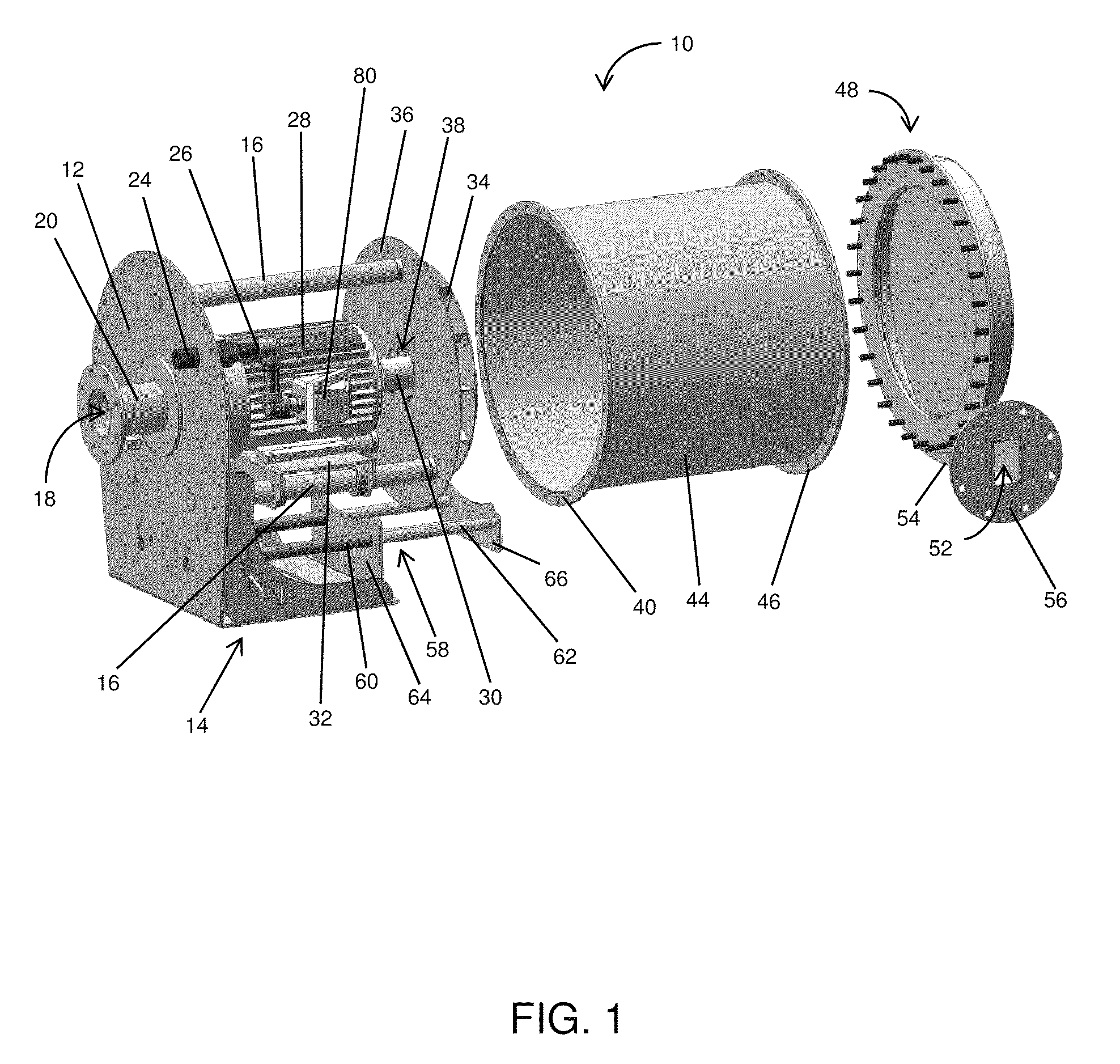

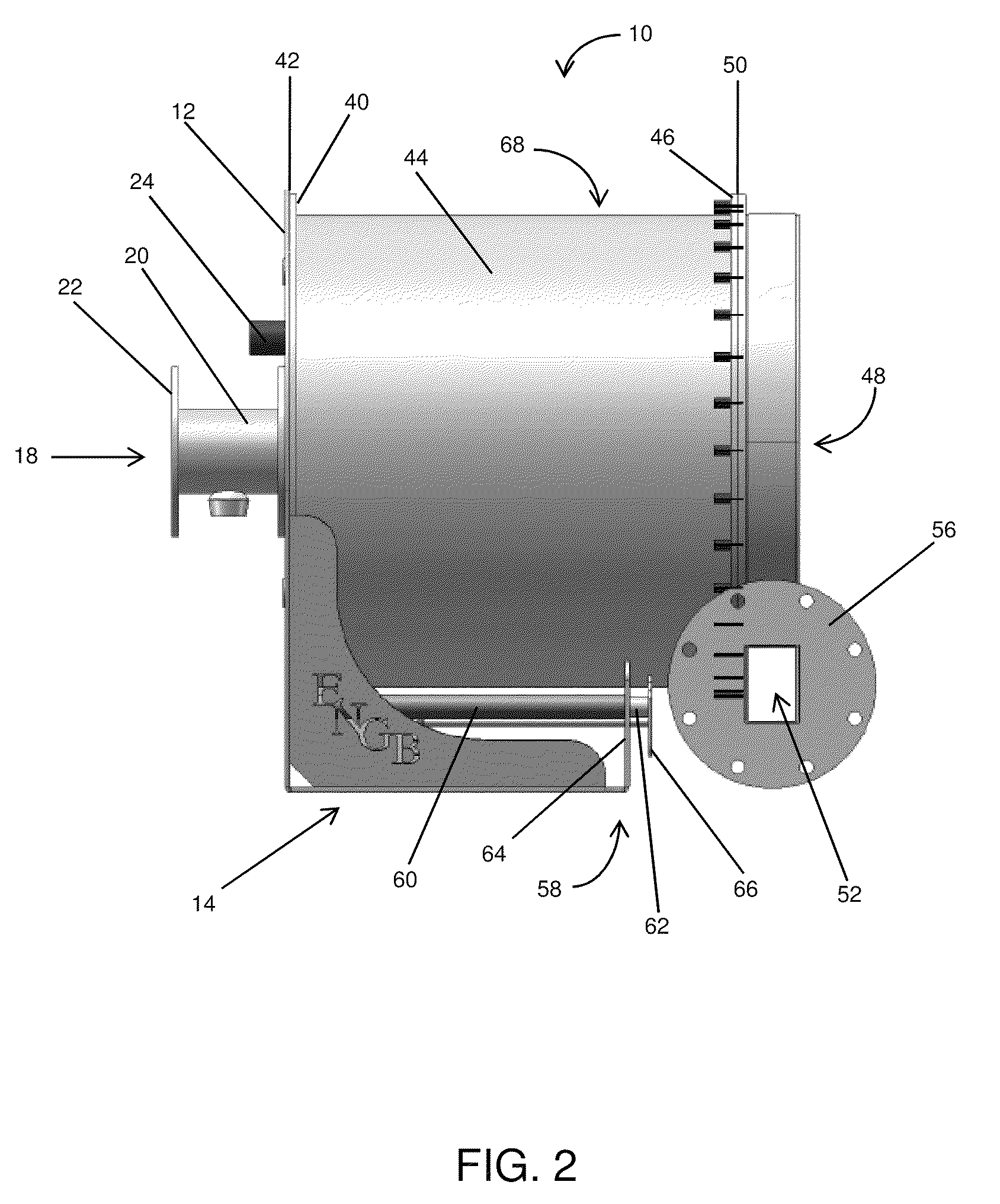

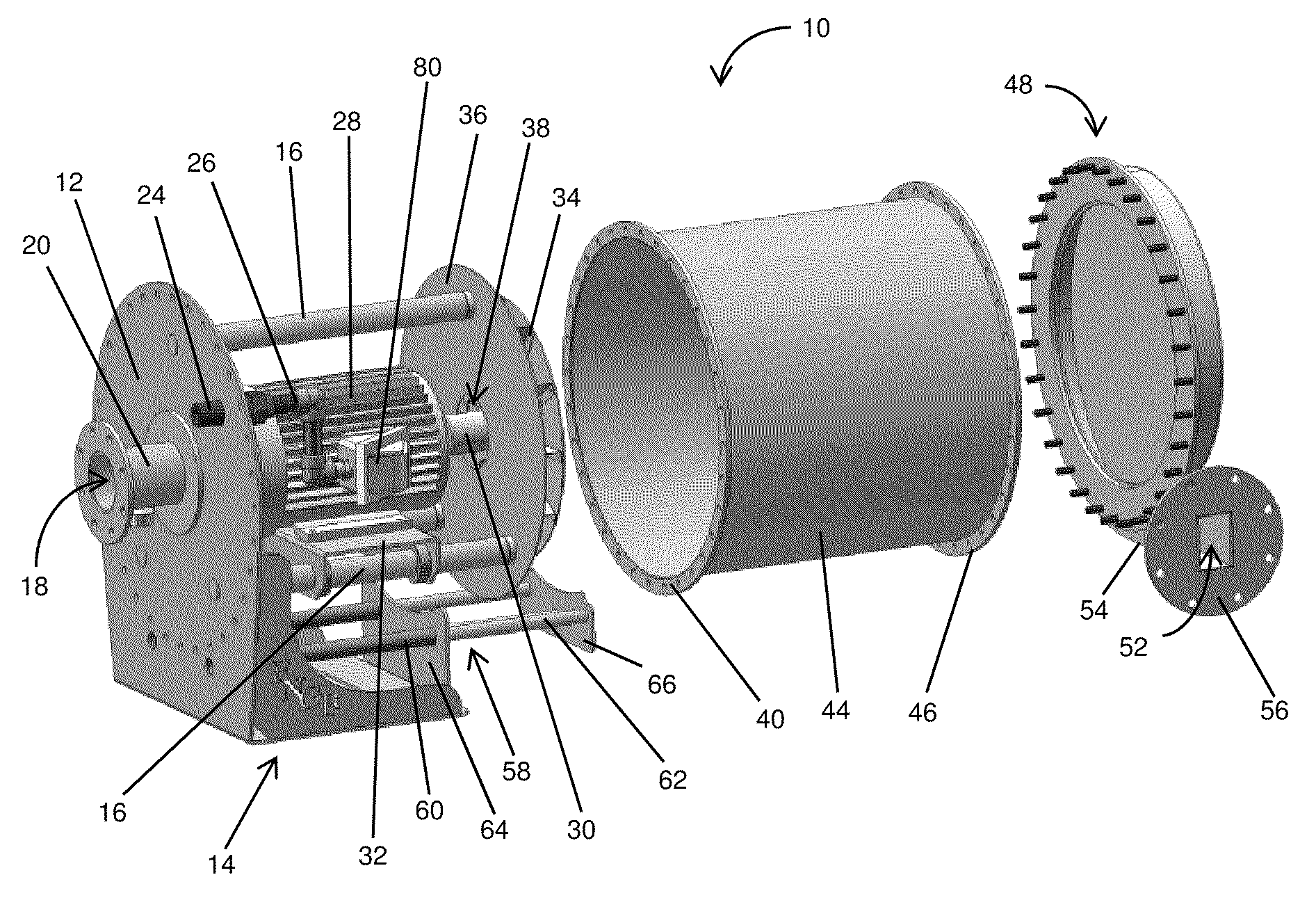

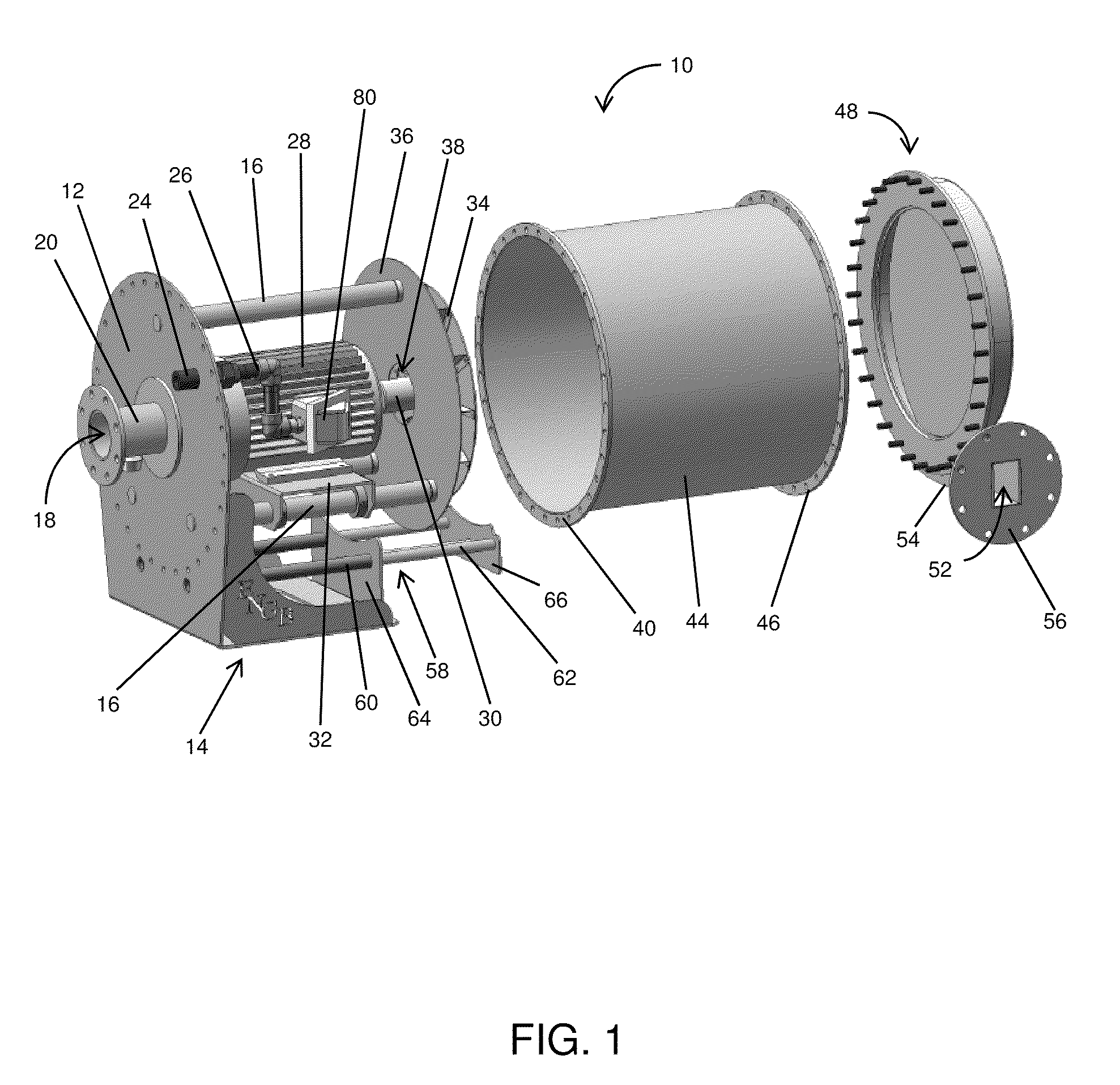

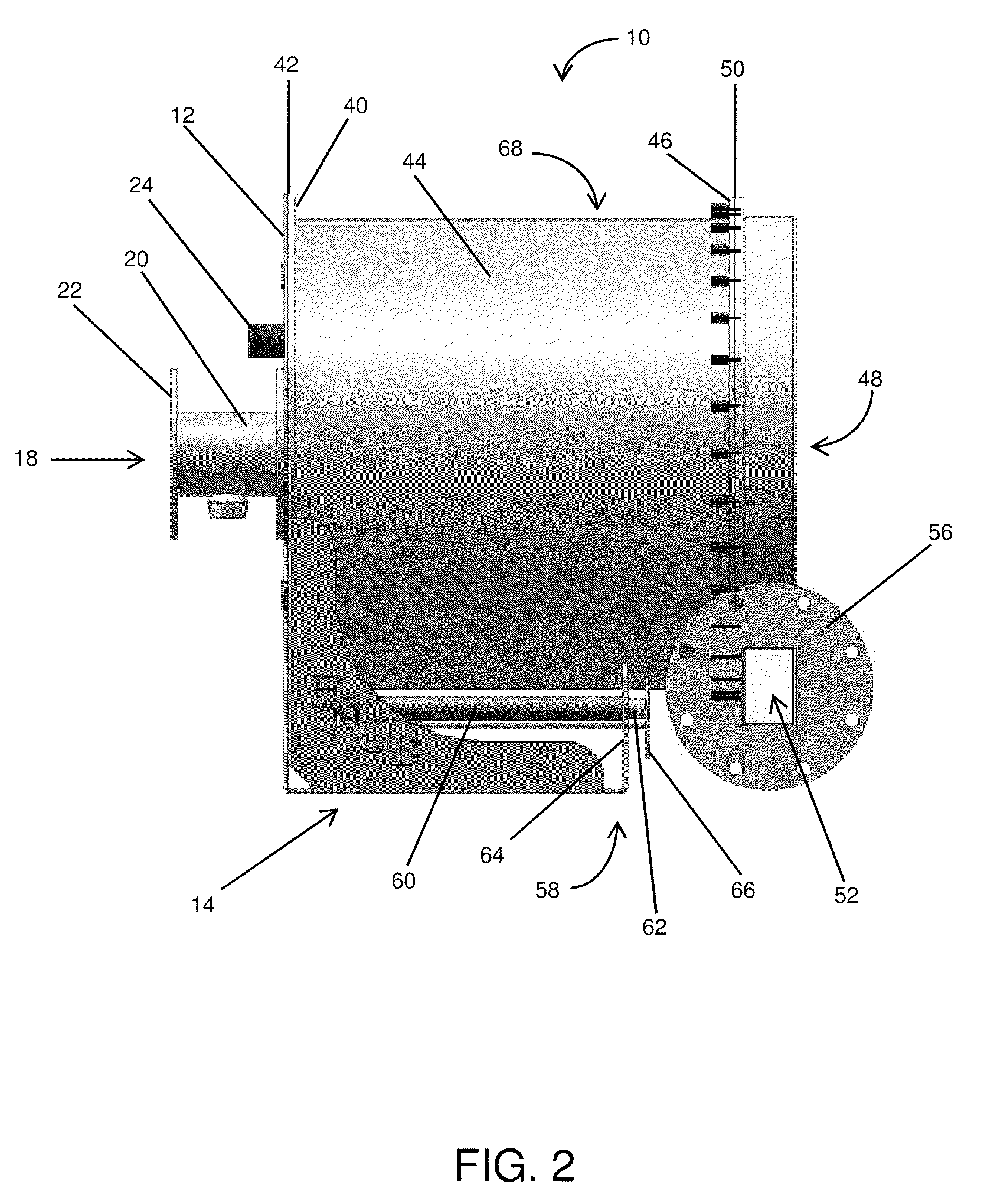

Gas booster system and related method

ActiveUS8851863B2The process is convenient and fastProvide supportPortable framesPositive displacement pump componentsElectricityImpeller

An improved booster for use in piped fluid systems includes a motor, a fan wheel and a hermetically sealed tank assembly. Fluids enter the tank assembly through an inlet and are compressed within the tank assembly by a rotating fan wheel, before leaving the tank assembly through an outlet, which may be aligned in a plurality of angular configurations. The motor is powered by a versatile electrical connection which enters the tank assembly through a connector that maintains the hermetically sealed condition in the tank assembly, and can accommodate power of any voltage or frequency. The incremental pressure gain provided by the booster may be controlled by modifying the speed of the rotating fan wheel, and a sled assembly provides structural support and positional alignment for portions of the tank assembly when the booster system is opened for access.

Owner:ETTER ENG

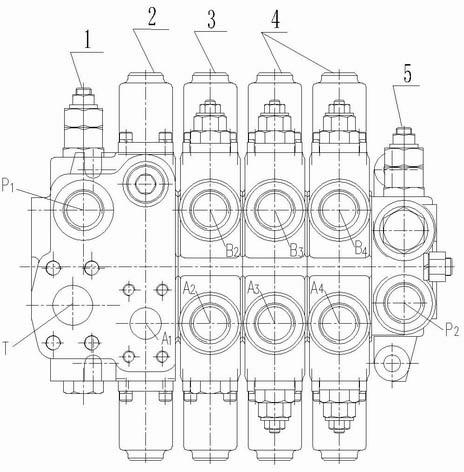

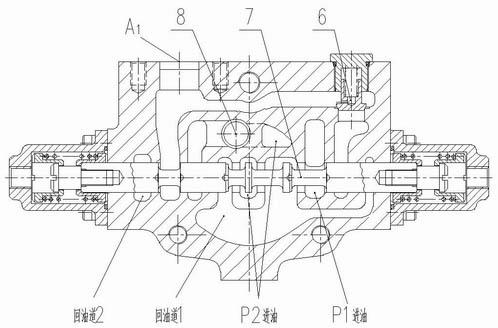

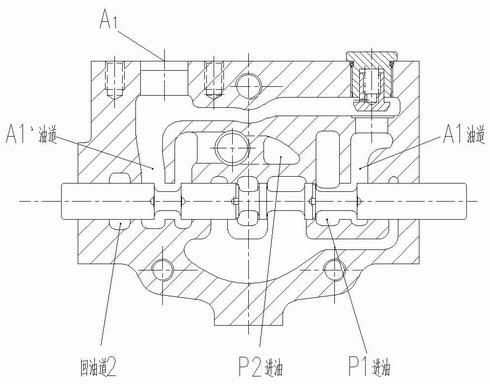

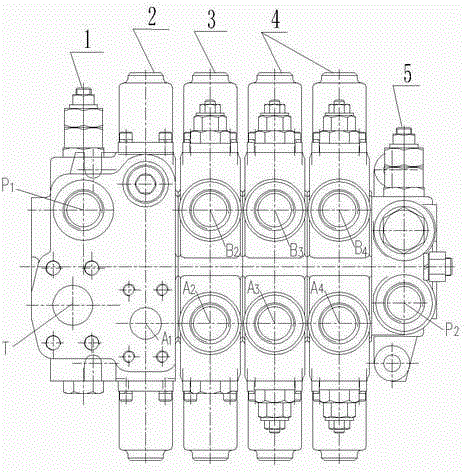

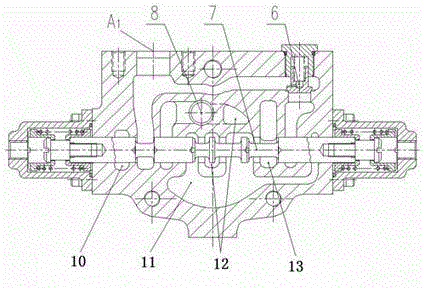

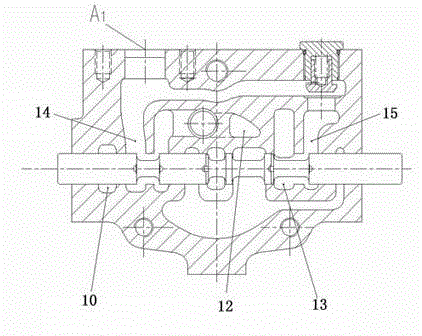

Lift converging multiway valve

ActiveCN102674210ANormal lifting actionReduce energy lossServomotor componentsLifting devicesInlet valveEngineering

A lift converging multiway valve belongs to the technical field of forklift multiway valves, and comprises an oil inlet and return valve plate and an oil inlet valve plate, wherein a lift converging valve plate, an inclined valve plate and an accessory valve plate are coordinately arranged between the oil inlet and return valve plate and the oil inlet valve plate, the oil inlet and return valve plate and the lift converging valve plate are arranged into an integral structure, a speed limit valve is arranged on the oil inlet and return valve plate, a lift valve rod is coordinately arranged in the lift converging valve plate, an oil channel and a group of oil ports are coordinately arranged in the multiway valve, an oil inlet check valve is coordinately arranged on the oil channel, and a safety valve is coordinately arranged at one side of the oil inlet and return valve plate. The double-pump working state is only applied when a forklift doorframe is lifted, for other motions of the doorframe, only one pump is required to work, the other pump unloads at low pressure, the normal lift motion of a forklift is ensured, the energy consumption loss of an engine or a motor is also decreased, the use of an oil pipe of a system is reduced, the lift converging multiway valve has a simple structure, the utilization rate of a valve body is improved, the manufacture costs of the valve and a pipeline can be saved, the pressure loss of the valve body can also be reduced, so an energy-saving effect is realized.

Owner:ZHEJIANG HAIHONG HYDRAULIC TECH

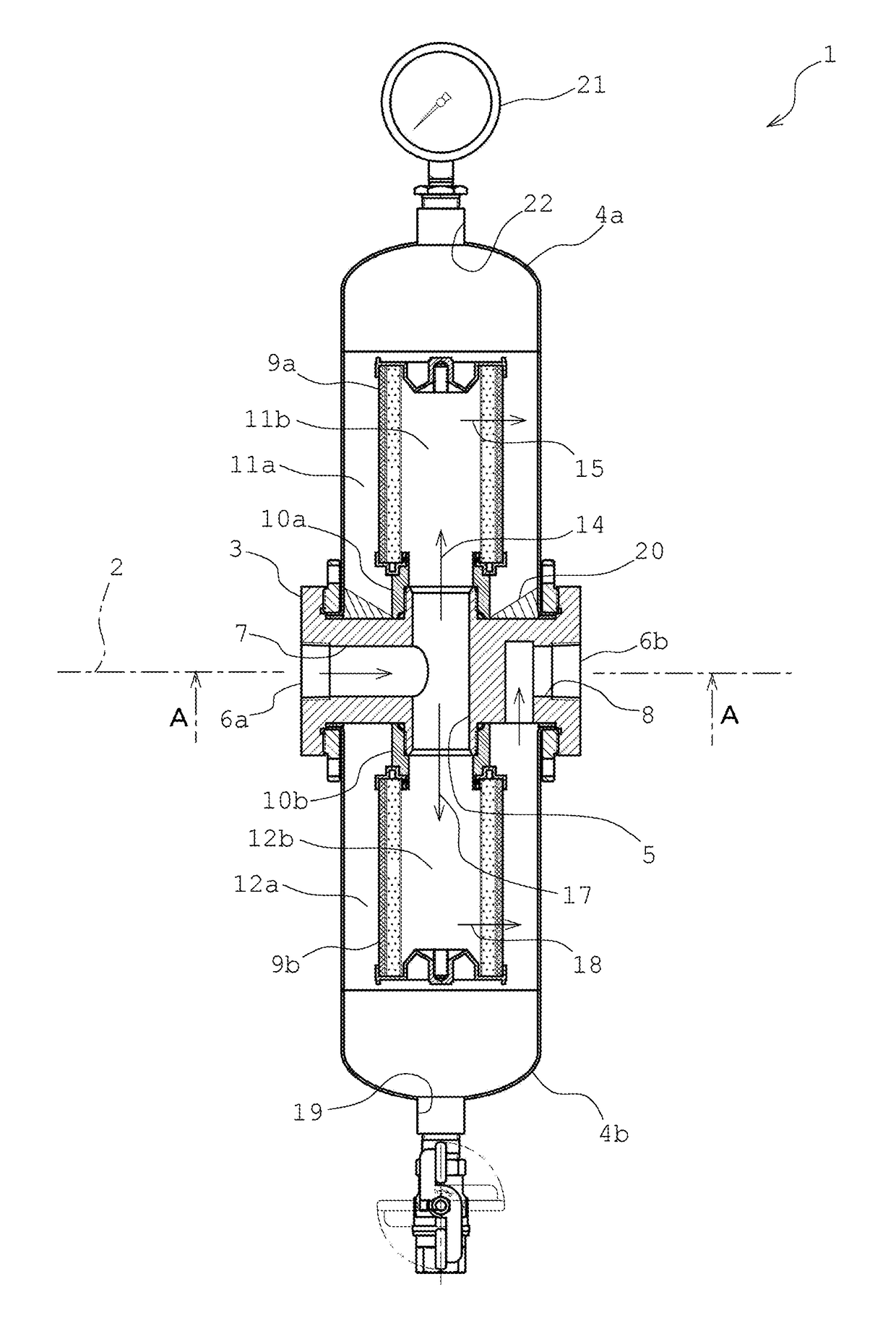

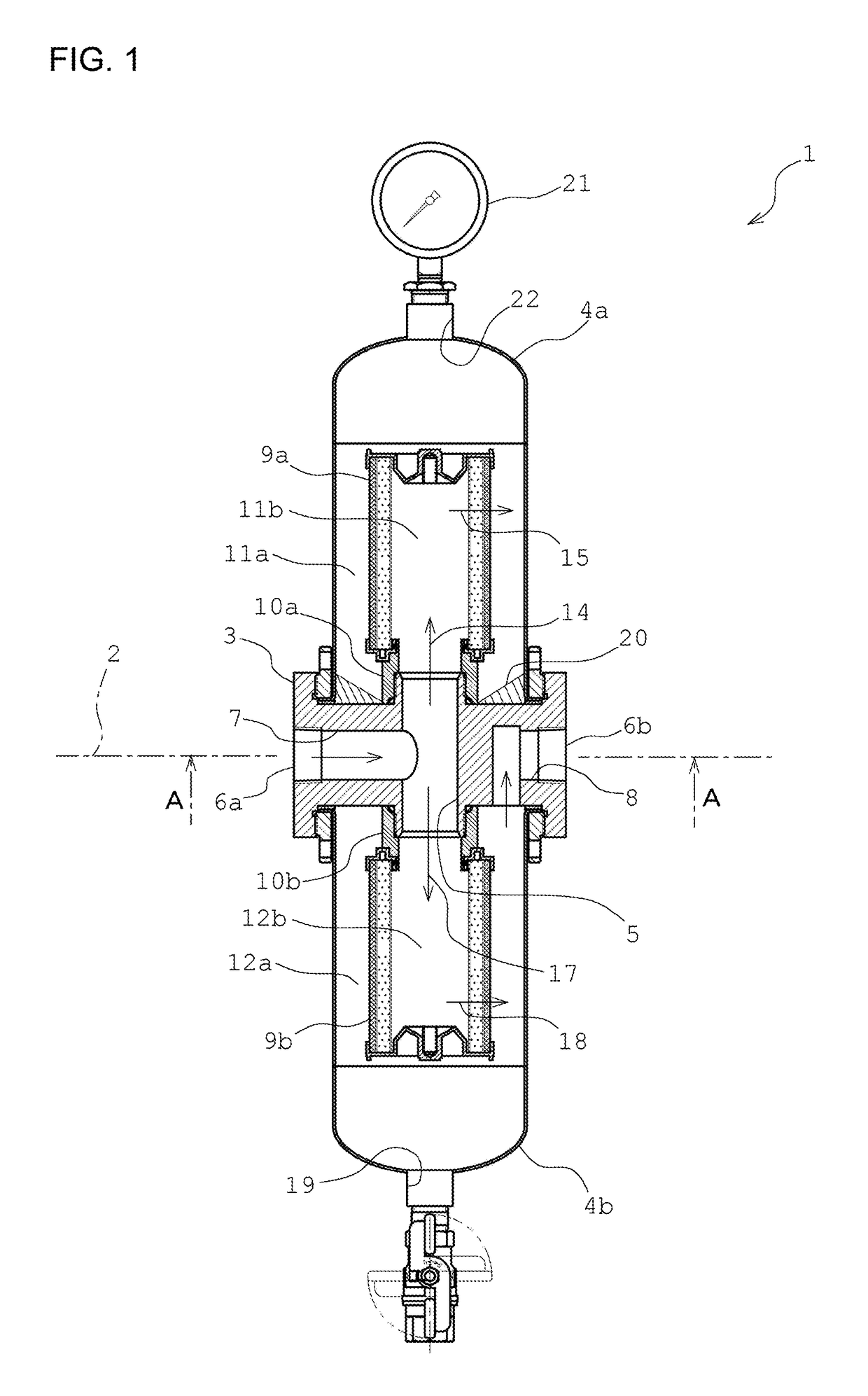

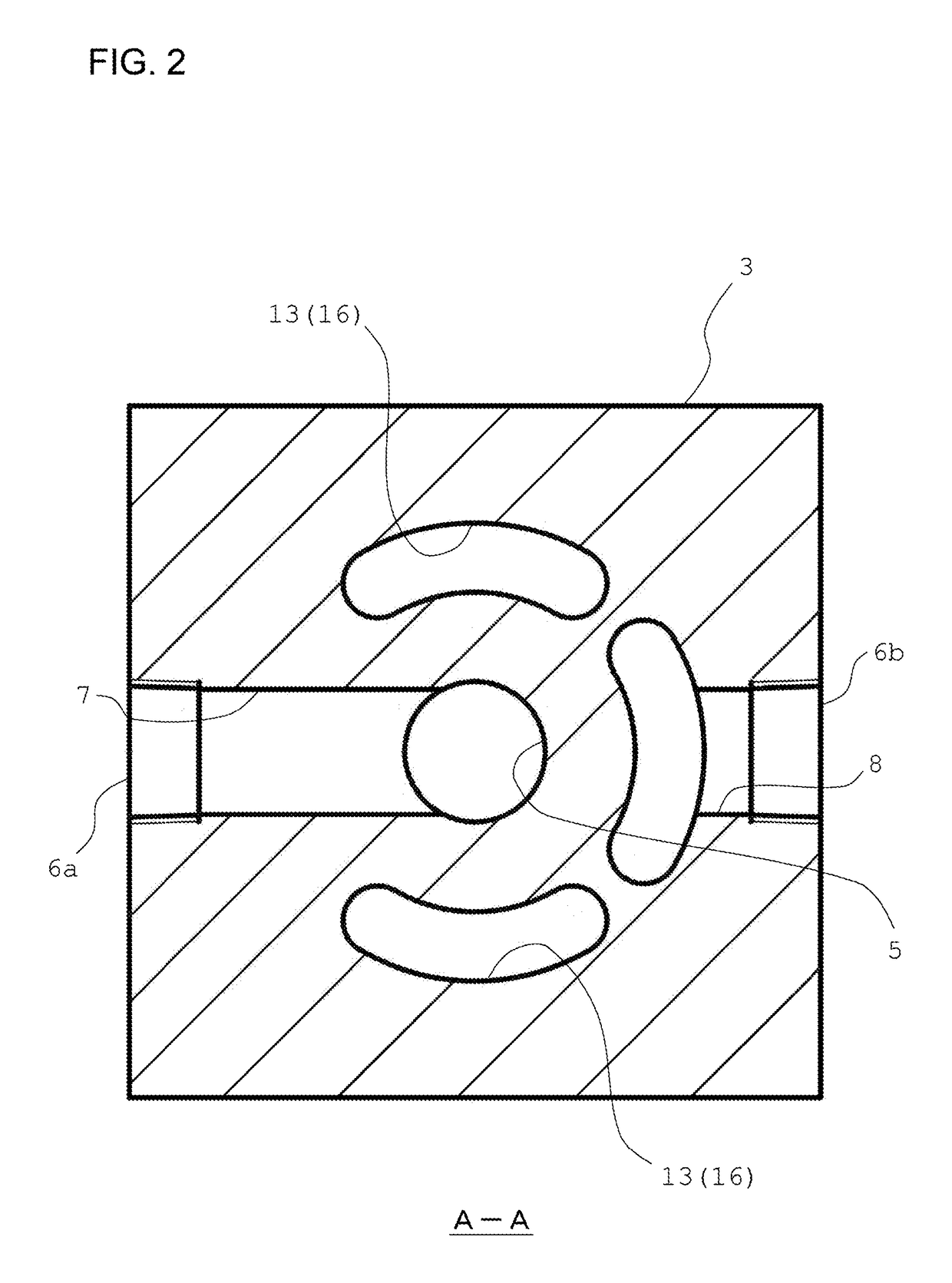

Gas Booster System and Related Method

ActiveUS20100183461A1The process is convenient and fastProvide supportPositive displacement pump componentsPiston pumpsElectricityImpeller

An improved booster for use in piped fluid systems includes a motor, a fan wheel and a hermetically sealed tank assembly. Fluids enter the tank assembly through an inlet and are compressed within the tank assembly by a rotating fan wheel, before leaving the tank assembly through an outlet, which may be aligned in a plurality of angular configurations. The motor is powered by a versatile electrical connection which enters the tank assembly through a connector that maintains the hermetically sealed condition in the tank assembly, and can accommodate power of any voltage or frequency. The incremental pressure gain provided by the booster may be controlled by modifying the speed of the rotating fan wheel, and a sled assembly provides structural support and positional alignment for portions of the tank assembly when the booster system is opened for access.

Owner:ETTER ENG

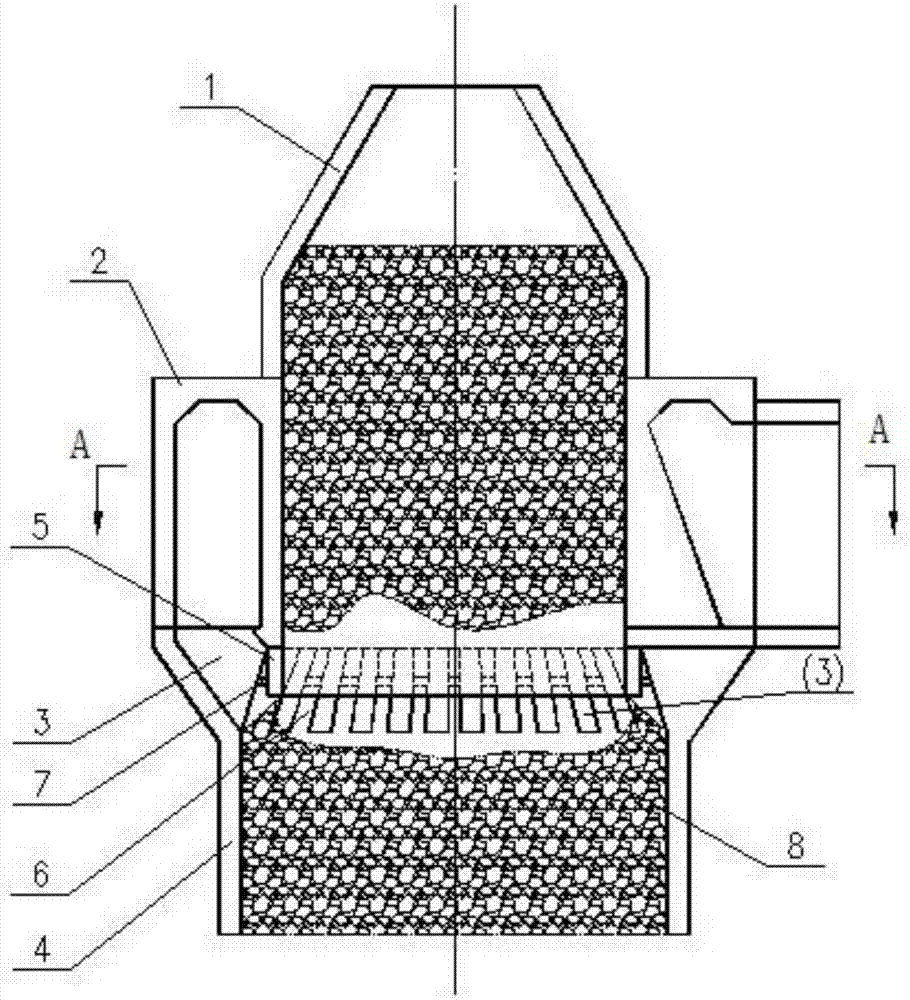

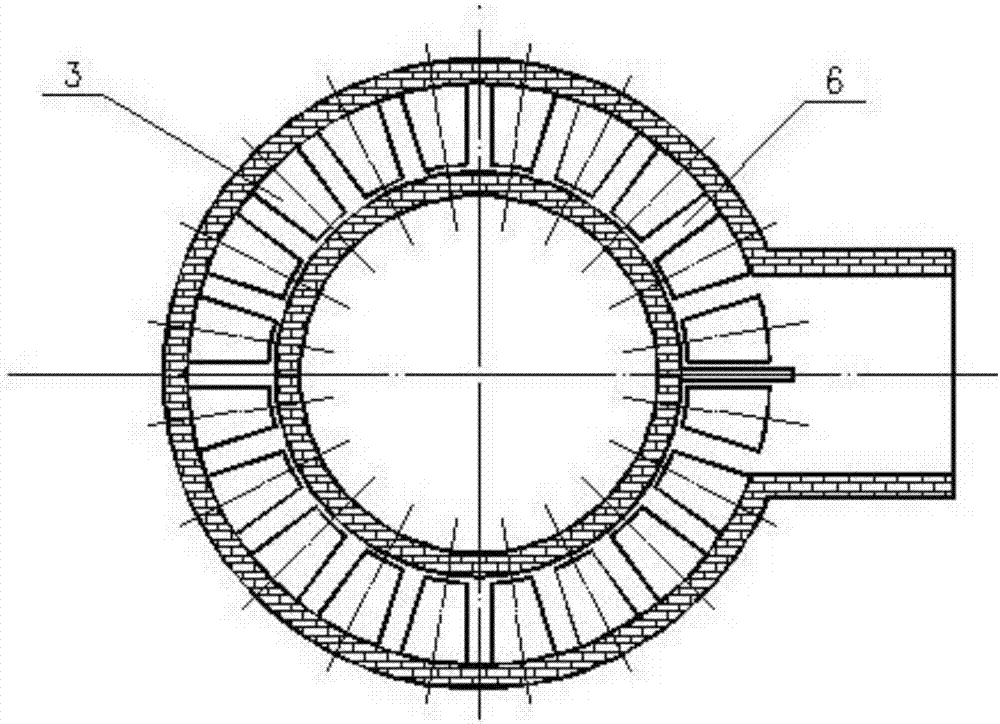

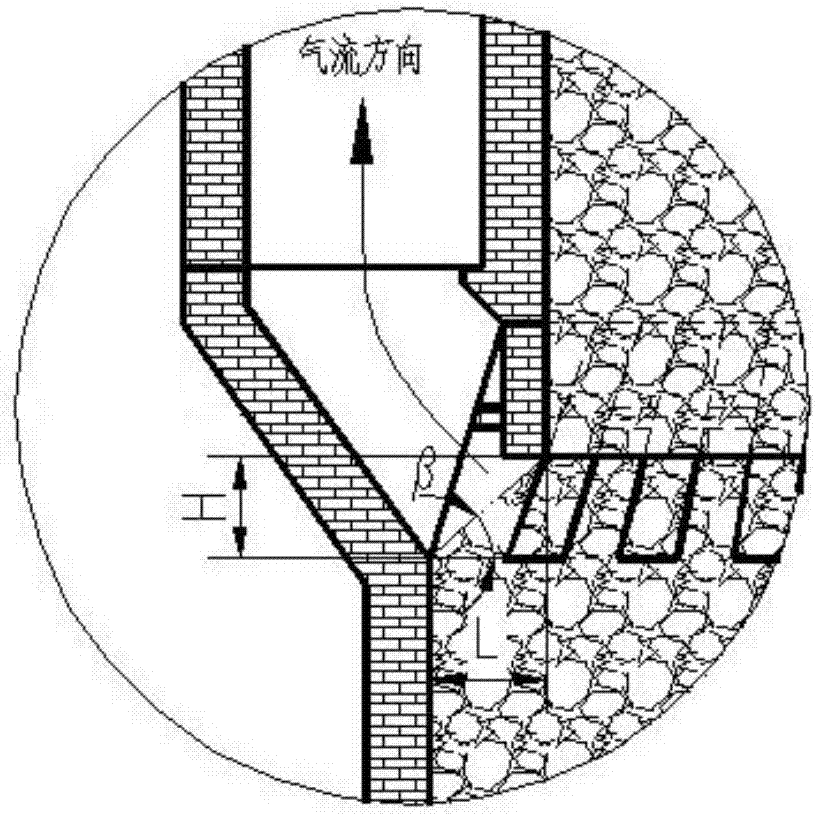

Dry quenching furnace having novel exhaust structure

ActiveCN106905988AImprove or eliminate the disadvantages of increased operating pressureGuaranteed uptimeCoke quenchingCooling chamberEngineering

The invention relates to a dry quenching furnace having a novel exhaust structure. The dry quenching furnace comprises a cooling chamber, a pre-store chamber, an inclined flue channel and an annular wind channel, the inclined flue channel communicated with the annular wind channel are arranged between the cooling chamber and the pre-store chamber, an inclined flue partition wall is arranged in the inclined flue channel; the diameter of the cooling chamber is greater than the diameter of the pre-store chamber, an annular coke barrier wall is arranged at the bottom of the pre-store chamber, and a coke barrier wall support is arranged between the annular coke barrier wall and the inclined flue baffle wall. The dry quenching furnace employs a mode for additionally installing the annular coke barrier wall on the bottom of the pre-store chamber, the coke particles are far from an inlet of the inclined flue channel, so that the phenomenon of the obstruction of the inclined flue channel by the coke can be basically solved, wearing of red coke on the inclined flue baffle wall can be prevented, operation effect and stability of the dry quenching furnace are greatly improved, investment cost is low, and the dry quenching furnace is suitable for reconstruction of newly built dry quenching furnace and the original dry quenching furnace.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

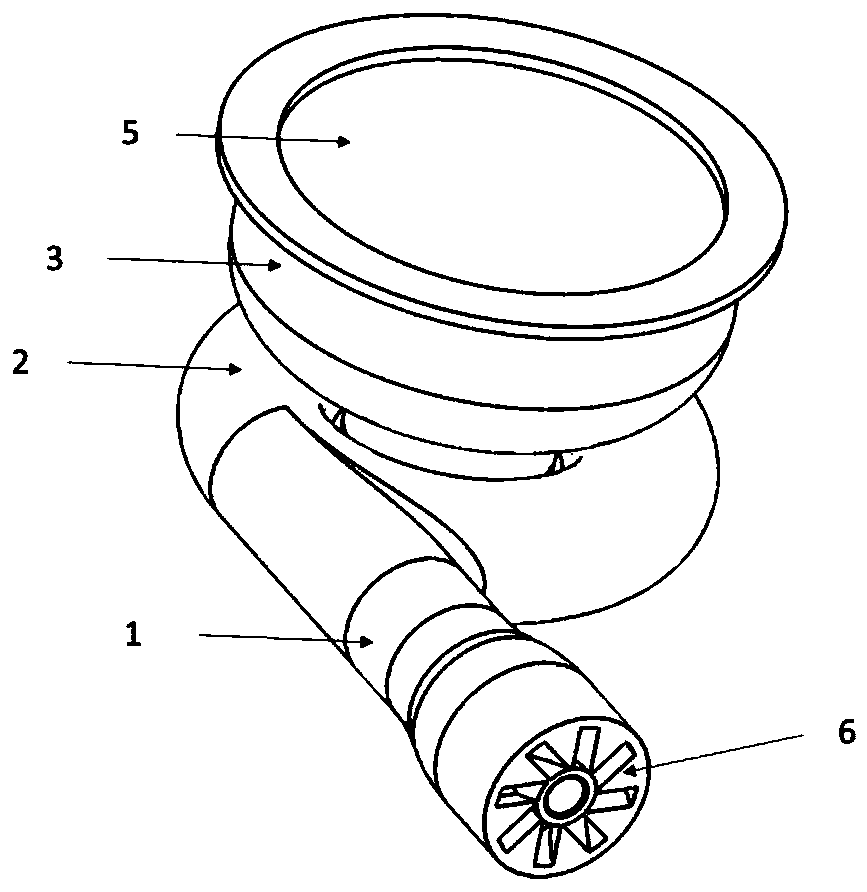

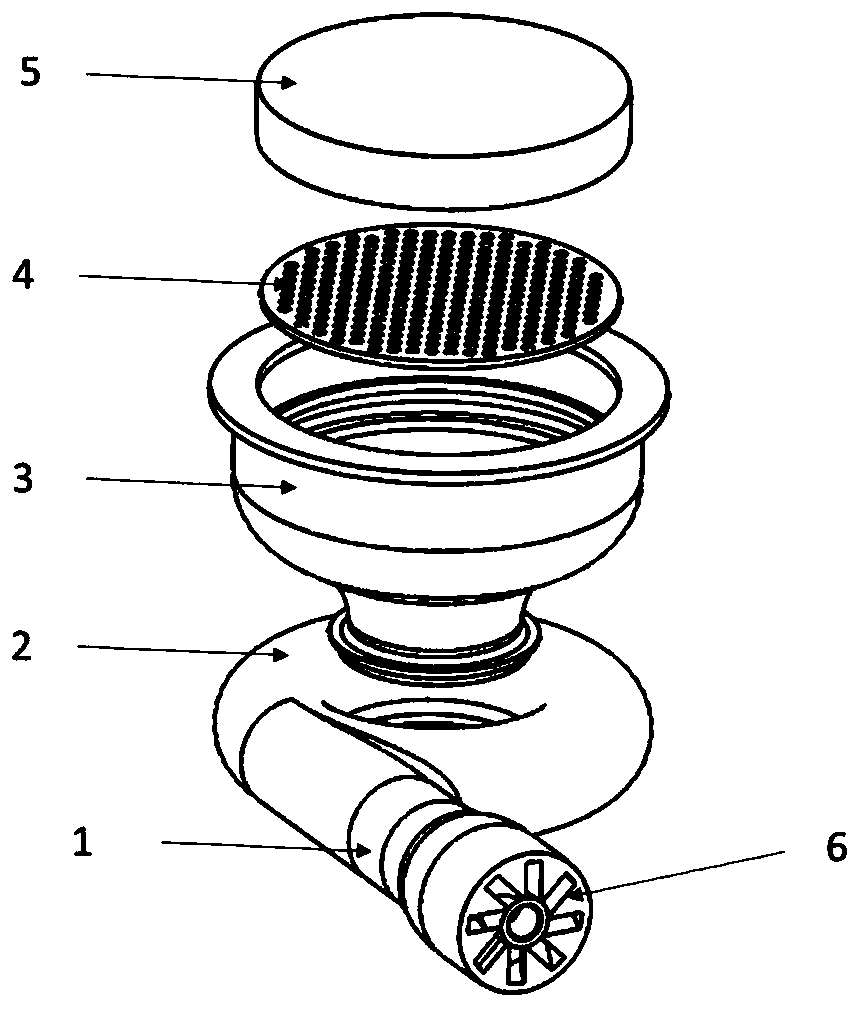

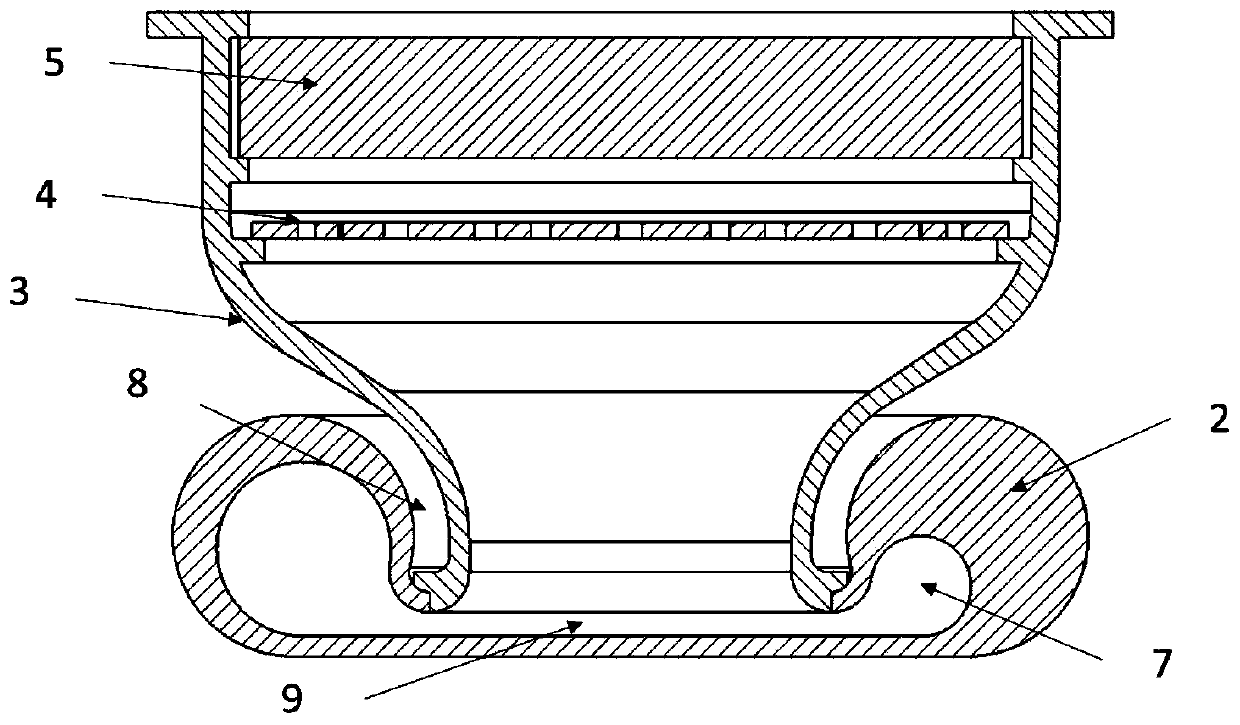

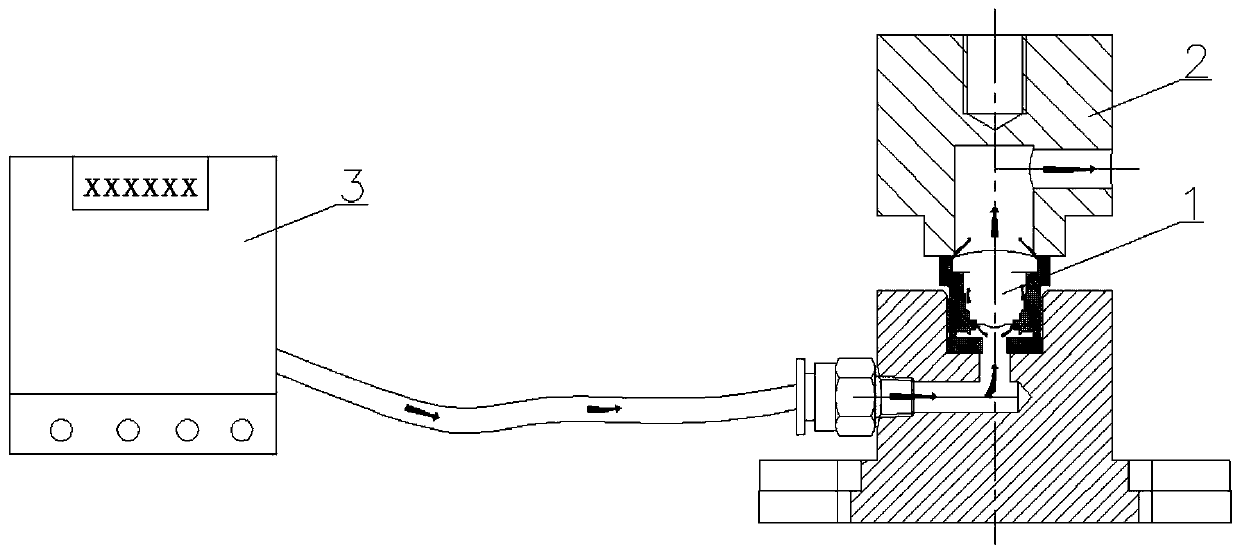

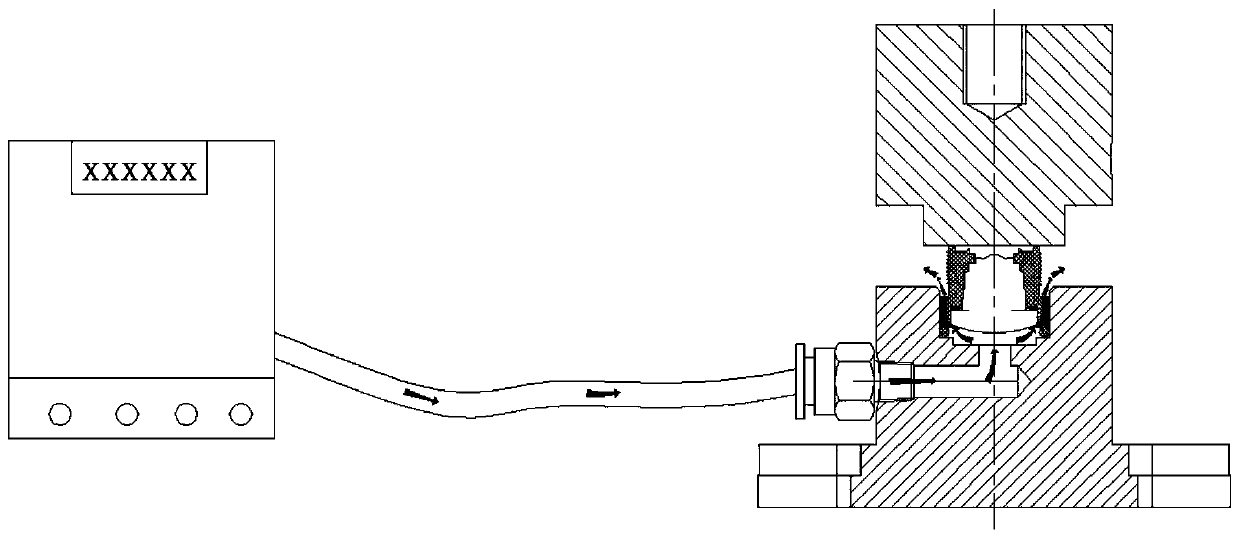

Burner for gas stove and gas stove

PendingCN111594836AExtend the mixing timeEliminate pressure lossDomestic stoves or rangesGaseous fuel burnerThermodynamicsEngineering

The invention relates to the technical field of stoves, in particular to a burner for a gas stove, and further relates to the gas stove comprising the burner. The burner for the gas stove comprises avolute, an ejector and a pot body; a gas mixing chamber with a volute flow channel is formed in the volute, a concave part with a closed bottom and an open top is formed in the middle of the volute, and a gas hole communicating with the volute flow channel and the concave part is formed in the volute; an air outlet in the ejector communicates with an air inlet in the gas mixing chamber, and the air outlet direction of the ejector is tangent to the volute flow channel; and the inlet end of the pot body is arranged in the concave part in a matched mode, an inlet in the pot body communicates withthe air hole, and an anti-backfire pore plate and a foam metal heating body are sequentially arranged at the outlet end of the pot body. According to the burner, the gas outlet direction of the ejector is tangent to the volute flow channel in the gas mixing chamber, so that the pressure loss caused by sudden expansion of the flow channel between the ejector and the gas mixing chamber is eliminated; and the gas mixing time is prolonged through the gas mixing chamber with the volute flow channel, so that the gas mixing effect is improved.

Owner:刘迪

Gas pressure wave generator for regenerative type refrigerator

InactiveCN104154669AImprove yieldSimple structureCompression machines with non-reversible cycleReciprocating motionSoft magnet

The invention relates to a gas pressure wave generator for a regenerative type refrigerator. The gas pressure wave generator comprises motors, a corrugated pipe component and a fixed housing. The motors and the corrugated pipe component are arranged in the fixed housing. The motors comprise stator components, mover components and soft magnets. The corrugated pipe component comprises a corrugated pipe, a base and a blind plate. The base and the blind plate are fixedly connected with two ends of the corrugated pipe respectively. The base is arranged in the corrugated pipe and provided with an air exhausting outlet. The base, the blind plate and the inner wall of the corrugated pipe are combined to form a sealed compressing chamber. One end, fixed to the base, of the corrugated pipe is fixedly connected with the stator components, and one end, fixed to the blind plate, of the corrugated pipe is fixedly connected with the mover components. The end, fixed with the mover components, of the corrugated pipe is driven by the mover components to do reciprocating motion along the axial direction of the corrugated pipe, allowing pressure surge to occur to the filled gas. According to the technical scheme, the gas pressure wave generator is free of a compressing piston and a compressing cylinder and overcomes the defects of difficult production, low compressing efficiency and requirement on high quantity of the gas of the conventional compressor.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

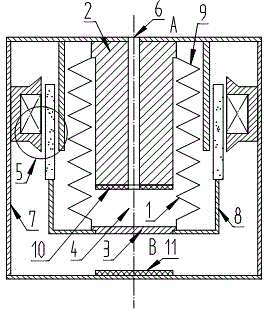

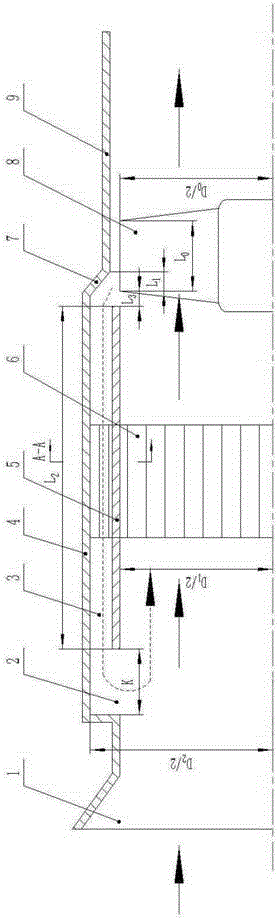

Saddle-area-free axial flow fan

InactiveCN105697421AEliminate the effects ofEliminate pressure lossPump componentsPumpsImpellerEngineering

The invention belongs to the field of fan technology and relates to a saddle-free axial flow fan, comprising a fan inlet, a conical annular flow stabilizer, a rectifying grid, a conical joint, a fan impeller and a fan outer cylinder; the conical annular flow stabilizer includes a stabilizer The outer cylinder of the current stabilizer and the inner cylinder of the current stabilizer; one end of the outer cylinder of the current stabilizer is fixedly connected to the inlet of the fan, and the other end is fixedly connected to the outer cylinder of the fan through the tapered joint; the rectifier grid is connected to the outer cylinder of the current stabilizer The tube is fixedly connected; the inner tube of the current stabilizer is welded on the rectifying grid; the inner tube of the current stabilizer has a missing ring at the inlet of the fan; the invention can transfer the secondary return flow generated by the top of the fan blade when the flow rate is small to the cone ring stabilizer The flow device is exported to the impeller, then merged into the main flow, and re-enters the impeller after being rectified by the rectifying grid, which can effectively eliminate the influence of the secondary backflow on the fan inlet, avoid the pressure loss caused by the impeller outlet airflow impacting the cylinder wall, and thus eliminate the performance curve of the axial flow fan The saddle area in the middle; can improve the stability and safety of the axial flow fan operation.

Owner:JIANGSU UNIV

Gas meter

InactiveUS8499648B2Negatively uniformity of flowEliminate pressure lossValve arrangementsVolume/mass flow by thermal effectsGas meterEngineering

A gas meter comprising a housing (2) with a gas inlet connection (5) and an inflow chamber (16) which is arranged downstream of the latter and into which gas flows via an inflow opening (14), arranged downstream of which inflow chamber (16) is a measuring section (19) arranged upstream of a gas outlet connection (6) and having a measuring device (20), in which the gas flow is measured, wherein projecting into the inflow chamber (16) there is a tube (15) which merges into the measuring section (19) or forms the latter and runs substantially perpendicularly to the gas flow direction through the inflow opening (14) and overlaps the inflow opening (14), at least in a certain section.

Owner:HYDROMETER GMBH

Filter apparatus for compressed air

ActiveUS20170232375A1High trafficReduce the number of timesGas treatmentDispersed particle filtrationEngineeringOuter space

A compressed air filter apparatus includes a main flow path as a flow path in which compressed air should circulate, formed in a body to extend from a first opening into a penetration hole, an upper inner flow path extending from the penetration hole to an upper inner space, an upper inner and outer flow path extending from the upper inner space to an upper outer space to pass through an upper filer element, a communication flow path extending from the upper outer space to a lower outer space to pass through a communication hole, a secondary flow path extending from the lower outer space to a second opening, a lower inner flow path extending from the penetration hole to a lower inner space, and a lower inner and outer flow path extending from the lower inner space to the lower outer space to pass through a lower filter element.

Owner:FUKUHARA KK

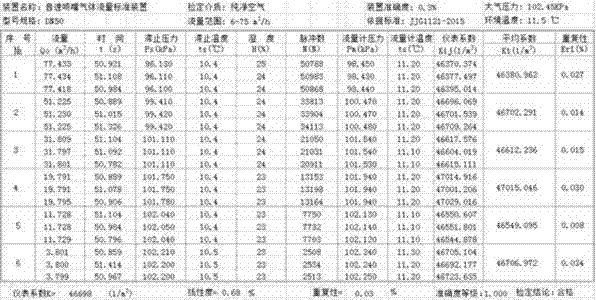

Intelligent corrosion-resistant anti-interference vortex precession flowmeter and processing and assembling process

ActiveCN107356295AImprove and extend service lifeExtended service lifeVolume/mass flow by dynamic fluid flow effectEngineeringNoise reduction

The invention provides an intelligent corrosion-resistant anti-interference vortex precession flowmeter and a processing and assembling process. The intelligent corrosion-resistant anti-interference vortex precession flowmeter comprises a vortex precession housing, a vortex generation body, a sensor and a control system. The vortex generation body is arranged in the vortex precession housing, the sensor is fixed on the exterior of the vortex precession housing and is electrically connected with the vortex generation body, the sensor is electrically connected with the control system, the vortex generation body is manufactured by means of a composite casting process, the body cavity of the vortex precession housing and the vortex generation body are both subjected to surface hardening and corrosion resisting processes, a control module of the sensor employs a 16-bit MSP430F5438A single-chip microcomputer, the MSP430F5438A single-chip microcomputer employs a compiler and can provide an IARWorkbench system having the C language standard characteristic, and program software of the control system is compiled through the C language. The intelligent corrosion-resistant anti-interference vortex precession flowmeter has performances of intelligence, corrosion resistance, anti-interference, noise reduction, full functionality and low power consumption and the like.

Owner:浙江裕顺仪表有限公司

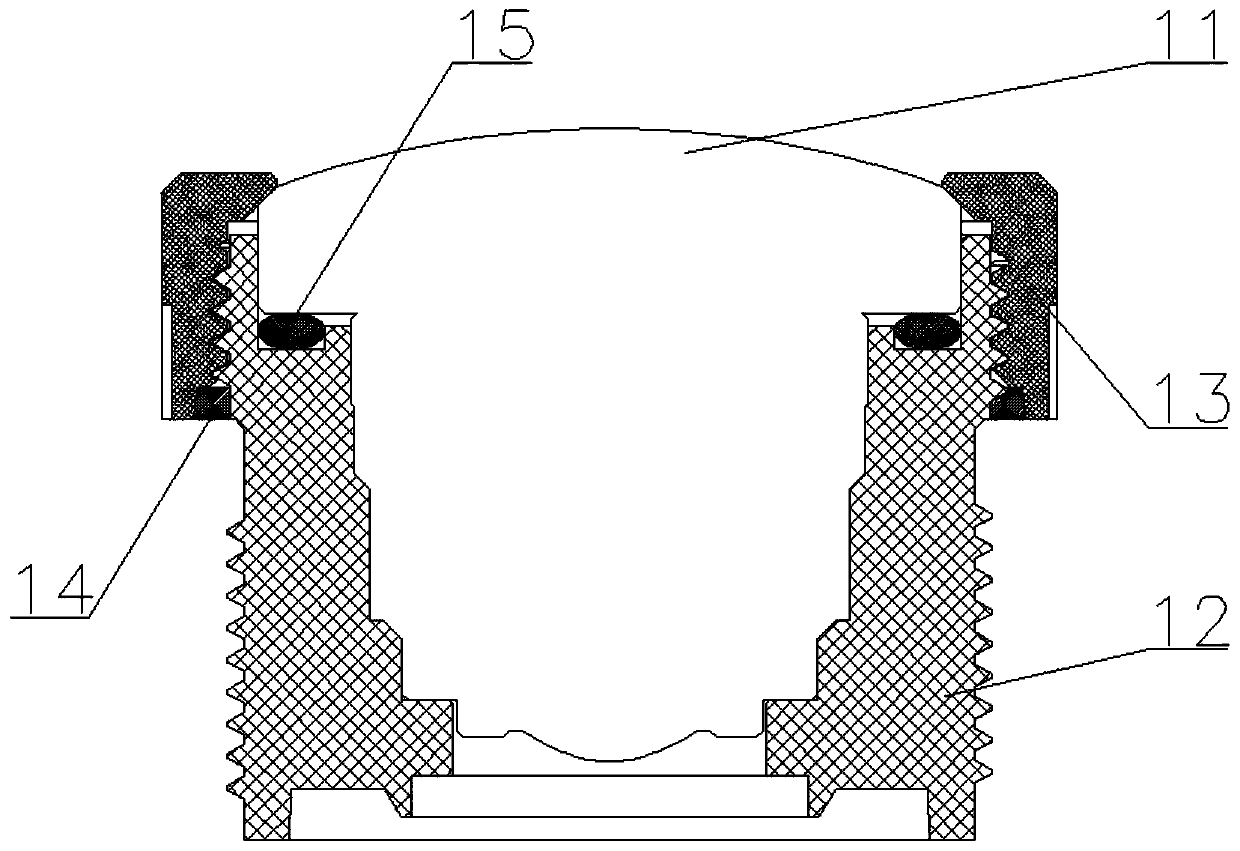

Noise reduction check valve applied to scroll compressor

InactiveCN106051238AEasy to installEasy to placeCheck valvesValve members for absorbing fluid energyFixed frameEngineering

The invention discloses a noise reduction check valve applied to a scroll compressor. The noise reduction check valve comprises a valve mounting base, a metallic round valve seat and a metallic round valve block, and further comprises a perforated-plate exhaust seat and a noise reduction guide sleeve, wherein the metallic round valve seat comprises a valve seat body and a cover; the perforated-plate exhaust seat comprises a fixed framework and noise reduction baffles; the noise reduction guide sleeve comprises a housing, noise reduction plates, a flow guide shade and a noise reduction cylinder; the housing comprises an inner housing and an outer housing; silencer cotton is arranged in a cavity between the inner housing and the outer housing; and the noise reduction plates, the flow guide shade and the noise reduction cylinder are all located in the housing. The noise reduction check valve is simple in structure and high in practicability; as the perforated-plate exhaust seat is arranged in the check valve, the check valve and a noise reduction cavity are combined, accordingly, noise generated by air impact is effectively reduced, the noise reduction effect of the scroll compressor is remarkably improved, and the scroll compressor can be used more safely and stably; and meanwhile, as the noise reduction guide sleeve is added, the noise reduction effect of the check valve is further improved, and the comprehensive utilization ratio is also improved.

Owner:嵊州市涡旋冷冻机有限公司 +1

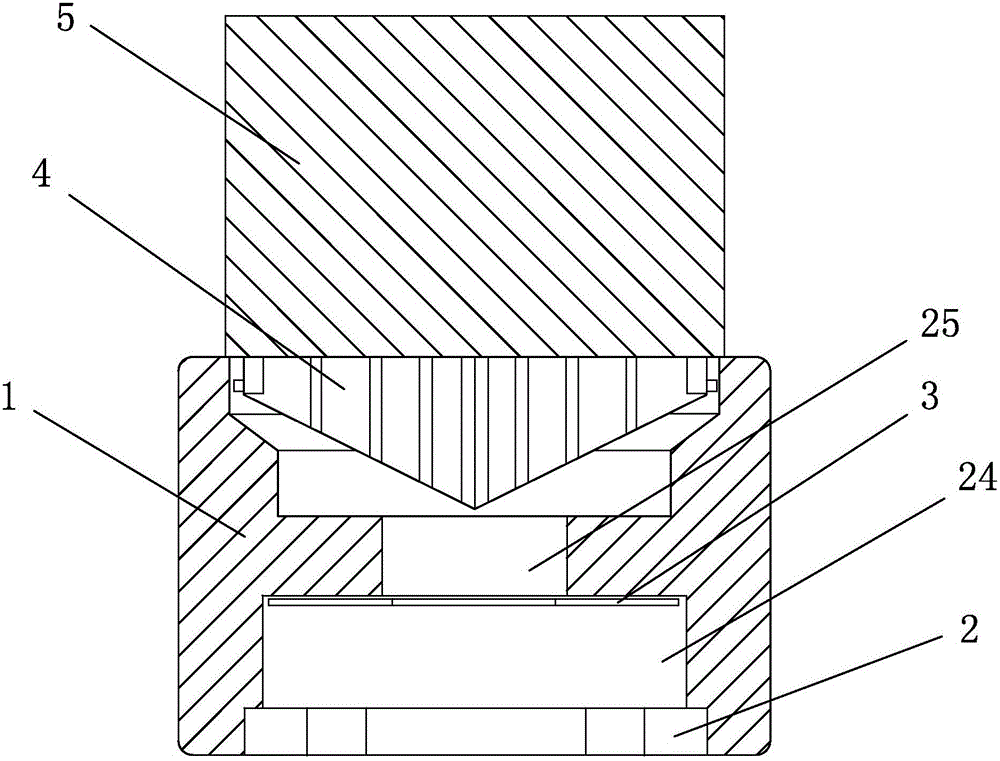

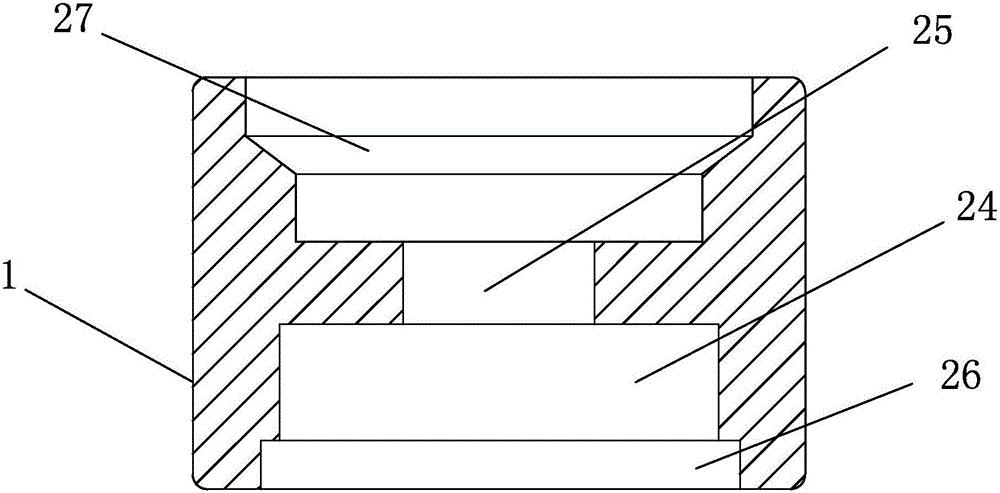

Vehicle-mounted lens sealing test device

PendingCN109855812AEliminate pressure lossSimplify detection stepsMeasurement of fluid loss/gain rateCamera lensTester device

The invention relates to the technical field of test equipment, in particular to a vehicle-mounted lens sealing test device. The vehicle-mounted lens sealing test device comprises a detection body andan air-sealing tester matched with the detection body, wherein the detection body is composed of a base and an upper pressing part. A cavity is formed in a joint transition position between the baseand the upper pressing part, and an extrusion abutting part is arranged in the cavity. Before a sealing test is carried out, the upper pressing part moves downwards until the cavity forms into a sealed cavity, and at the same time, elastic deformation of the extrusion abutting part occurs so that the extrusion abutting part abuts against a vehicle-mounted lens. A test air passage is arranged in the upper pressing part, so that two sealing parts on the vehicle-mounted lens are in communication with the air-sealing tester. Through the way, on one hand, the vehicle-mounted lens is fixed through the elastic deformation action of the extrusion abutting part, and thus the pressing loss of the vehicle-mounted lens is eliminated; and on the other hand, the sealing condition of the two sealing parts can be detected at the same time through one test process, and the orientation of the vehicle-mounted lens during the test process does not need to be changed.

Owner:SIRTEC INT SUZHOU

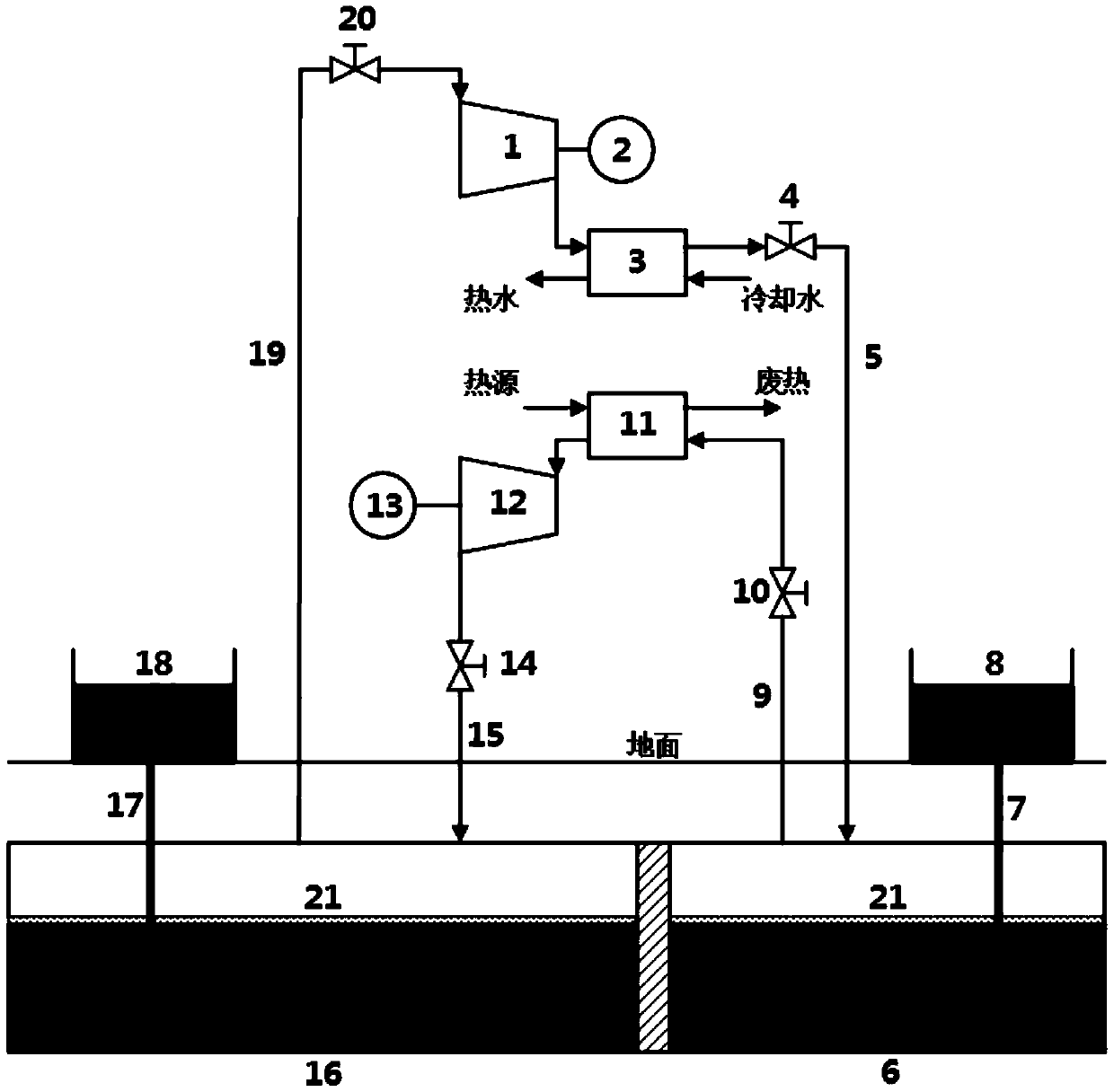

A closed isobaric compressed air energy storage system and method

ActiveCN108953099BLower pressure ratioLow expansion ratioPipeline systemsPiston pumpsLiquid storage tankMechanics

The invention provides a closed type isobaric compressed air energy storage system and method. The system comprises a compressor set, a motor, a high-pressure gas storage chamber, a high-pressure liquid storage tank and an expansion set, a generator, a low-pressure gas storage chamber and a low-pressure liquid storage tank; an outlet of the low-pressure gas storage chamber communicates with an inlet of the high-pressure gas storage chamber through the compressor set, an outlet of the high-pressure gas storage chamber communicates with an inlet of the low-pressure gas storage chamber through the expansion set, so that a closed loop is formed; the low-pressure gas storage chamber is connected with the low-pressure liquid storage tank through a low-pressure liquid conveying pipeline, and thehigh-pressure gas storage chamber is connected with the high-pressure liquid storage tank through a high-pressure liquid conveying pipeline; and the compression net is provided with the motor; and theexpansion set is provided with the generator. According to the system and the method, the expansion ratio of the expansion set of the system is reduced, and air is fully expanded in each stage of expansion machines; and the complexity of the system is reduced, the pressure loss caused by a throttling pressure-stabilizing valve of a traditional compressed air energy storage system is eliminated, the compressor set and the expansion set of the system can be operated under a stable working condition, and the efficiency and economical efficiency of the system are improved.

Owner:XI AN JIAOTONG UNIV

Lift converging multiway valve

ActiveCN102674210BNormal lifting actionReduce energy lossServomotor componentsLifting devicesInlet valveEngineering

A lift converging multiway valve belongs to the technical field of forklift multiway valves, and comprises an oil inlet and return valve plate and an oil inlet valve plate, wherein a lift converging valve plate, an inclined valve plate and an accessory valve plate are coordinately arranged between the oil inlet and return valve plate and the oil inlet valve plate, the oil inlet and return valve plate and the lift converging valve plate are arranged into an integral structure, a speed limit valve is arranged on the oil inlet and return valve plate, a lift valve rod is coordinately arranged in the lift converging valve plate, an oil channel and a group of oil ports are coordinately arranged in the multiway valve, an oil inlet check valve is coordinately arranged on the oil channel, and a safety valve is coordinately arranged at one side of the oil inlet and return valve plate. The double-pump working state is only applied when a forklift doorframe is lifted, for other motions of the doorframe, only one pump is required to work, the other pump unloads at low pressure, the normal lift motion of a forklift is ensured, the energy consumption loss of an engine or a motor is also decreased, the use of an oil pipe of a system is reduced, the lift converging multiway valve has a simple structure, the utilization rate of a valve body is improved, the manufacture costs of the valve and a pipeline can be saved, the pressure loss of the valve body can also be reduced, so an energy-saving effect is realized.

Owner:ZHEJIANG HAIHONG HYDRAULIC TECH

Water draining structure of dehumidifier and dehumidifier

ActiveUS10365010B2Increased riskHigh pumping pressureCondensate preventionFlexible member pumpsEngineeringCondensed water

Owner:JIANGSU YOAU ELECTRIC CO LTD

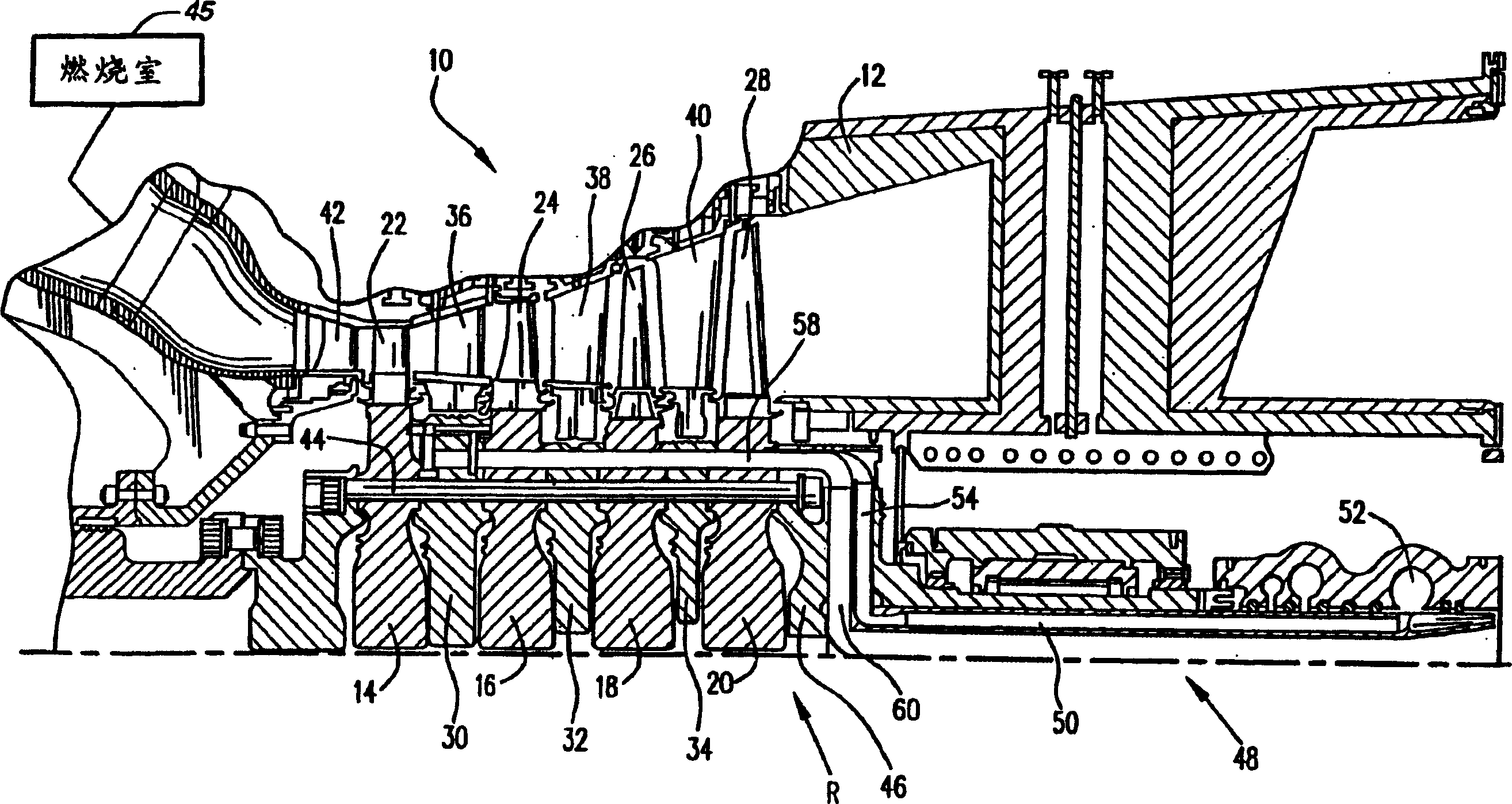

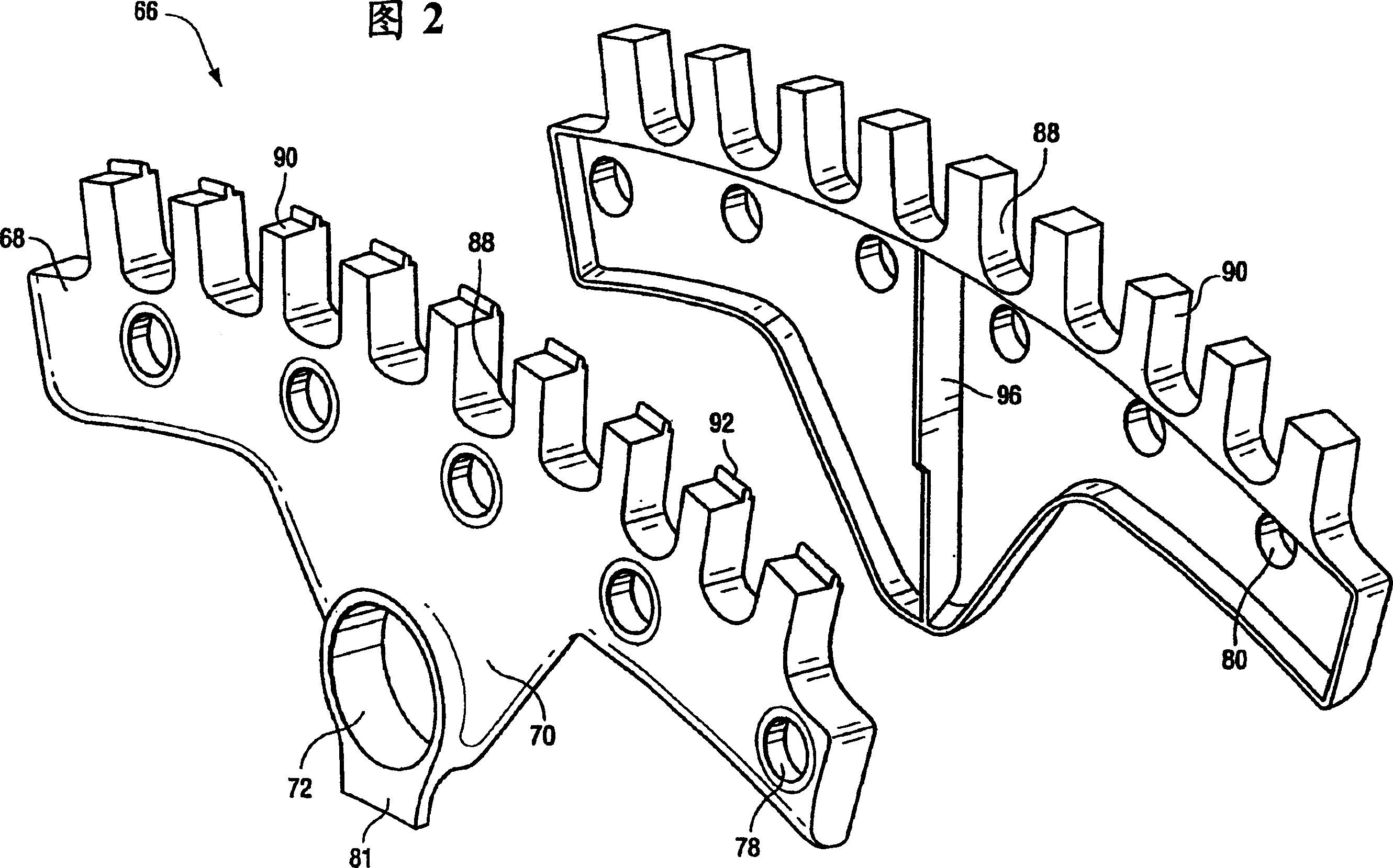

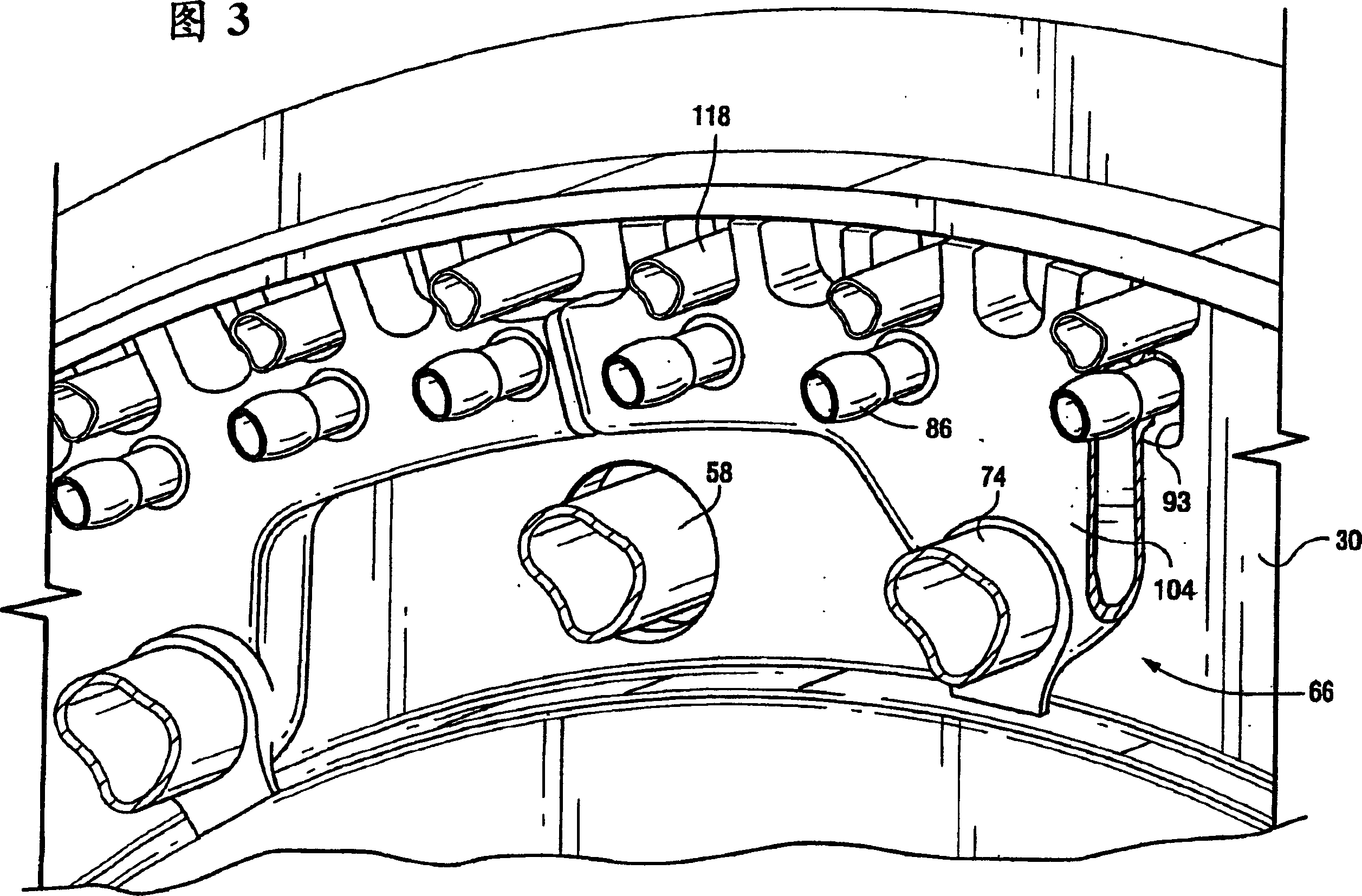

Cooling system for gas turbine

InactiveCN1298978CEliminate pressure lossPrevent axial movementTurbine/propulsion engine coolingEngine fuctionsGas turbinesEngineering

A plurality of arcuate circumferentially spaced supply and return manifold segments are arranged on the rim of a rotor for respectively receiving and distributing cooling steam through exit ports for distribution to first and second-stage buckets and receiving spent cooling steam from the first and second-stage buckets through inlet ports for transmission to axially extending return passages. Each of the supply and return manifold segments has a retention system for precluding substantial axial, radial and circumferential displacement relative to the rotor. The segments also include guide vanes for minimizing pressure losses in the supply and return of the cooling steam. The segments lie substantially equal distances from the centerline of the rotor and crossover tubes extend through each of the segments for communicating steam between the axially adjacent buckets of the first and second stages, respectively.

Owner:GENERAL ELECTRIC CO

Method for operating a static gas turbine, and intake duct for intake air of a gas turbine

ActiveUS9447756B2High power outputReduce the required powerGas turbine plantsTurbine/propulsion air intakesMicro gas turbineAmbient air

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

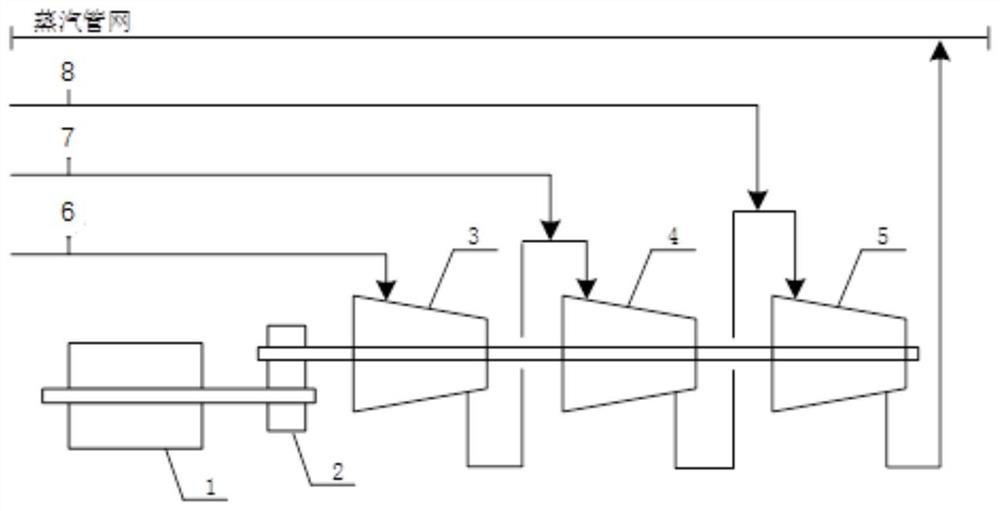

Device for simultaneously recycling different pressure dead steam and using method of device

PendingCN111648935AEliminate pressure lossLow powerPiston pumpsMulti-stage pumpsProcess engineeringSystem pressure

The invention provides a device for simultaneously recycling different pressure dead steam. The device comprises a driver and a steam compressor, the steam compressor is a multistage steam compressor,the multistage steam compressor is driven by the driver, the series of the multistage steam compressor is not less than the pressure rating number of raw material steam to be compressed, an externally-connected steam inlet is formed in each stage of the multistage steam compressor, the raw material steam with different pressure rating sequentially enter the stages of the steam compressor throughthe externally-connected steam inlets according to pressure from small to large, the stages of the steam compressor lift and press the raw material steam to the same with the next-stage raw material steam pressure rating, the raw material steam is jointly fed into the next stage for compressor, the final stage of the steam compressor lifts and presses the raw material steam to the same with steampipe system pressure rating, and the raw material steam is fed into a steam pipe system. Dead steam of different pressure can be simultaneously recycled, the pressure loss formed by the dead steam being mixed into a stream of dead steam to enter the steam compressor can be eliminated, and the power of the steam compressor is reduced.

Owner:SHANGHAI HUIDE ENERGY INTEGRATION TECH

Novel double-gland high-pressure pipeline displacement compensator

ActiveCN102003592BReduce gapGuaranteed uptimePipeline expansion-compensationChemical industryEngineering

Owner:陈墅庚

Filter apparatus for compressed air

ActiveUS9757671B2Eliminate pressure lossHigh trafficGas treatmentDispersed particle filtrationEngineeringOuter space

Owner:FUKUHARA KK

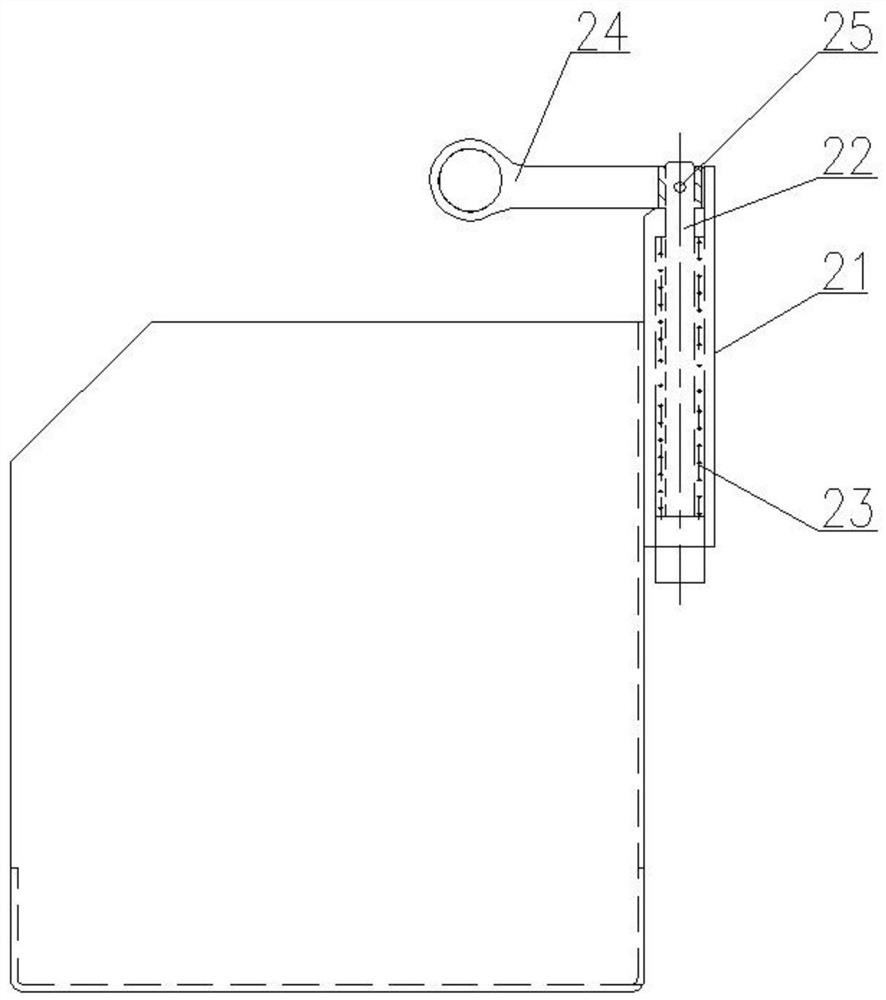

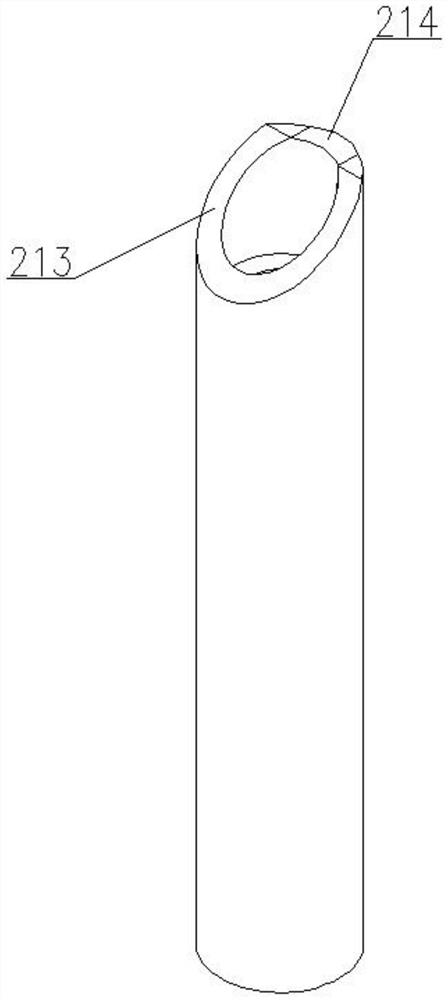

Fixing support suitable for large vehicle-mounted medical equipment

PendingCN113294669AAchieve elastic compressionEliminate pressure lossSurgical furnitureStands/trestlesMedical equipmentIn vehicle

The invention relates to a fixing support suitable for large vehicle-mounted medical equipment. The fixing support comprises a tray and an elastic material pressing device. The tray comprises a bearing bottom wall, a bending limiting wall and a bending mounting wall. The bending limiting wall and the bending mounting wall are formed by continuously extending the bearing bottom wall outwards and bending the bearing bottom wall upwards by 90 degrees. The elastic material pressing device is fixed to the bending mounting wall. After the medical equipment is placed in place relative to the bearing bottom wall, the bending limiting wall and the bending mounting wall act cooperatively to limit the plane displacement movement of the medical equipment, and the elastic material pressing device is subjected to action control to achieve elastic pressing or loosening of the top wall of the medical equipment. In the actual operation of locking the position of the medical equipment, the operation can be completed by one person, and the time consumed is relatively short; in addition, the force directly applied by the elastic material pressing device and used for limiting the displacement movement of the medical equipment in the height direction is elastic force, and therefore the phenomenon that the top wall of the medical equipment is pressed and damaged can be effectively eradicated.

Owner:SUZHOU JIANGNAN AEROSPACE MECHANICAL& ELECTRICAL IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com