Noise reduction check valve applied to scroll compressor

A scroll compressor and one-way valve technology, which is applied in the types of functional valves, components of pumping devices for elastic fluids, and devices for absorbing fluid energy of valves, etc. Increase the volume of related parts and reduce the volume of the machine to achieve the effect of good isolation, prolonging service life and preventing backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

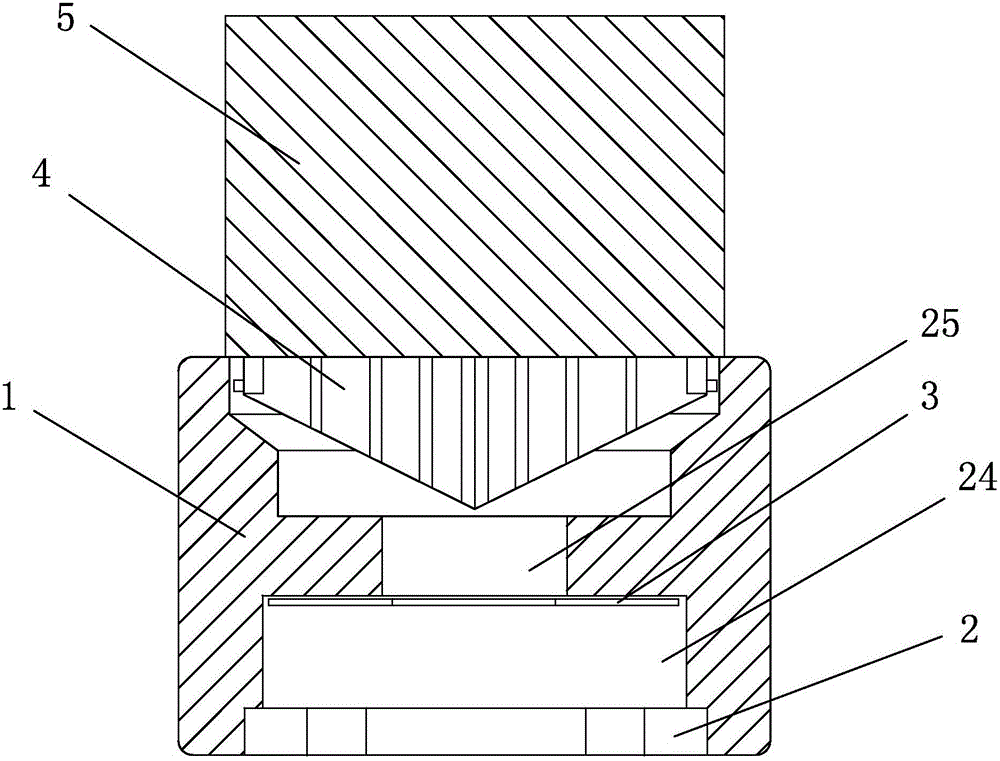

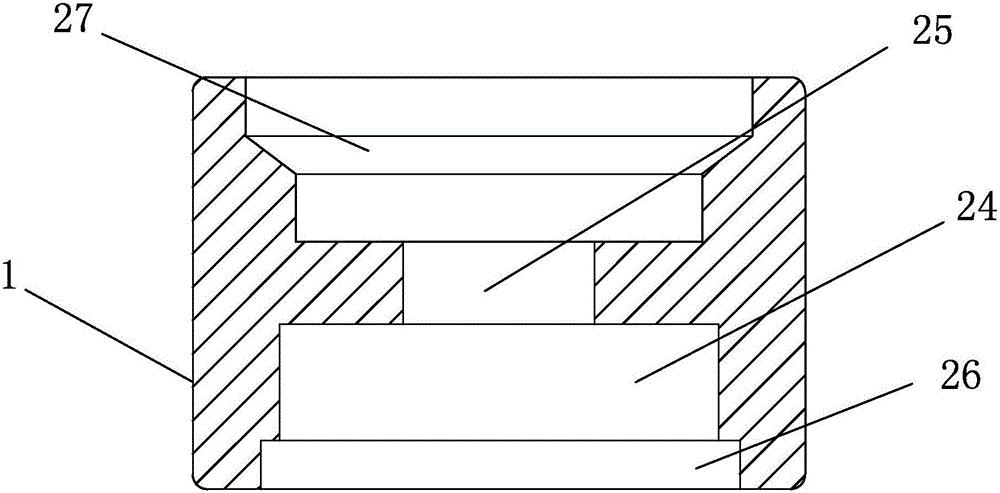

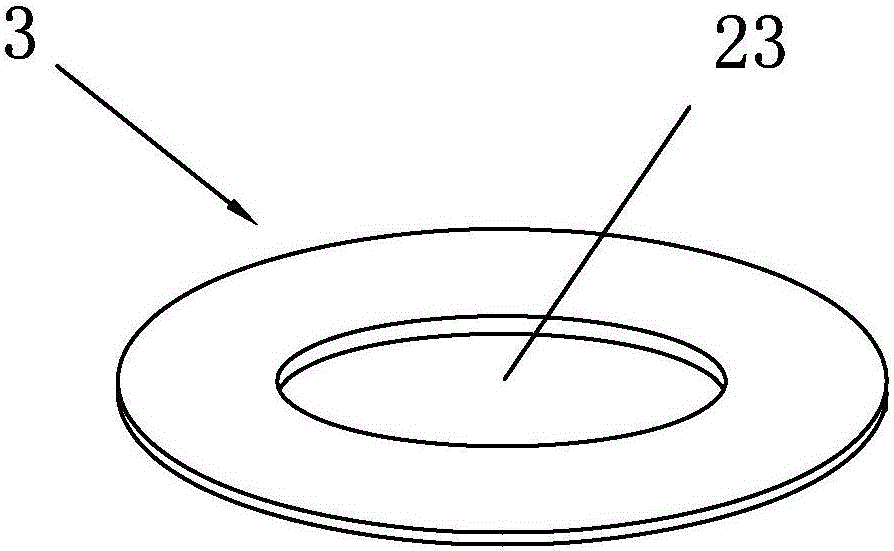

[0029] Such as Figure 1 to Figure 6 As shown, it is a one-way valve with noise reduction function applied to scroll compressors according to the present invention. The one-way valve includes a valve mounting seat 1, a metal circular valve seat 2 and a metal circular valve plate 3, and the metal circular valve The center of the sheet 3 is provided with a through hole 23, the diameter of the through hole 23 is smaller than the diameter of the cover 7, and the metal circular valve sheet 3 matches the metal circular valve seat 2, the design of the through hole 23 can facilitate the gas from the metal The through hole 23 of the circular valve plate 3 flows out, and then flows out from the air flow channel. The diameter of the through hole 23 is less than the diameter of the retaining cover 7, so that when the metal circular valve plate 3 is closed, it is ensured that the retaining cover 7 closes the metal circular valve. The through hole 23 of the valve plate 3 is blocked, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com