Cooling system for gas turbine

A technology of cooling system and cooling medium, which is applied in the field of manifold system and can solve the problems of large loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

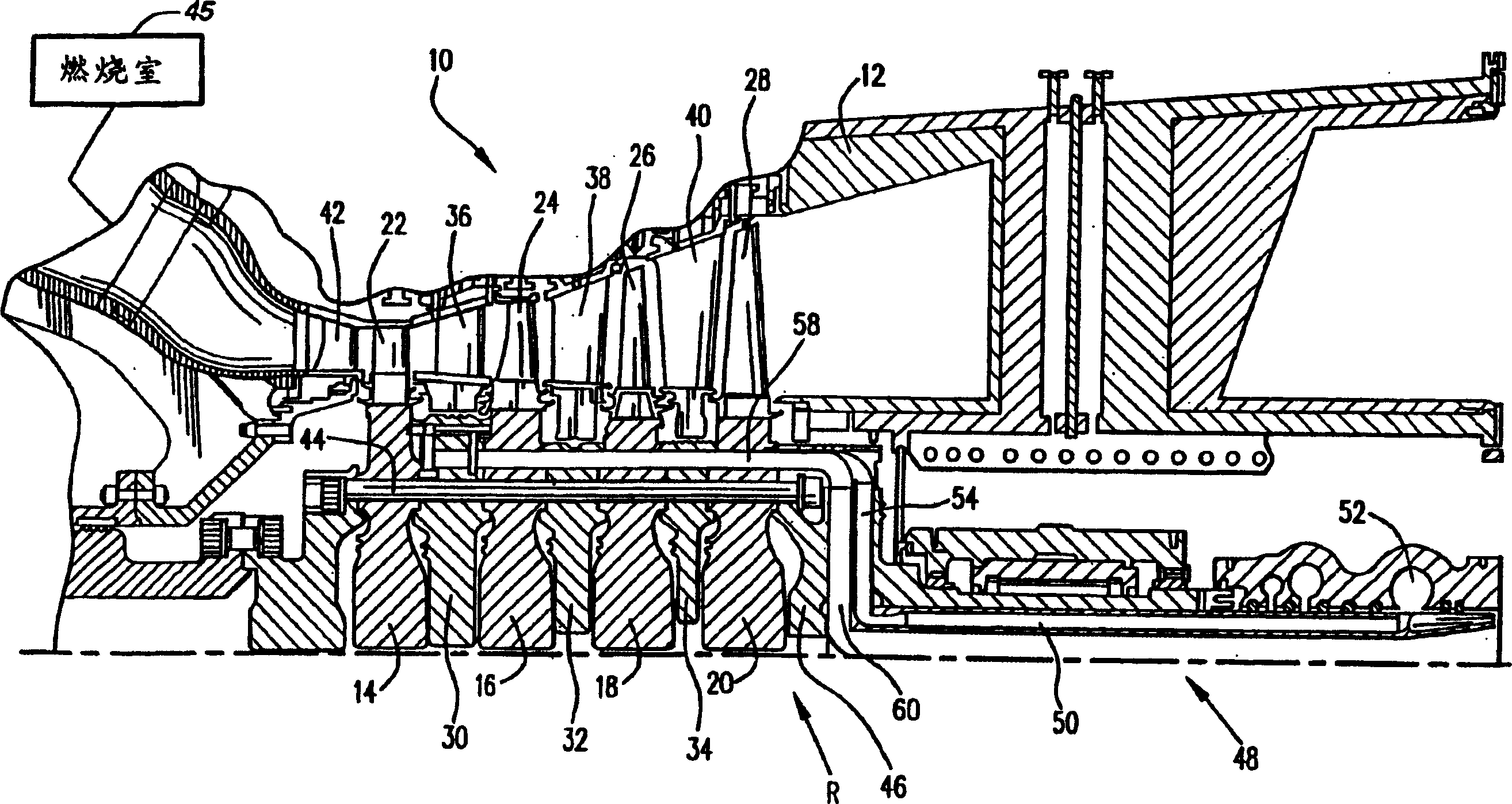

[0021] Referring now to the attached drawings especially figure 1 , there is shown a turbine section indicated generally at 10 which incorporates a preferred embodiment of the present invention. The turbine section 10 includes a turbine housing 12 surrounding a turbine rotor R. As shown in FIG. The rotor R in this example comprises four successive stages comprising impellers 14, 16, 18 and 20 with a plurality of circumferentially spaced buckets or blades 22, 24, 26 and 28, respectively. The impellers are arranged alternately between the spacers 30 , 32 and 34 . The outer edges of the spacers 30 , 32 and 34 are radially aligned with a plurality of stator buckets or nozzles 36 , 38 and 40 , with a first set of nozzles 42 forward of the first bucket 22 . It will therefore be appreciated that a four stage turbine is shown where the first stage includes the nozzle 42 and buckets 22, the second stage includes the nozzle 36 and buckets 24, the third stage includes the nozzle 38 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com