Device for simultaneously recycling different pressure dead steam and using method of device

A technology of pressure and pressure level, applied in the field of vapor compression process equipment, can solve the problems of pressure energy loss, unrecoverable exhausted steam, waste of heat resources, etc., and achieve the effect of eliminating pressure loss and reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

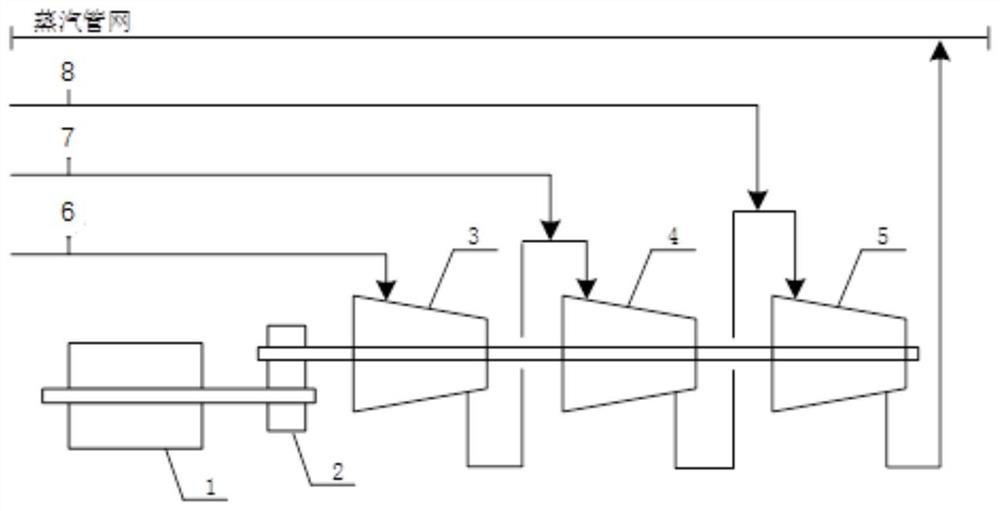

Embodiment 1

[0018] Such as figure 1 As shown, this embodiment is an example of an optimization process of using the multi-stage vapor compression device of the present invention for exhaust steam of a certain petrochemical company with different pressure levels, including a multi-stage vapor compressor, a driving machine 1 and a gear box 2, and the multi-stage vapor compression The machine has three stages, including the first stage 3 of the compressor, the second stage 4 of the compressor and the third stage 5 of the compressor. The number of stages can also be increased or decreased according to actual needs, but the total number should not be less than two. The driving machine 1 drives the multi-stage steam compressor to run through the gear box 2 . The steam flow rate of the first raw material steam 6 is 20t / h at 0.1MPa, the steam flow rate of the second raw material steam 7 is 25t / h at 0.3MPa, the steam flow rate of the third raw material steam 8 is 0.7MPa and 35t / h, and the steam pi...

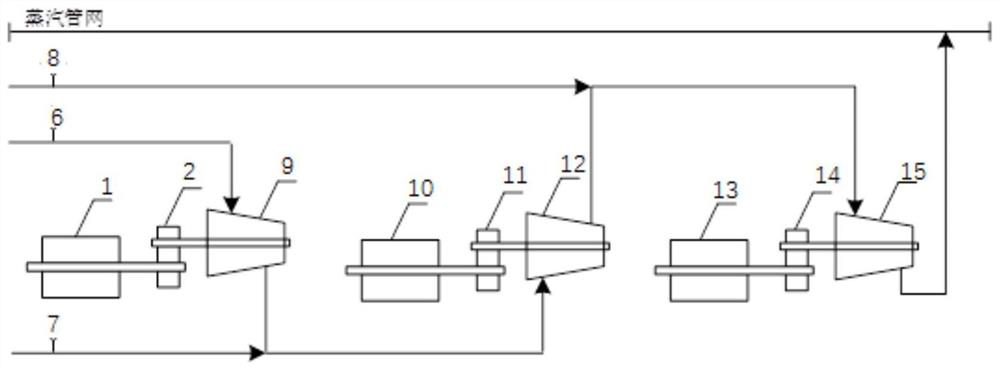

Embodiment 2

[0024] Such as figure 2 As shown, this embodiment is an example of the optimization process of a multi-stage vapor compression device invented by a petrochemical company for exhaust steam with different pressure levels. Compared with Embodiment 1, this embodiment uses three single-stage vapor compressors to Instead of multi-stage compressors, the number of steam compressors can also be increased or decreased according to actual needs, but the total number should not be less than two. This embodiment includes a compressor 1, a gear box 2, a first compressor 9, a second driver 10, a second gear box 11, a second compressor 12, a third driver 13, a third gear box 14 and a third Compressor 15, the first raw material steam 6 is 0.2MPa steam flow rate 25t / h, the second raw material steam 7 is 0.5MPa steam flow rate 30t / h, the third raw material steam 8 is 0.8MPa steam flow rate 15t / h, and the steam pipe network is 1.5Mpa. The first raw steam 6 is connected to the external steam pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com