Novel double-gland high-pressure pipeline displacement compensator

A high-pressure pipeline and displacement compensation technology, which is applied to expansion compensation devices for pipelines, pipe components, pipes/pipe joints/fittings, etc., can solve problems such as large friction coefficient, pressure loss, and limited flow of fluid media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

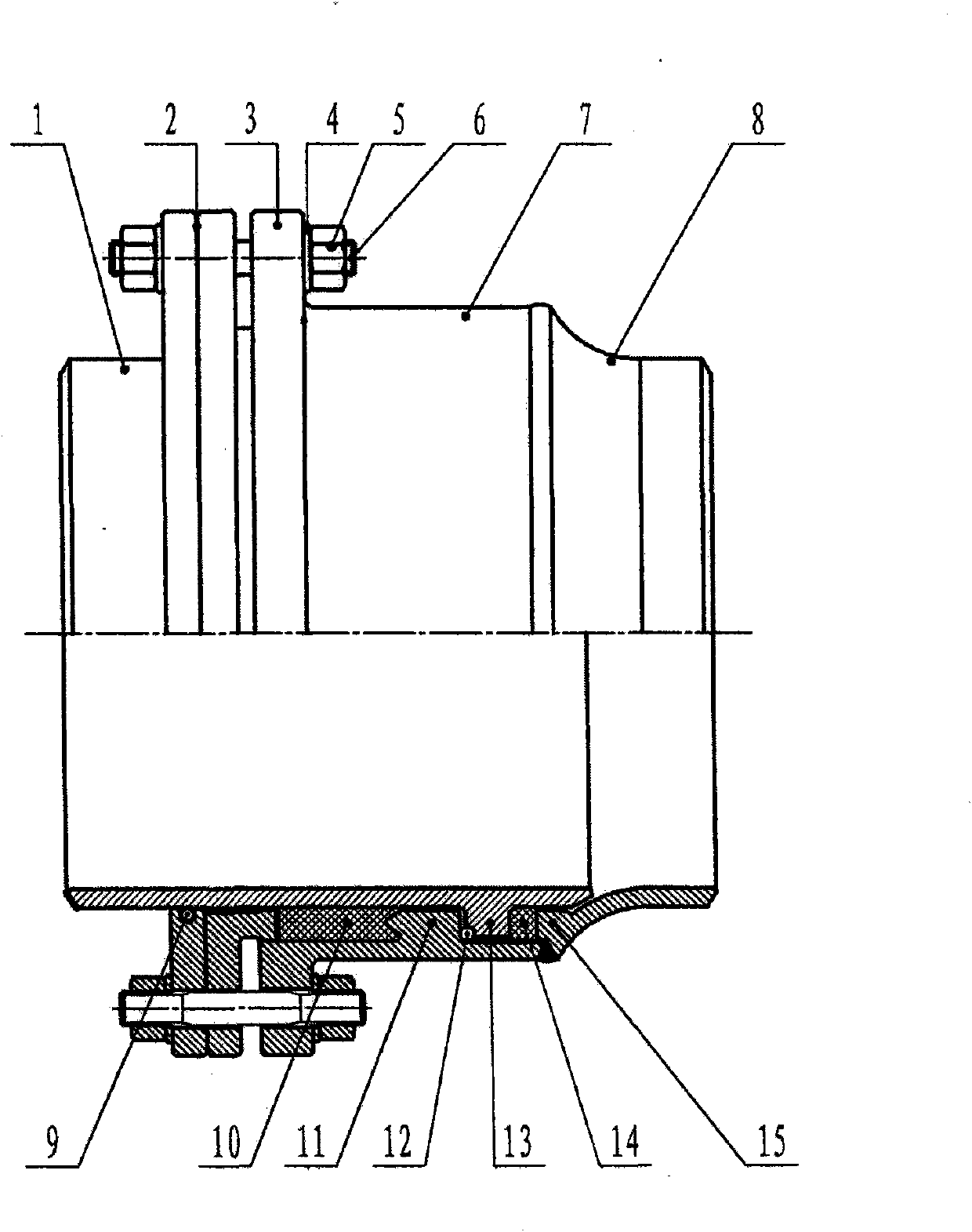

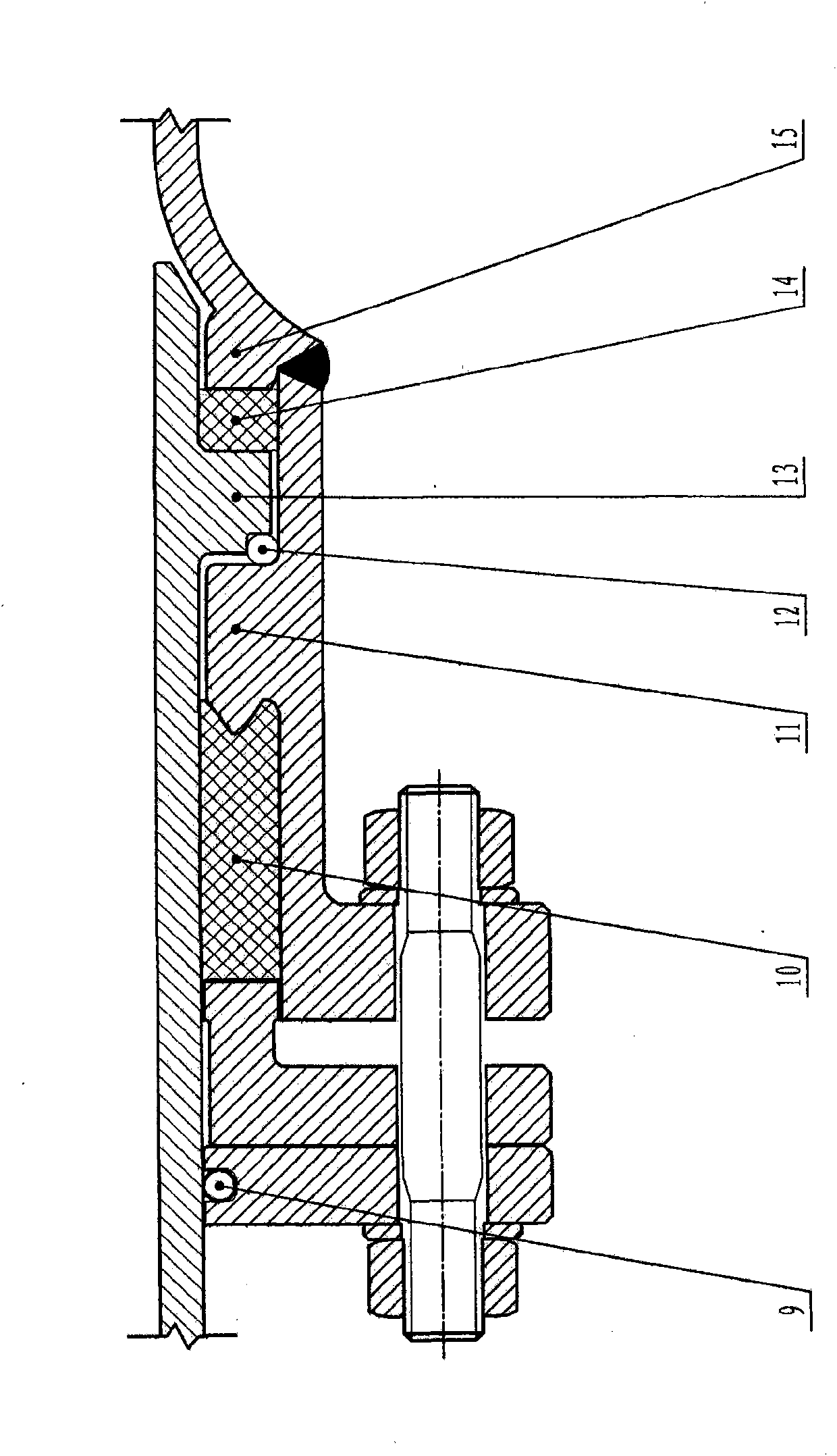

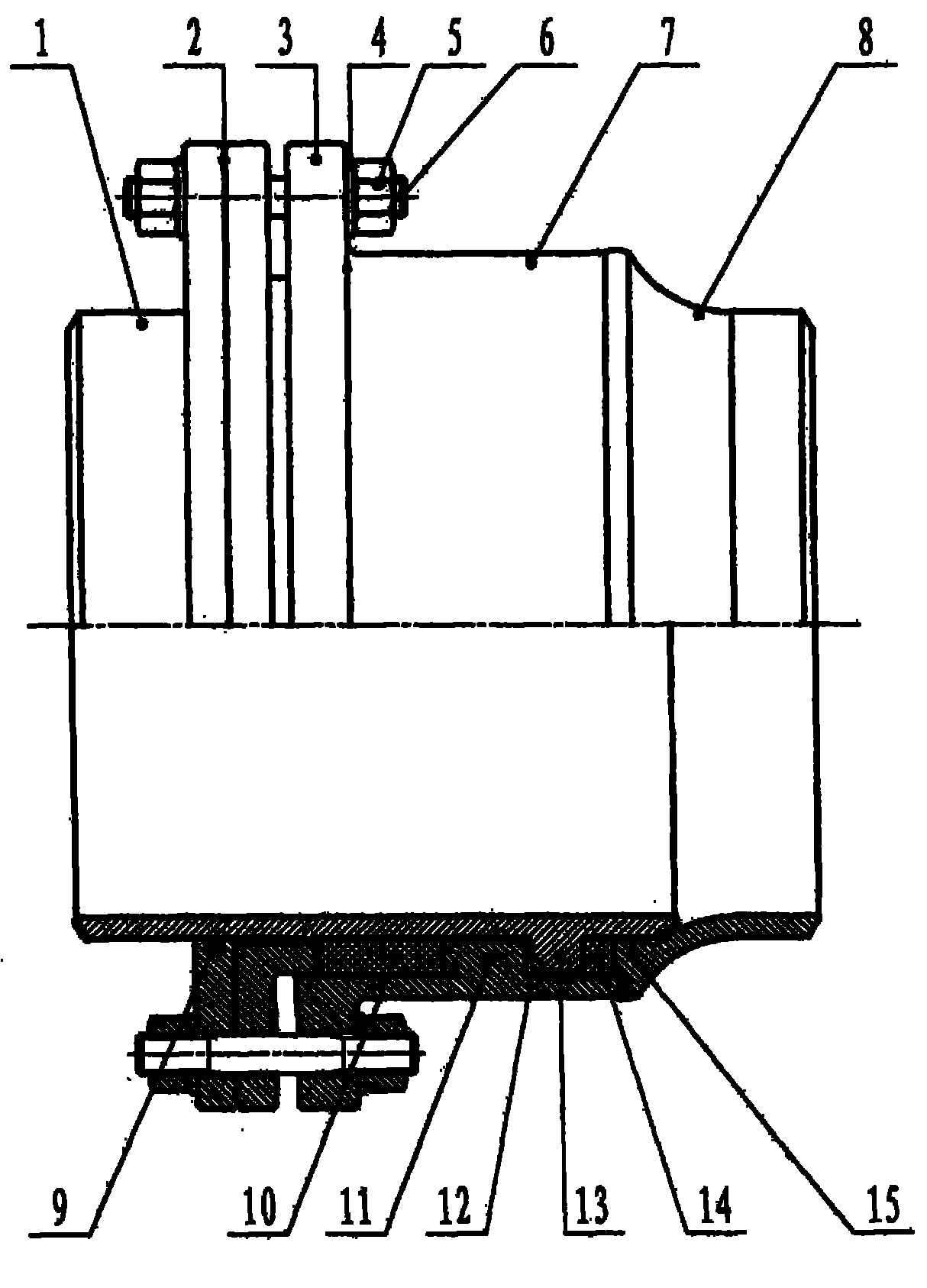

[0059] The technical solutions of the present invention are described in detail below in conjunction with the accompanying drawings.

[0060] like figure 1 and figure 2 As shown, a new double-gland high-pressure pipeline displacement compensator includes an inner tube 1, a packing gland flange 2, an outer sleeve flange 3, a gasket 4, a nut 5, a bolt 6, an outer sleeve 7, and a variable diameter extension Tube 8, steel ball A9, sealing packing 10, outer casing inner cap 11, steel ball B12, inner tube convex outer ring 13, composite sealing ring 14 and variable diameter tube cap 15 are composed of:

[0061] One end of the inner tube 1 is integrally provided with an inner tube protruding outer ring 13 along the outer ring surface, and this end is inserted into the outer casing 7 cylinder body, that is, the inner tube 1 is a cylindrical tube structure, and its outer ring surface is biased to one side The position of the port (this port can be called the inner port or the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com