Patents

Literature

75results about How to "Pressure loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

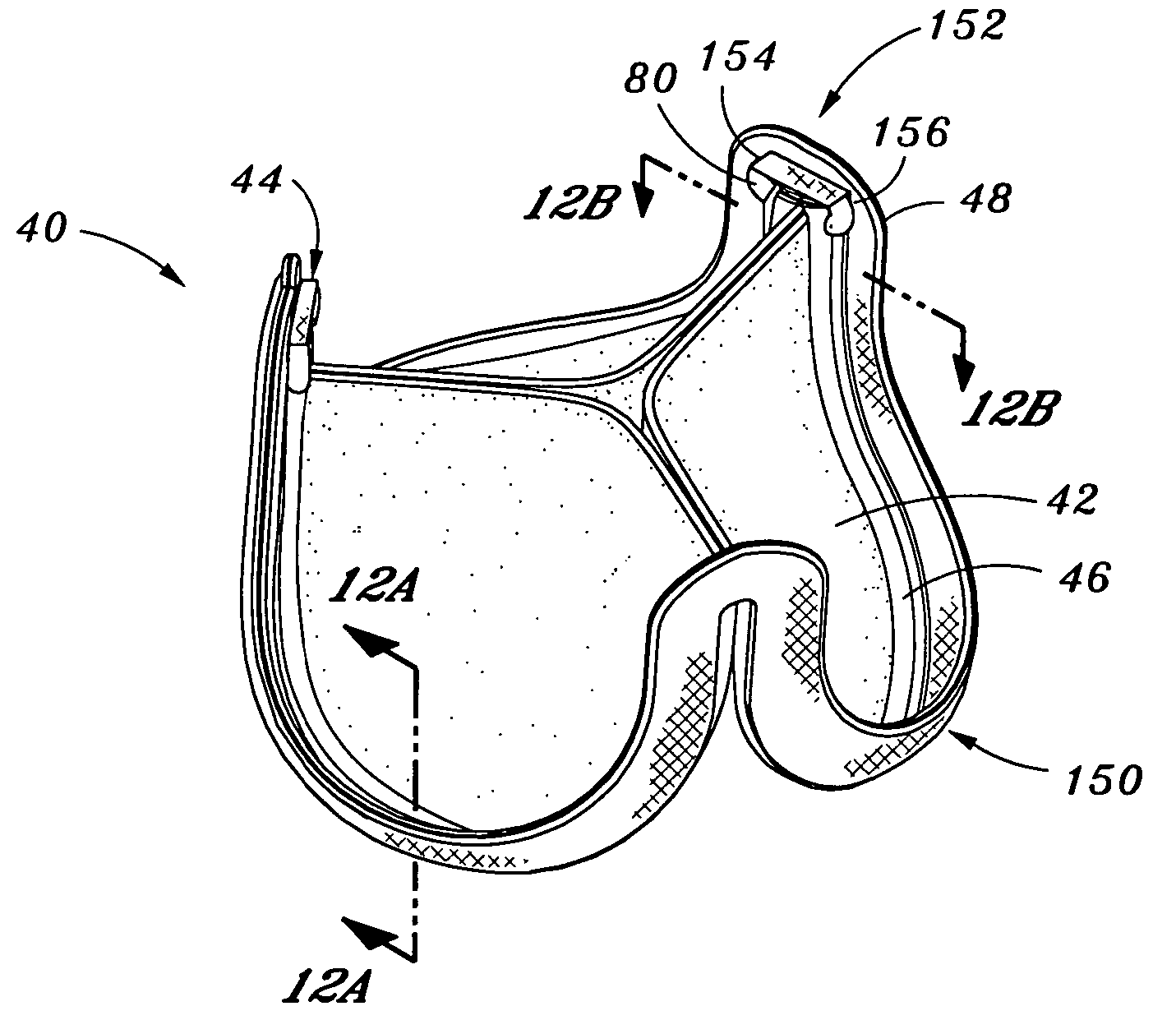

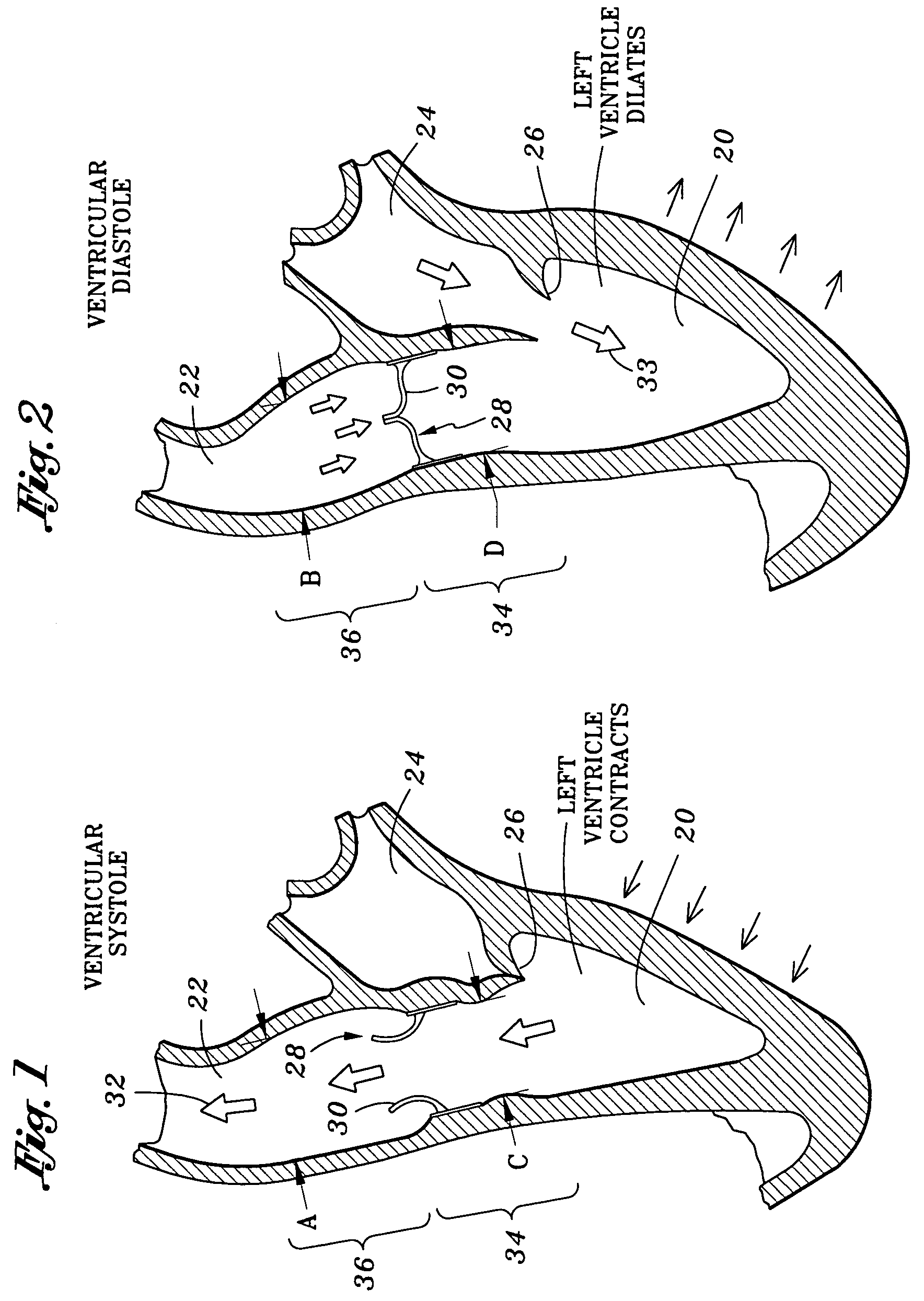

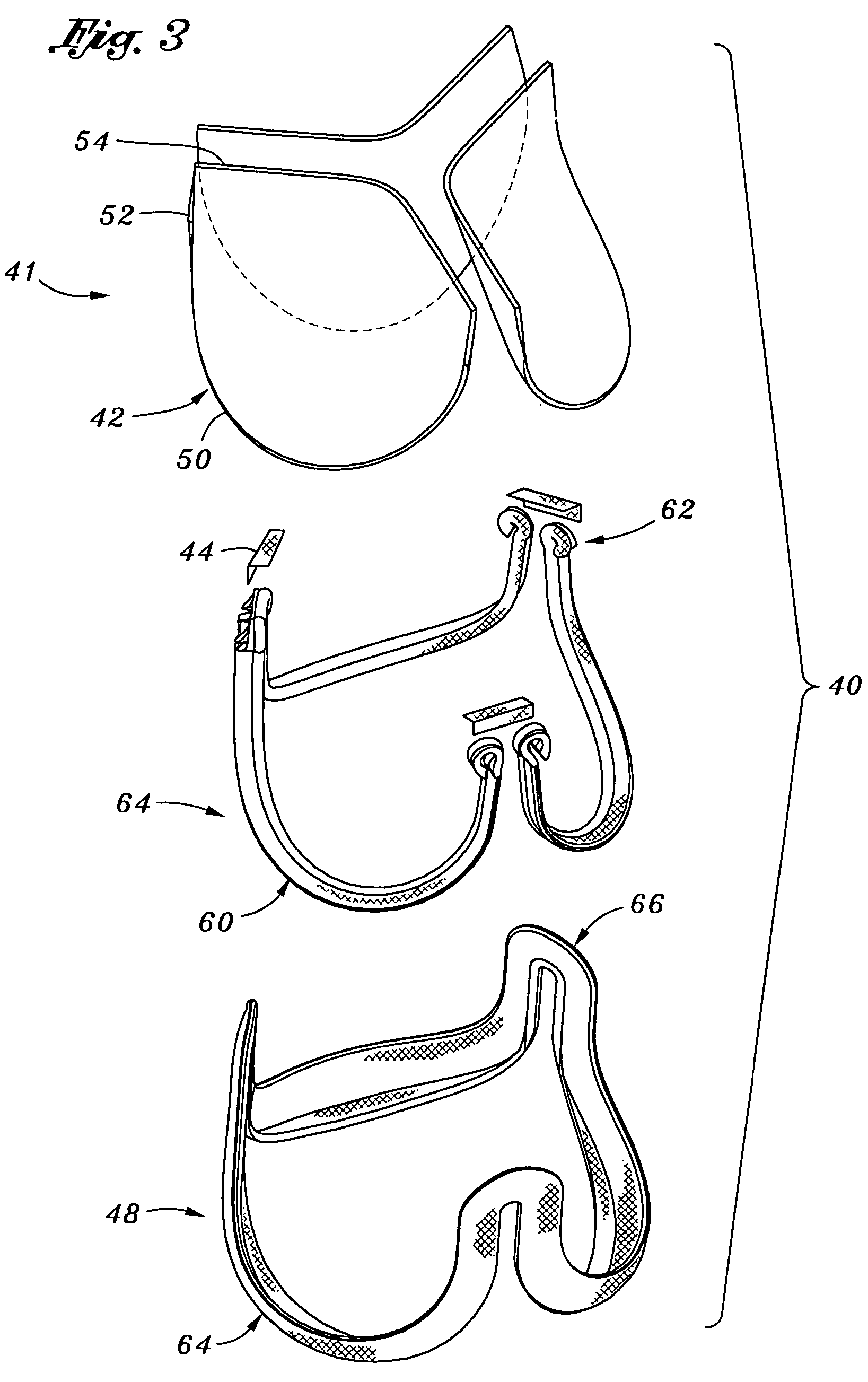

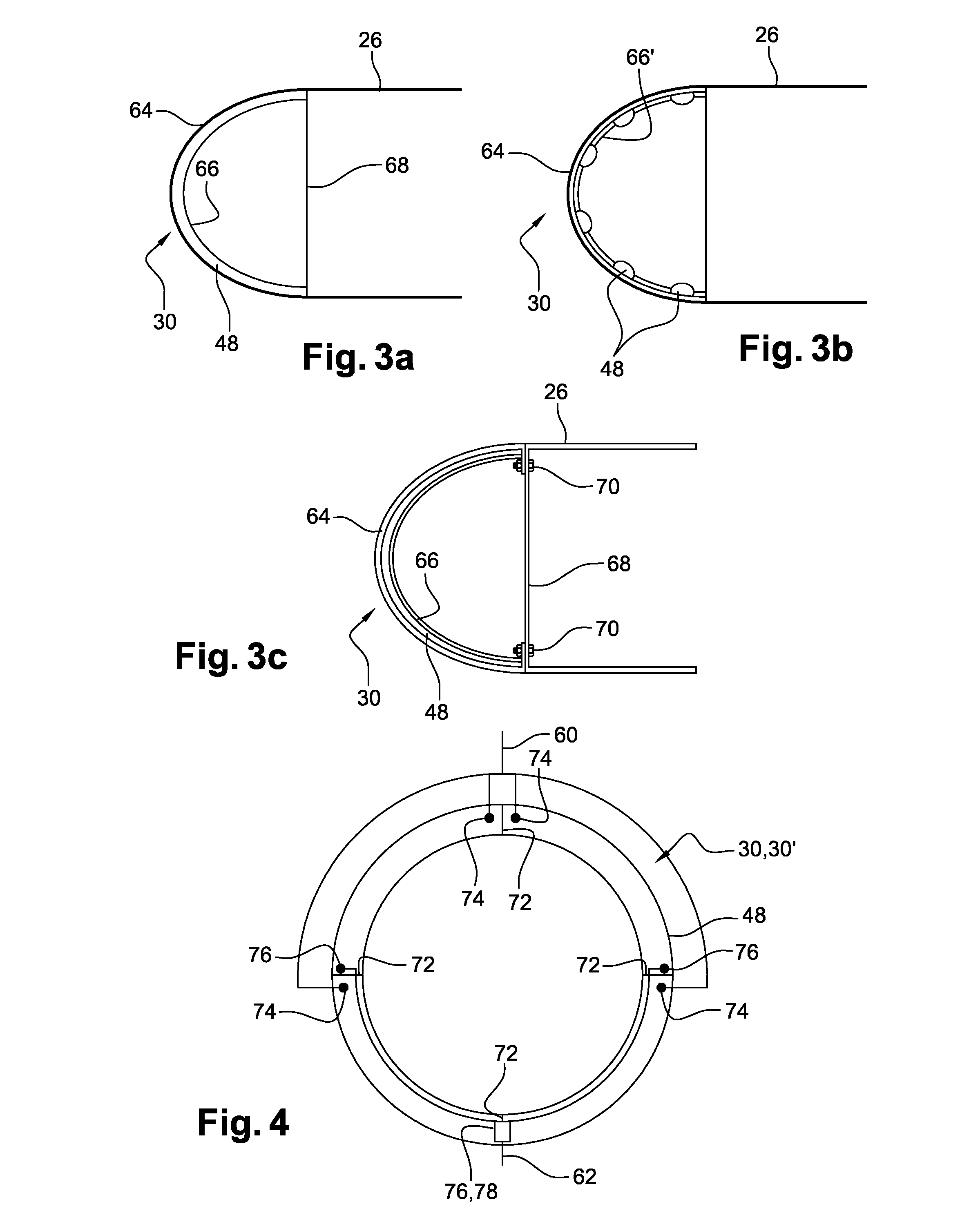

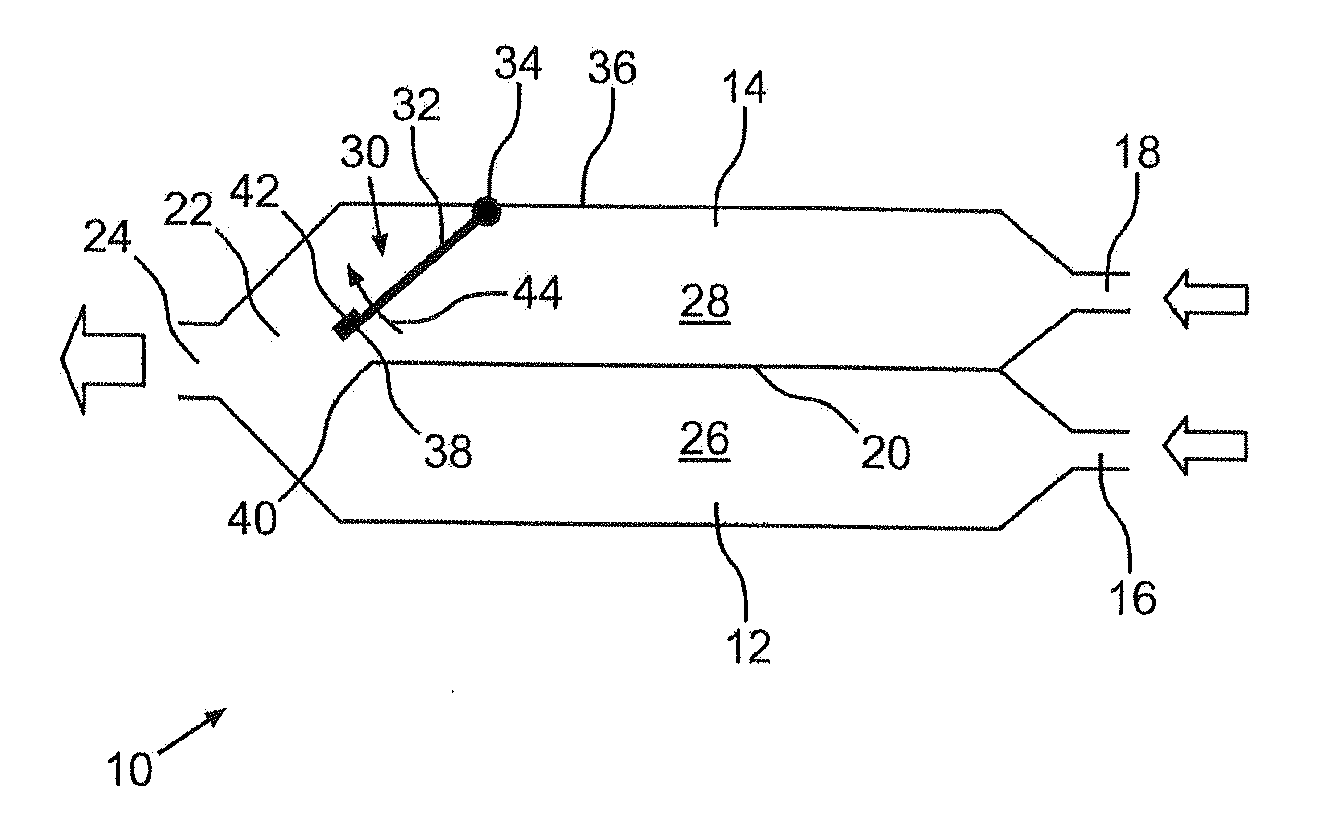

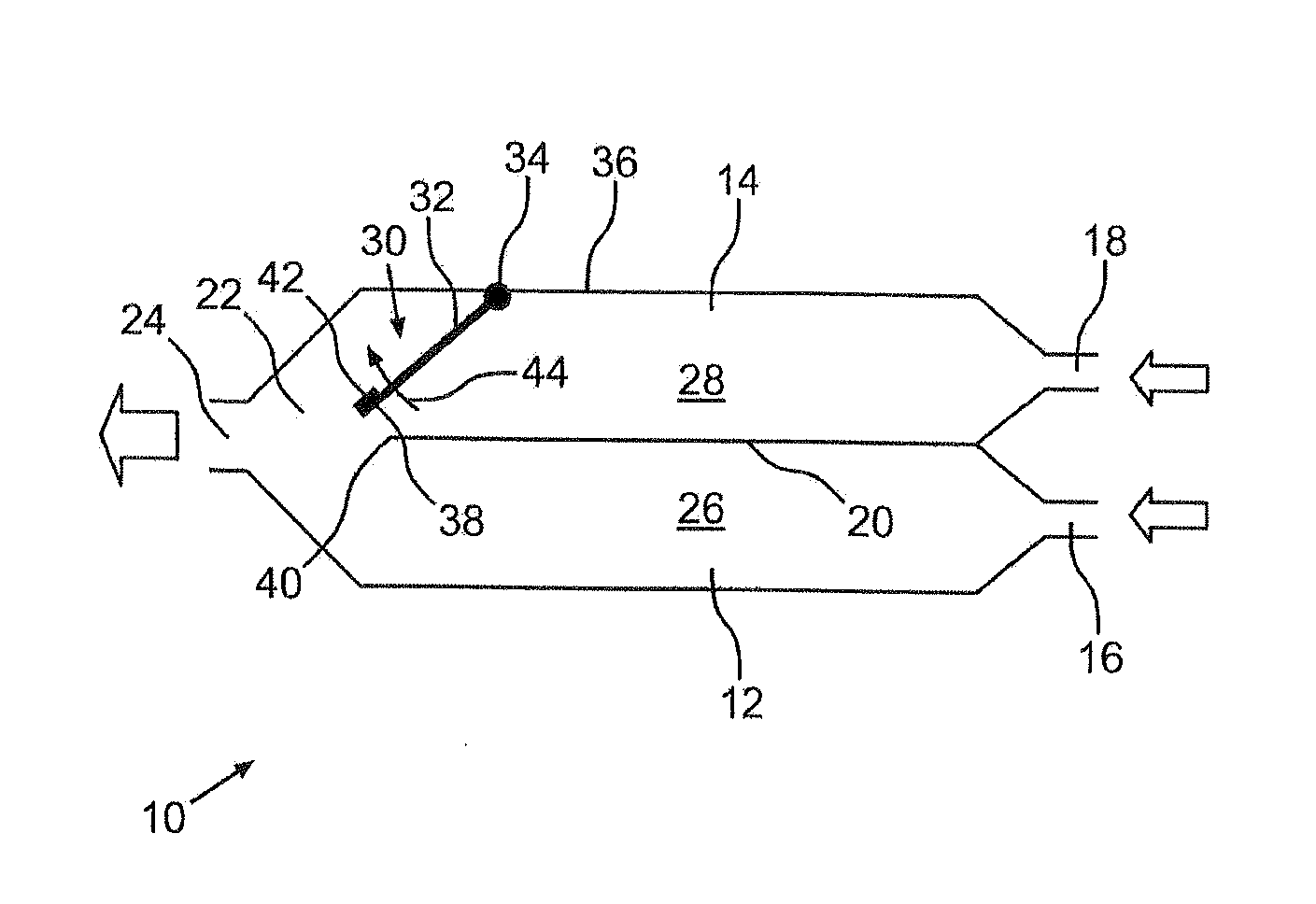

Flexible heart valve and associated connecting band

A highly flexible tissue-type heart valve is disclosed having a structural stent in a generally cylindrical configuration with cusps and commissures that are permitted to move radially. The stent commissures are constructed so that the cusps are pivotably or flexibly coupled together at the commissures to permit relative movement therebetween.

Owner:EDWARDS LIFESCIENCES CORP

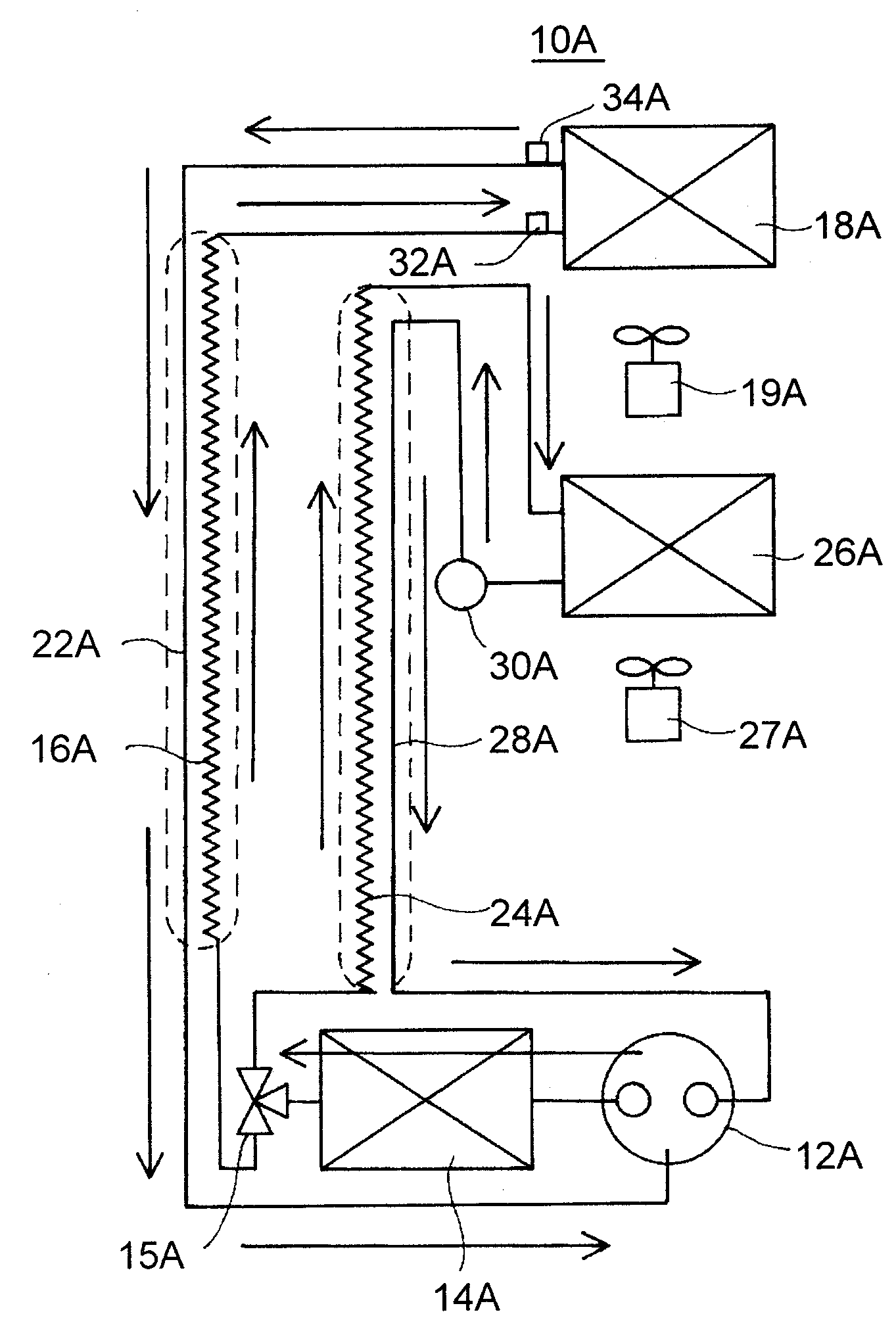

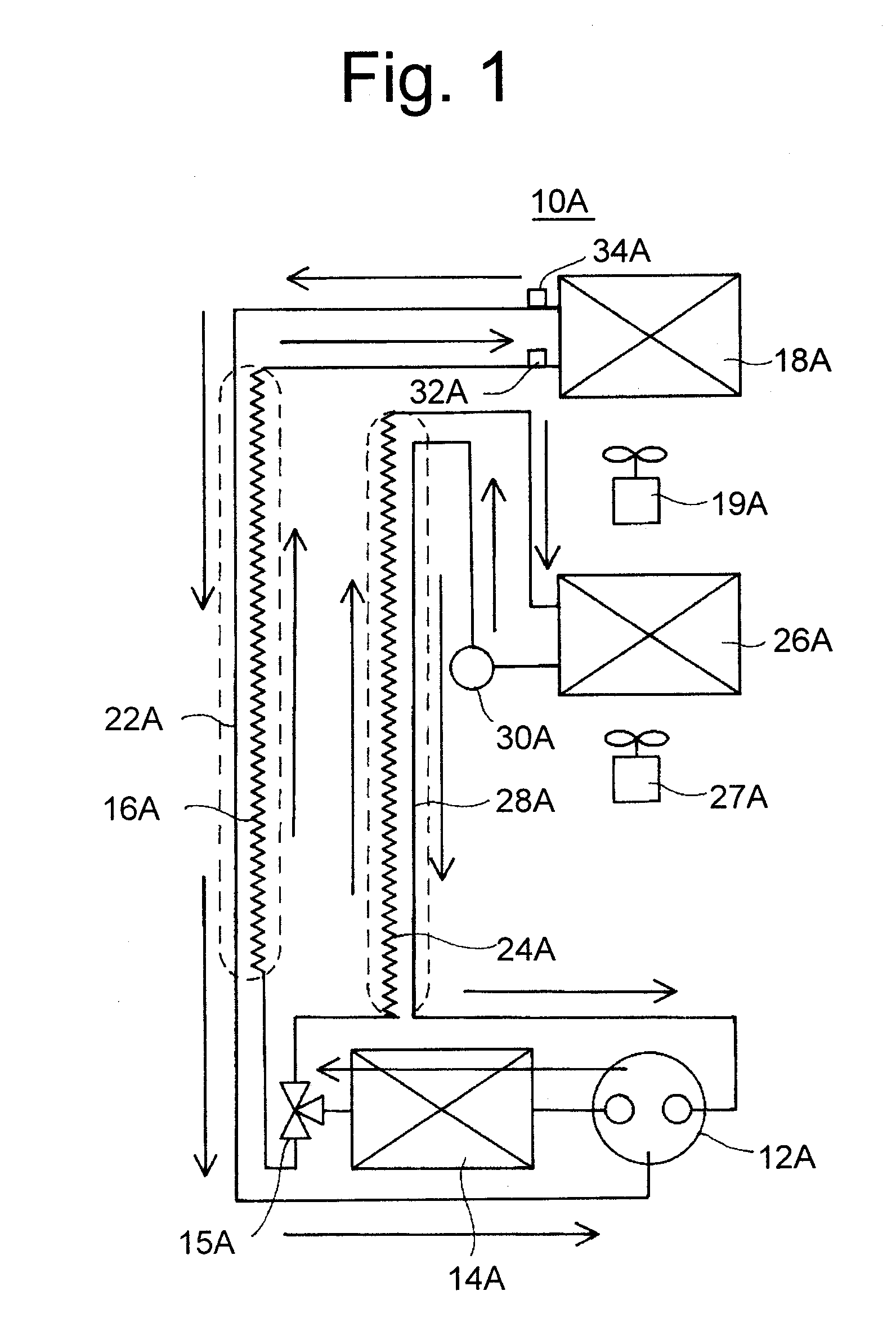

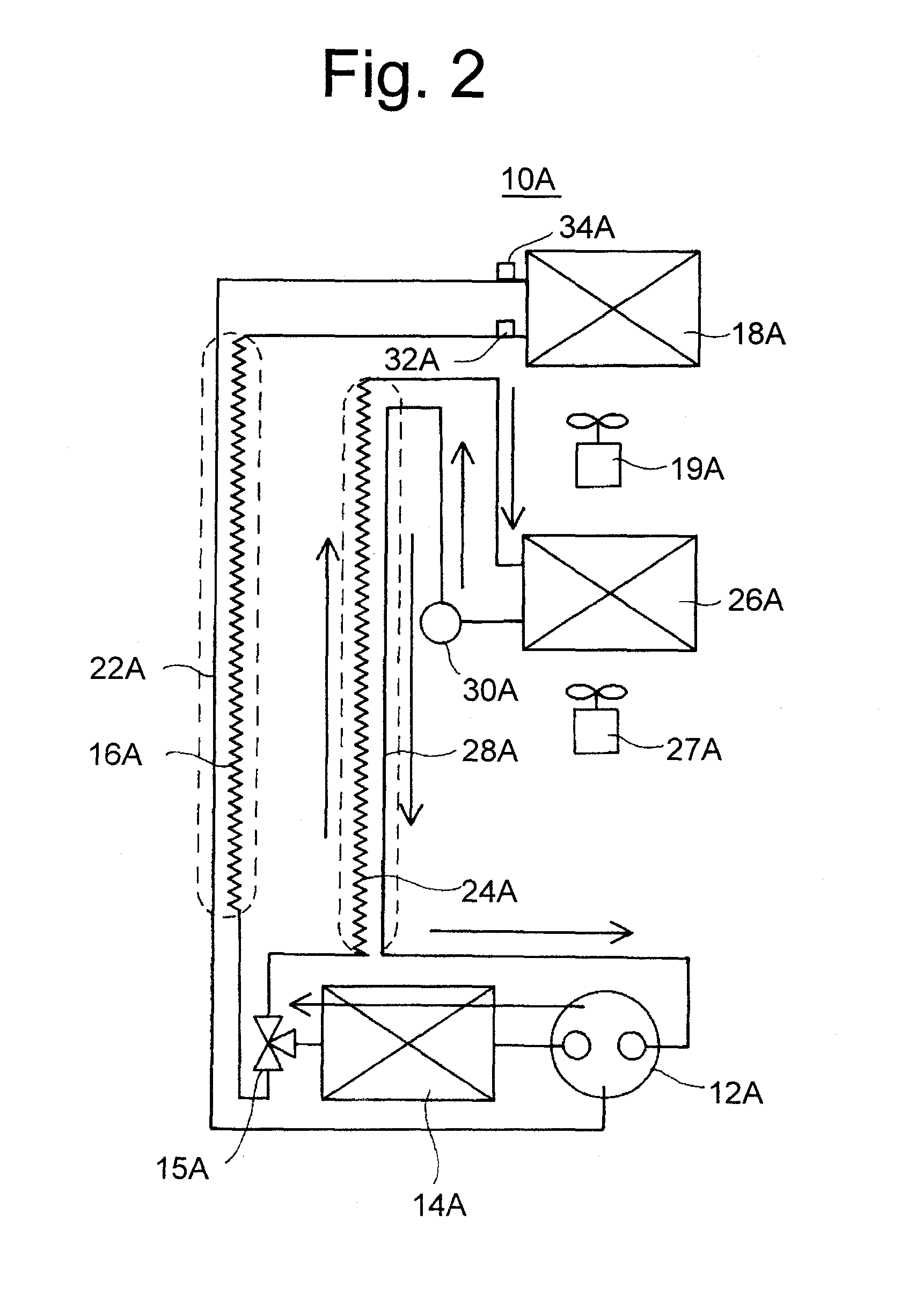

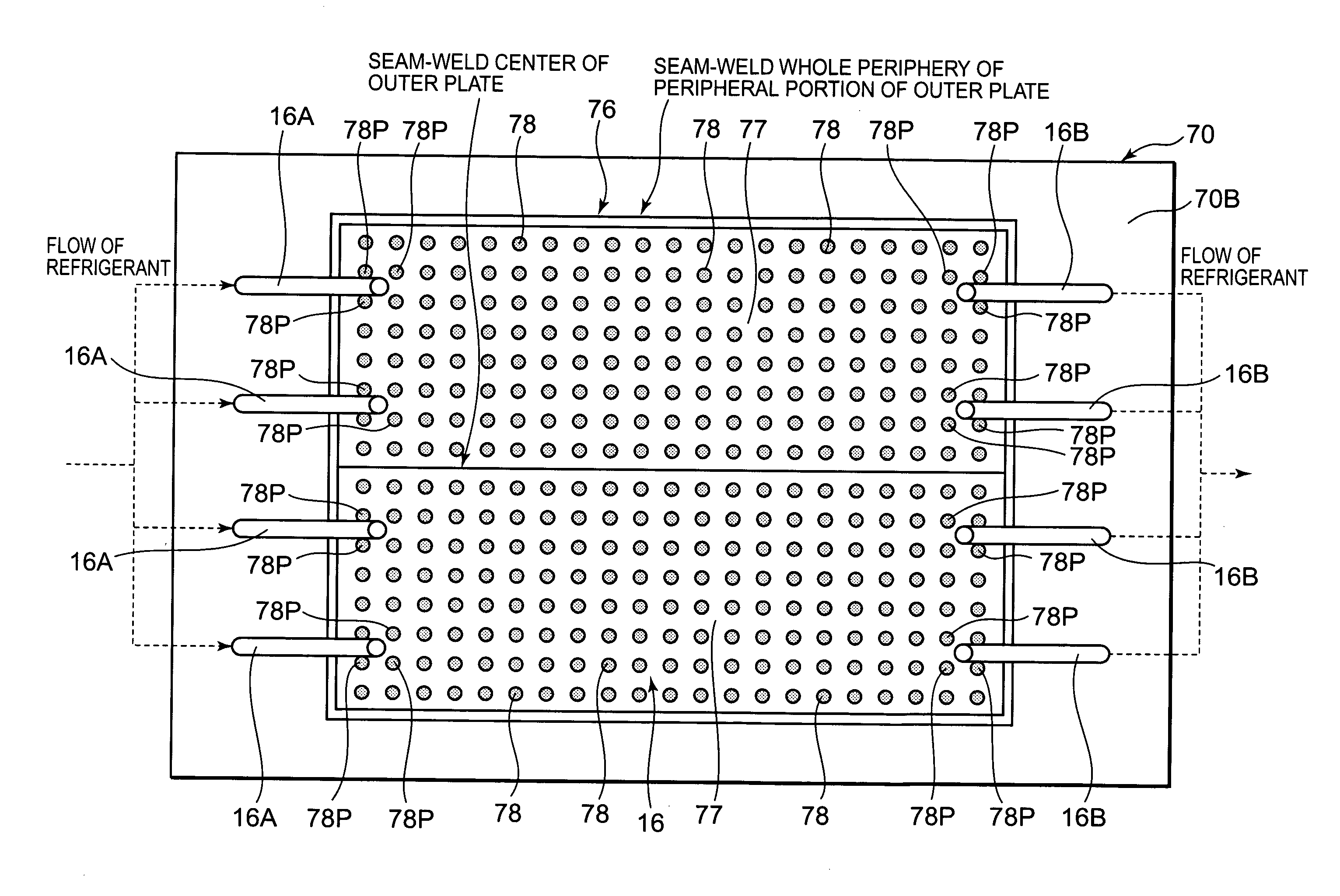

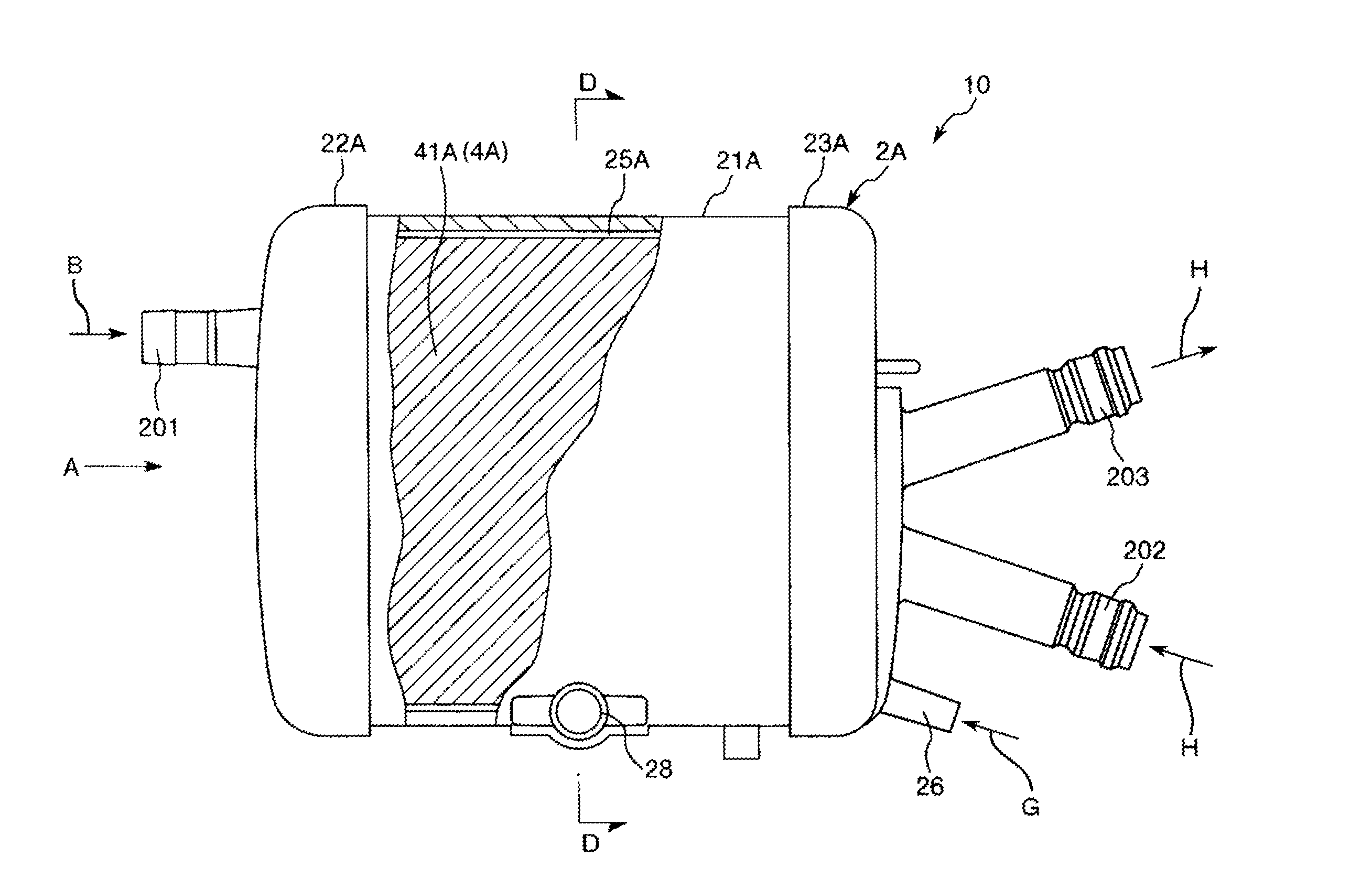

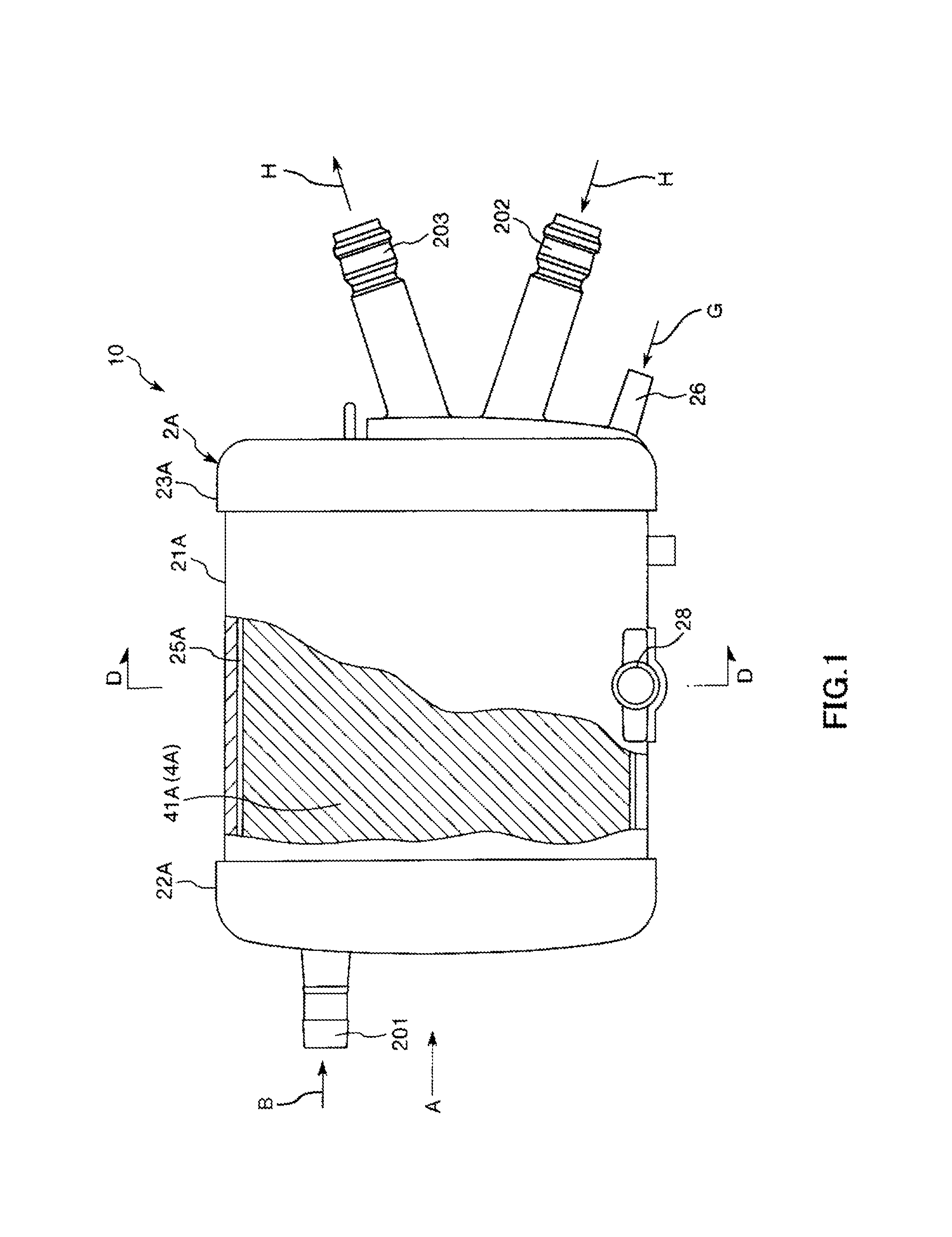

Refrigerator

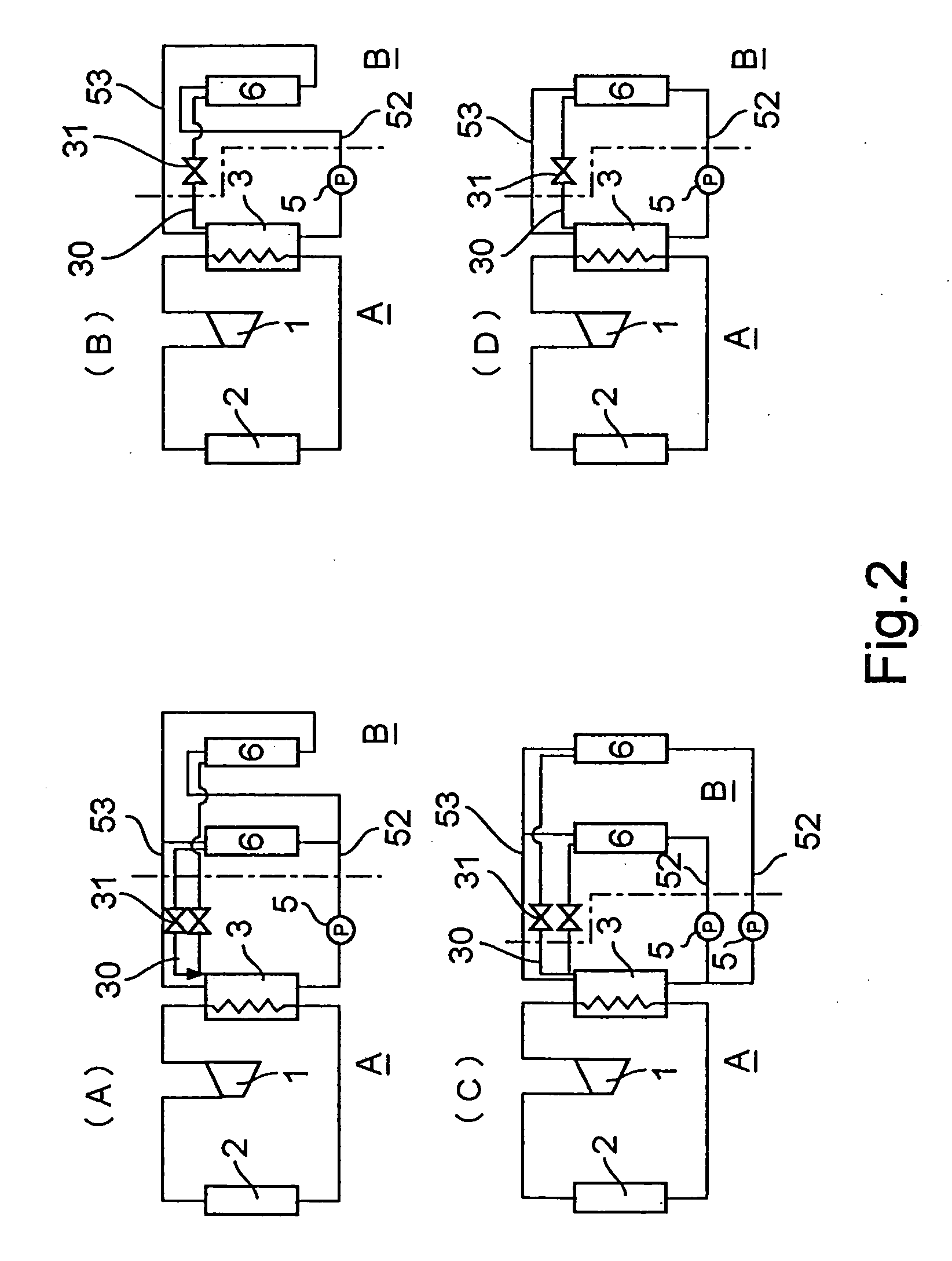

InactiveUS20080190125A1Easy to controlReduce cooling efficiencyCompression machines with non-reversible cycleDomestic refrigeratorsEngineeringTemperature difference

A high-pressure side discharge port of a two-stage compressor (12A) and a condenser (14A) are connected, condenser (14A) and a PMV (15A) are connected, a refrigerating side exit of PMV (15A) is connected to a medium pressure side suction port of two-stage compressor (12A) via an R capillary tube (16A) and an F evaporator (18A), connected to an F evaporator (26A) via an F capillary tube (24A), F evaporator (26A) is connected to a low-pressure side suction port of two-stage compressor (12A) via a low-pressure suction pipe (28A), PMV (15A) can switch a simultaneous cooling mode and a freezing mode, and in the simultaneous cooling mode, a refrigerant flow rate toward R evaporator (18A) is adjusted by PMV (15A), and thereby a temperature difference control is performed so as to make a difference between an entrance temperature and an exit temperature of R evaporator (18A) equal to a preset temperature difference (for example, 4° C.).A controller (22), on the basis of the detection condition of a temperature sensor (23) for a freezing chamber and a temperature sensor (24) for a refrigerating chamber, controls a freezing cycle device (10). Here, controller (22) controls an opening of a regulating valve (12) so as to make a superheat amount which is a difference between an exit temperature and an entrance temperature of a refrigerating evaporator (5) equal to a target superheat amount, and thereby adjusts a refrigerant flow rate to refrigerating evaporator (5) in a limited state.In this case, when a power is turned on, the entrance temperature and the exit temperature of refrigerating evaporator (5) are the same, so that controller (22), when the power is turned on, calibrates detected temperatures of an entrance temperature sensor (27) and an exit temperature sensor (26) so as to coincide with each other, and thereby can execute surely the subsequent limiting adjustment of regulating valve (12) on the basis of the superheat amount.Further, in this case, when a refrigerant supply to refrigerating evaporator (5) is stopped and the temperature of refrigerating evaporator (5) rises suddenly, controller 22 increases an opening of a valve opening (42) to refrigerating evaporator (5) of regulating valve (12) to a predetermined return value, so that the refrigerant supply amount to refrigerating evaporator (5) is increased at a stretch, and thus the refrigerating evaporator can be cooled quickly.A refrigerator having a two-stage compressor (12A) for cooling efficiently both a refrigerating chamber (2A) and a freezing chamber (5A) will be provided.When limiting and adjusting a refrigerant flow rate to one evaporator according to an opening of a valve body so as to make a superheat amount of one evaporator appropriate on the basis of the superheat amount which is a difference between an exit temperature and an entrance temperature of one evaporator, a refrigerator for detecting accurately the entrance temperature and the exit temperature of one evaporator will be provided.When limiting and adjusting a refrigerant flow rate to one evaporator according to an opening of a valve body, a refrigerator for causing no delay in a refrigerant supply to one evaporator will be provided.

Owner:TOSHIBA HA PROD +2

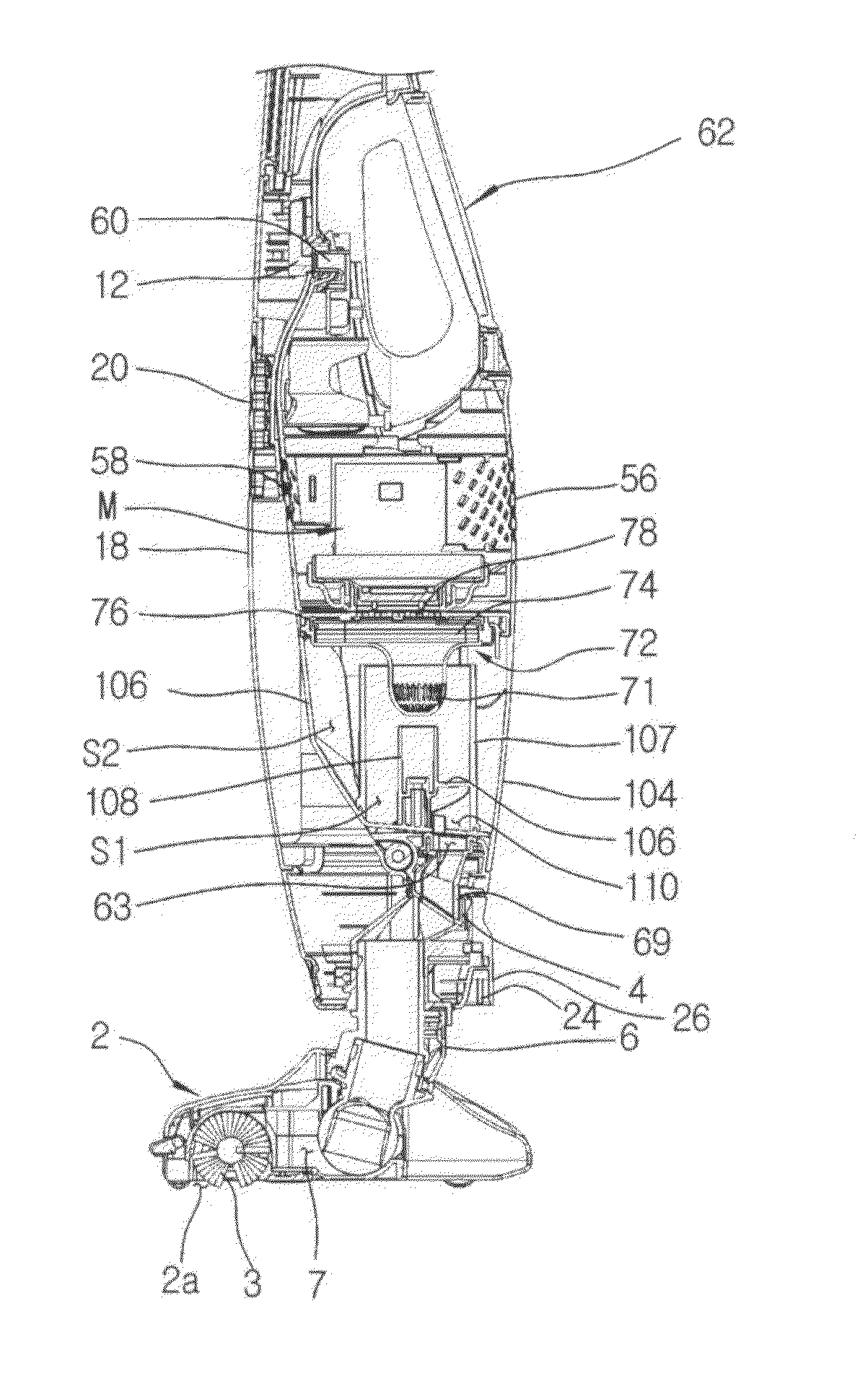

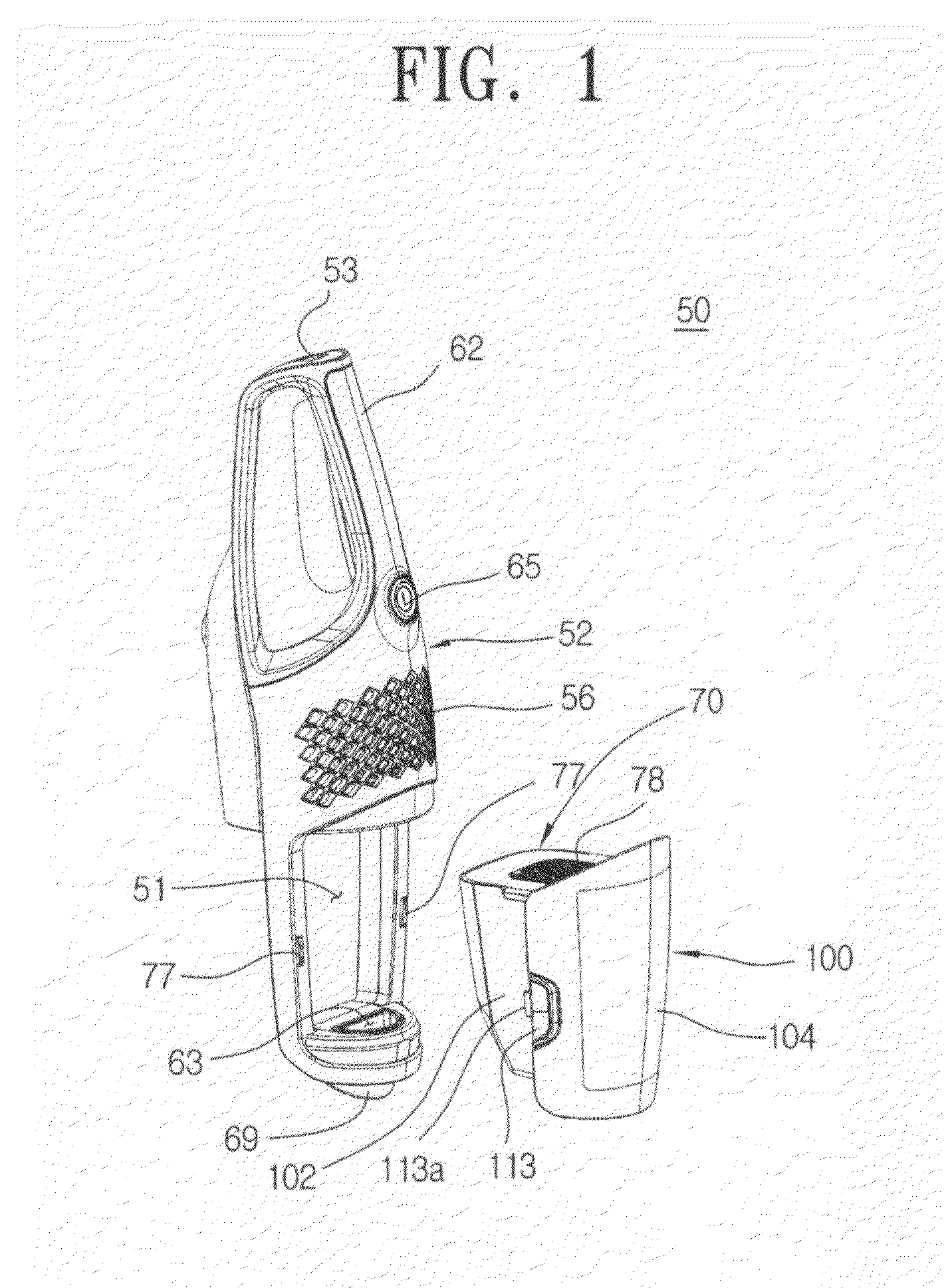

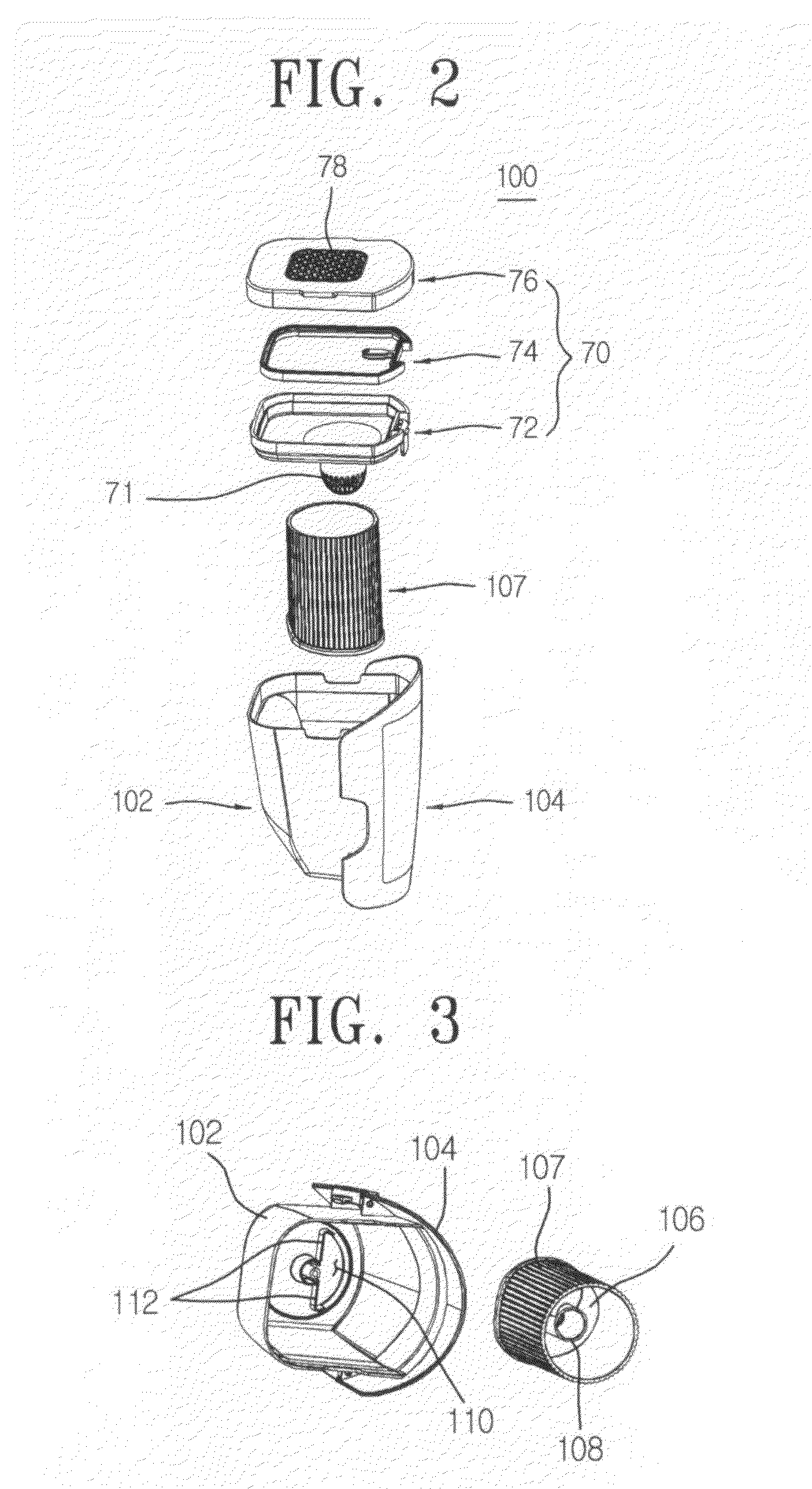

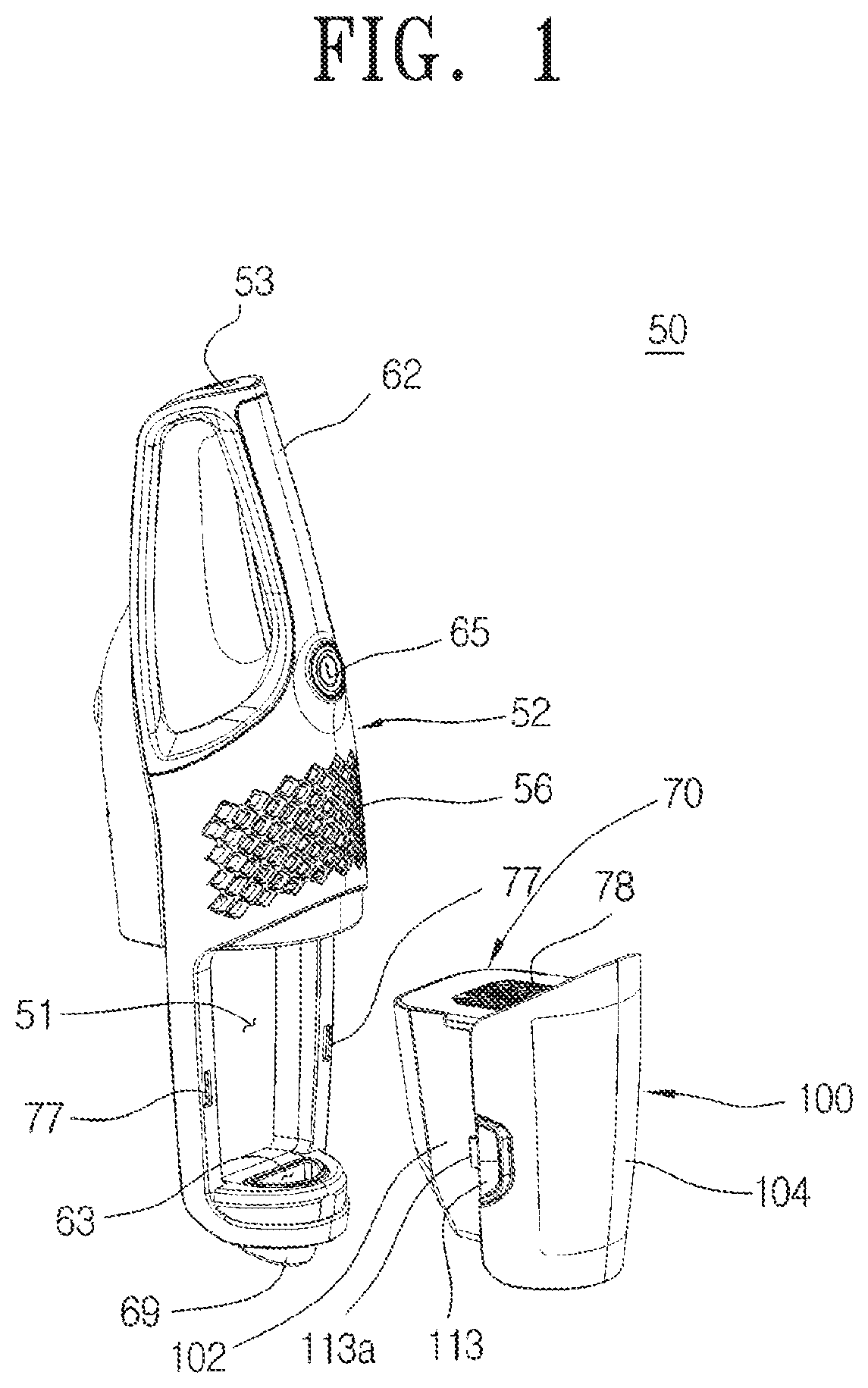

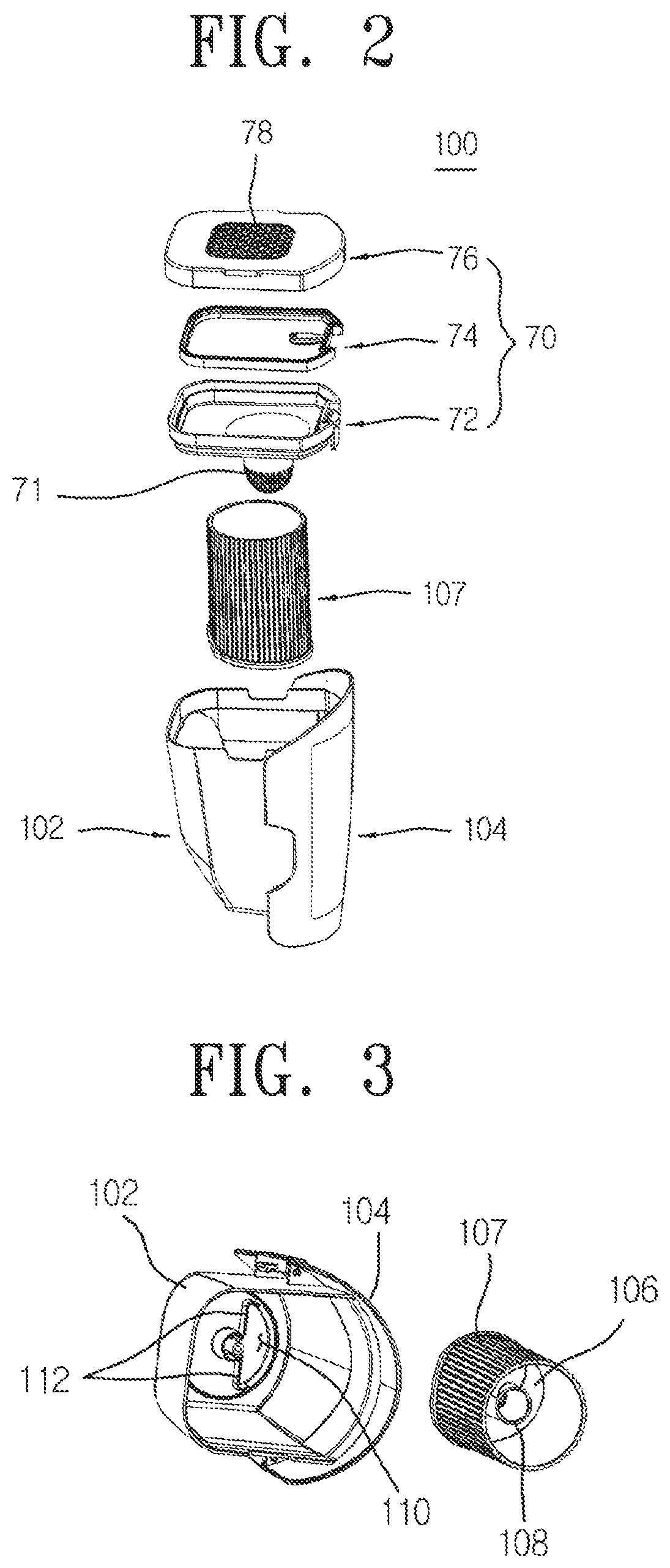

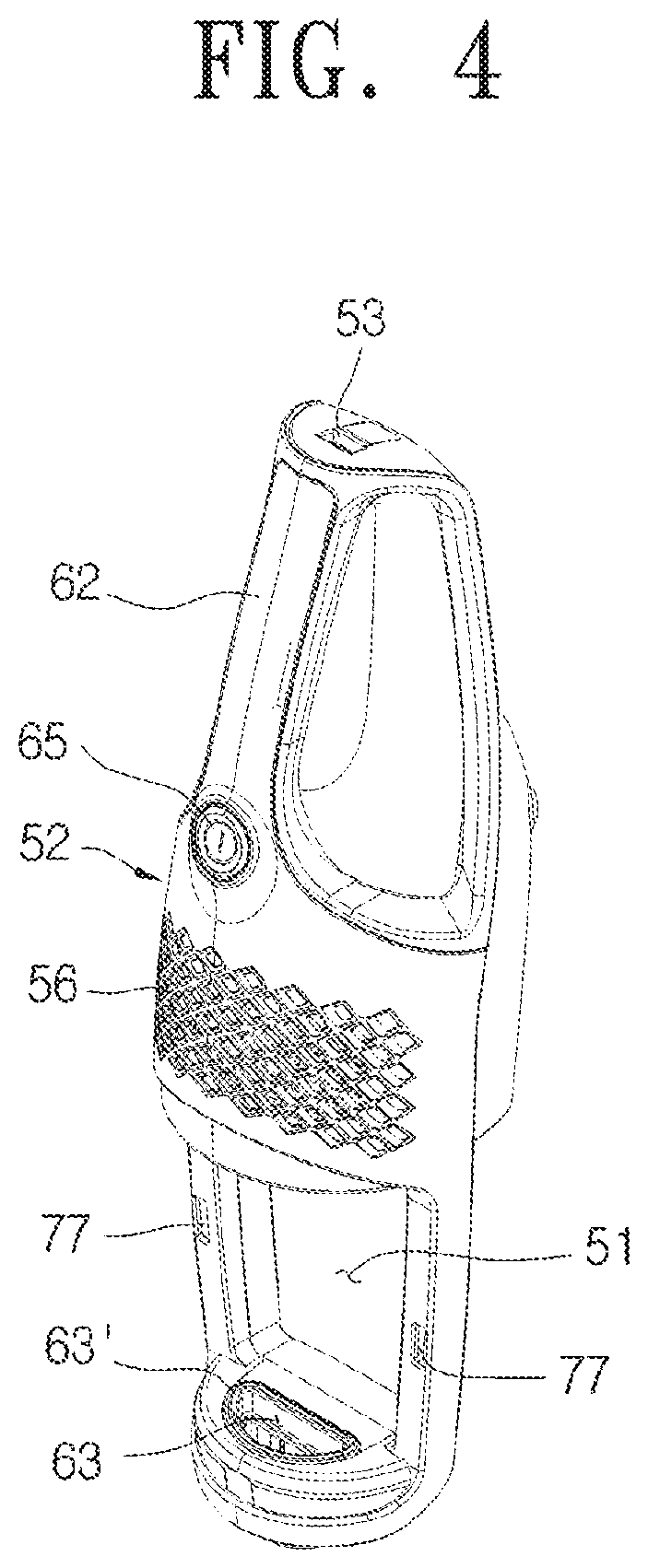

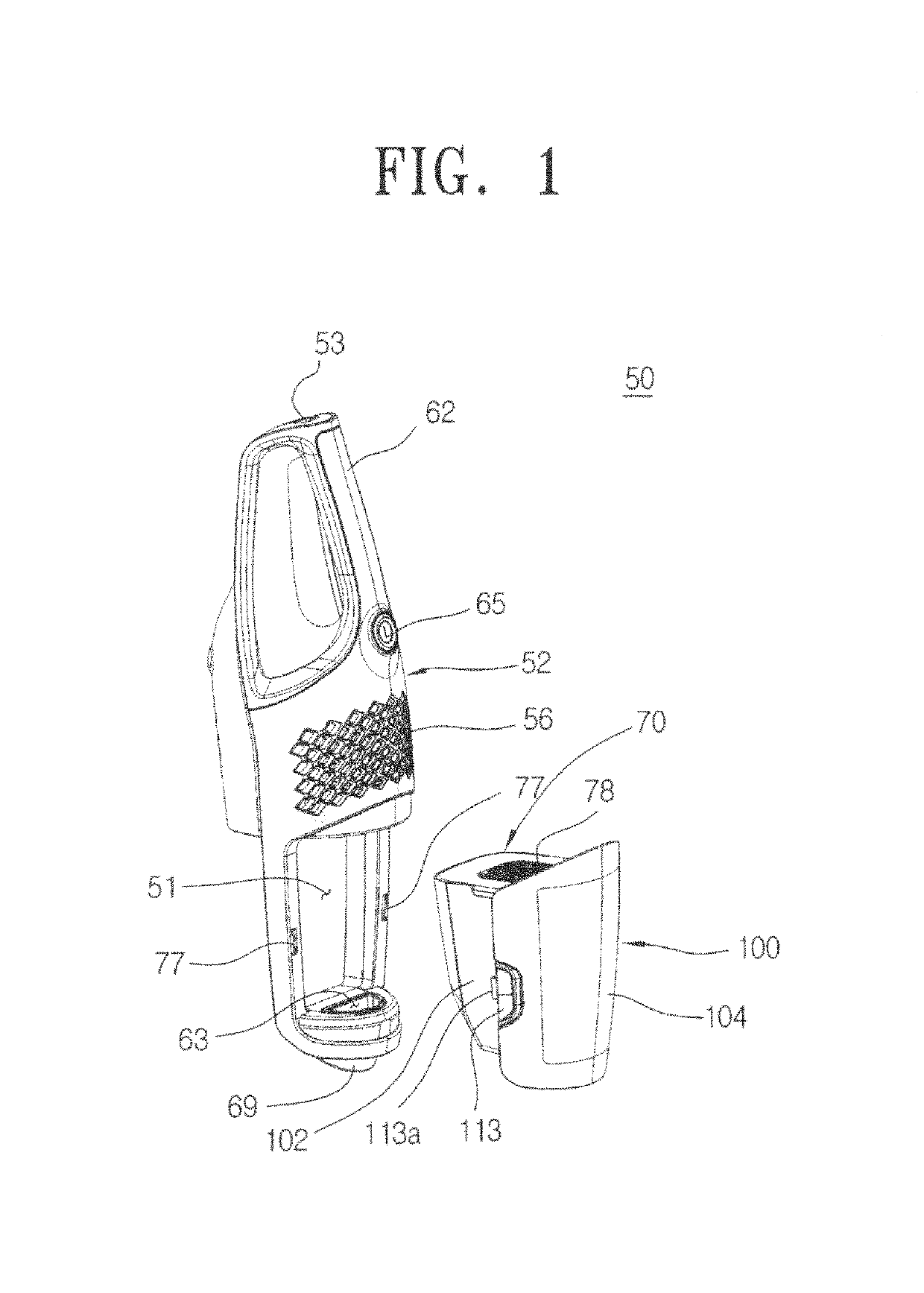

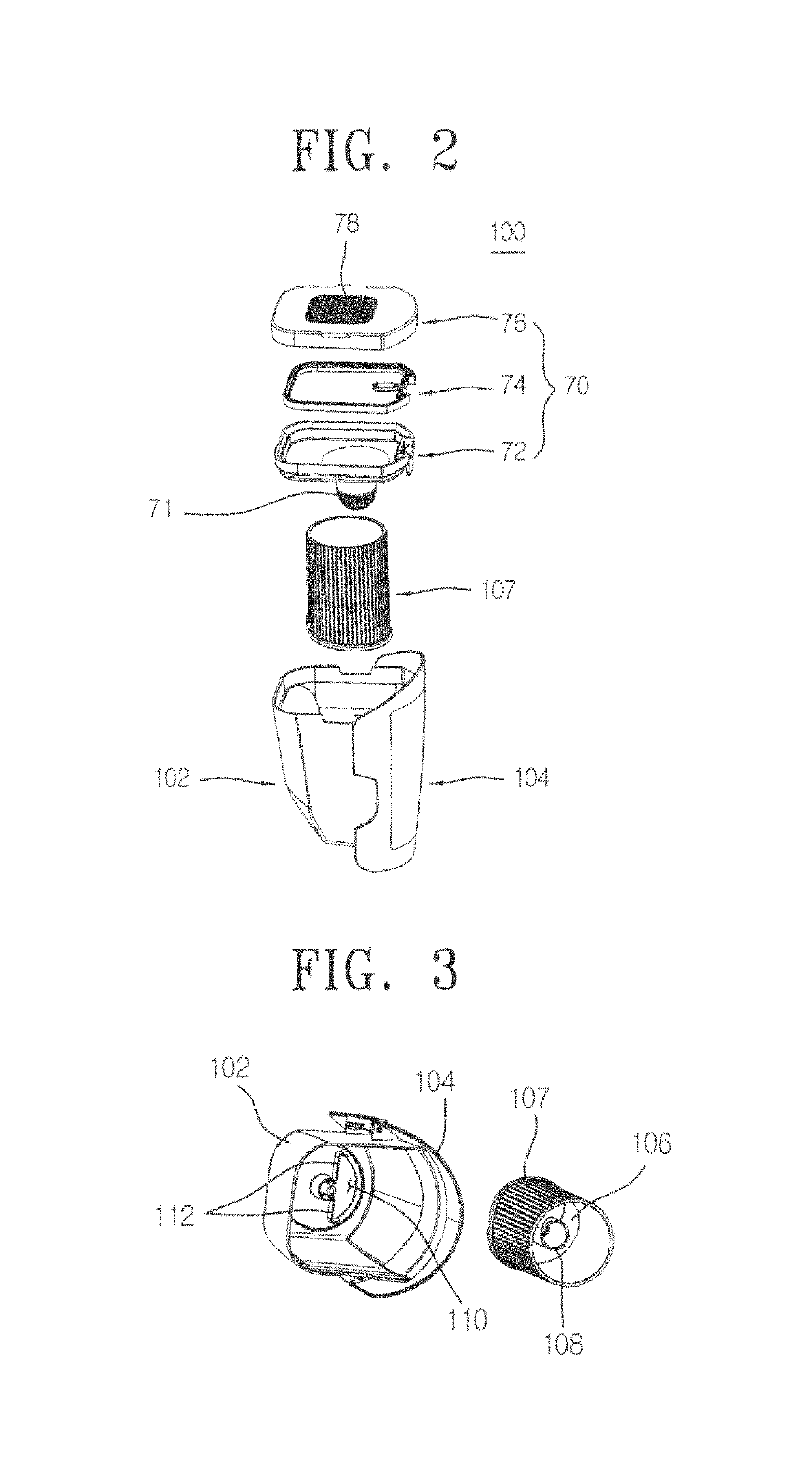

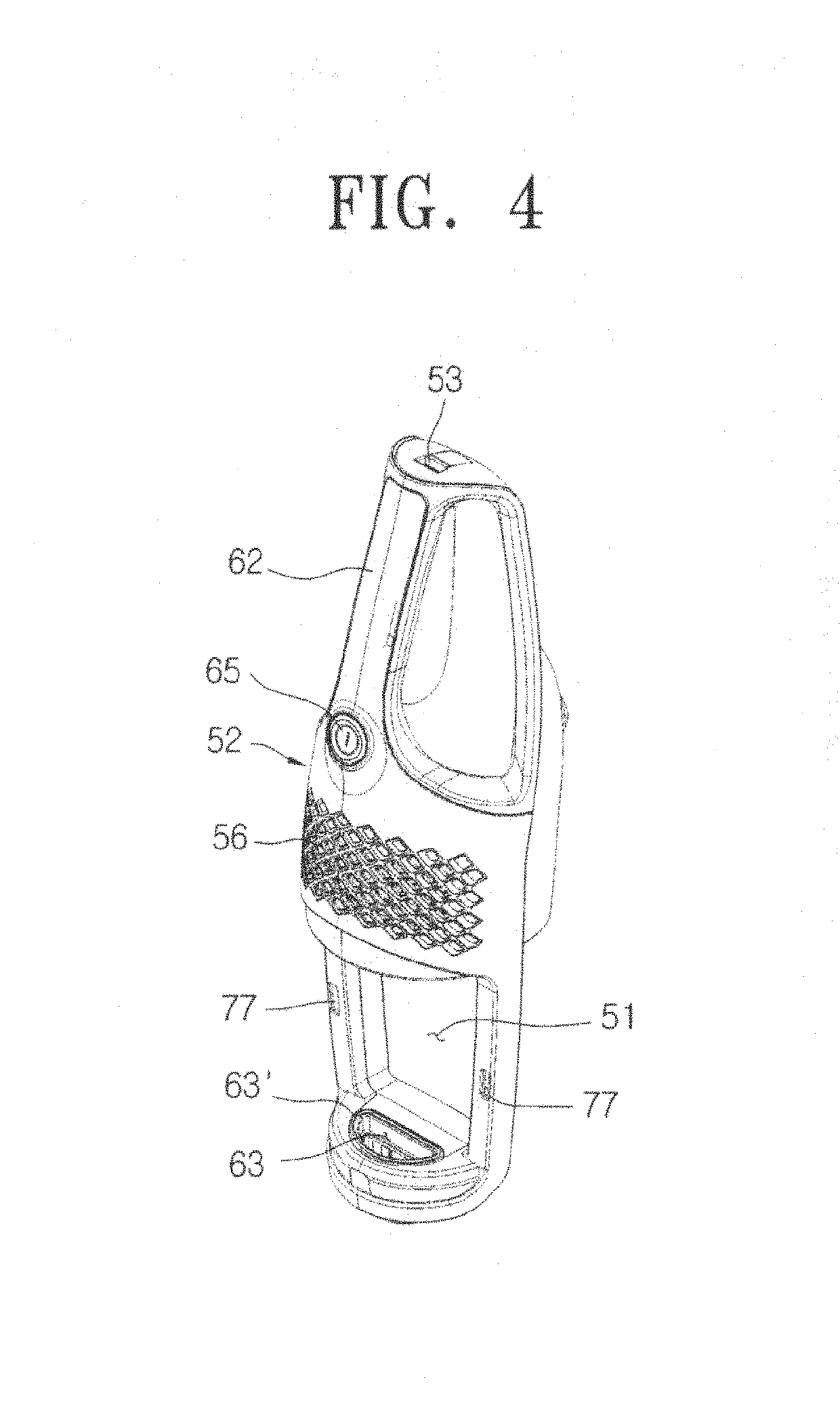

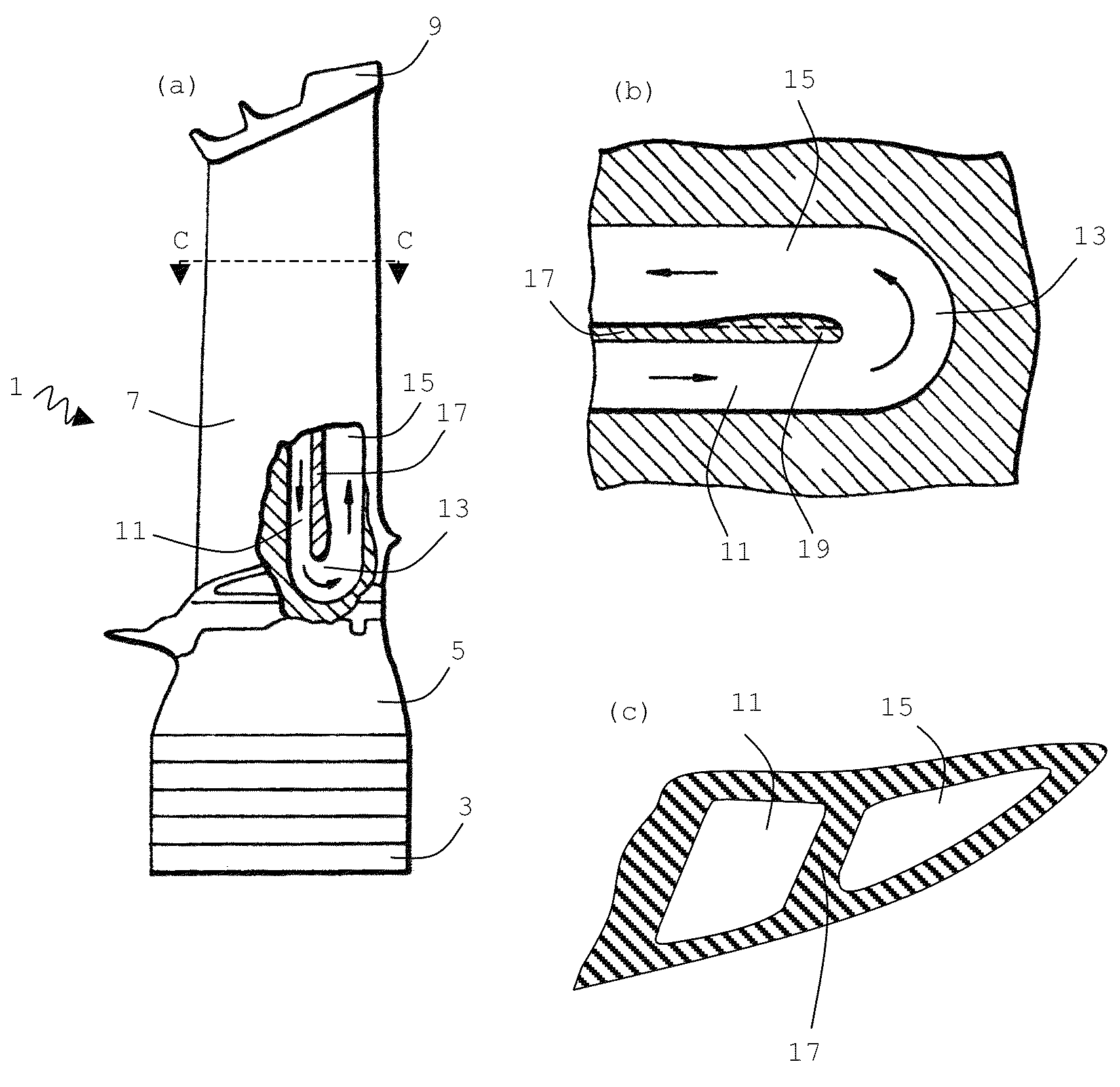

Cyclone dust collecting apparatus and hand-held cleaner having the same

ActiveUS20110289720A1Reduce total pressure lossImprove efficiencyCombination devicesVortex flow apparatusCycloneSpiral flow

The hand-held cleaner includes a body, and a cyclone dust collecting apparatus detachably mounted in the body. The cyclone dust collecting apparatus includes a pre-motor filter unit having a filter grill and a filter member, a dust collecting bin having one end to which the pre-motor filter unit is coupled and the other end opposite to the one end in which an cyclone inlet is formed, and a cyclone bin disposed in the dust collecting bin and having a spiral flow path-guide member integrally formed therein. A moving path of air drawn into the cyclone inlet is maintained in the same direction until the air is discharged through the pre-motor filter unit via the cyclone bin.

Owner:SAMSUNG ELECTRONICS CO LTD

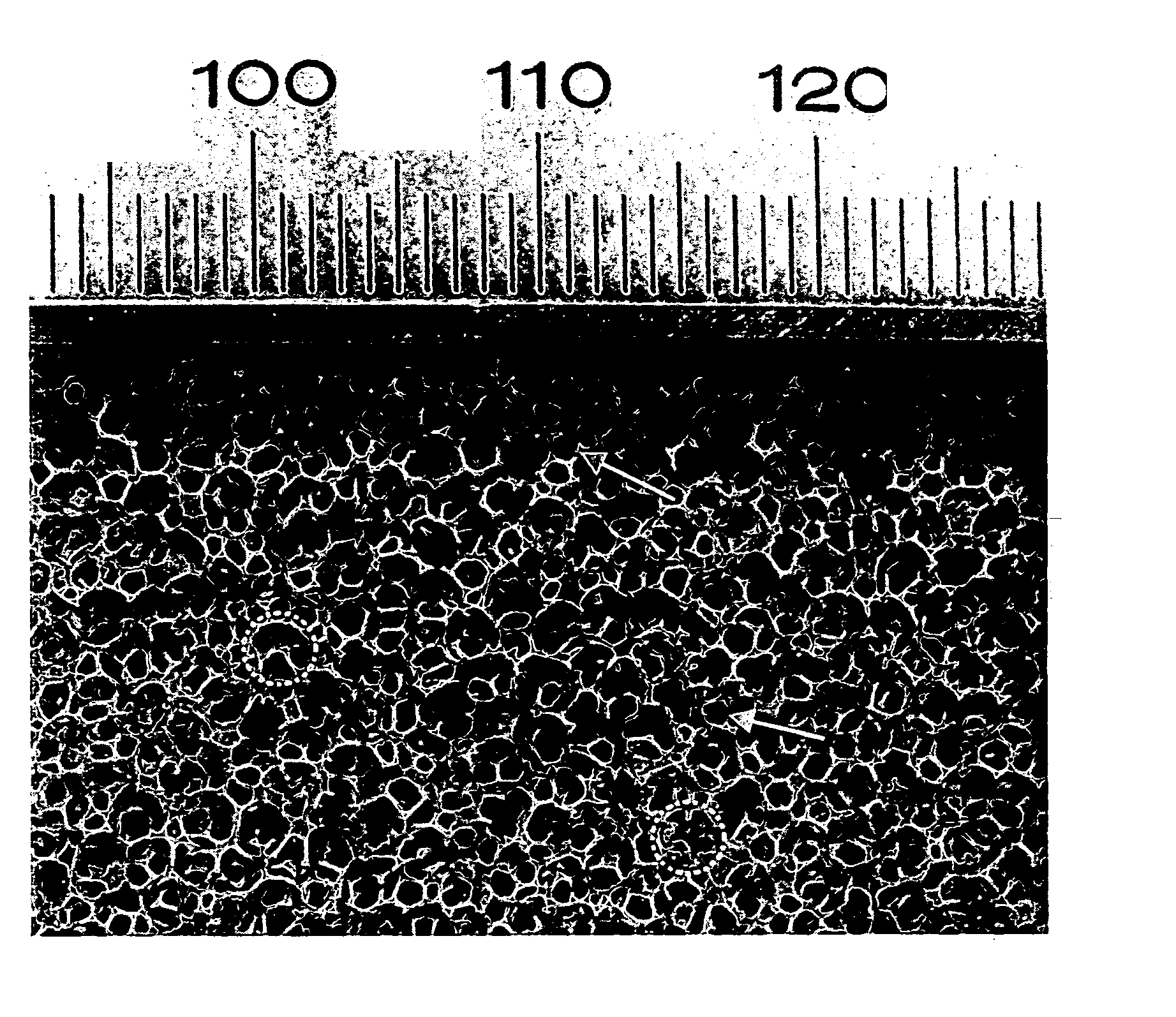

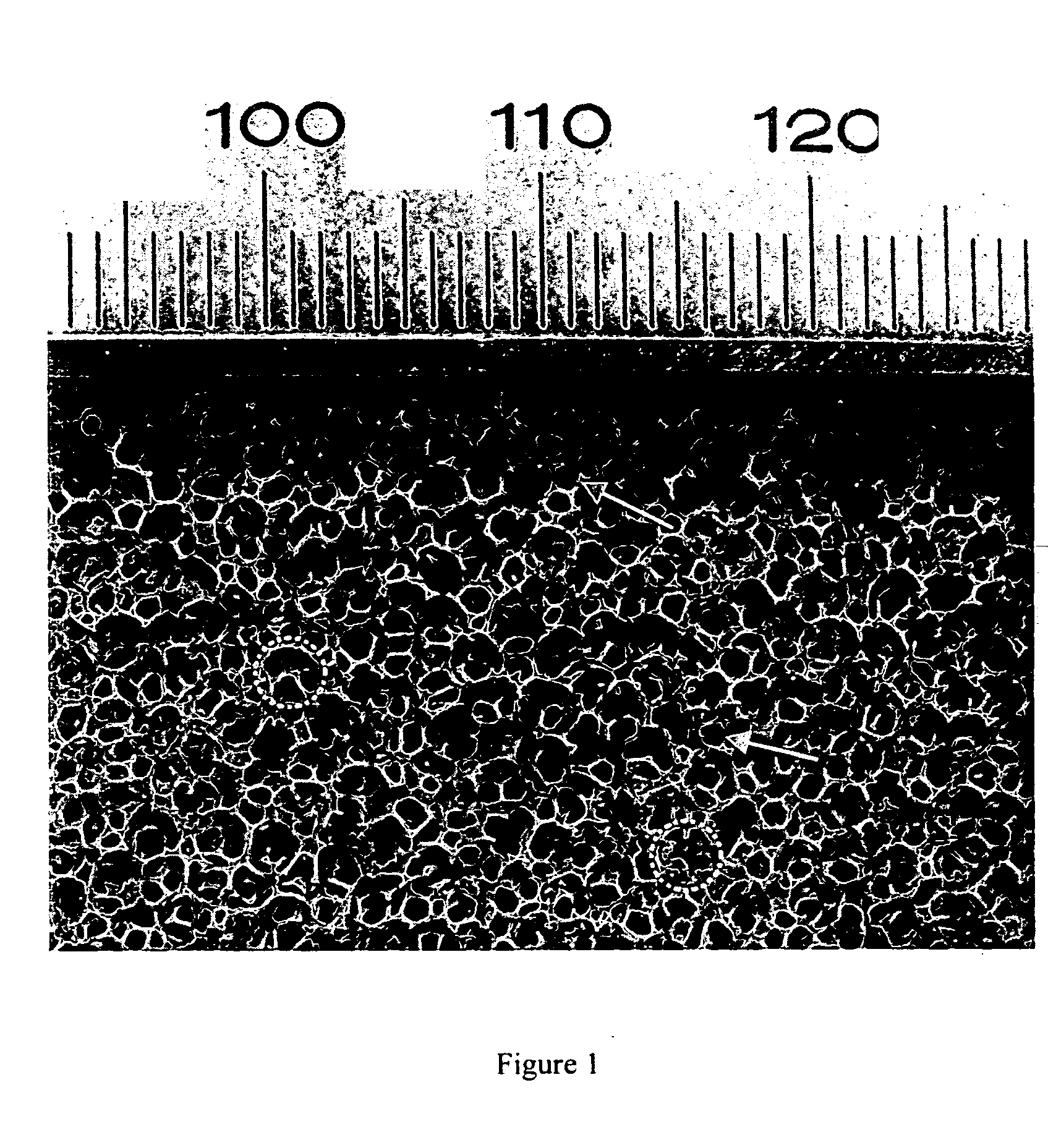

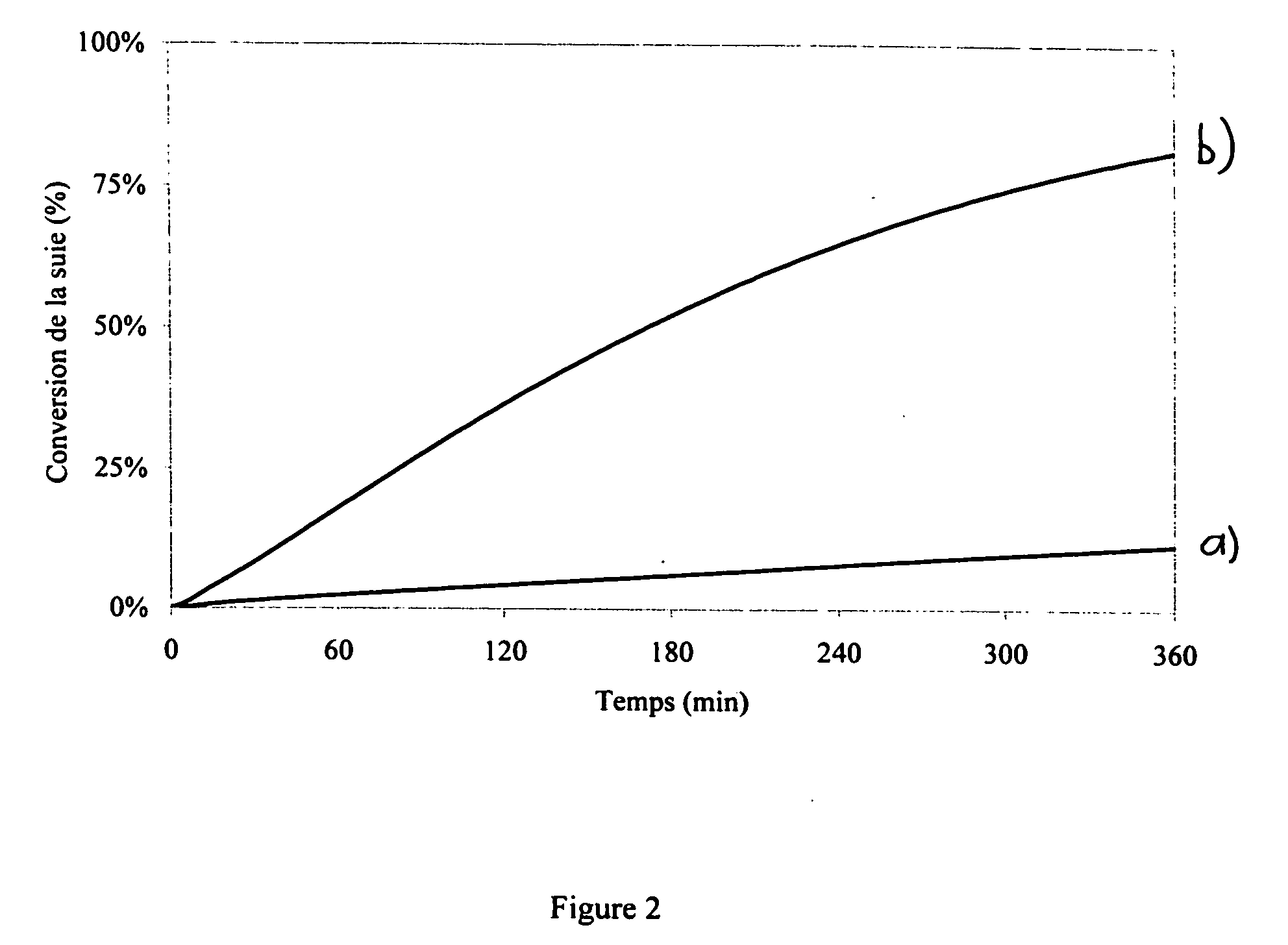

Catalytic filter based on silicon carbide (beta-SiC) for combustion of soot derived from exhaust gases from an internal combustion engine

InactiveUS20050159292A1Reduce manufacturing costIncrease surface areaGas treatmentOther chemical processesPorosityChemical transformation

This invention relates to β-SiC foam parts with a specific surface area preferably equal to at least 5 m2 / g and with at least two zones A and B with a different cellular porosity distribution, wherein the parts were made by chemical transformation of a porous precursor medium comprising at least two blocks A′ and B′, each having a different cellular porosity distribution, and in that the at least two zones A and B are derived from the chemical transformation of the two blocks A′ and B′. This foam, optionally after deposition of an active layer, may be used as a filter medium in cartridges designed for the purification of exhaust gases. The invention also relates to manufacturing processes for preparing such a filter medium.

Owner:MAPLE VISION TECH +3

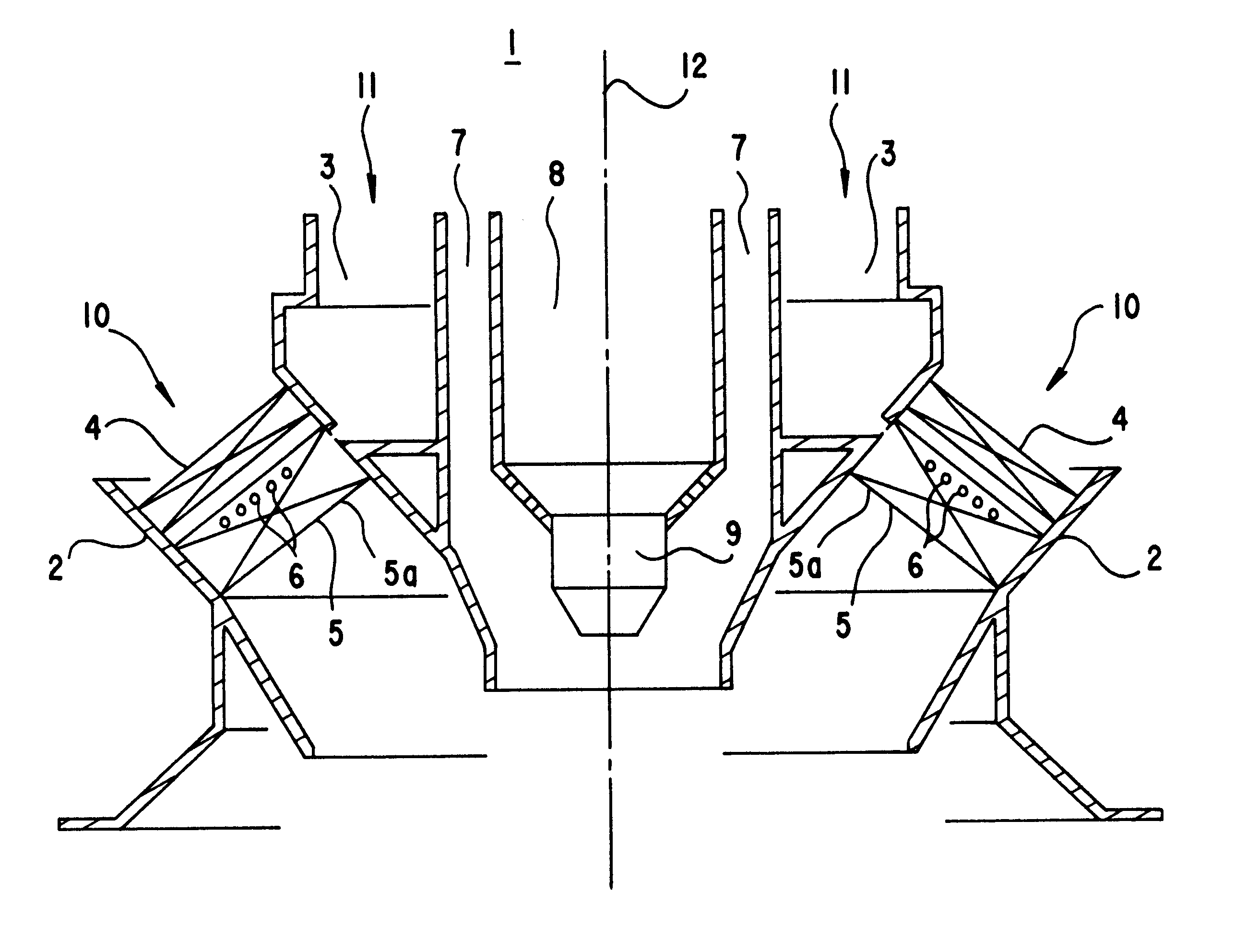

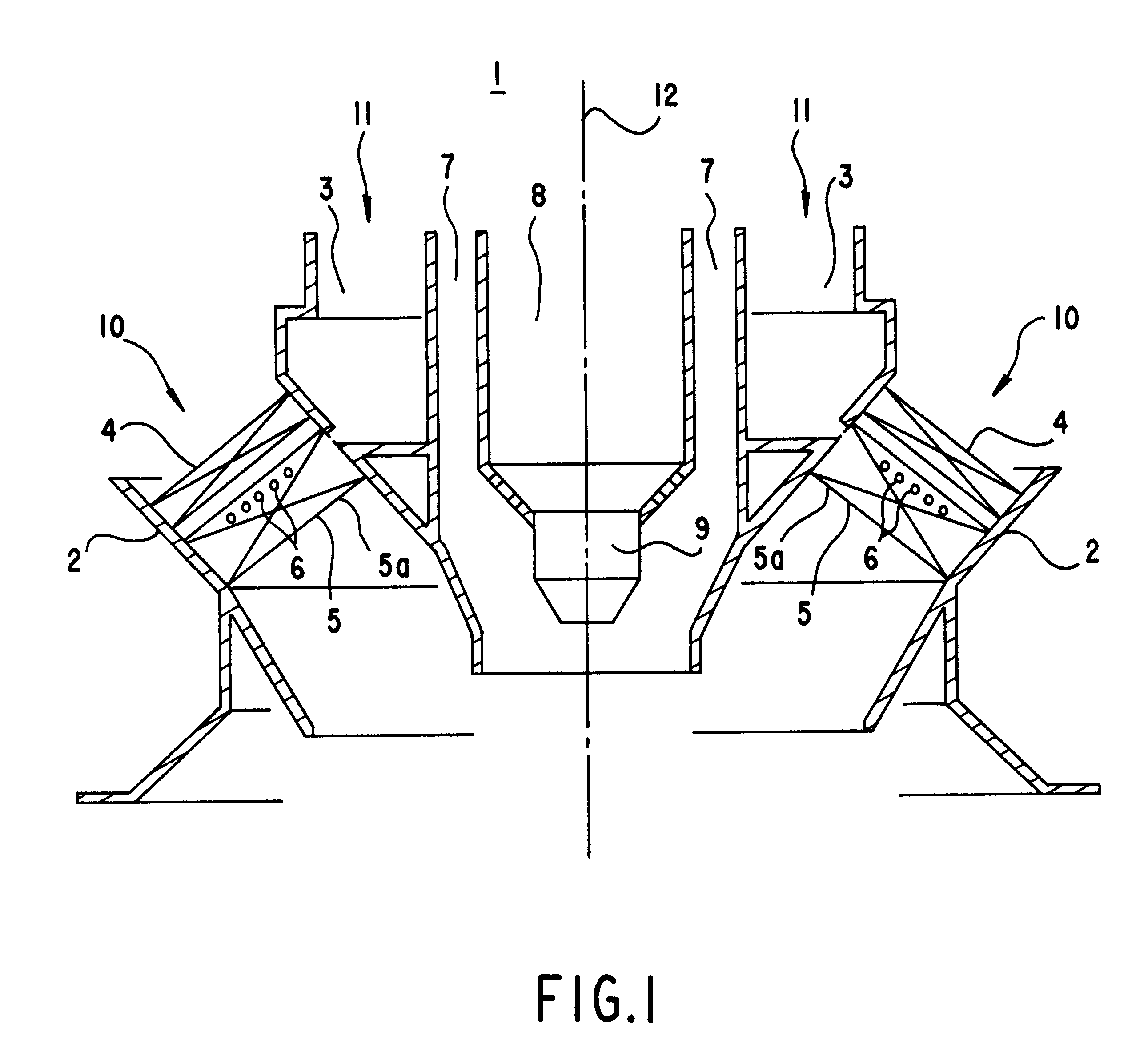

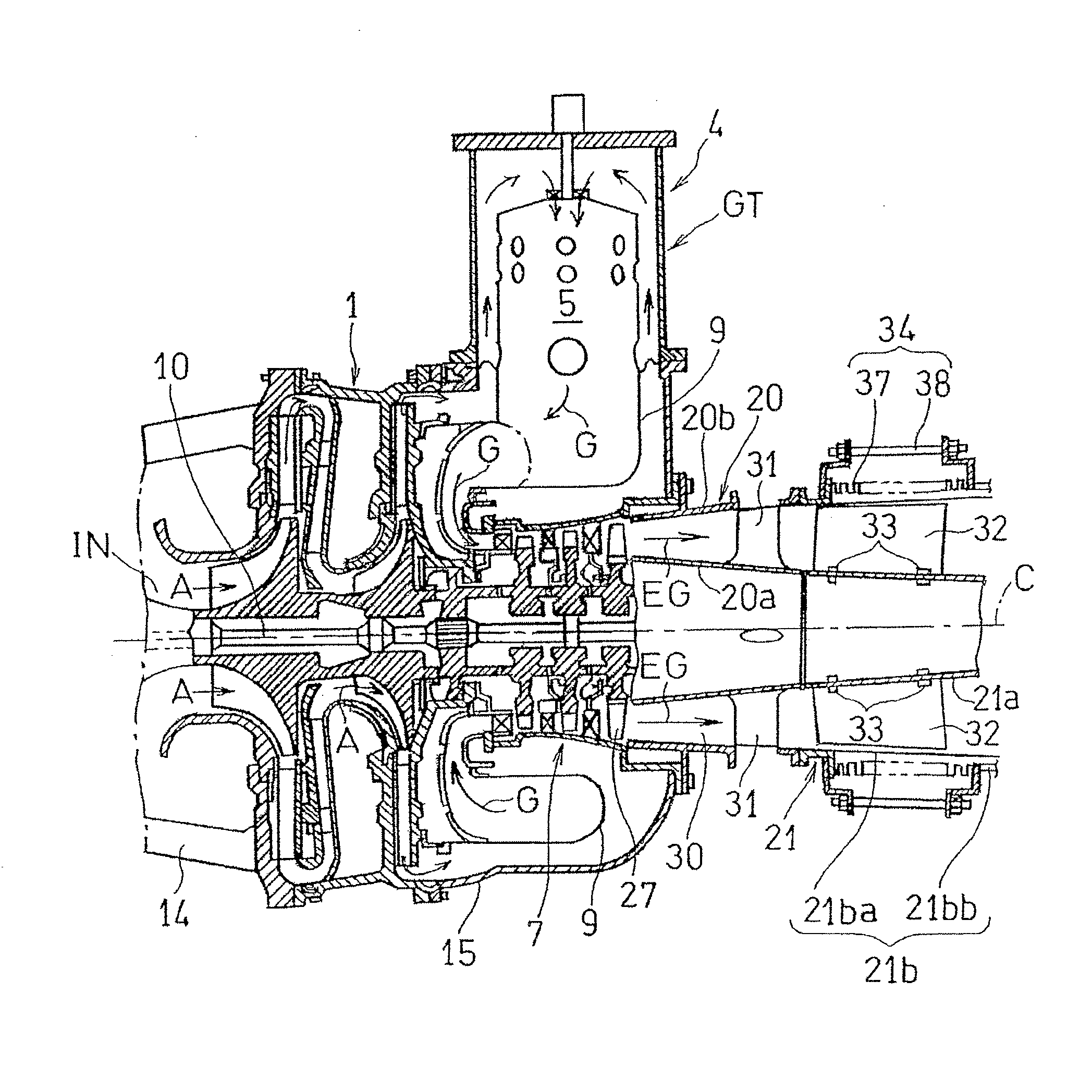

Burner for fluidic fuels having multiple groups of vortex generating elements

InactiveUS6189320B1Efficient mixingImprove spatial uniformityContinuous combustion chamberFlow mixersCombustorEngineering

A burner, in particular for a gas turbine, in which combustion air is subjected to a vorticity by a vortex element, admits fuel to the vortical combustion air. At the same time, a pressure loss produced by the vortex element is small. A low NO.sub.x emission at virtually the same efficiency is achieved.

Owner:SIEMENS AG

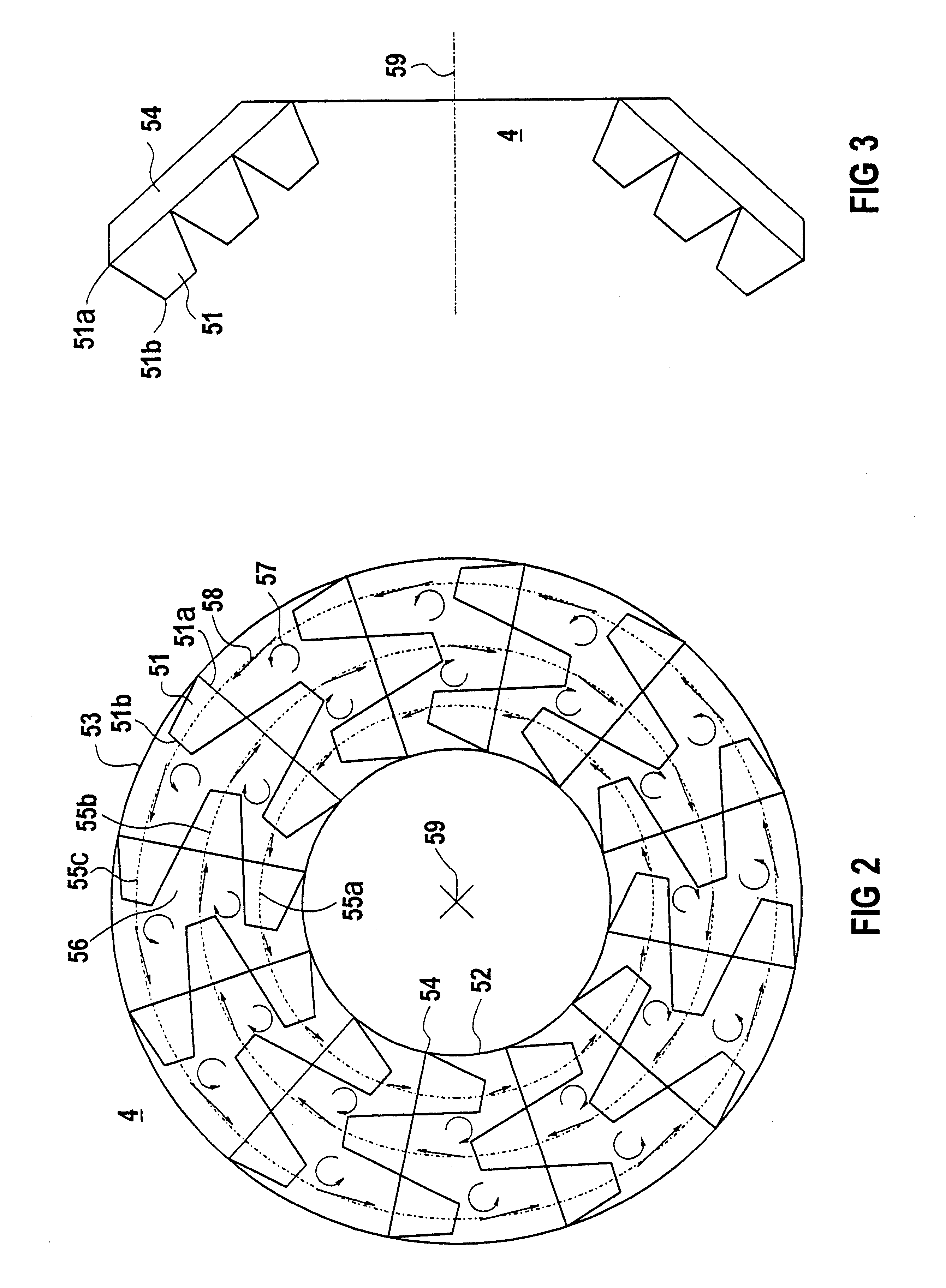

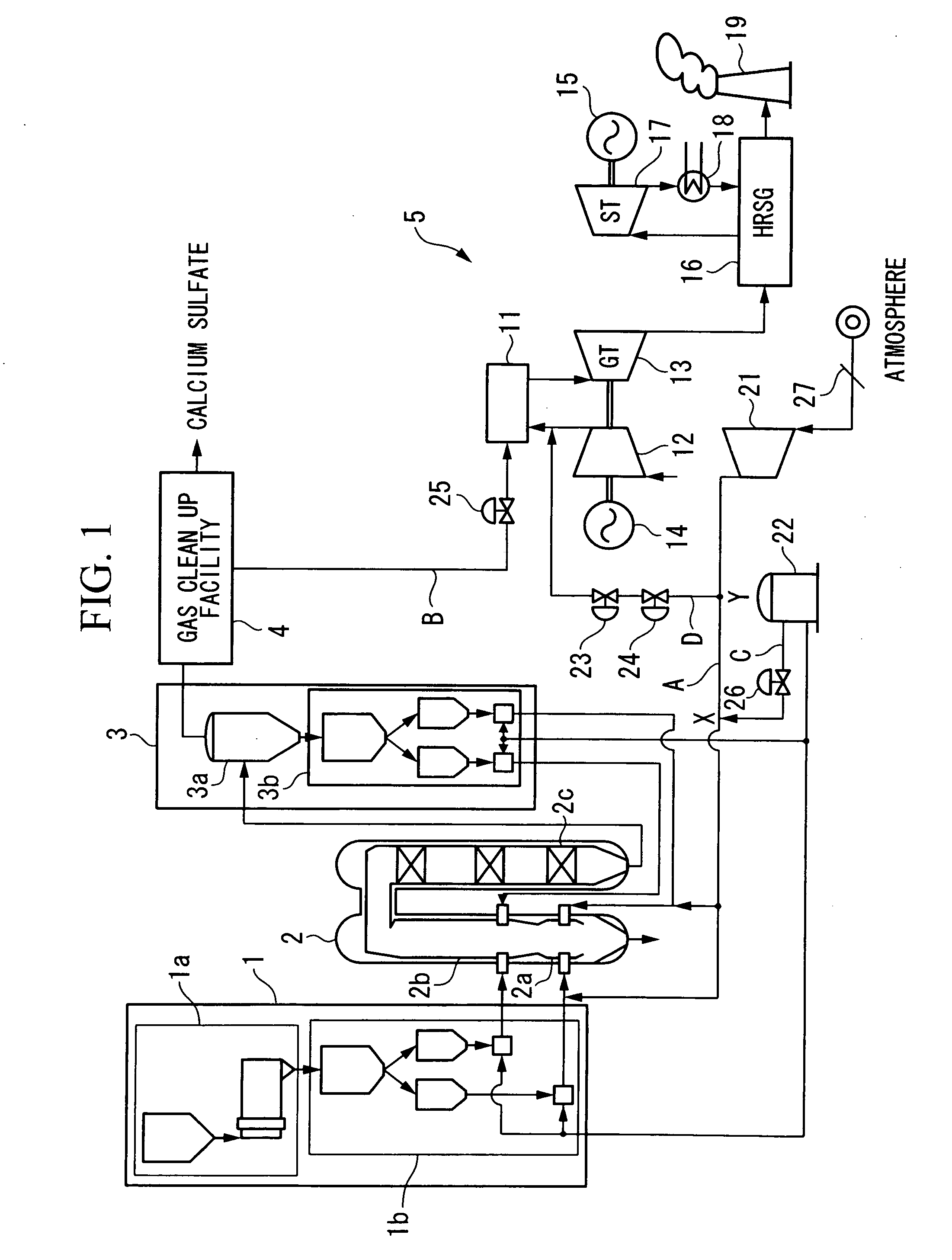

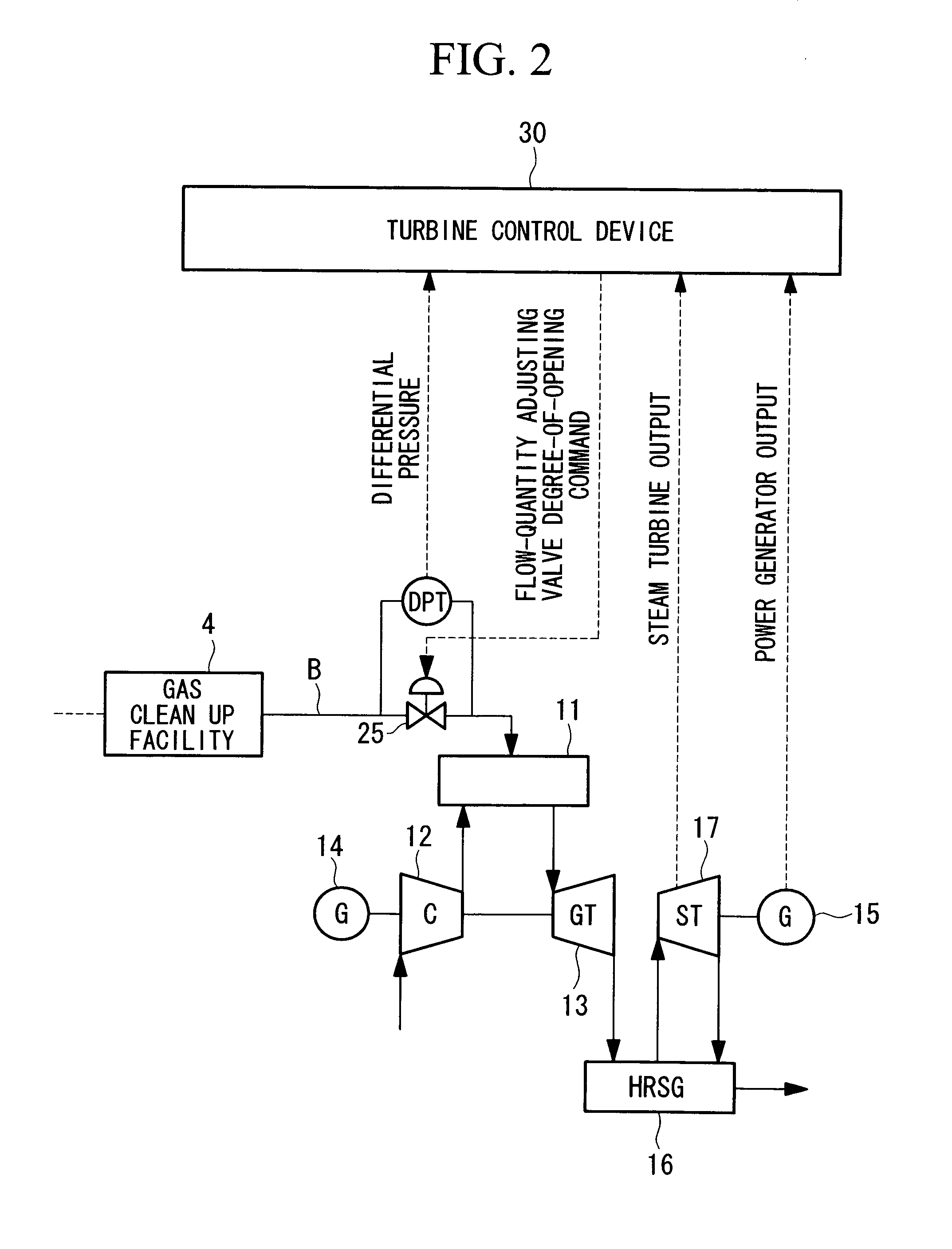

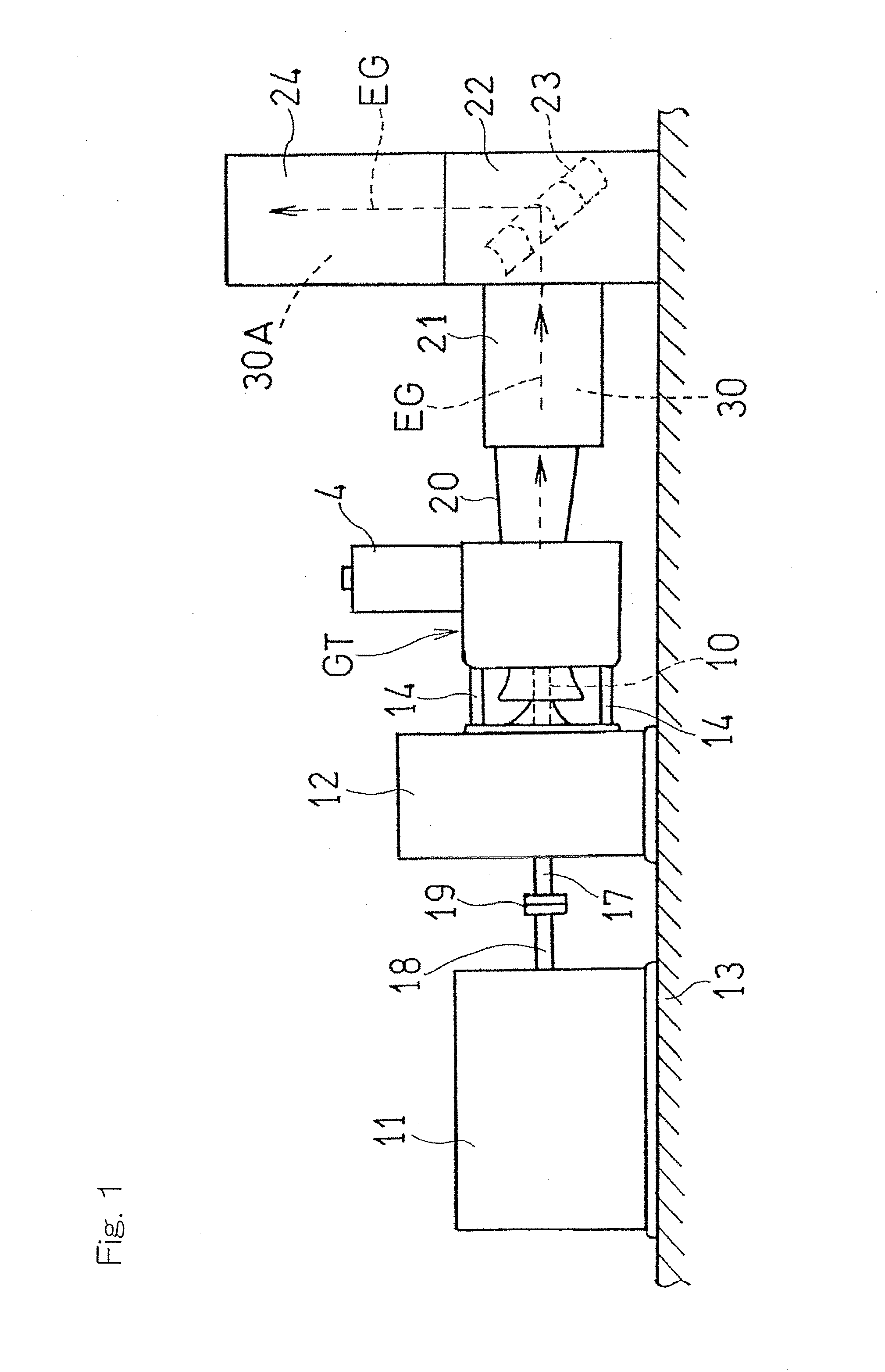

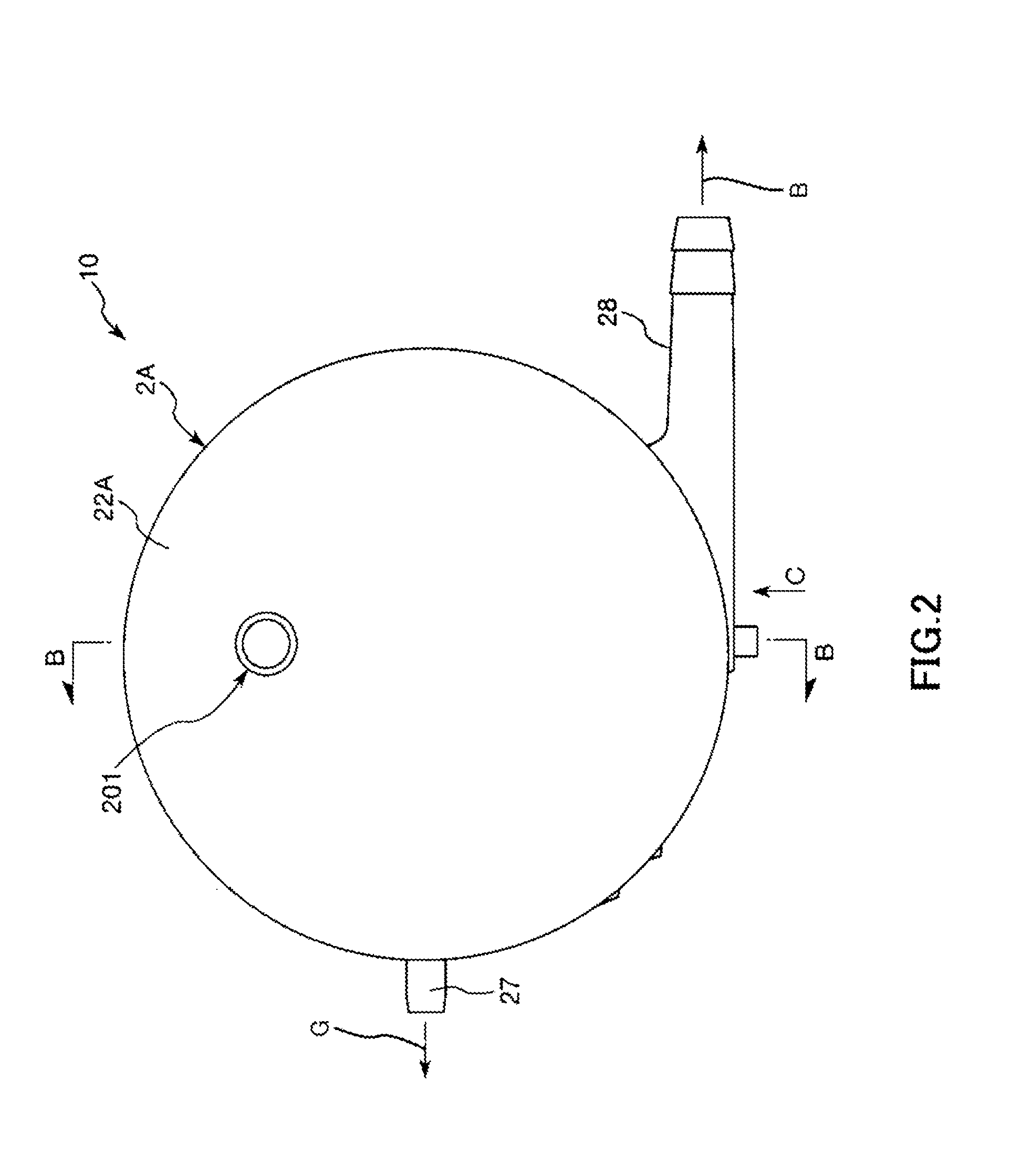

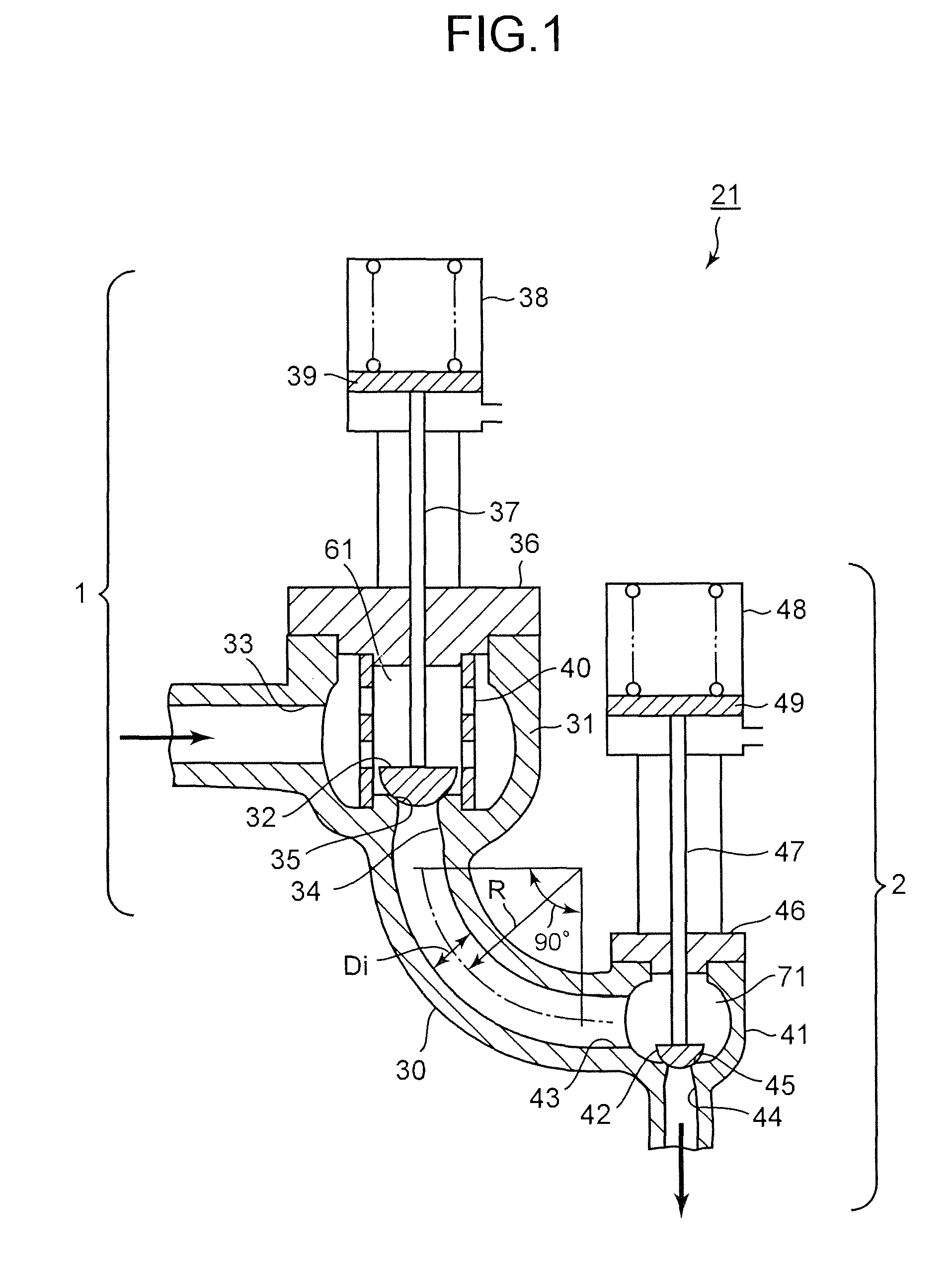

Integrated gasification combined cycle power generation plant

InactiveUS20080295480A1Boost overall plant efficiencyRelieve supply pressureCombustion enginesGas turbine plantsPower stationControl valves

A gasifying agent supply path A from an axial flow compressor 21 which boosts pressure of a gasifying agent to a gasifying furnace 2 is branched, and a gasifying agent bypass path D having an escaping pressure adjusting valve 23 is provided. The flow quantity or pressure of the gasifying agent supplied to the gasifying furnace 2 from the gasifying agent supply path A can be adjusted according to the degree of opening of the adjusting valve 23 disposed in the gasifying agent bypass path D, whereby providing a control valve in the gasifying agent supply path A is no longer necessary. Thus, pressure loss at the gasifying agent supply path A can be suppressed, and the discharge pressure of the axial flow compressor 21 can be greatly reduced.

Owner:MITSUBISHI HEAVY IND LTD

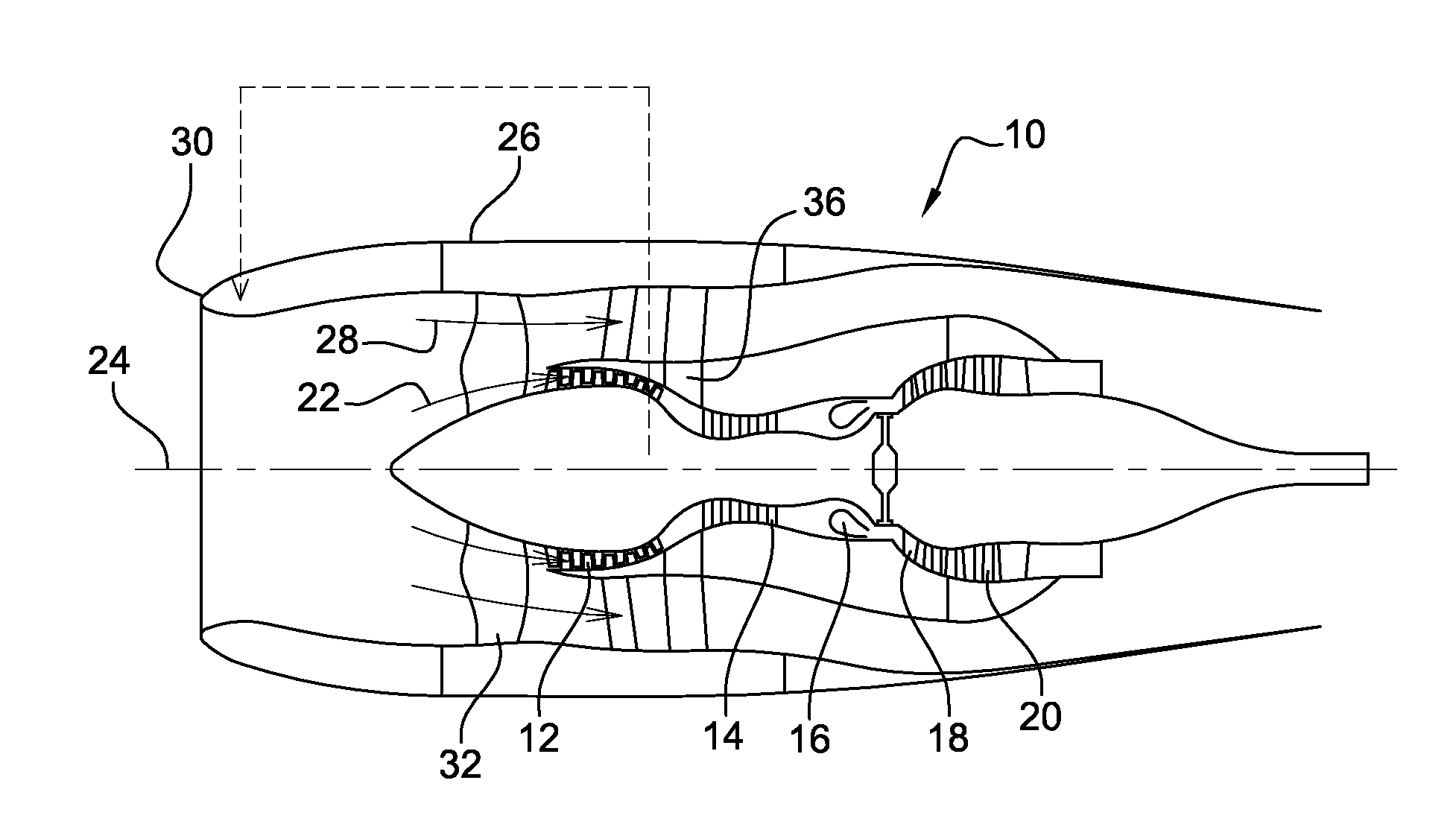

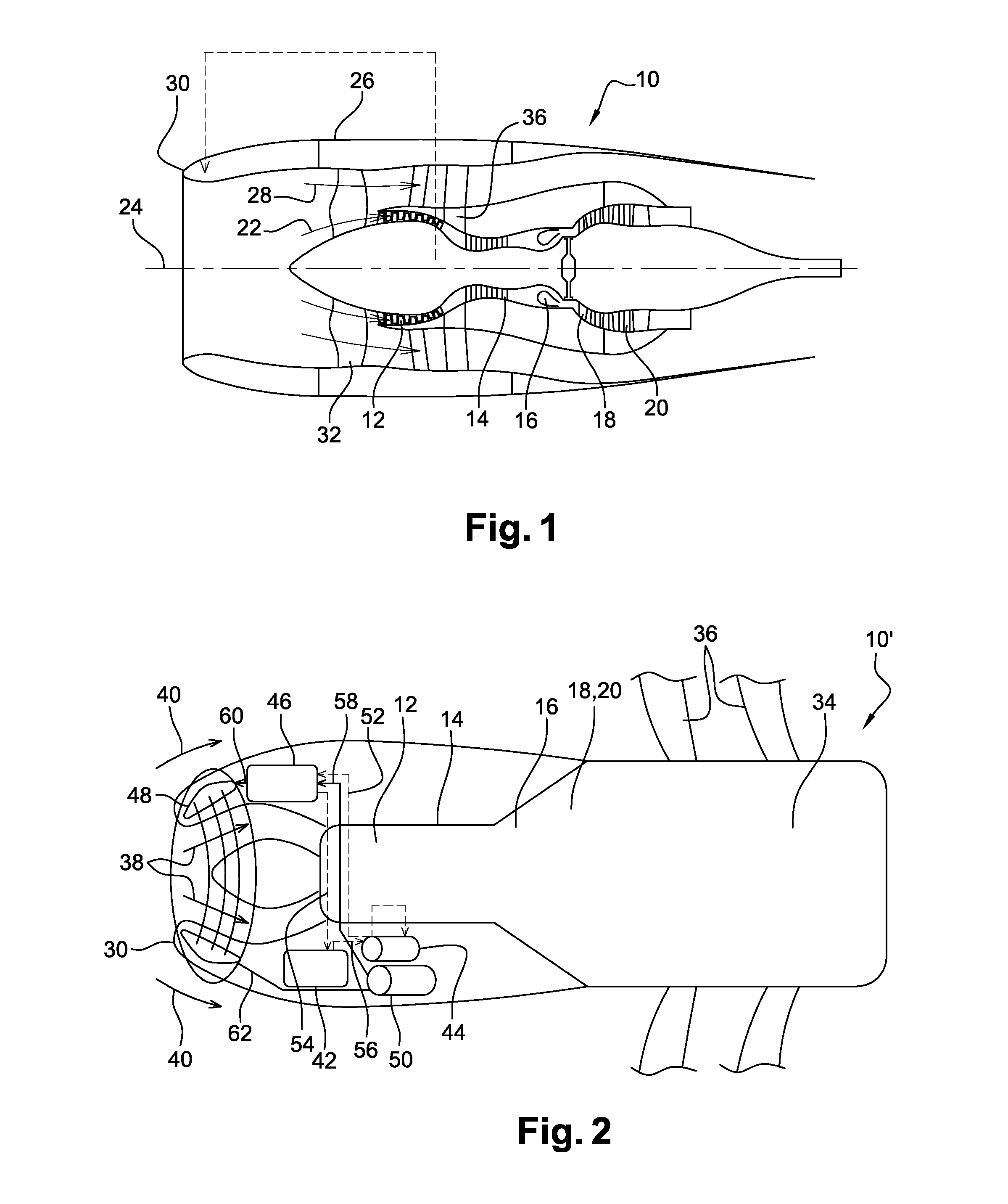

Circuit for de-icing an air inlet lip of an aircraft propulsion assembly

InactiveUS20160114898A1Reduce total pressure lossSpeed up heat exchangePump componentsTurbine/propulsion engine coolingNacelleHeat transfer fluid

Propulsion assembly, comprising a turbine engine surrounded by a nacelle comprising an annular air inlet lip, the propulsion assembly further comprising a circuit for lubricating elements of the turbine engine and a circuit for de-icing the air inlet lip, characterised in that said de-icing circuit comprises a heat exchanger comprising a primary circuit of oil supplied by said lubrication circuit and a secondary circuit of a heat transfer fluid for supplying at least one de-icing channel extending into said air inlet lip, said de-icing circuit further comprising a pump for circulating the heat transfer fluid into said at least one channel.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

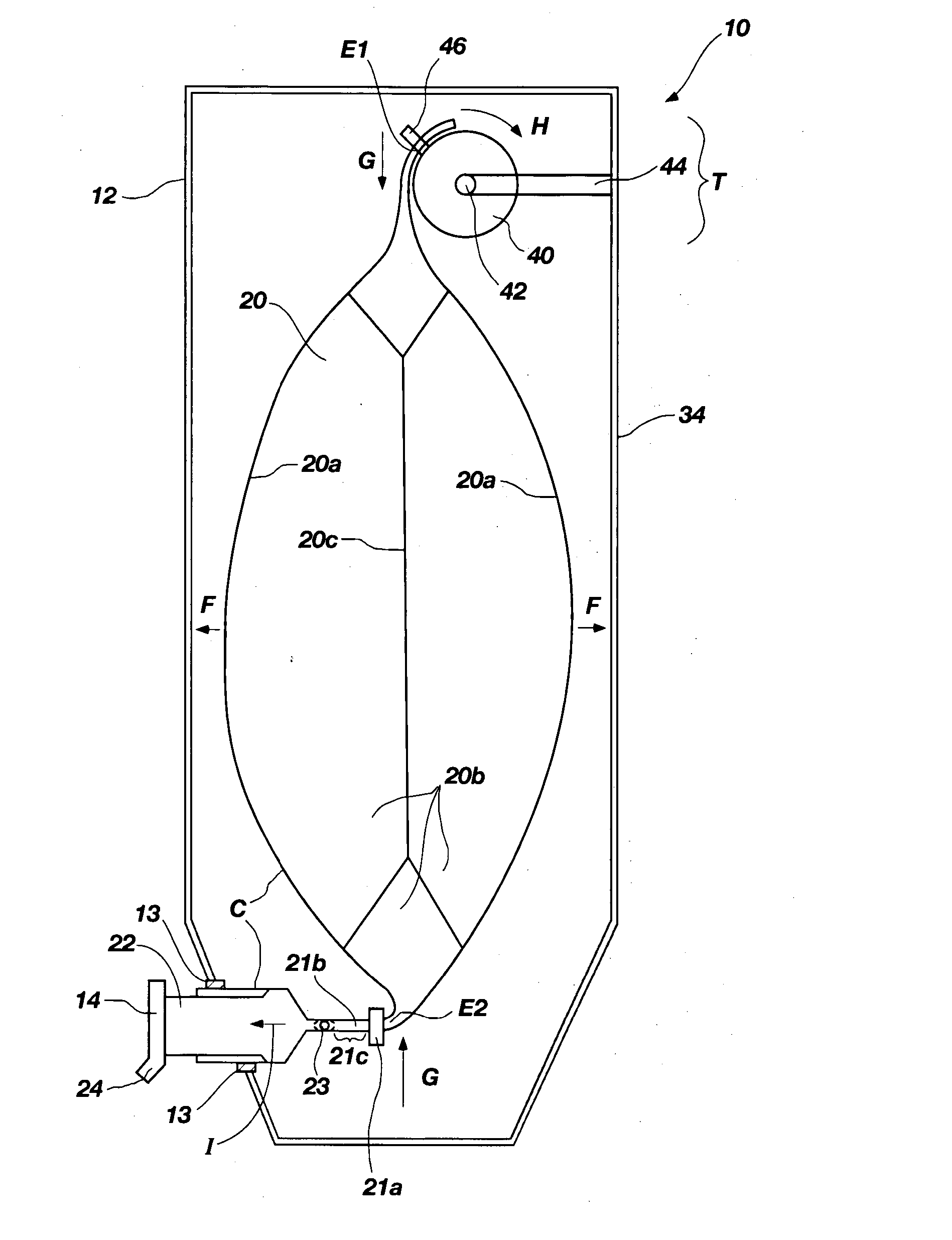

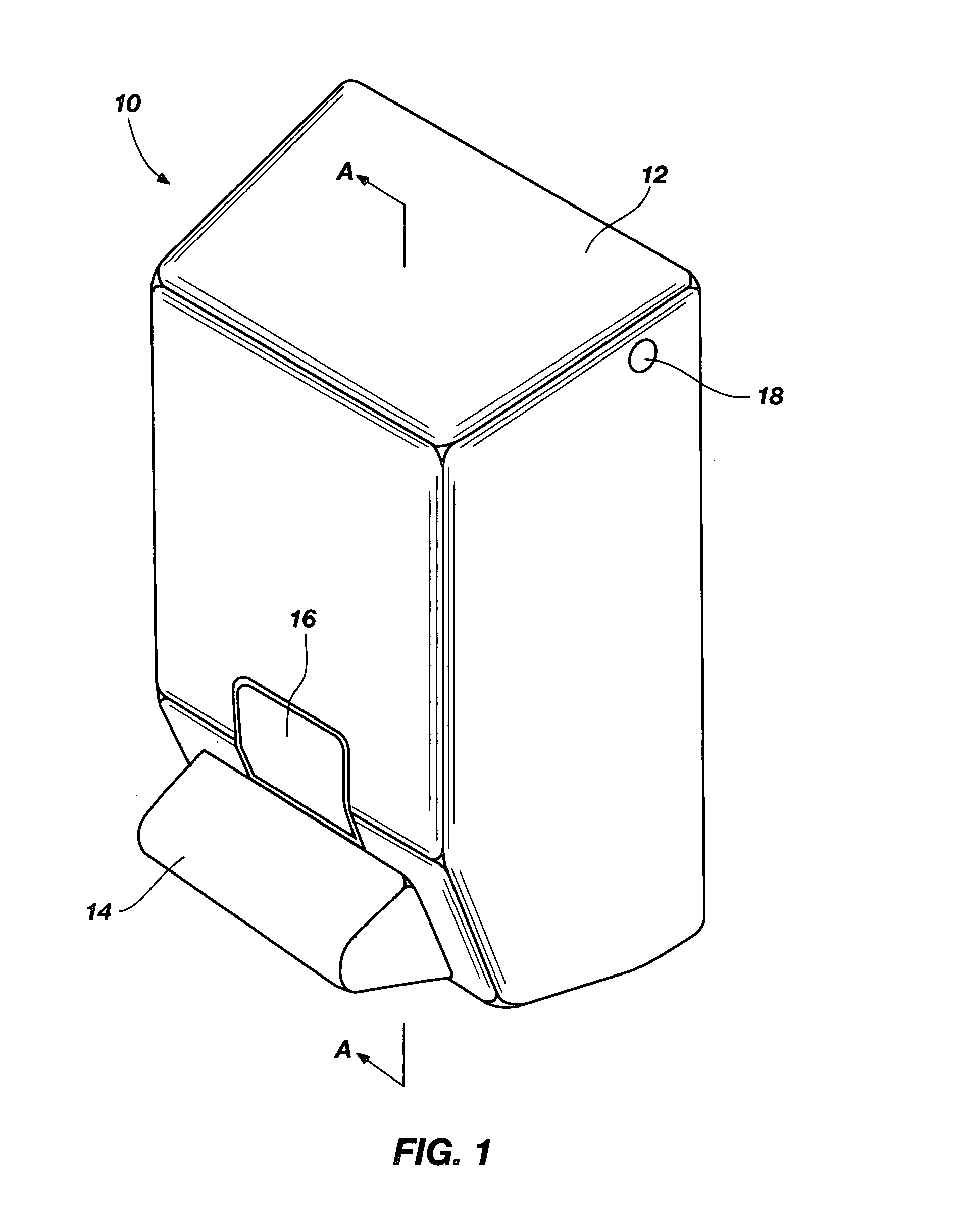

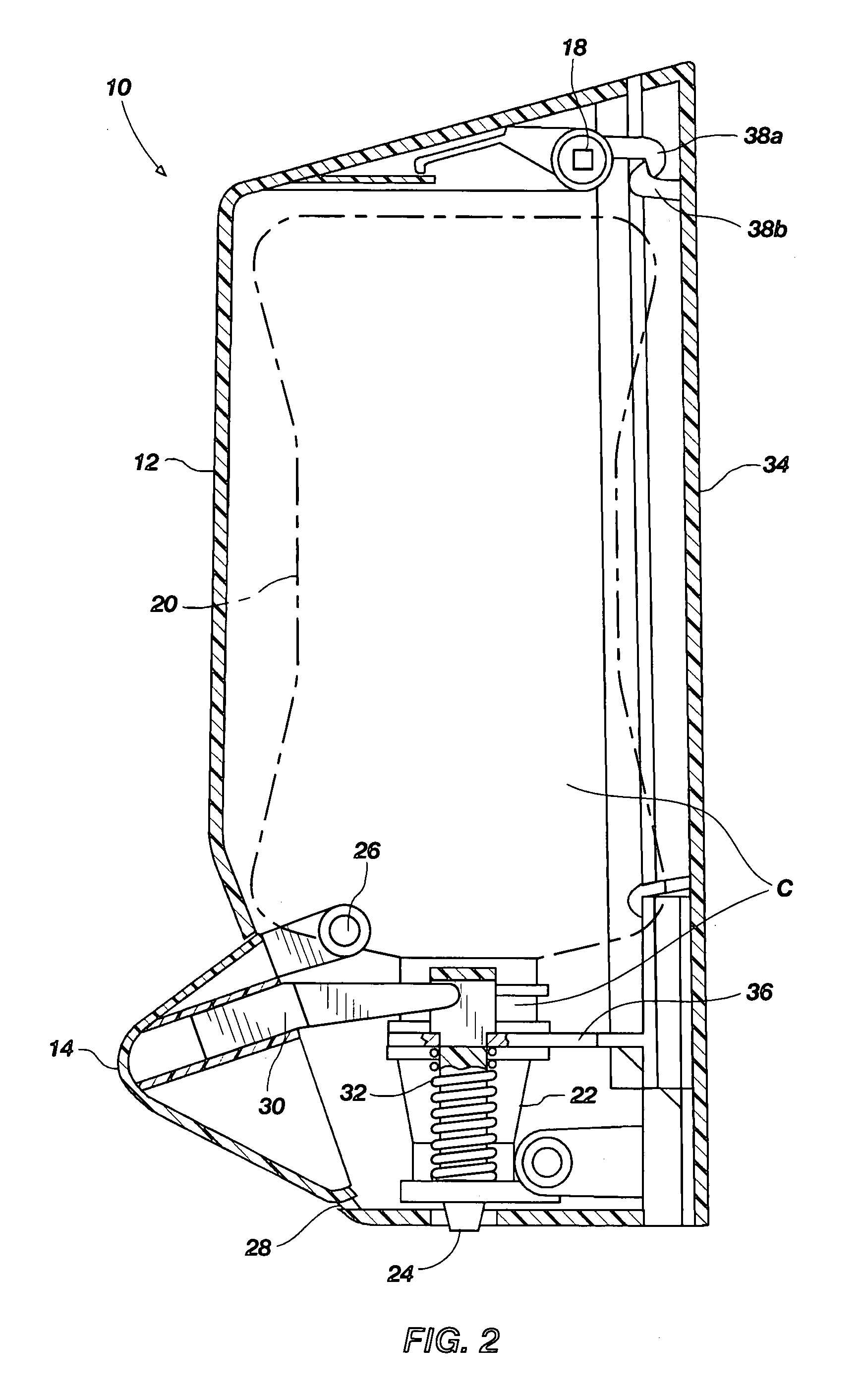

Fluid product dispenser with collapsible reservoir and tensioning means therefor

InactiveUS20080023487A1Minimize migrationMinimizes accumulationHolders and dispensersLiquid transferring devicesBiomedical engineering

A dispenser for dispensing a fluid product includes an assembly of a collapsible reservoir and a pump, a housing for removably accommodating the assembly, and means for actuating the pump. The housing includes a tensioning element, or tensioning means, which is configured to counteract, or negate, compression of the collapsible reservoir as fluid is removed from the collapsible reservoir. By counteracting compression of the collapsible reservoir, the tensioning element, or tensioning means, may prevent trapping of fluid product in the collapsible reservoir.

Owner:TECHN CONCEPTS BENTFIELD

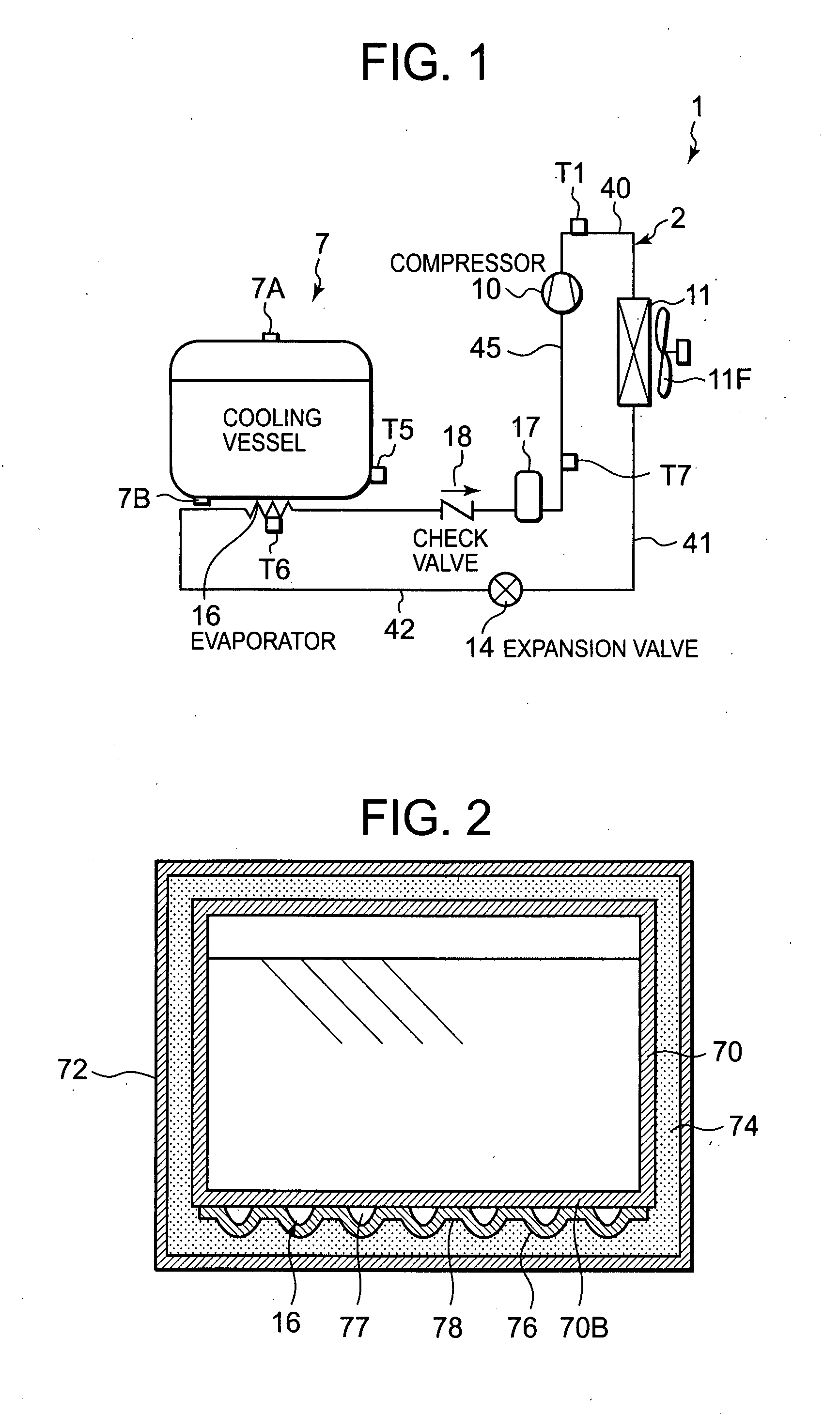

Intercooler

ActiveUS20100050997A1Reduced space required for installationAdvantageously relayed more quickly toInternal combustion piston enginesThermal treatment of fuelMobile vehicleEngineering

The invention relates to an intercooler for a motor vehicle with an internal combustion engine that is supercharged in steps. In this case, the intercooler has an air outlet opening as well as two air inlet openings, a heat exchanger module being associated with each air inlet opening. Air channels of the two heat exchanger modules are ultimately brought together in an air box of the intercooler, which is connected to the air outlet opening. It is thus made possible to bring together compressed charging air from two supercharging assemblies only in the area of the intercooler. To improve the pressure ratios during operation of only one supercharging assembly, a non-return valve is provided in an air channel. Thus, a module for separately bringing the airways together can be eliminated, thereby reducing the installation space requirement.

Owner:AUDI AG

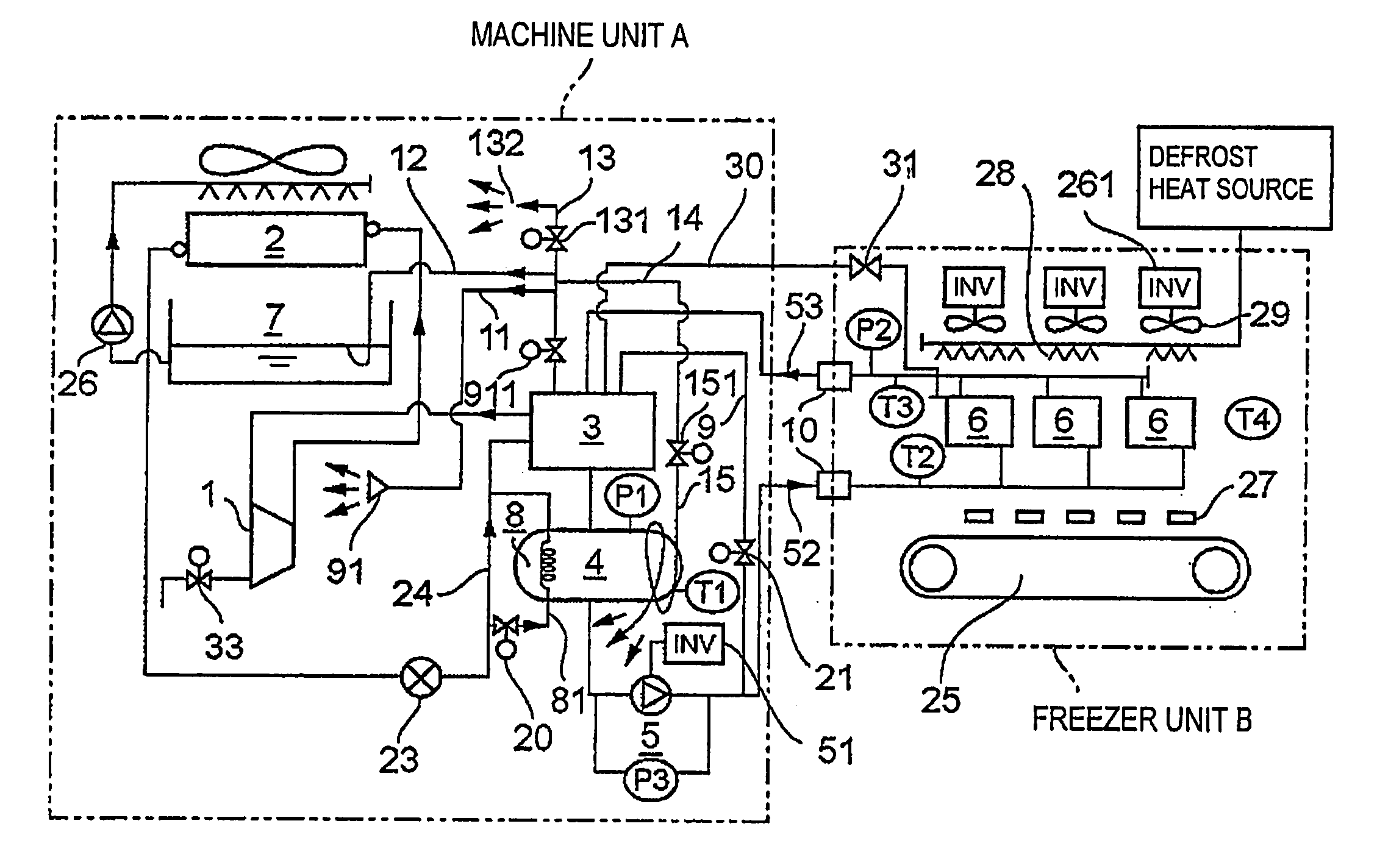

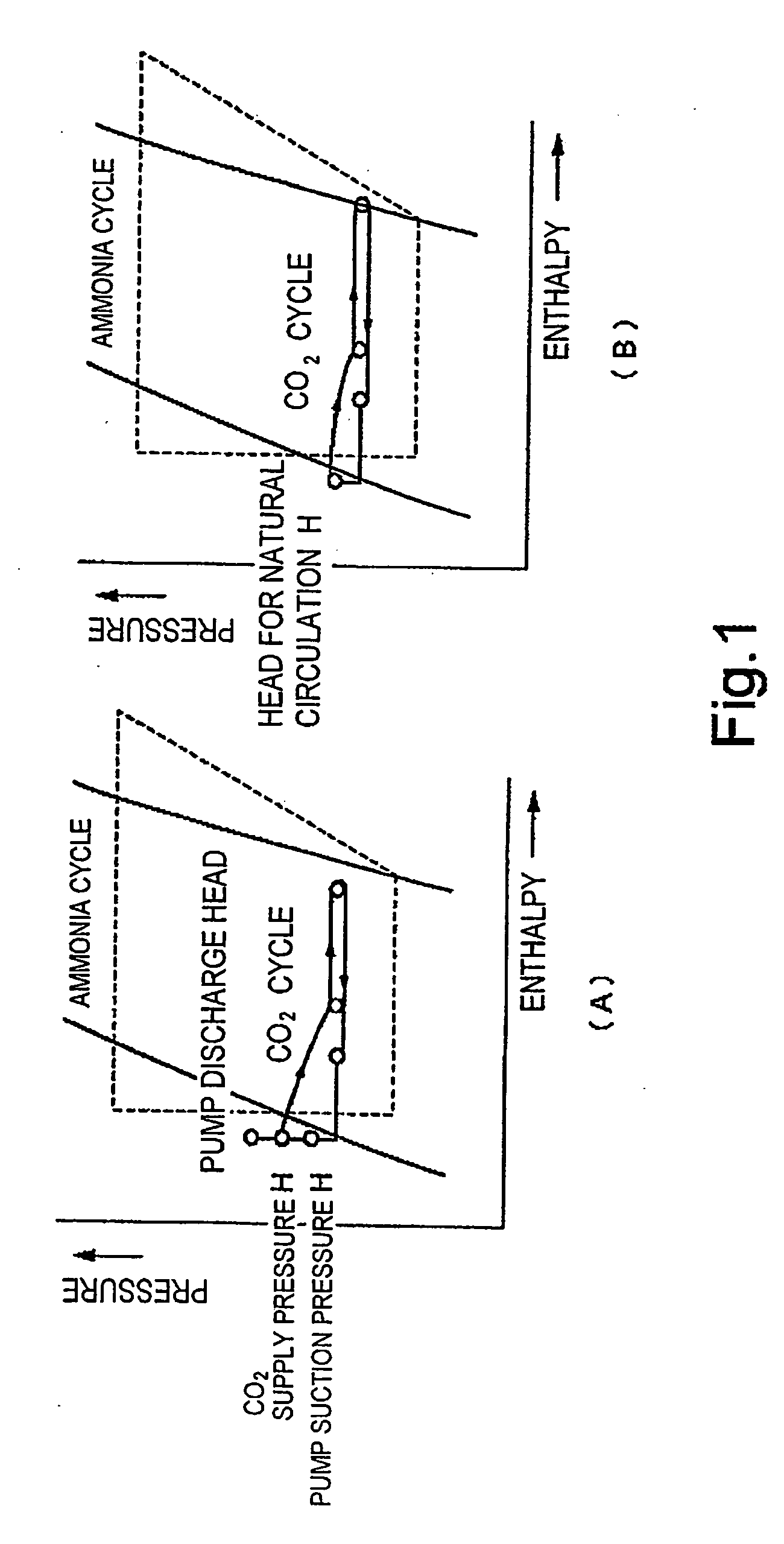

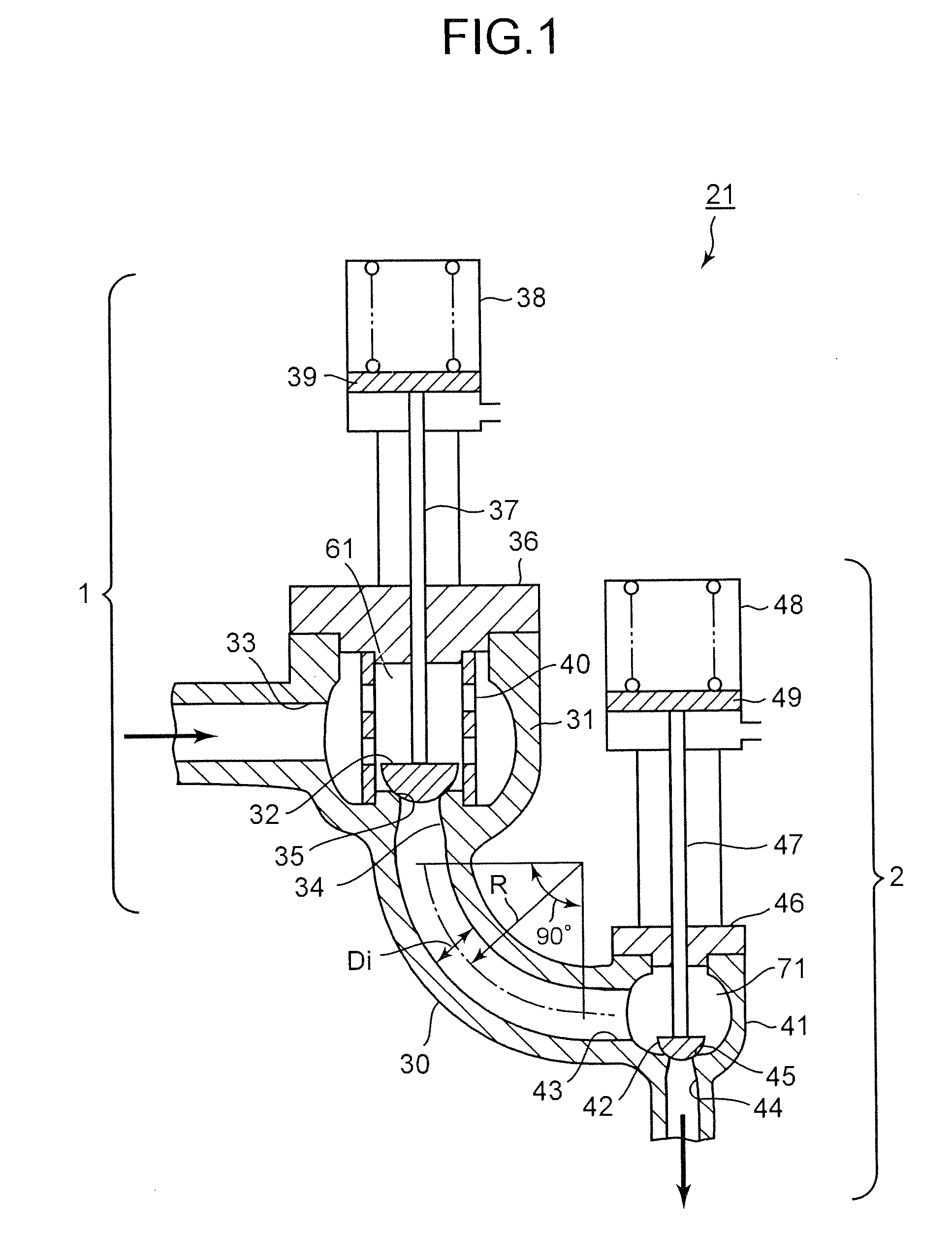

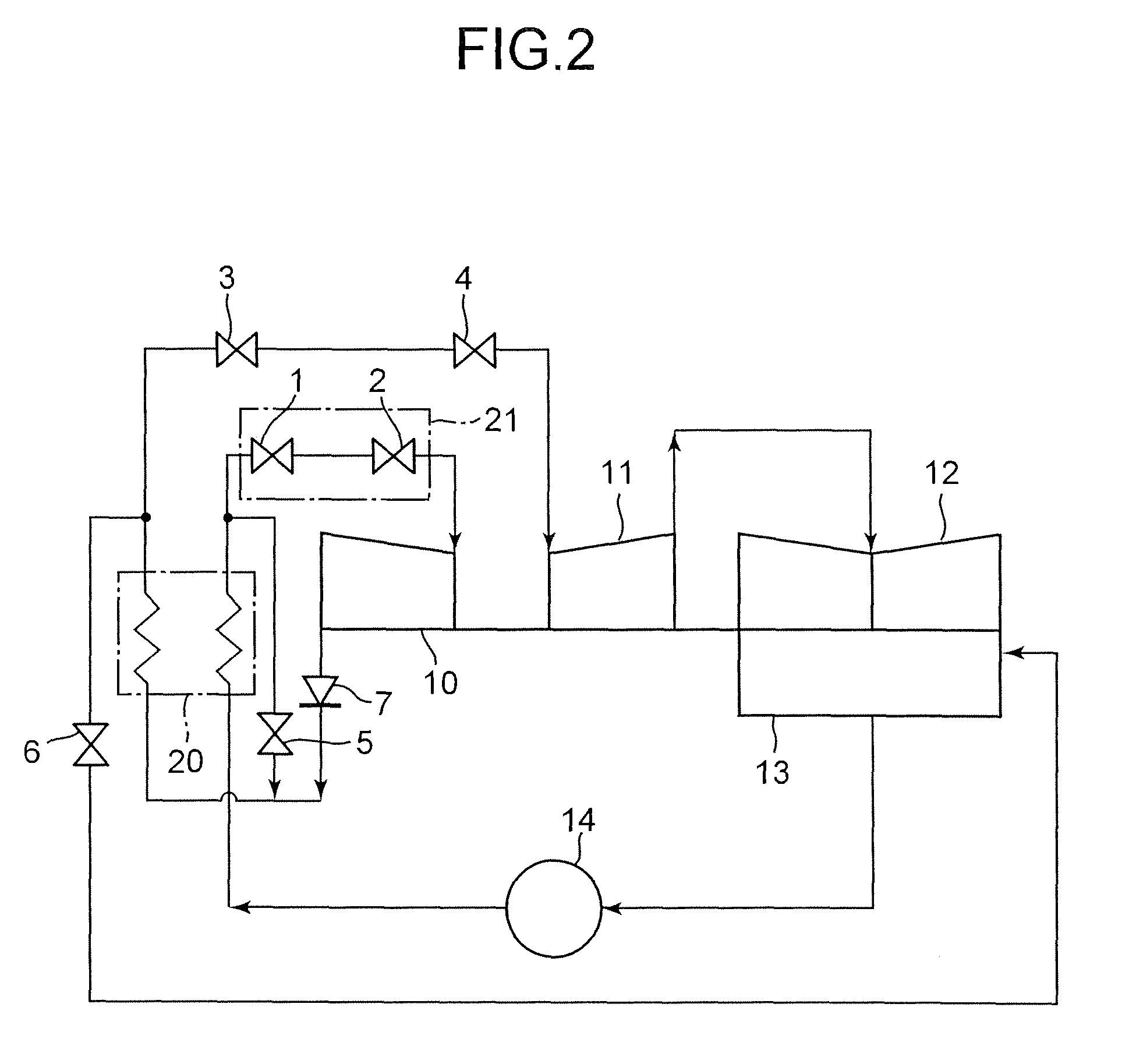

Ammonia/CO2 refrigeration system, CO2 brine production system for use therein, and ammonia cooling unit incorporating that production system

ActiveUS20060266058A1Pressure lossReduce heightCompression machines with non-reversible cycleEvaporators/condensersProcess engineeringChiller

The object of the invention is to provide an ammonia / CO2 refrigeration system in which the ammonia cycle and CO2 brine cycle can be combined without problems even when refrigeration load such as refrigerating showcase, etc. is located at any place in accordance with circumstances of customer's convenience. The system comprises apparatuses working on an ammonia refrigerating cycle, a brine cooler for cooling and condensing CO2 by utilizing the latent heat of vaporization of the ammonia, and a liquid pump provided in a supply line for supplying the cooled and liquefied CO2 to a refrigeration load side cooler, wherein said liquid pump is a variable-discharge pump for allowing CO2 to be circulated forcibly, and the forced circulation flow is determined so that CO2 is recovered from the outlet of the cooler of the refrigeration load side in a liquid or liquid / gas mixed state.

Owner:MAYEKAWA MFG CO LTD

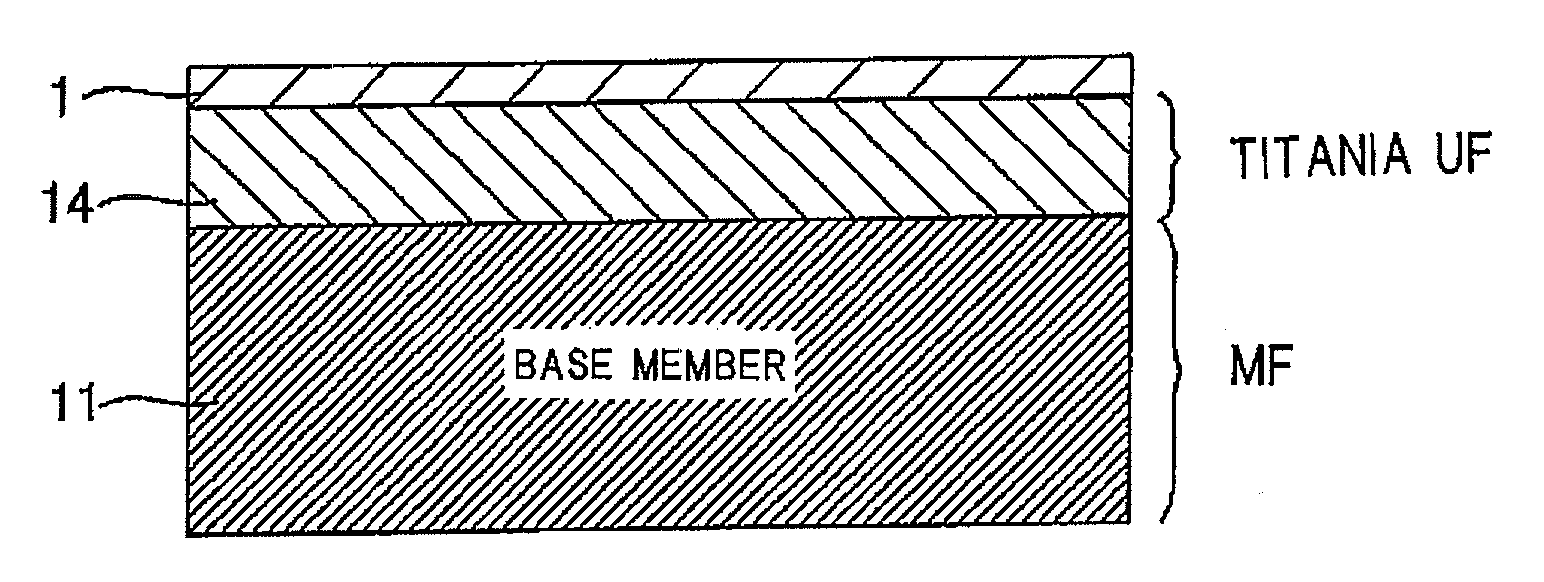

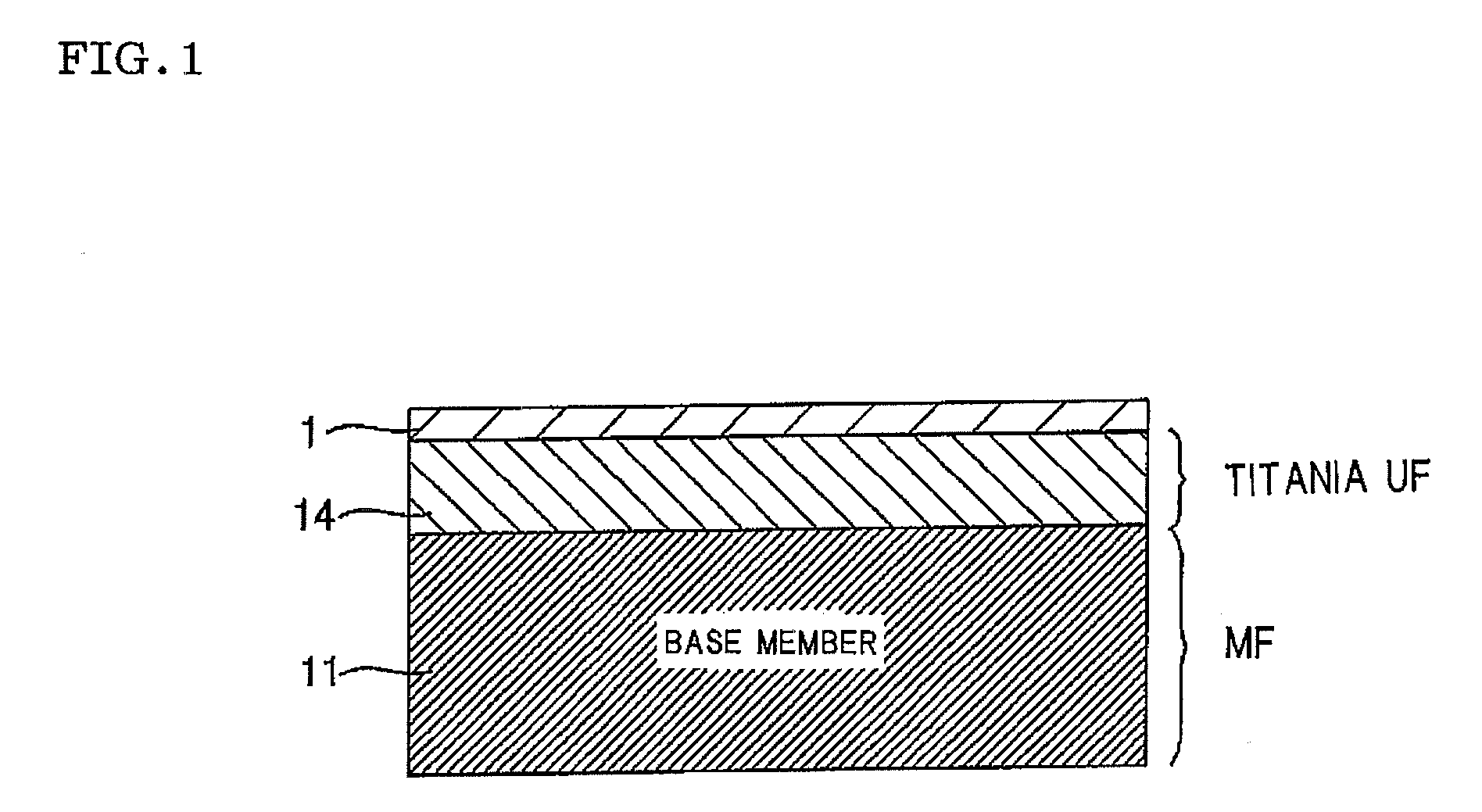

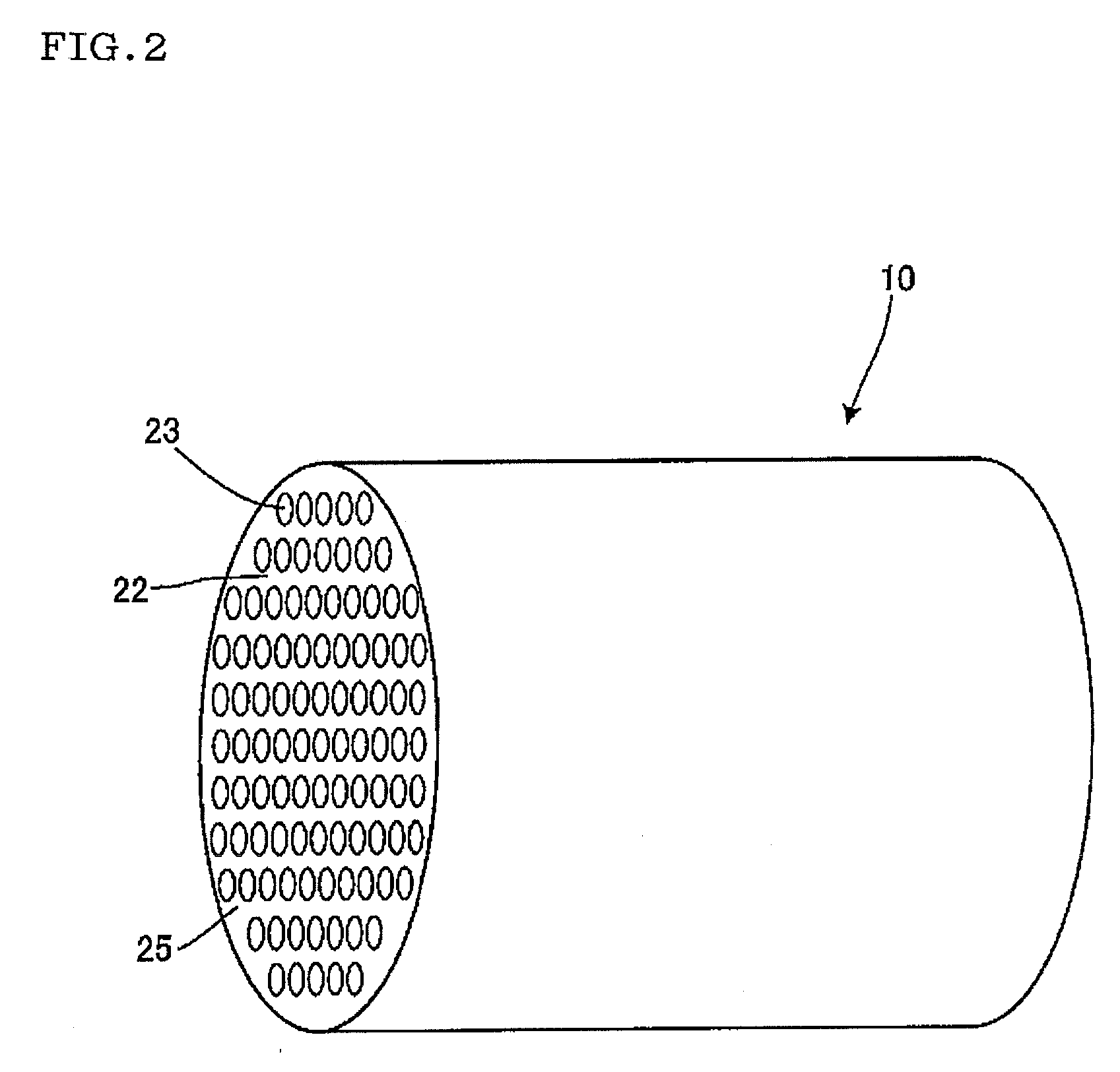

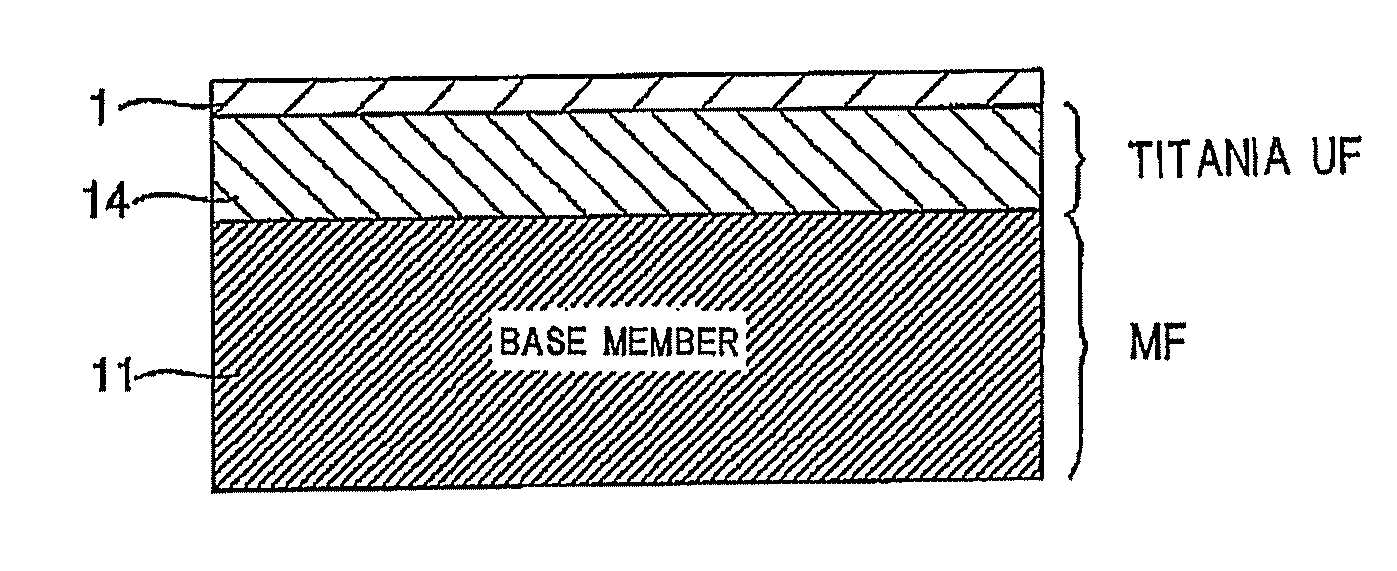

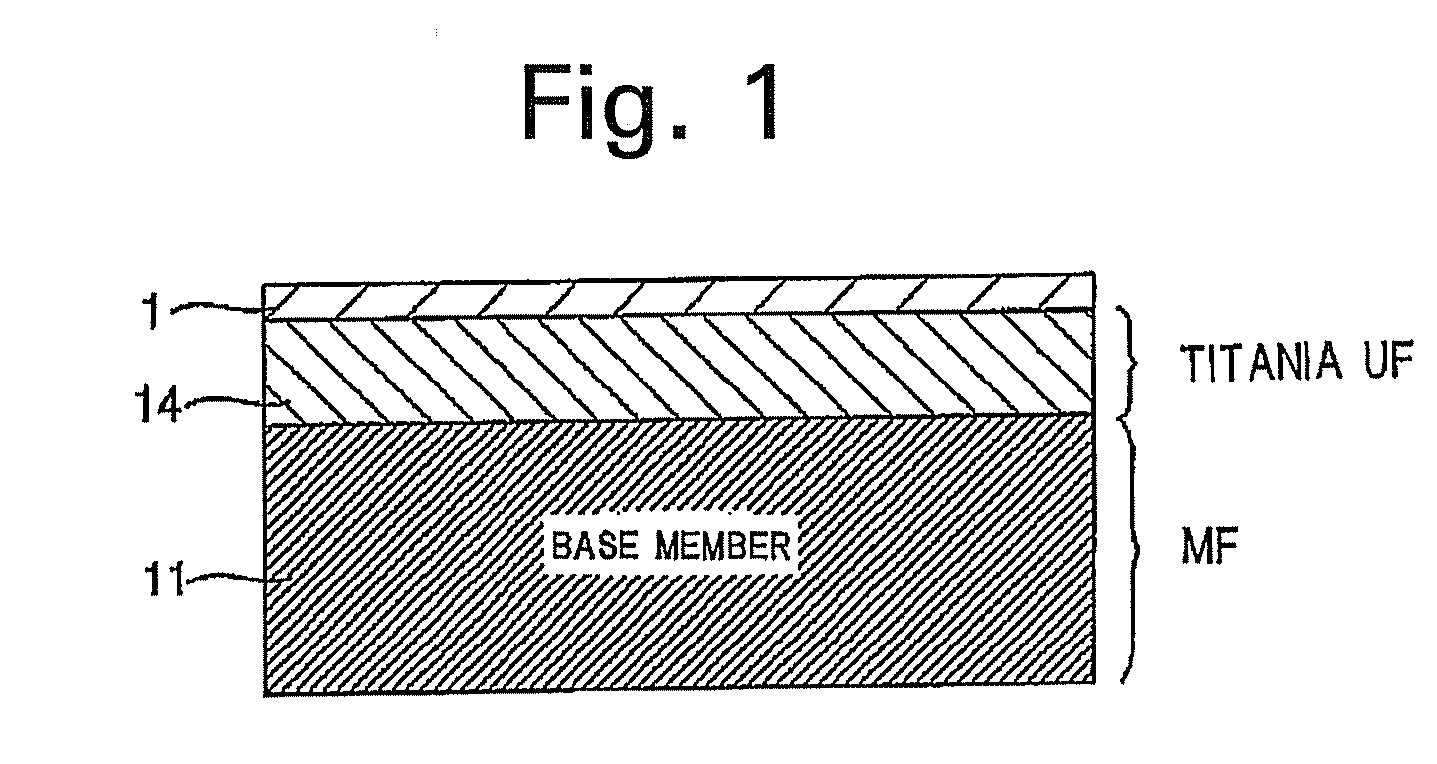

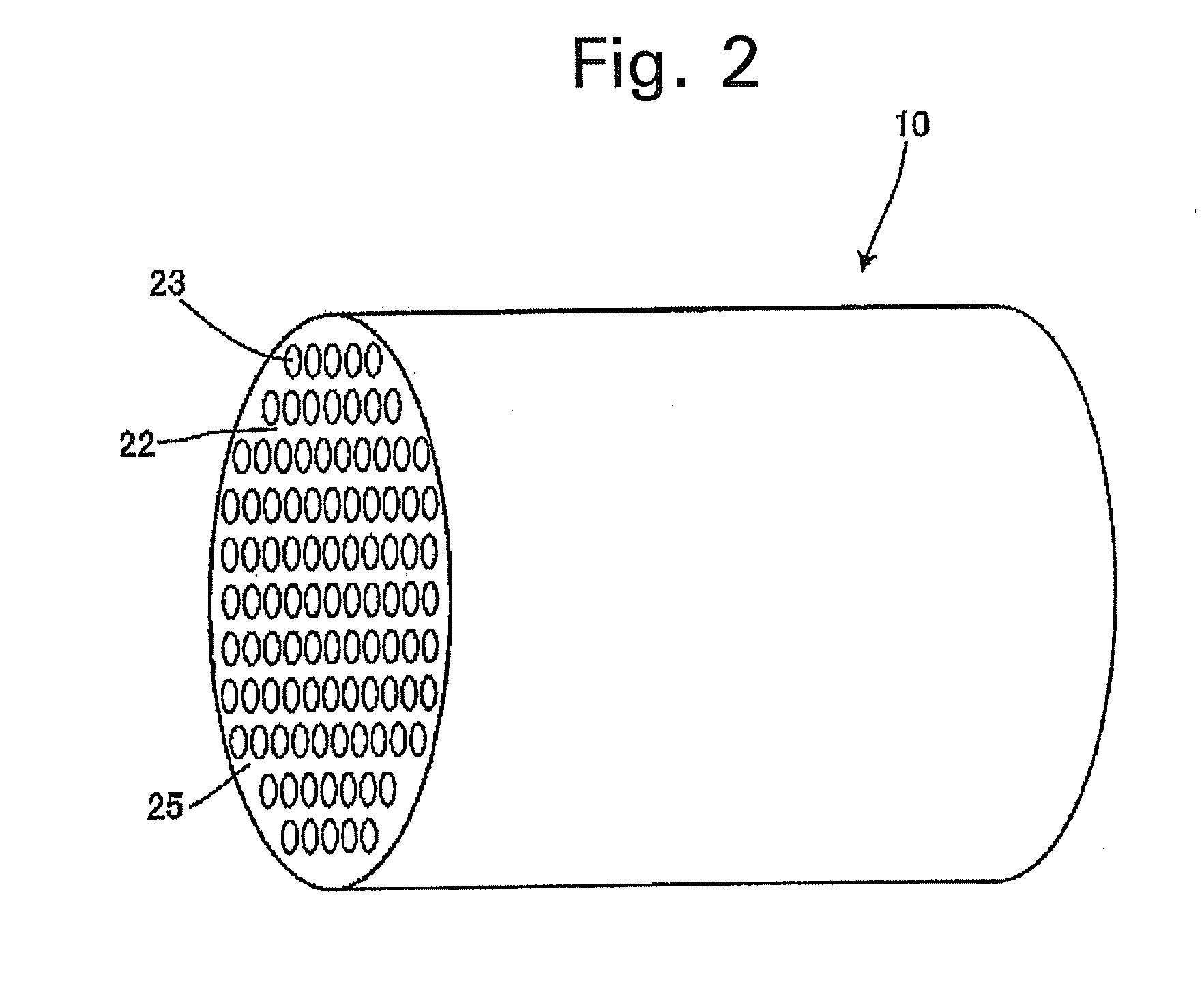

Ceramic porous membrane and ceramic filter

InactiveUS20080093291A1Few defectImprove throughputMembranesSemi-permeable membranesUltrafiltrationHigh flux

There are disclosed a ceramic porous membrane formed with less membrane formation times and having less defects, a small and uniform thickness and a high flux, and a ceramic filter. A silica membrane is formed on a titania UF membrane as an ultrafiltration membrane (a UF membrane) formed on a porous base member which is a microfiltration membrane (also referred to as an MF membrane) and having an average pore diameter smaller than that of the porous base member, and the silica membrane has an average pore diameter smaller than that of the titania UF membrane, and does not substantially permeates the titania UF membrane.

Owner:NGK INSULATORS LTD

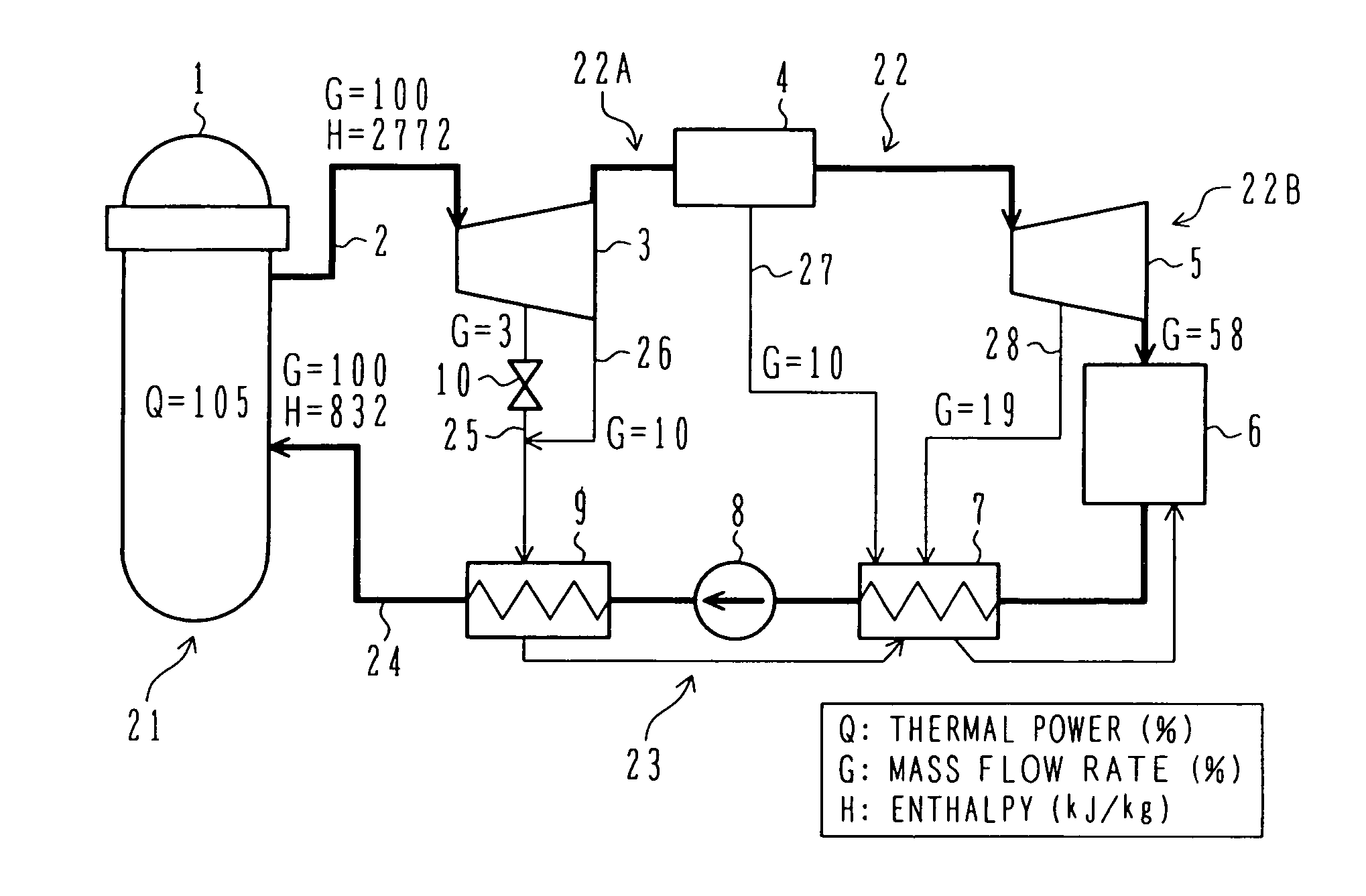

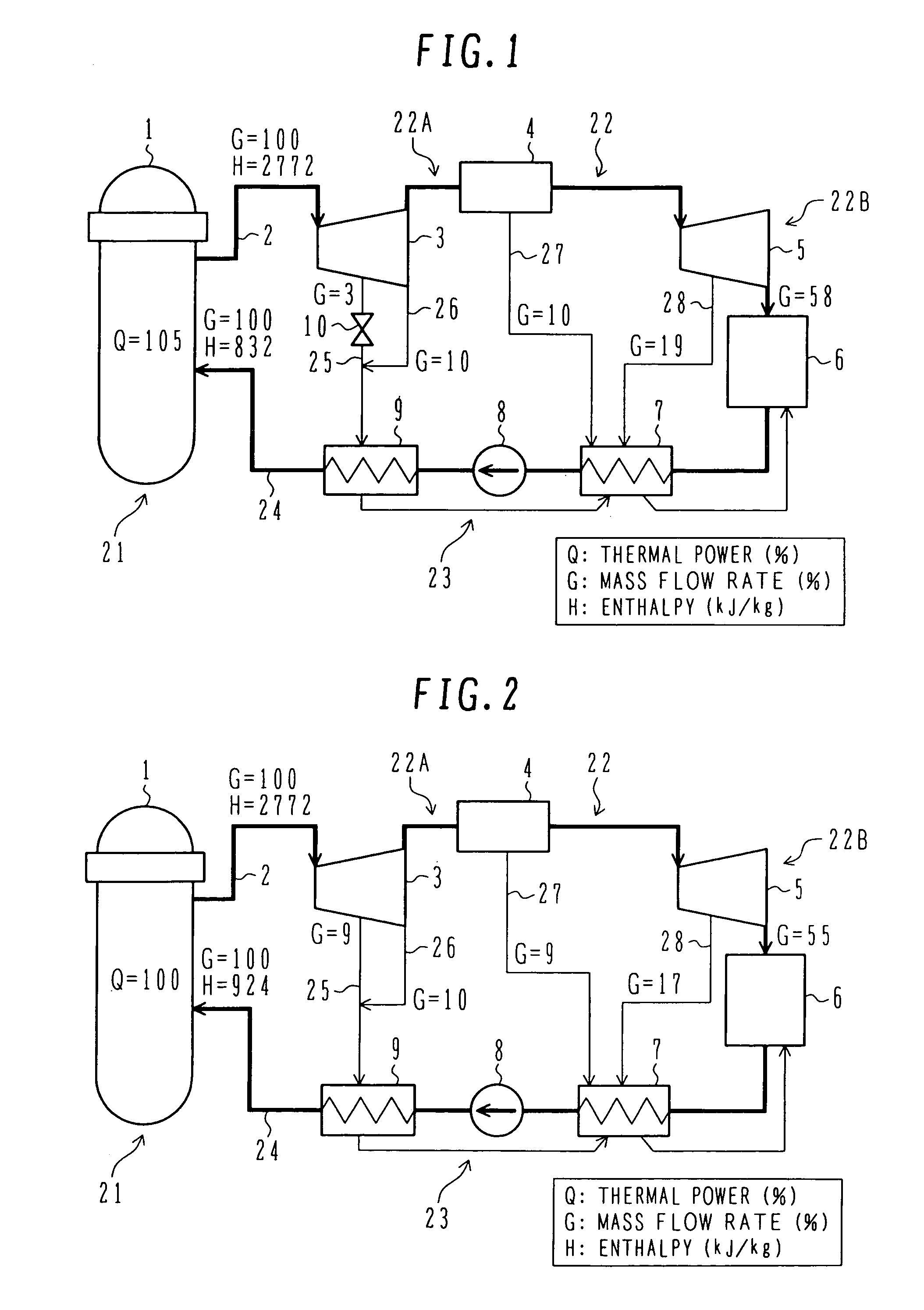

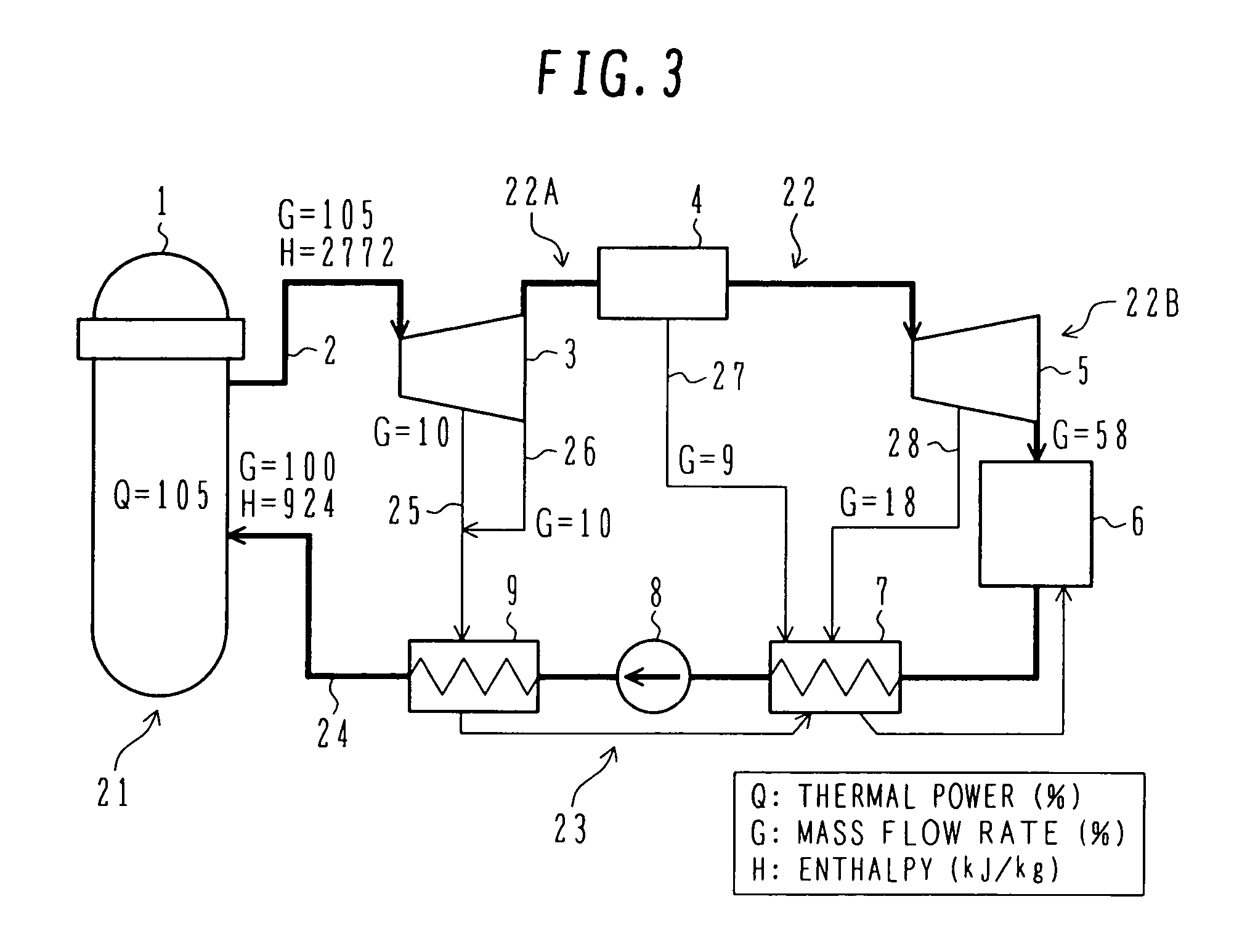

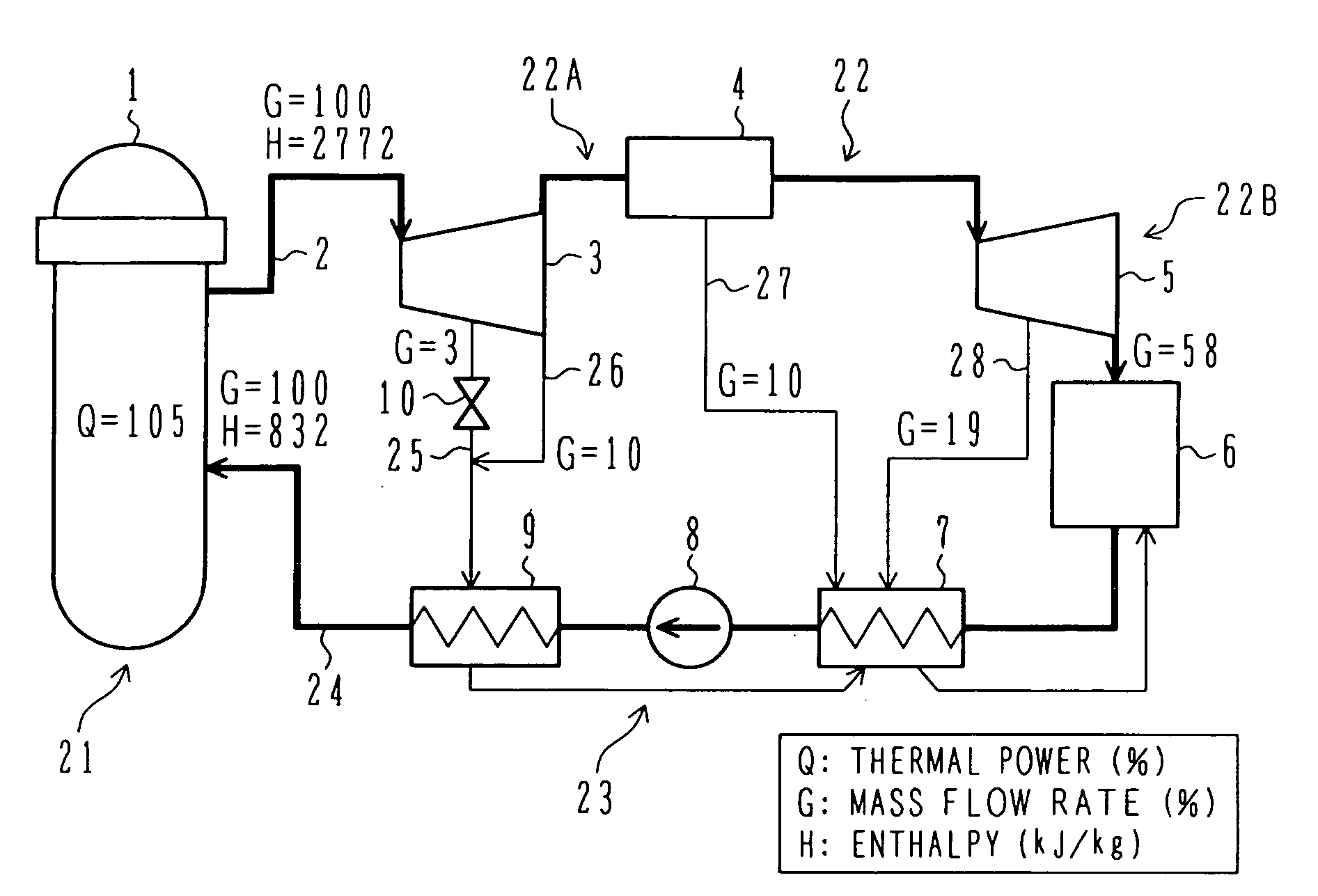

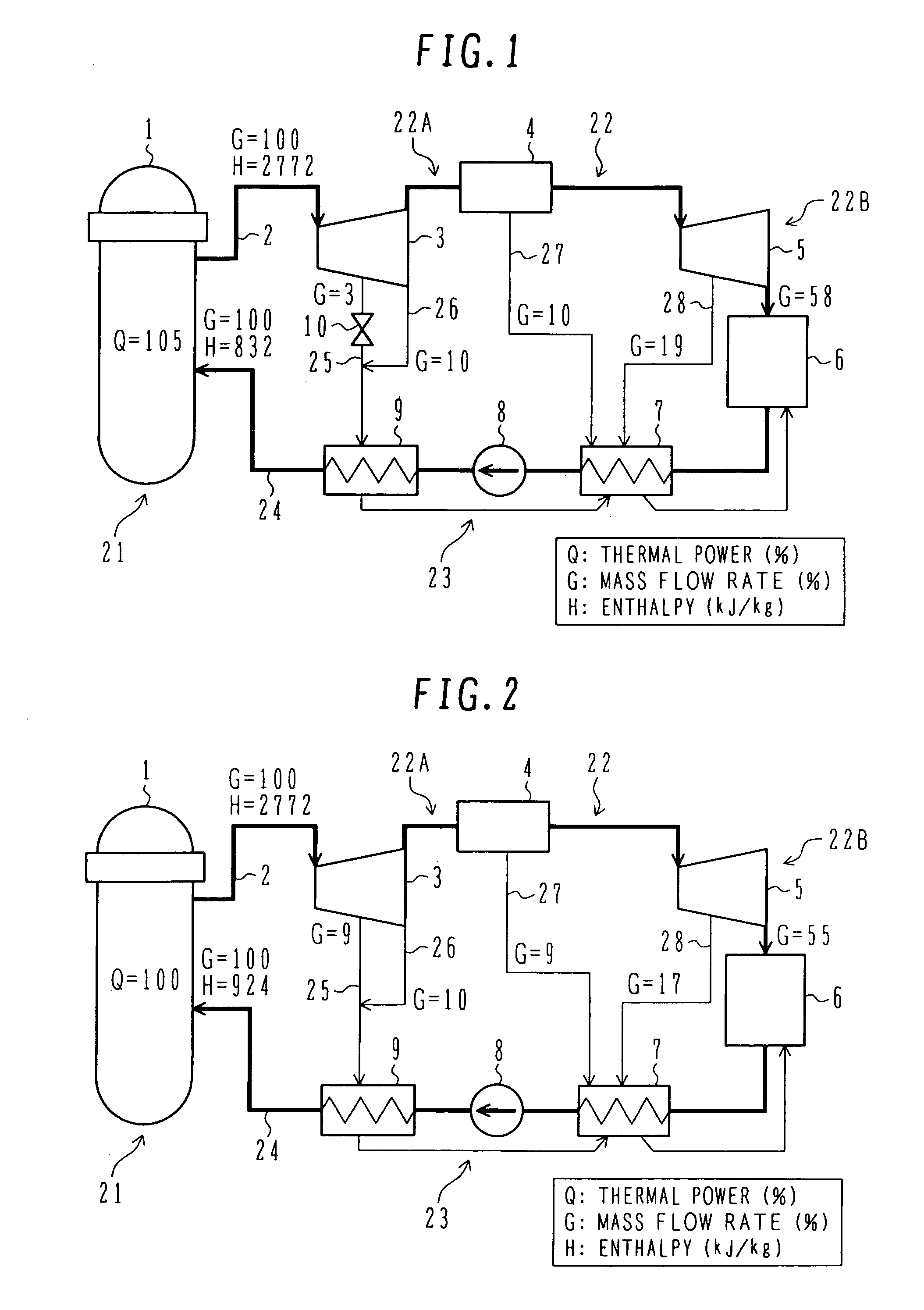

Operation method of nuclear power plant

ActiveUS7614233B2Increase thermal powerIncrease flow rateNuclear energy generationNuclear power plant controlNuclear reactorNuclear power

In a nuclear power plant, thermal power in a second operation cycle of a nuclear reactor is uprated from thermal power in a first operation cycle preceding the second operation cycle by at least one operation cycle. A proportion of steam extracted from a steam system and introduced to a feedwater heater, which is in particular extracted from an intermediate point and an outlet of a high pressure turbine, with respect to a flow rate of main steam, is reduced in the second operation cycle from that in the first operation cycle such that the temperature of feedwater discharged from the feedwater heater is lowered by 1° C. to 40° C. in the second operation cycle.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

Operation method of nuclear power plant

ActiveUS20070000250A1Increase thermal powerIncrease flow rateNuclear energy generationNuclear power plant controlNuclear powerHigh pressure

A nuclear power plant and an operation method of the nuclear power plant, which can uprate plant power without greatly modifying the construction of plant equipment, while keeping a core's pressure loss characteristic, a safety margin, and a design margin in the transient state substantially the same as those before the power uprate. Thermal power in a second operation cycle of a nuclear reactor is uprated from thermal power in a first operation cycle preceding the second operation cycle at least one operation cycle. A proportion of steam extracted from a steam system and introduced to a feedwater heater, which is in particular extracted from an intermediate point and an outlet of a high pressure turbine, with respect to a flow rate of main steam is reduced in the second operation cycle from that in the first operation cycle such that temperature of feedwater discharged from the feedwater heater lowers in the range of 1° C. to 40° C. in the second operation cycle.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

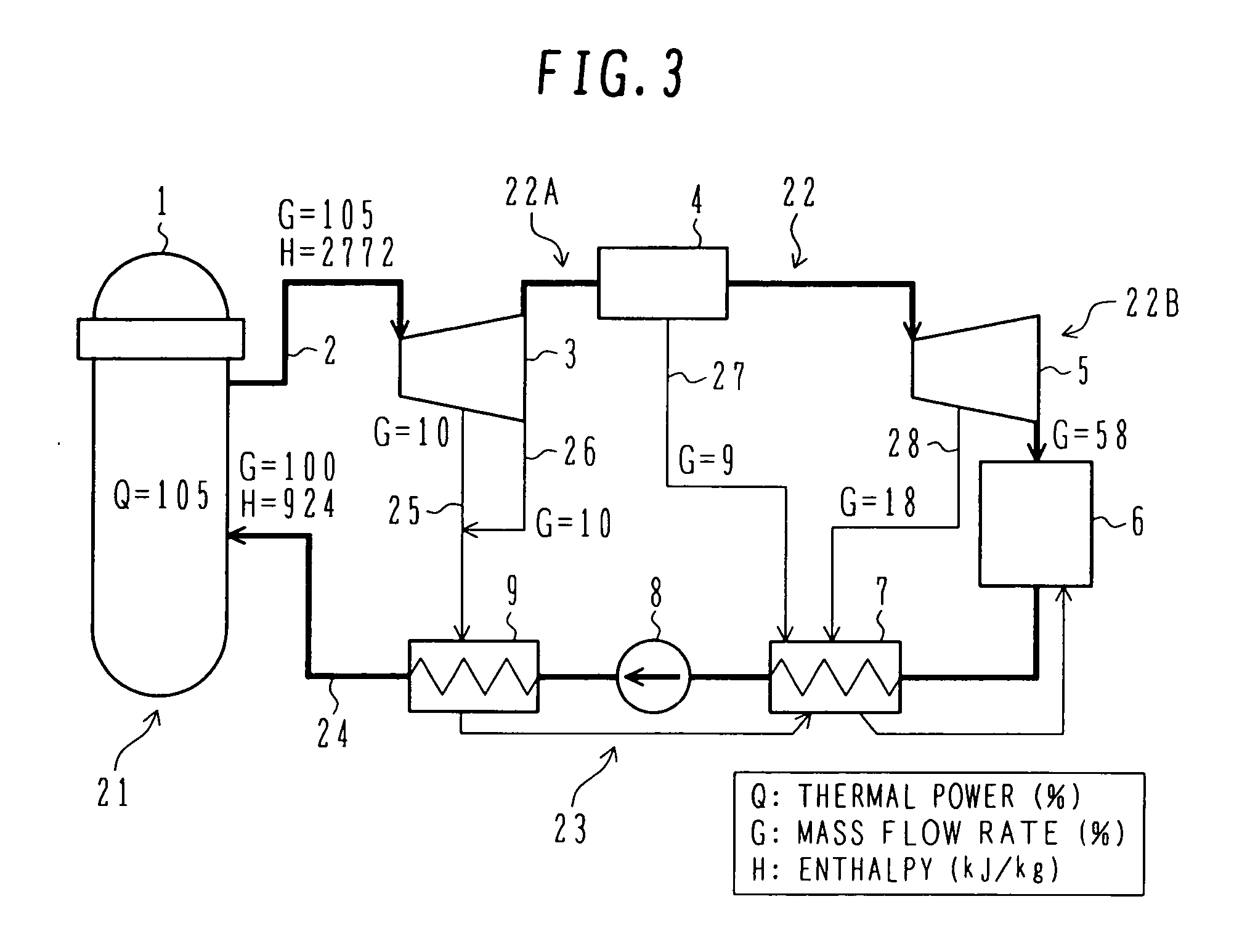

Heat exchanger and refrigeration cycle device using the same

InactiveUS20070214829A1Improve thermal efficiencyPressure lossCompression machines with non-reversible cycleEvaporators/condensersEngineeringRefrigeration

An object is to improve a pressure resistance and a thermal performance of a heat exchanger and to provide the heat exchanger suitable for use in a refrigeration cycle device in which carbon dioxide is used as a refrigerant. The evaporator (the heat exchanger) includes a pair of plate materials, the whole periphery of a peripheral portion of an outer plate as at least one of the plate materials is secured to the other plate material constituting a bottom surface of an inner tank to constitute a sealed refrigerant passage space between the plate materials, a portion of the outer plate other than the peripheral portion is provided with a plurality of secured inner portions which are secured at predetermined intervals to the bottom surface, and a plurality of refrigerant inlet tubes and refrigerant outlet tubes are attached so as to communicate with the refrigerant passage space.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

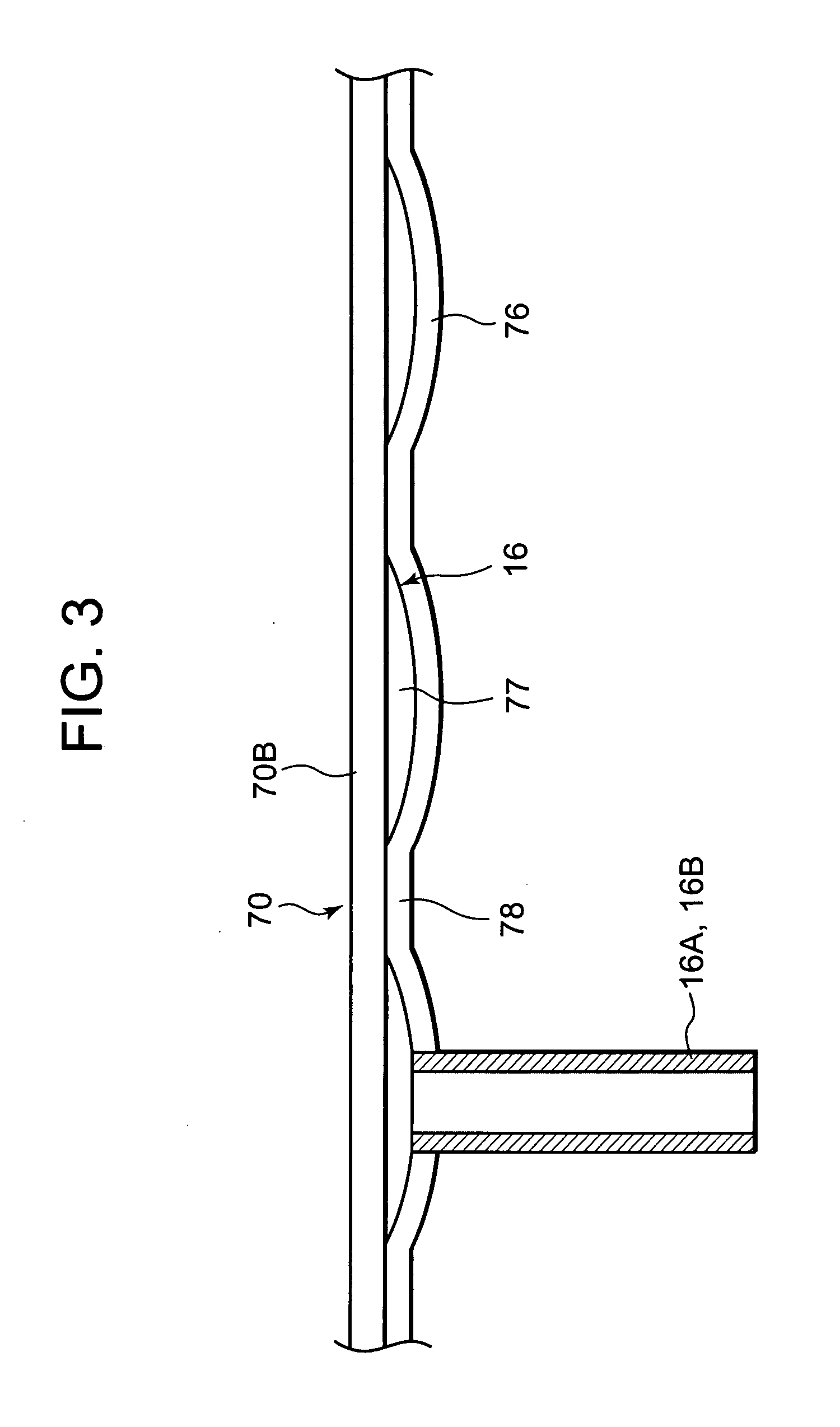

Guiding Device For A Continuous Sheet

InactiveUS20080010852A1Good emergency running propertyPressure lossAutomatic control devicesPrecision positioning equipmentPaper sheetEngineering

The invention relates to a guiding device for a continuous paper sheet comprising at least one guiding element which is disposed downstream with respect to an application group and used in the form of an air circulating channel in order to ensure a contactless guiding in a machine producing and / or processing a continuous material sheet, in particular a paper or paperboard sheet. Said guiding element consists of a guiding surface made at least partially of an air-permeable porous material which is exposed to a compressed air pressure in such a way that air can circulate therethrough, thereby forming an air cushion between said guiding surface and a moving material sheet.

Owner:VOITH PATENT GMBH

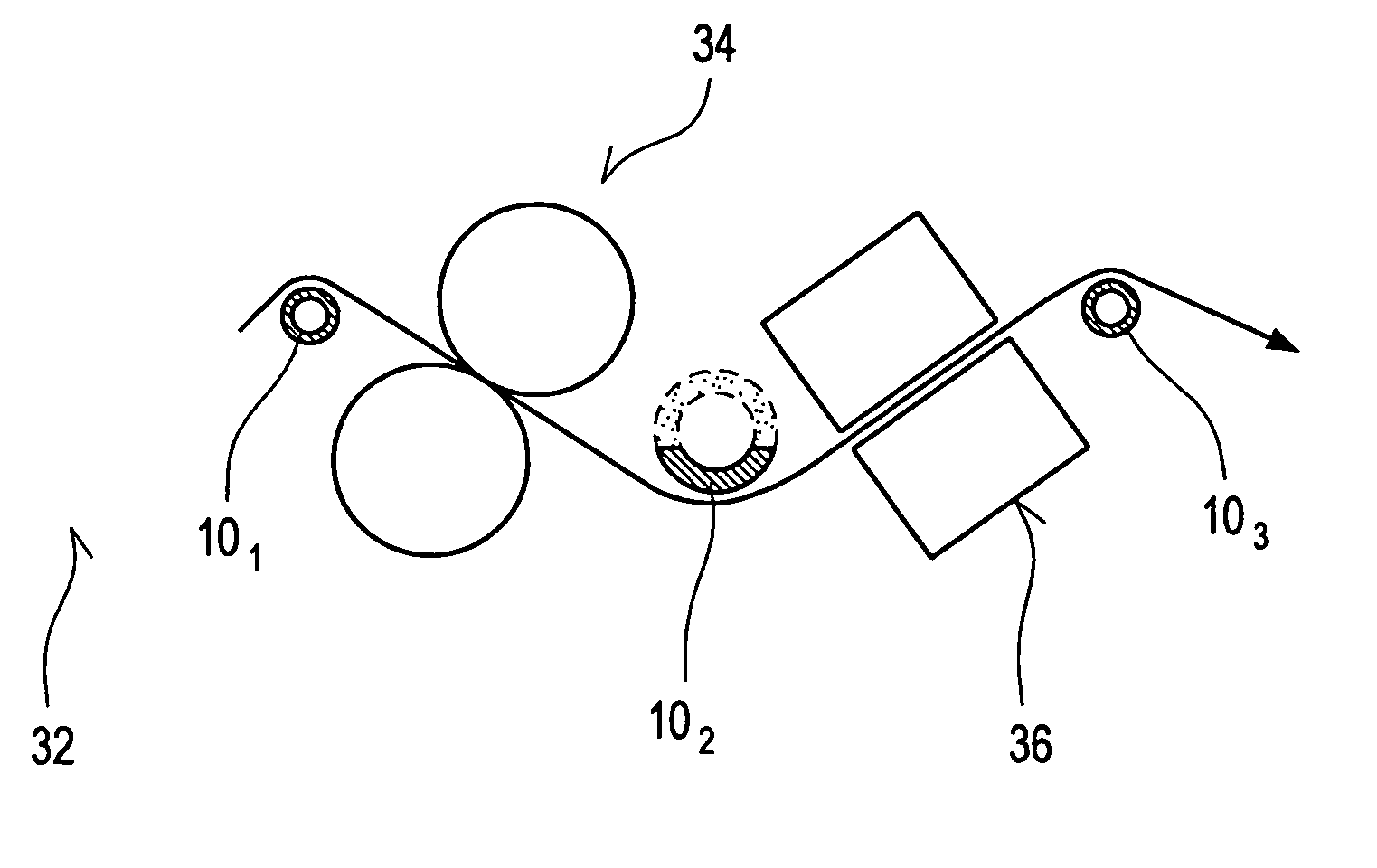

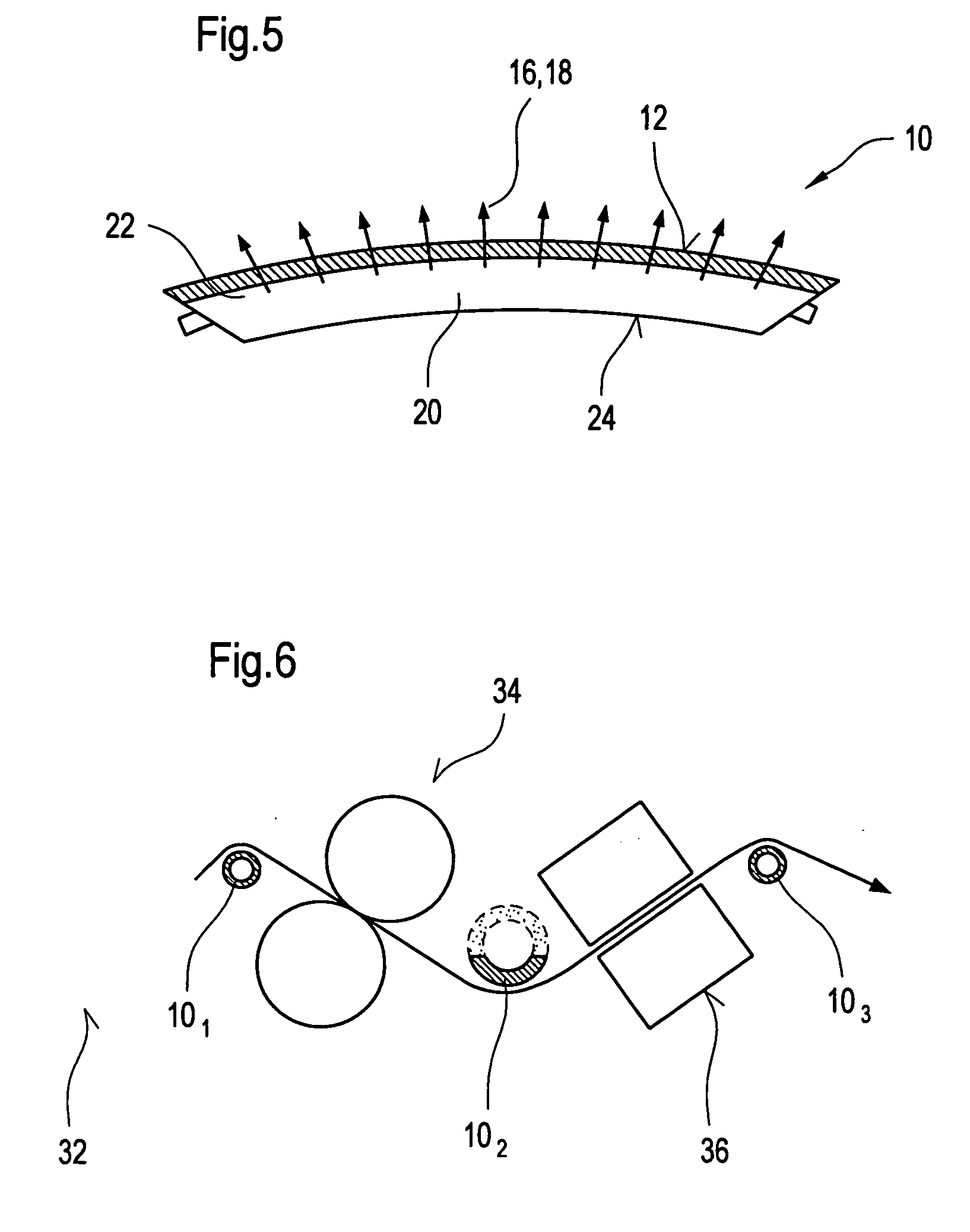

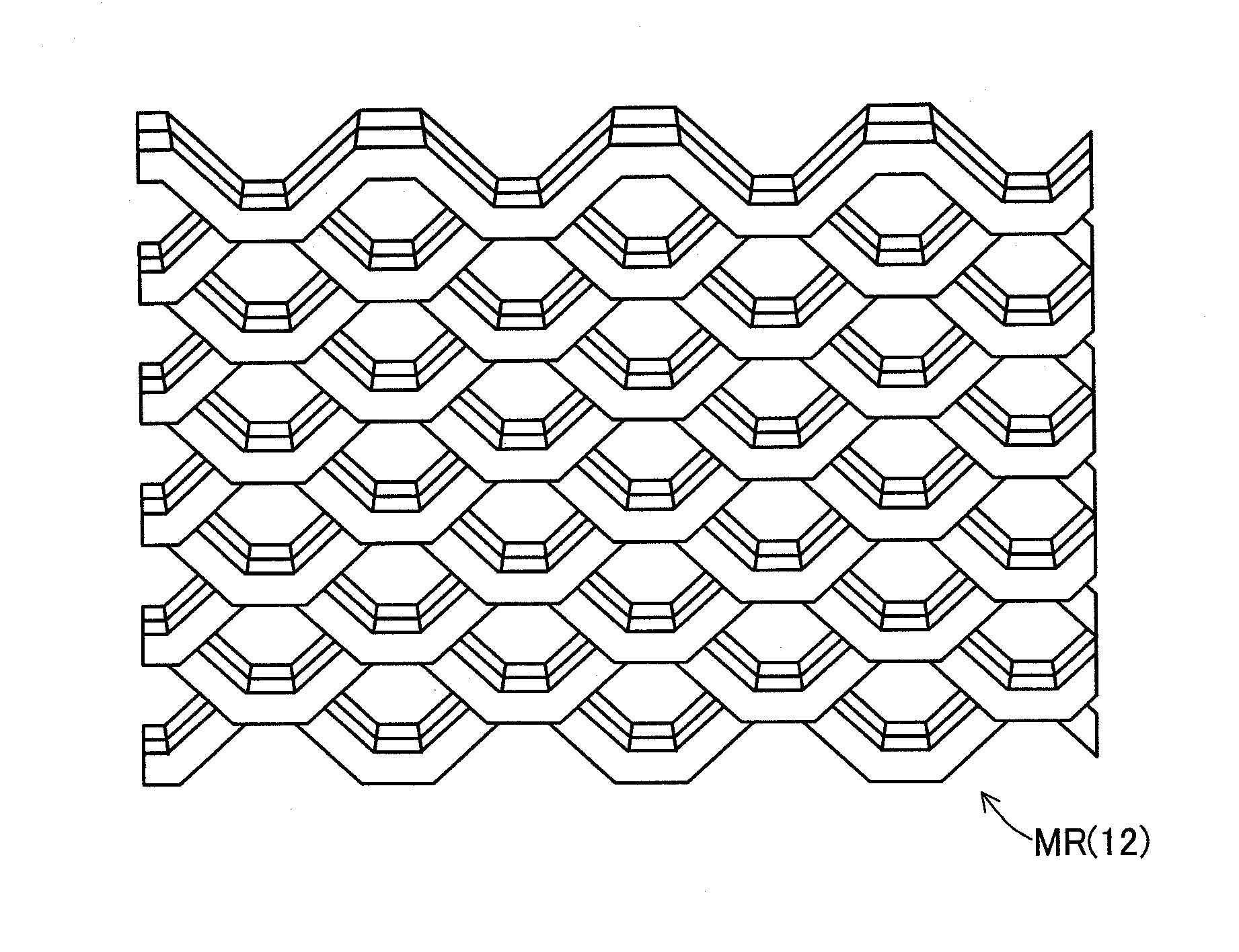

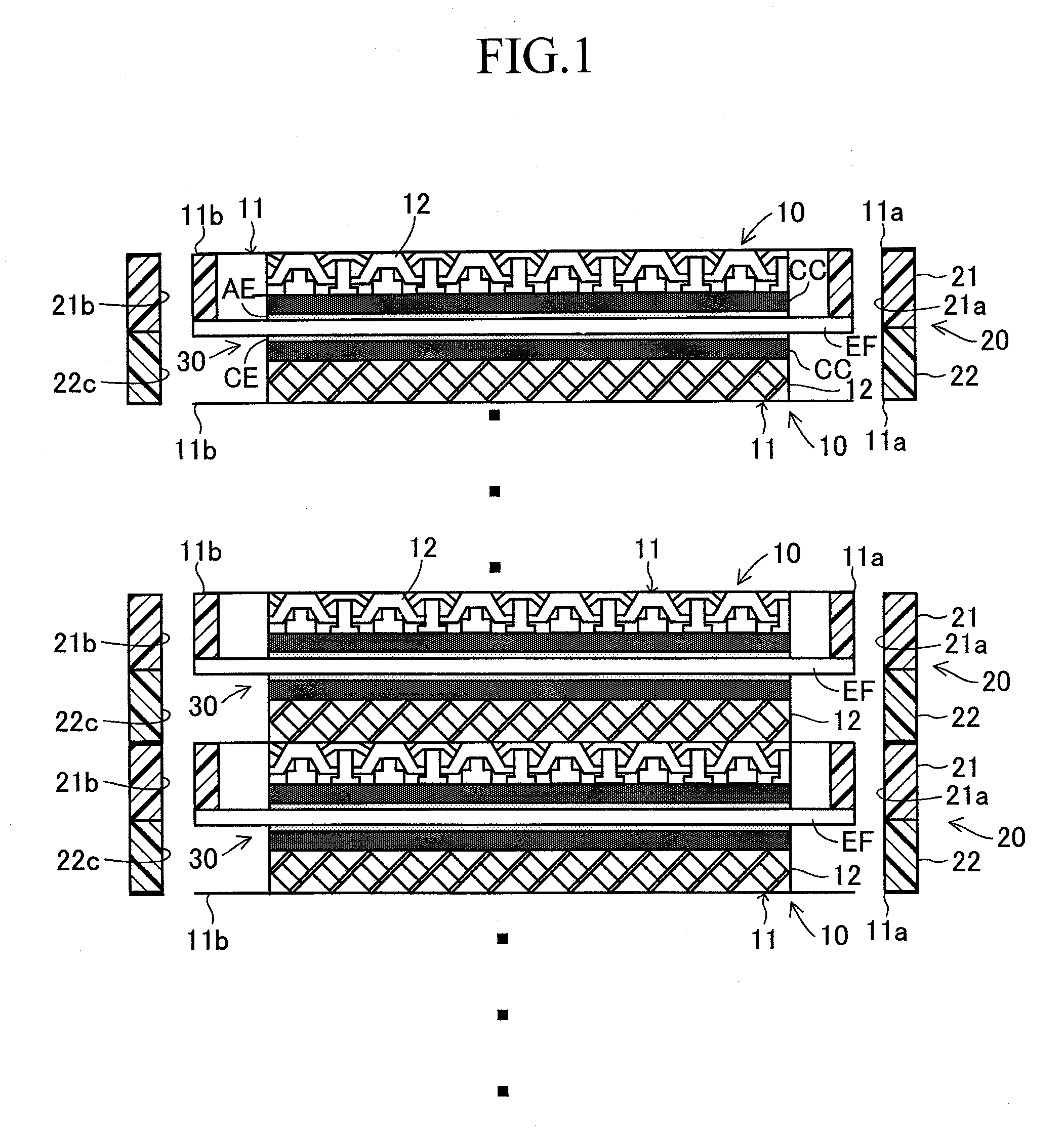

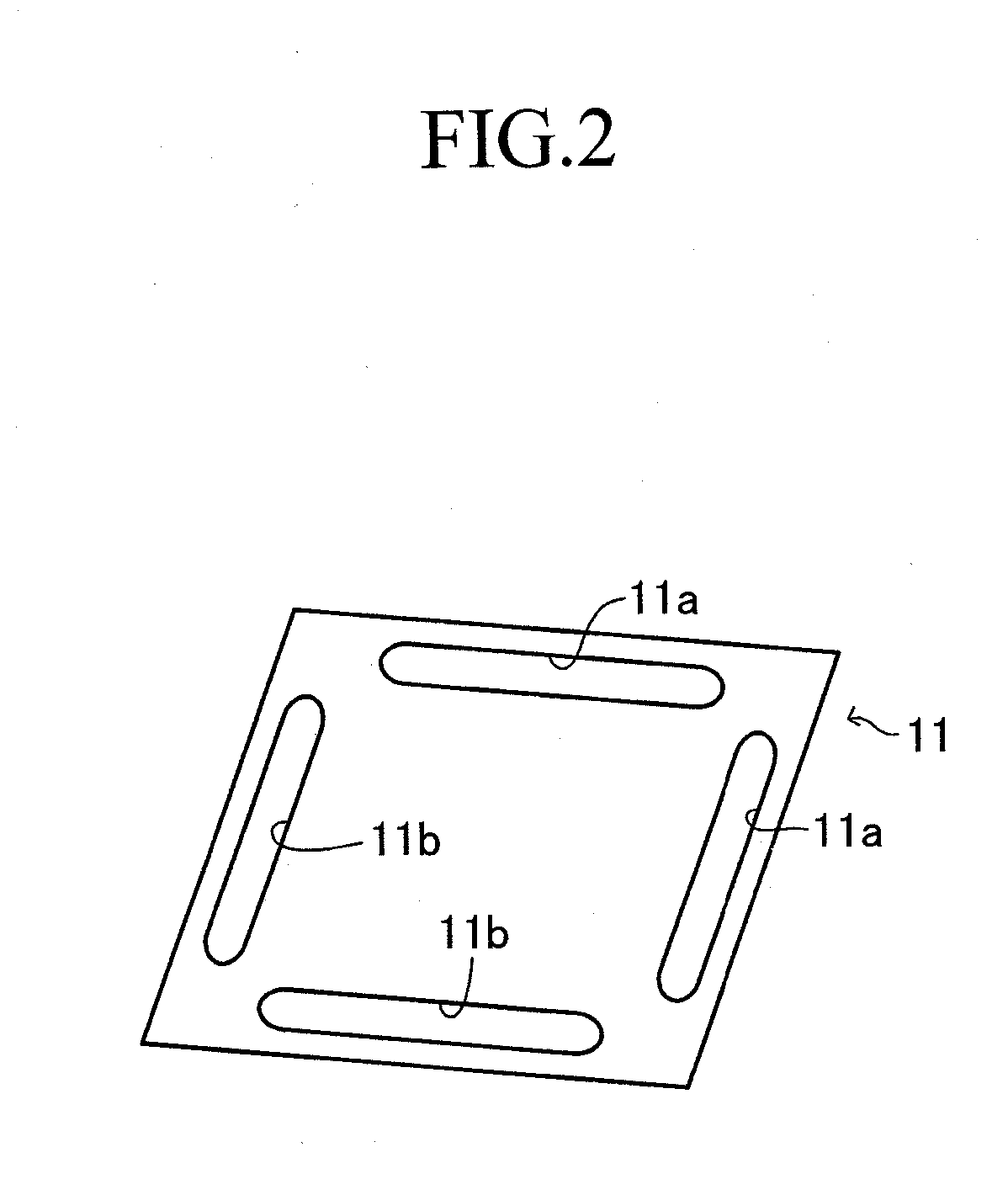

Method of forming gas diffusion layer for fuel cell

InactiveUS20090089989A1Forming accuratelyUniform shapeFinal product manufactureElectrode carriers/collectorsFuel cellsForming gas

A collector 12 which serves as a gas diffusion layer for a fuel cell; i.e., a metal lath MR, is formed by a method consisting of a first step and a second step. In the first step, while an upper blade UH is positioned at a first machining position along the width direction of a stainless steel sheet S, generally hexagonal through holes are formed in the stainless steel sheet S at two positions which are biased from each other by a machining pitch. In the second step, while the upper blade UH is positioned at a second machining position along the width direction of the stainless steel sheet S, generally hexagonal through holes are formed in the stainless steel sheet S at two positions which are biased from each other by the machining pitch. The first step and the second step are alternated repeatedly, thereby forming the metal lath MR having a uniform shape and a predetermined thickness.

Owner:TOYOTA SHATAI KK +1

Cyclone dust collecting apparatus and hand-held cleaner having the same

ActiveUS20200100633A1Reduce total pressure lossImprove efficiencySuction filtersVortex flow apparatusThermodynamicsElectric machine

The hand-held cleaner includes a body, and a cyclone dust collecting apparatus detachably mounted in the body. The cyclone dust collecting apparatus includes a pre-motor filter unit having a filter grill and a filter member, a dust collecting bin having one end to which the pre-motor filter unit is coupled and the other end opposite to the one end in which an cyclone inlet is formed, and a cyclone bin disposed in the dust collecting bin and having a spiral flow path-guide member integrally formed therein. A moving path of air drawn into the cyclone inlet is maintained in the same direction until the air is discharged through the pre-motor filter unit via the cyclone bin.

Owner:SAMSUNG ELECTRONICS CO LTD

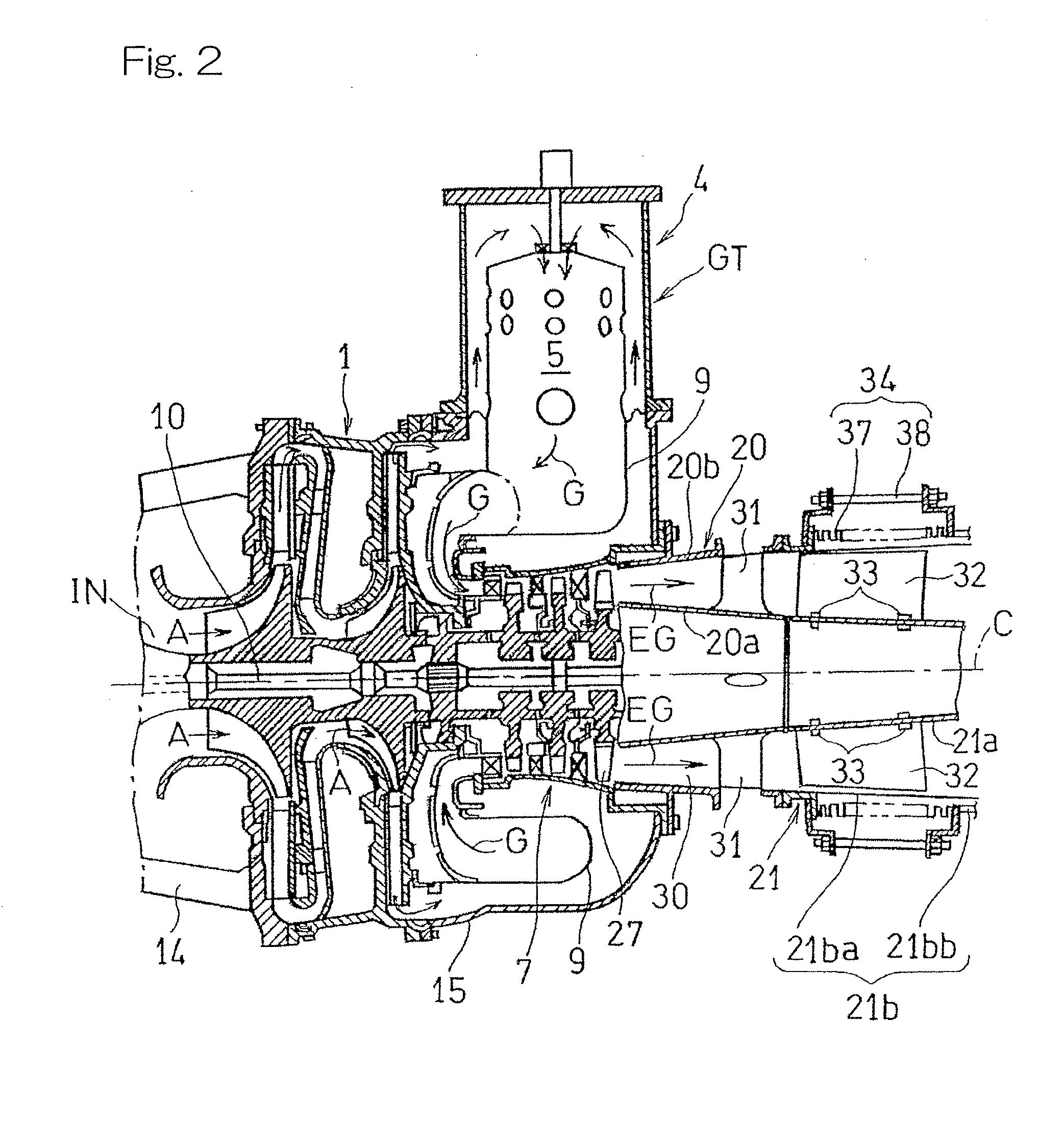

Gas turbine device

InactiveUS20150167693A1Reducing exhaust pressure lossAvoid swirlsPump componentsEngine fuctionsLow frequency vibrationGas turbines

A gas turbine device in which the low frequency vibrations or the low frequency noises during the low load operation can be effectively suppressed with no increase of the pressure loss of the exhaust gas being triggered includes a gas turbine engine provided with an exhaust diffuser forming an upstream portion of an exhaust gas passage, an exhaust strut provided in the diffuser (20), and a swirling flow blocking plate. The swirling flow blocking plate is disposed on a downstream side of the exhaust strut in the exhaust gas passage so as to extend in an axial direction.

Owner:KAWASAKI HEAVY IND LTD

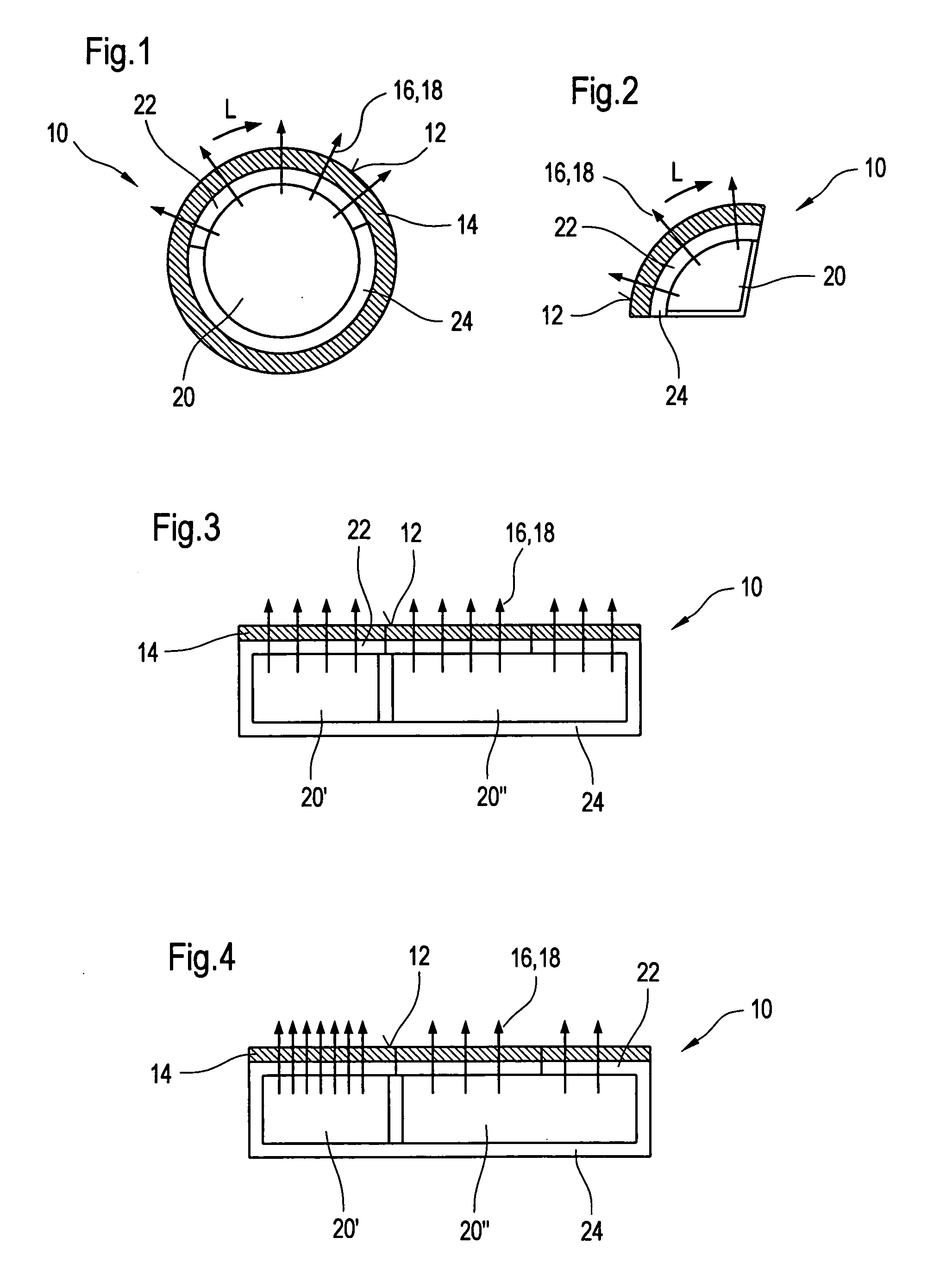

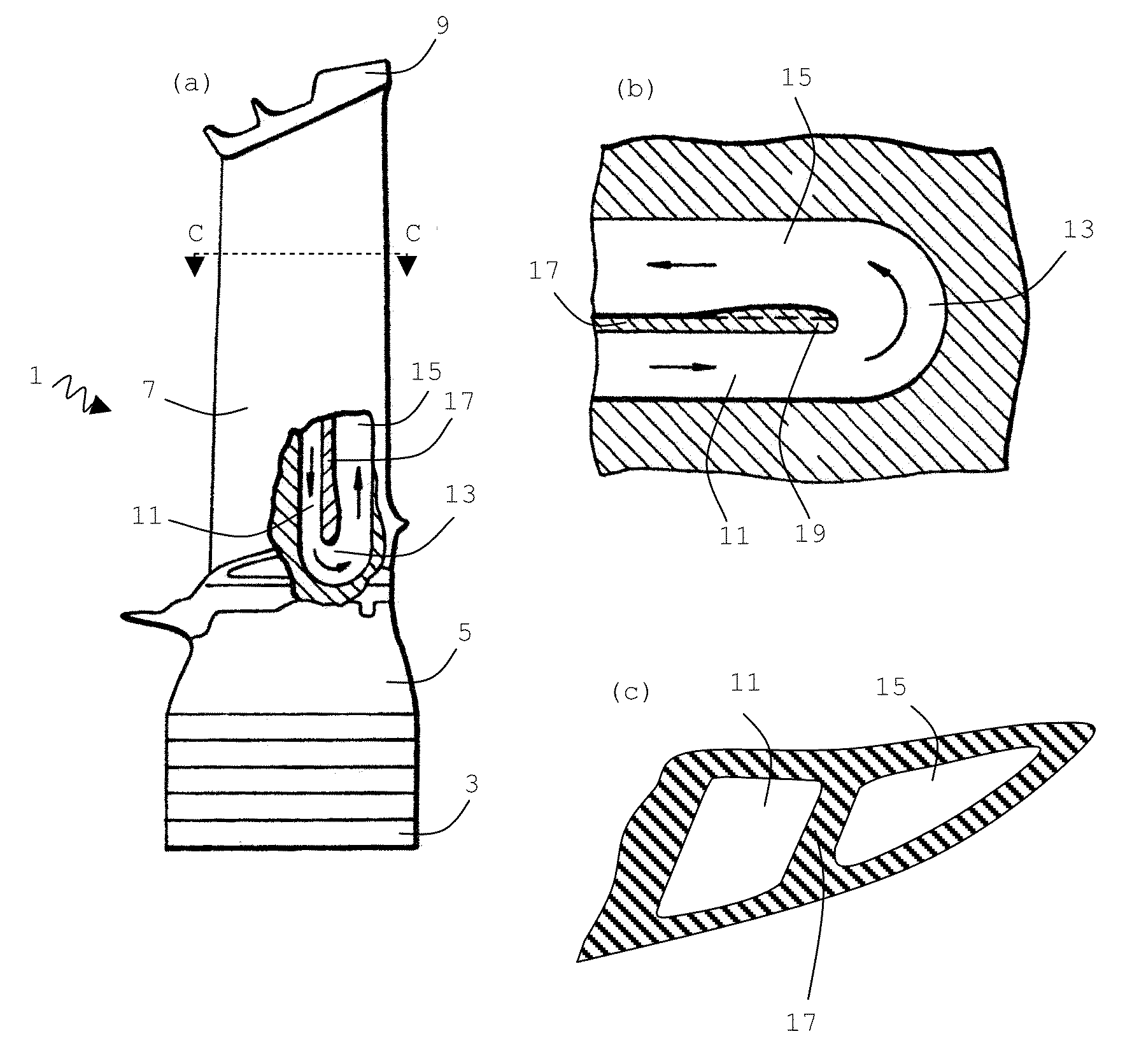

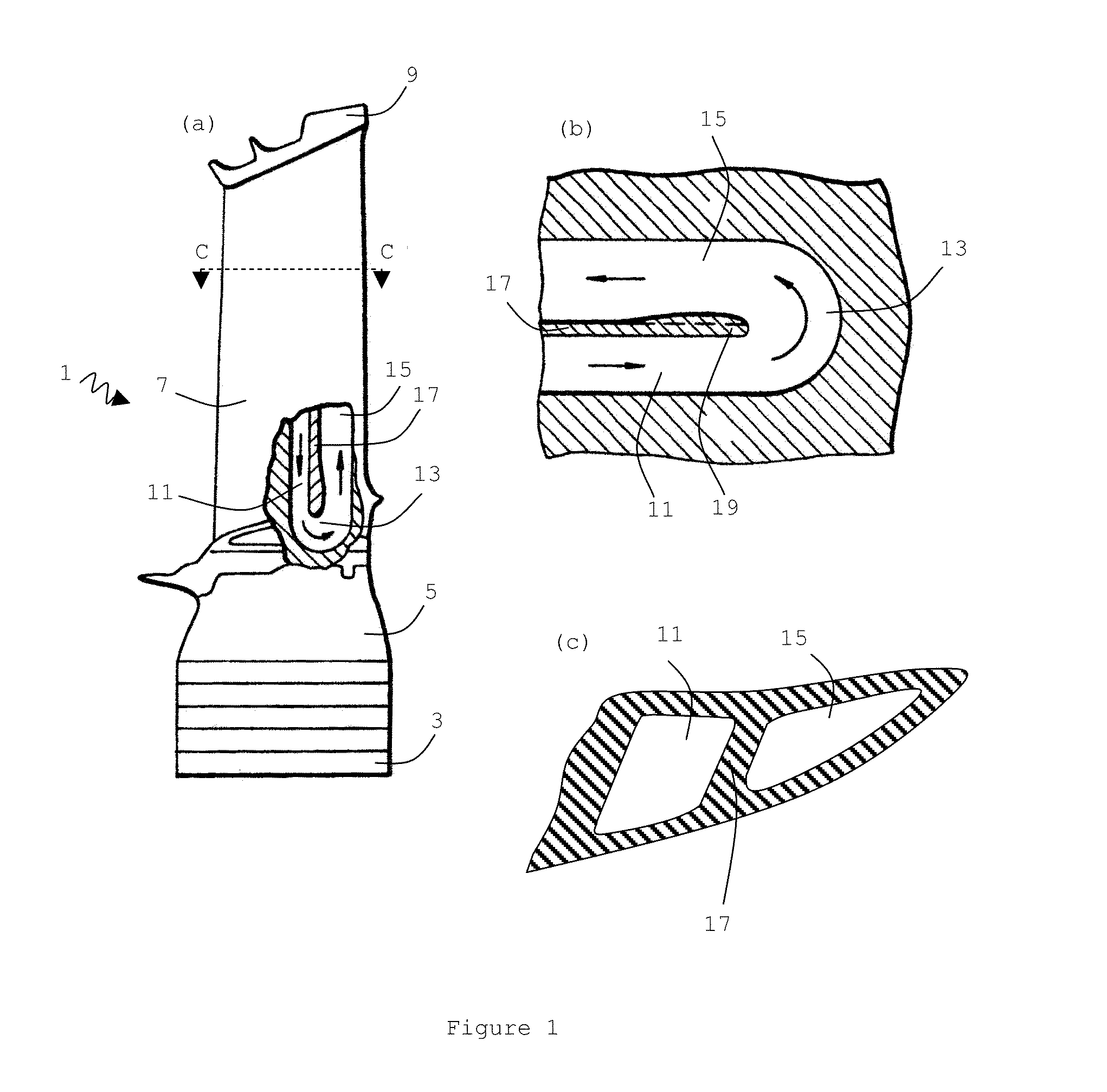

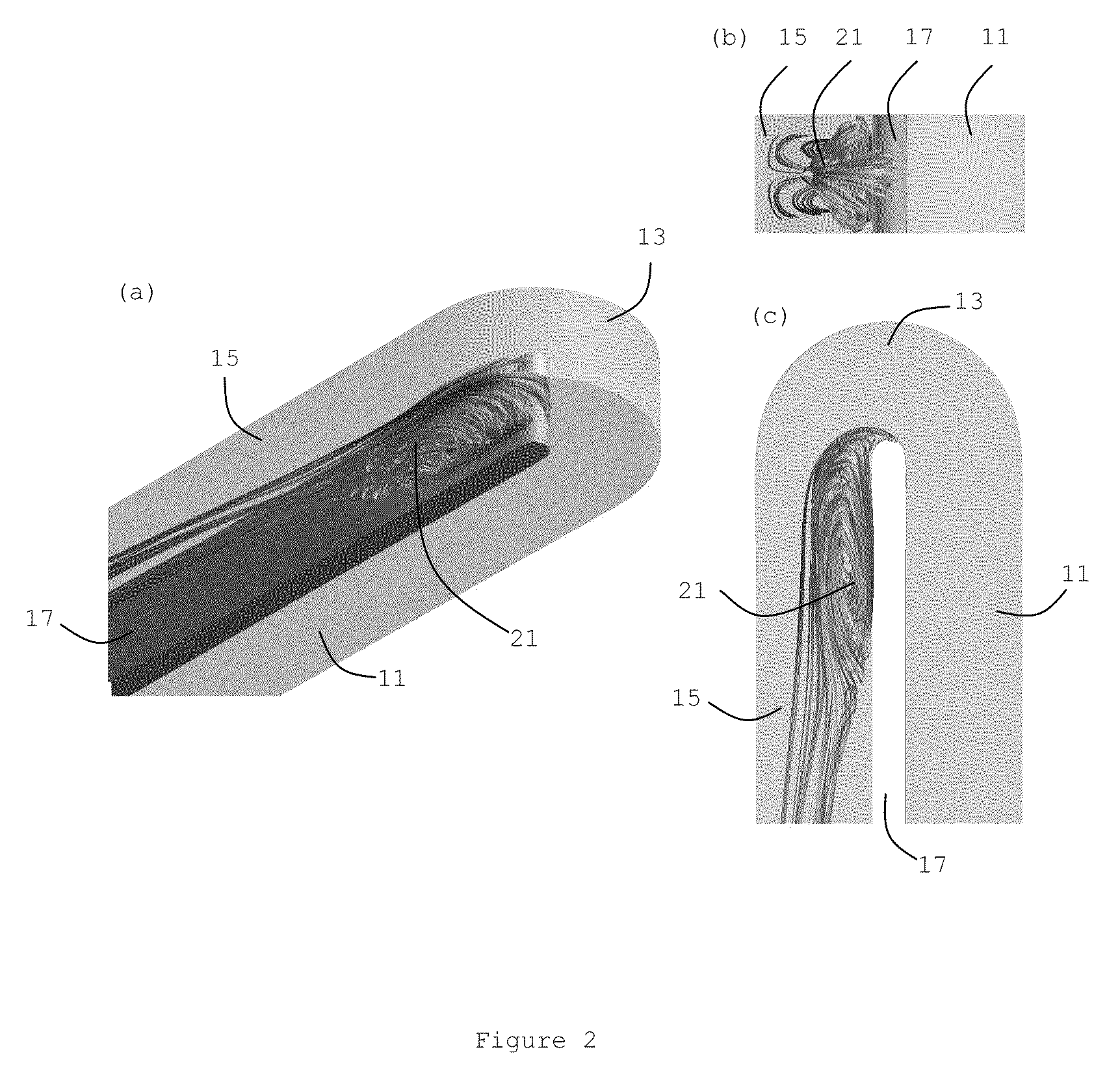

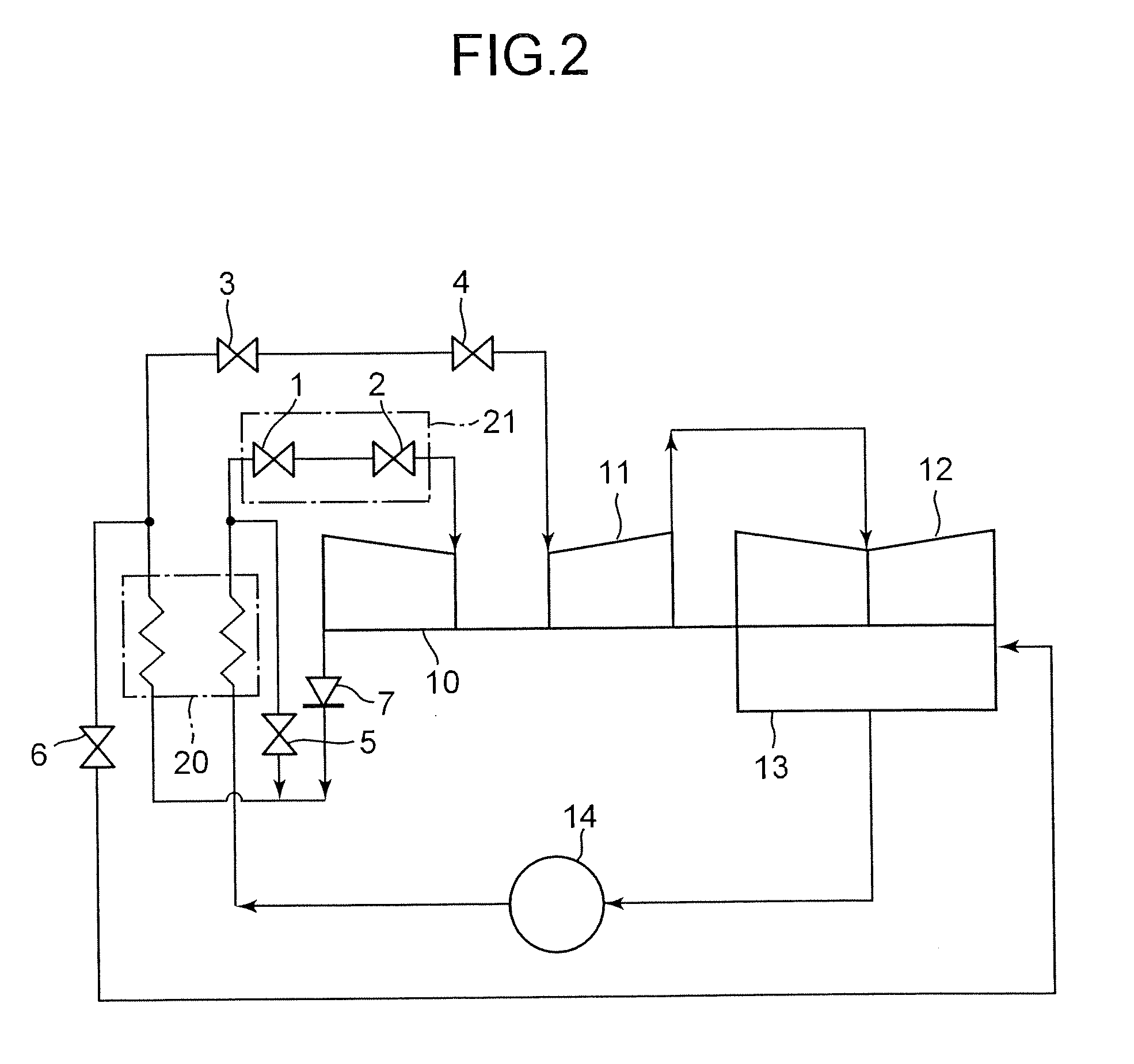

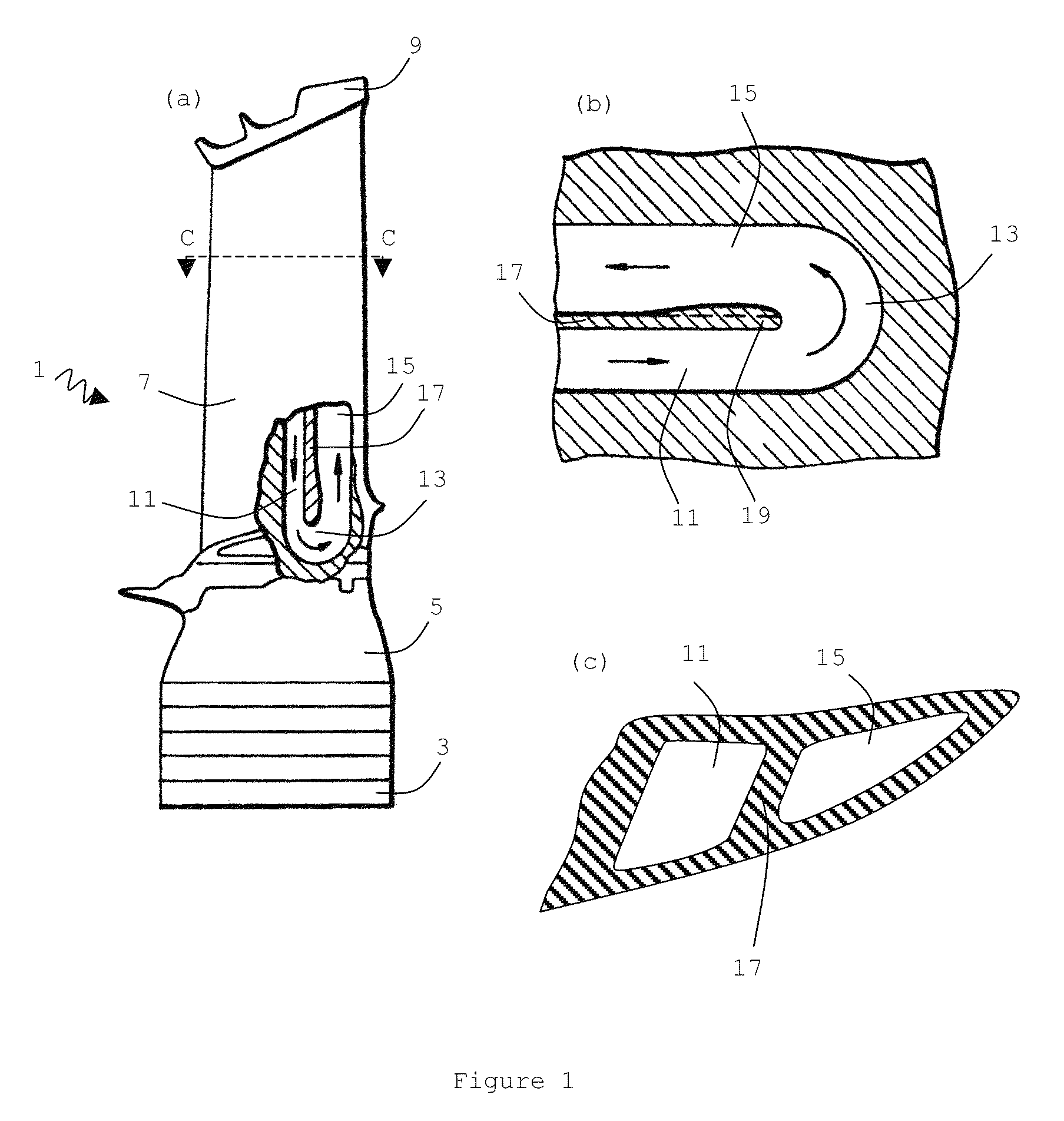

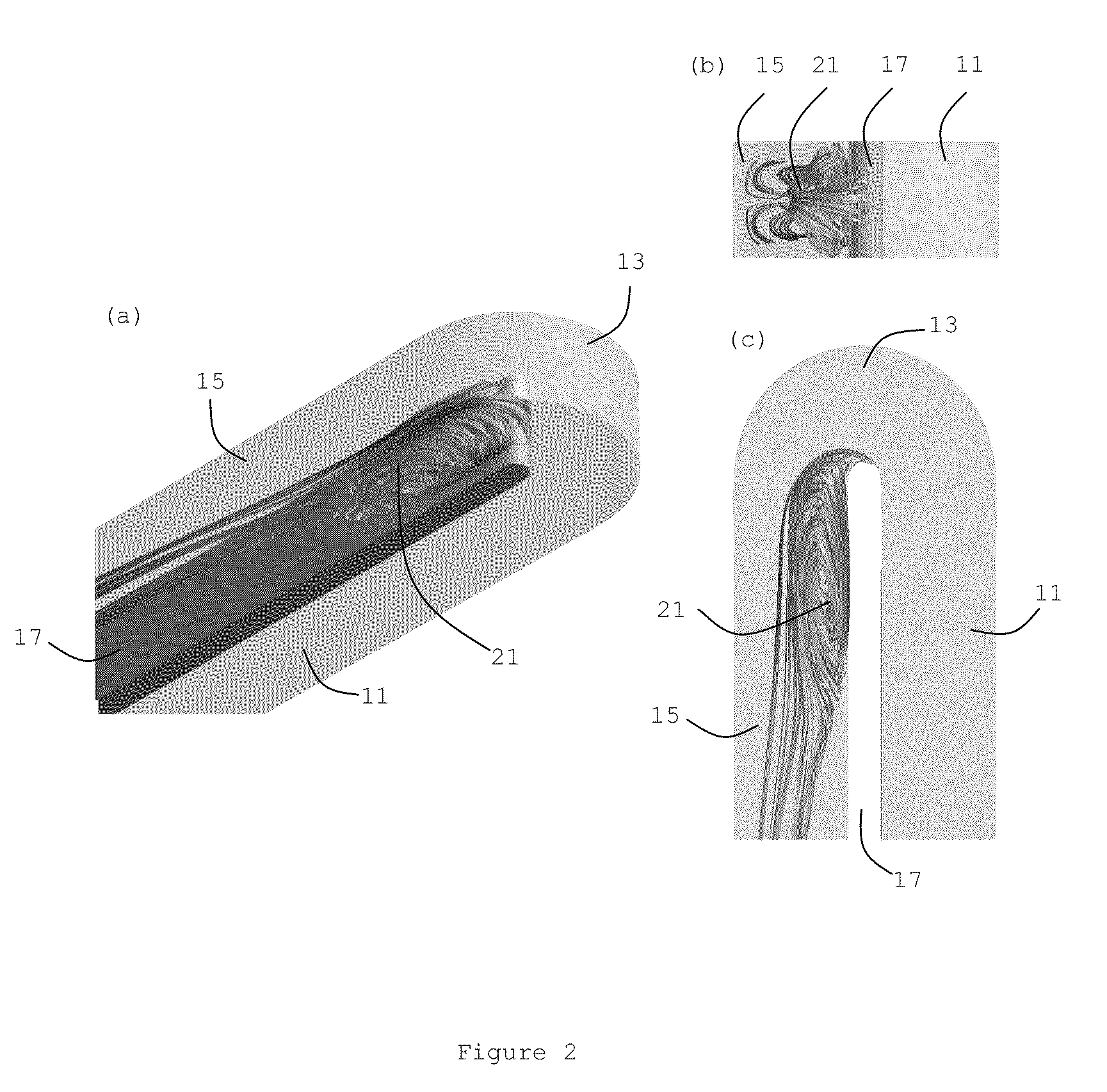

Cooled aerofoil blade or vane

ActiveUS20110058958A1Less momentumReduce tendencyEngine manufactureBlade accessoriesGas turbinesCooling fluid

An aerofoil blade or vane (1) suitable for the turbine of a gas turbine engine includes a longitudinally extending aerofoil portion (7) having facing wall parts (20, 22). The wall parts being interconnected by a generally longitudinally extending divider member (17) to partially define first and second cooling fluid passage portions (11, 15) disposed in side-by-side generally longitudinally extending relationship. The first and second passage portions being interconnected in series fluid flow relationship by a bend passage portion (13). The first passage portion is adapted to direct cooling fluid to the bend portion and the second passage portion being adapted to exhaust cooling fluid from the bend portion. The divider member has a first local thickening (33) in the region of the bend portion to provide a localised contraction of the downstream end of the first passage portion to accelerate the cooling fluid flow before it enters the bend passage portion. The divider member has a second local thickening (31) in the region of the bend portion to provide a localised progressive series narrowing and opening of the upstream end of the second passage portion in the general direction of cooling fluid flow.

Owner:ROLLS ROYCE PLC

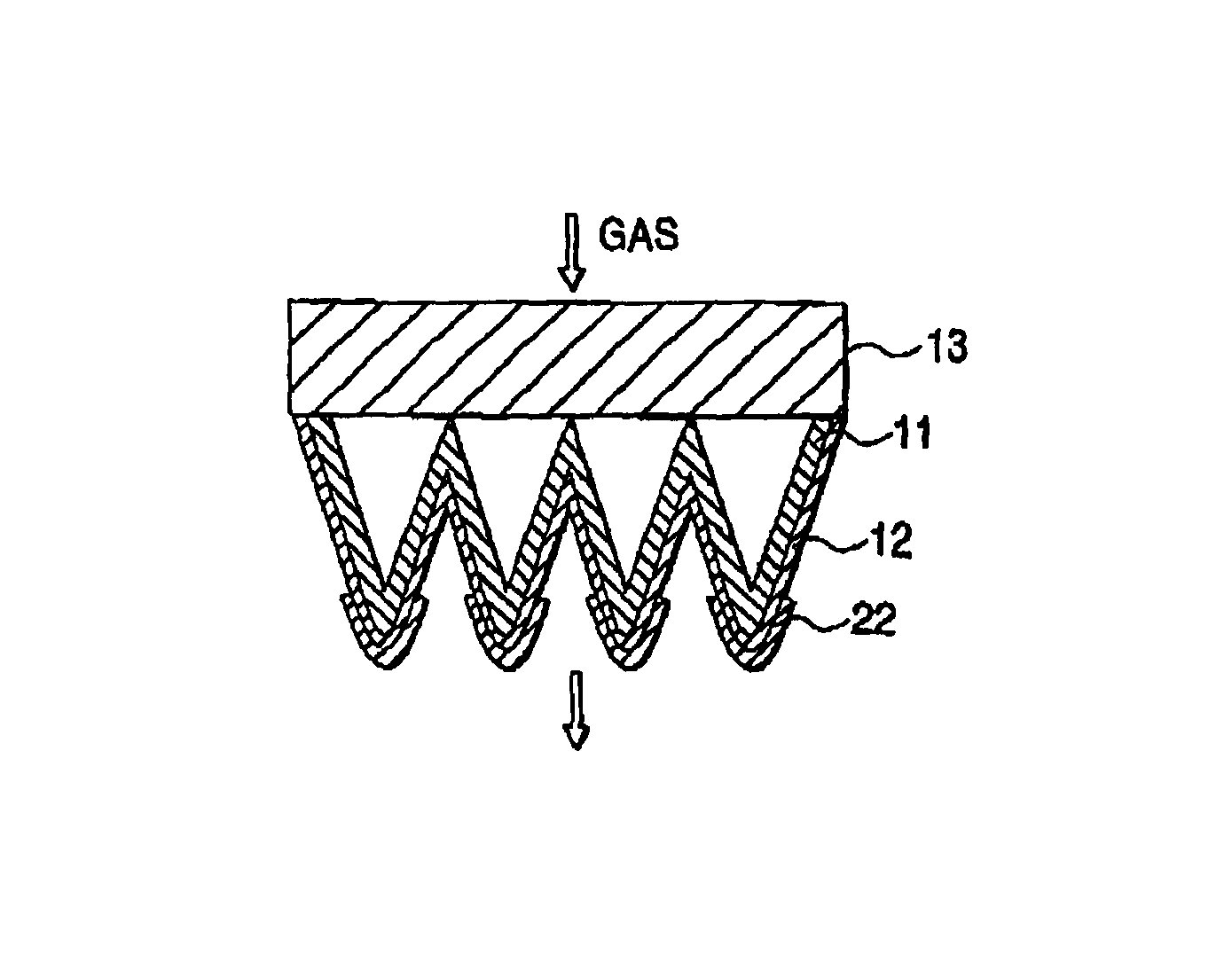

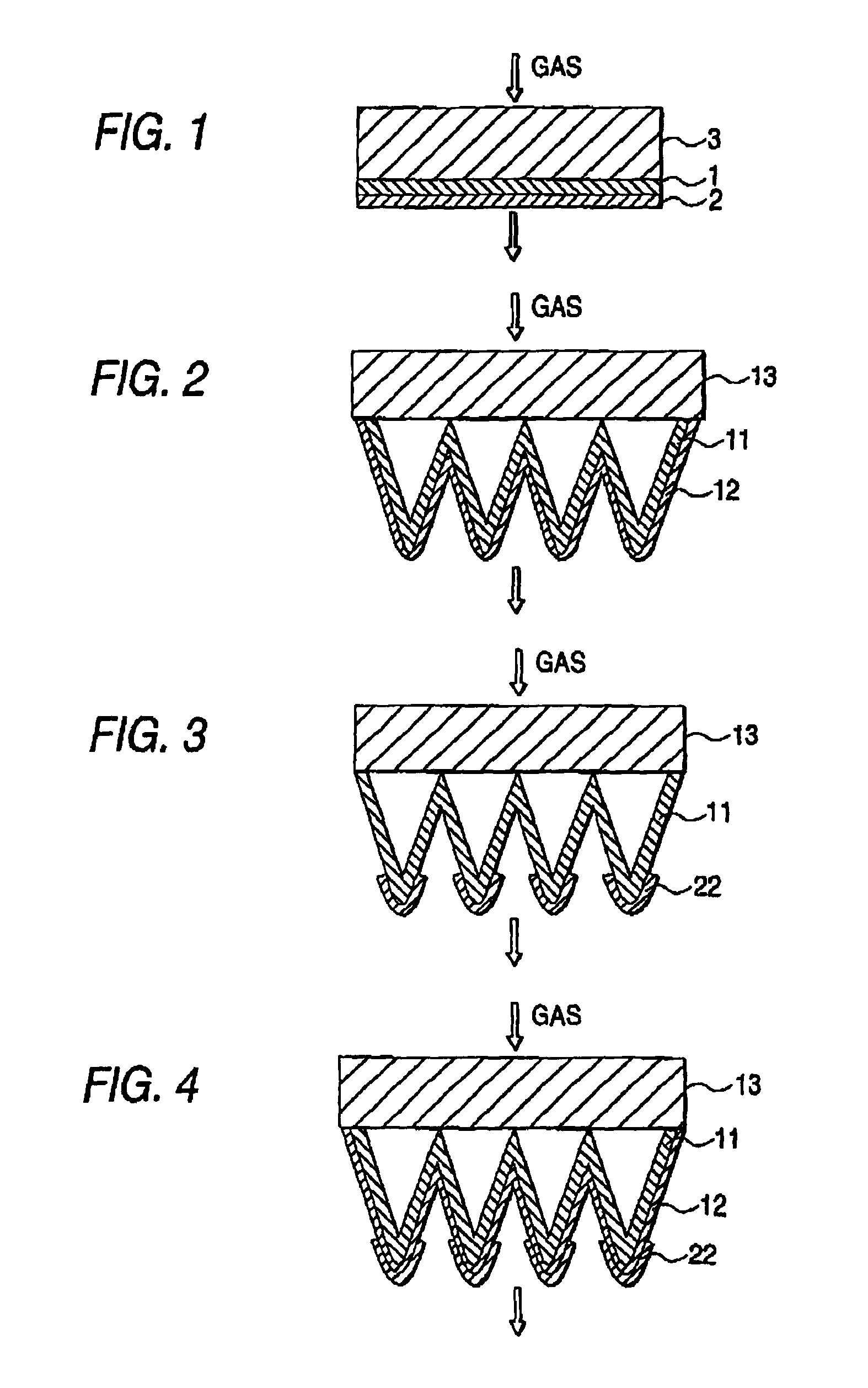

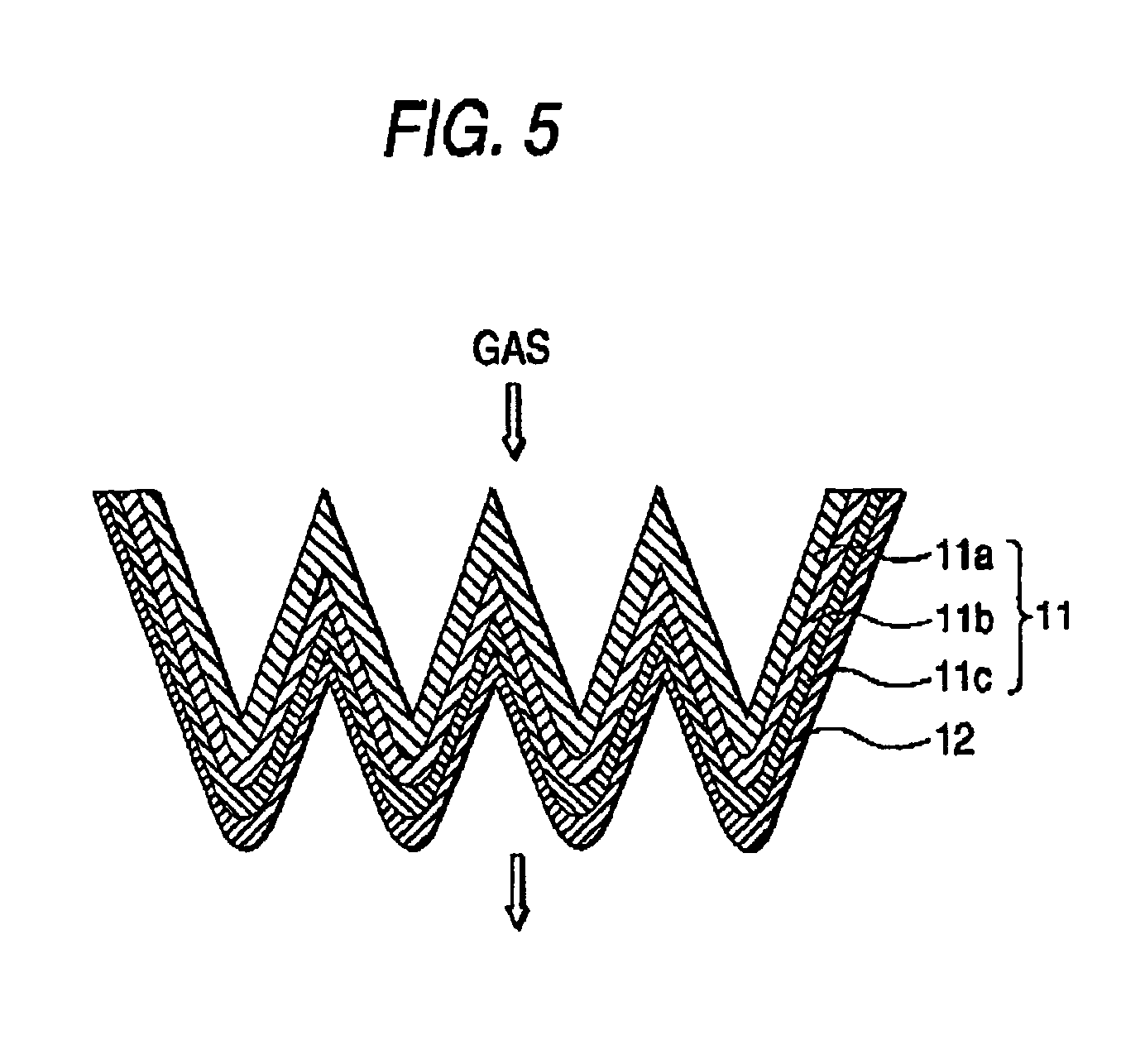

Filter element

InactiveUS6926750B2Improve cleaning efficiencyExtended service lifeCombination devicesDispersed particle filtrationFolded structureRidge

A filter element comprises an oil-impregnated filtering member, and a transmission preventing layer formed on a downstream side of the filtering member, for restricting transmission of at least the carbon dusts from the oil-impregnated filtering member. The filtering member may be formed like a ridge-like-folded structure. The transmission preventing layer may be formed of a coating layer having a resistance against a viscous oil that is impregnated in the filtering member. This coating layer may be formed uniformly as a whole or the thickness or the content of the coating layer may be increased partially. A ventilation shutting-off member (filling layer) may be formed as the transmission preventing layer in the root portion areas of the ridge portions. The transmission preventing layer may comprise a resistant component that is insoluble in the oil that is impregnated in the filtering member.

Owner:HONDA MOTOR CO LTD +1

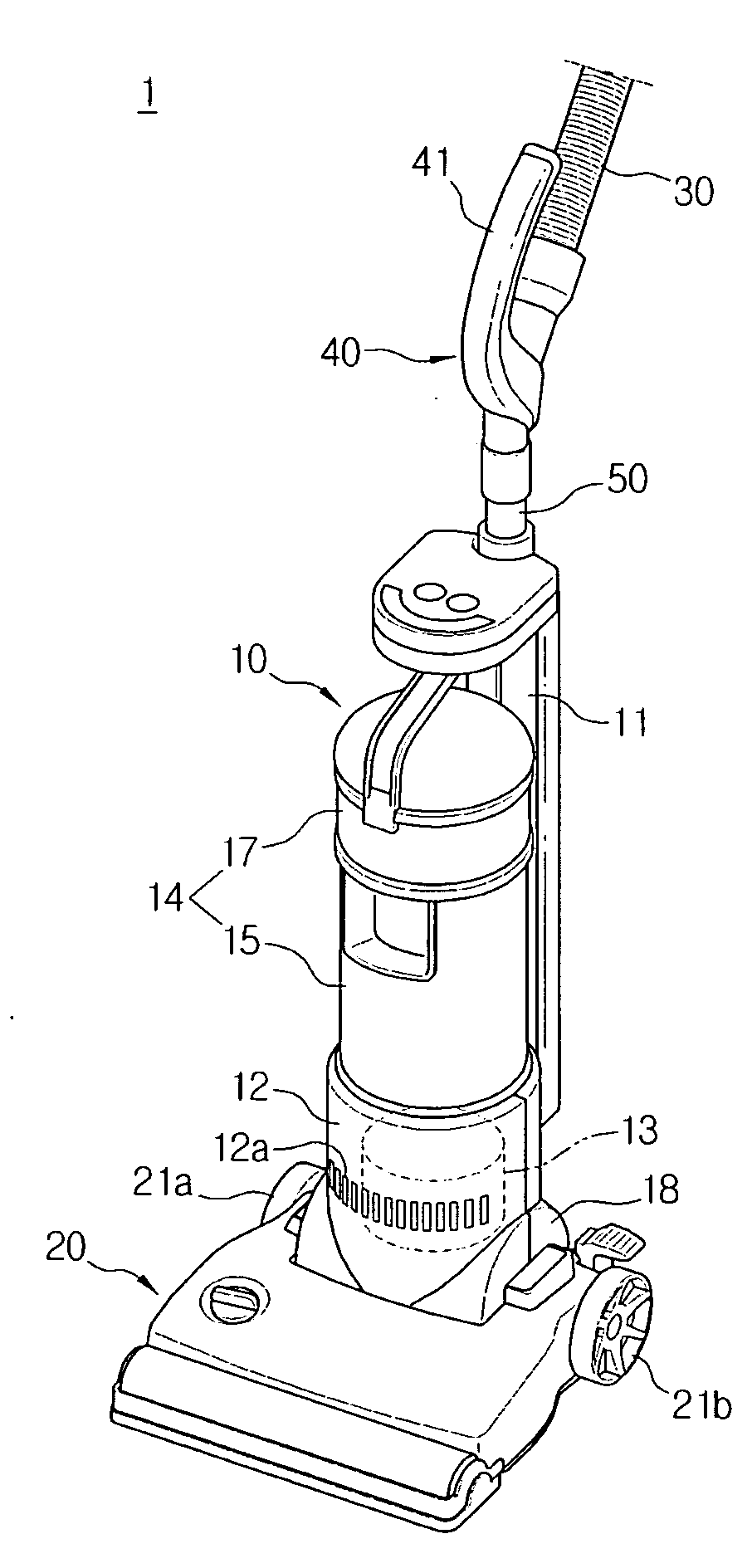

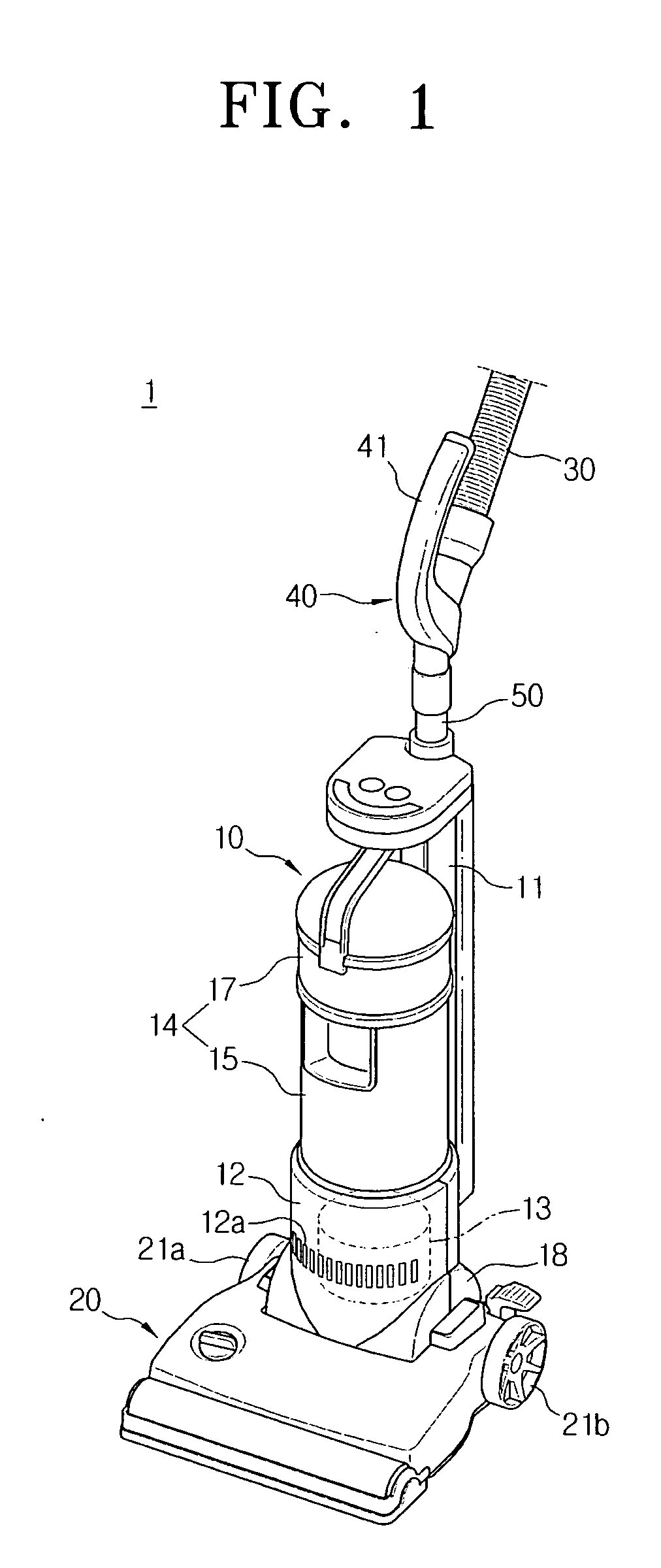

Vacuum cleaner having suction path switching unit

InactiveUS20090089961A1Reducing unnecessary pressure lossReducing air-flowing noiseSuction cleanersEngineeringPath switching

A vacuum cleaner having a suction path switching unit is provided that includes a cleaner body having a body frame; a suction inlet body hinged to the body frame; an extension pipe assembly having a hose and an extension pipe connected in fluid communication with the hose; and a suction path switching unit disposed on the body frame. The suction path switching unit has a switching duct, at least a portion of which is elastically arranged on a suction path to be displaceable on the suction path. As the extension pipe is fixed on or separated from the body frame, the switching duct is selectively displaced to a first position of opening a first suction path flowing from the suction inlet body to the dust collecting unit or a second position of opening a second suction path flowing from the extension pipe to the dust collecting unit.

Owner:SAMSUNG ELECTRONICS CO LTD

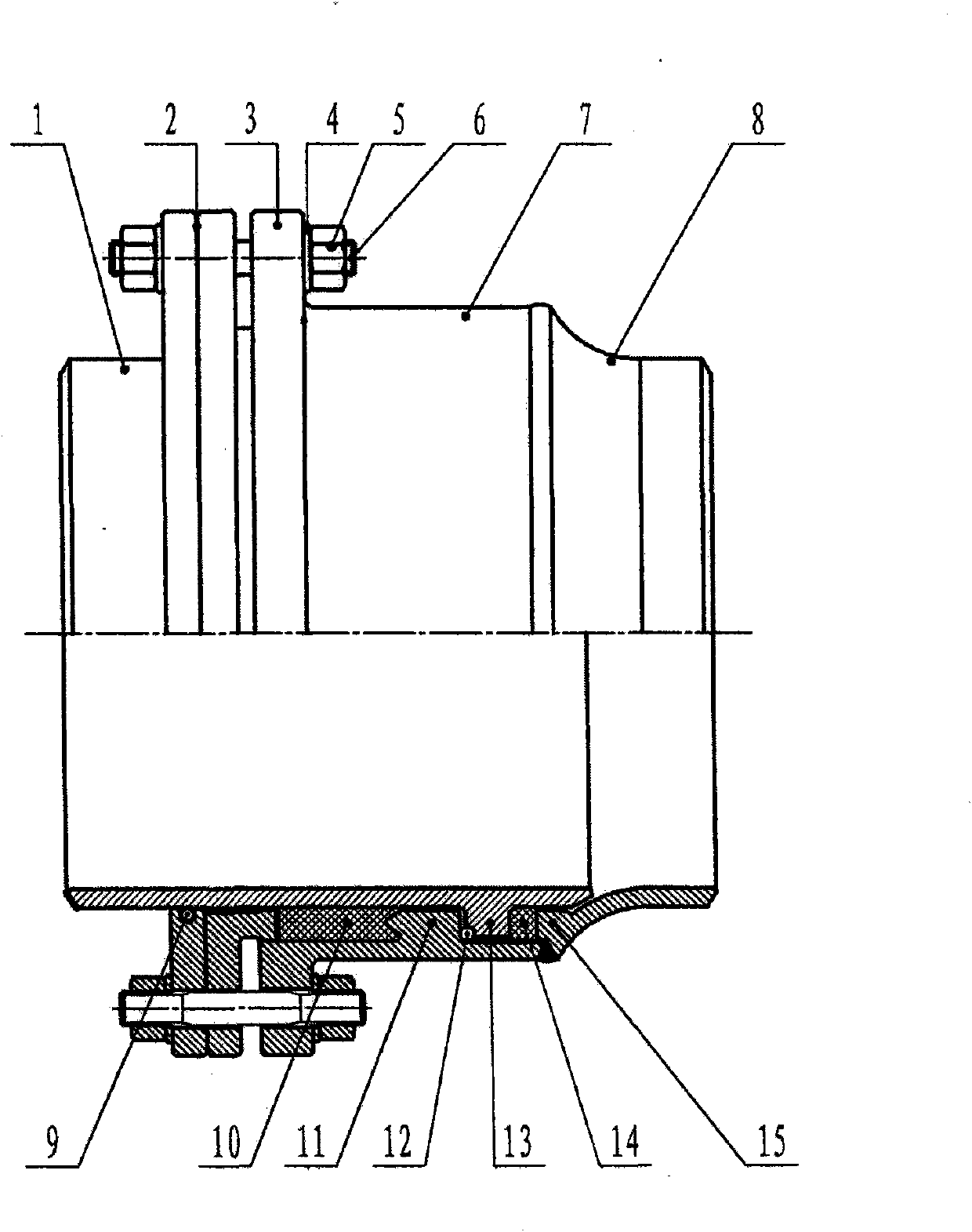

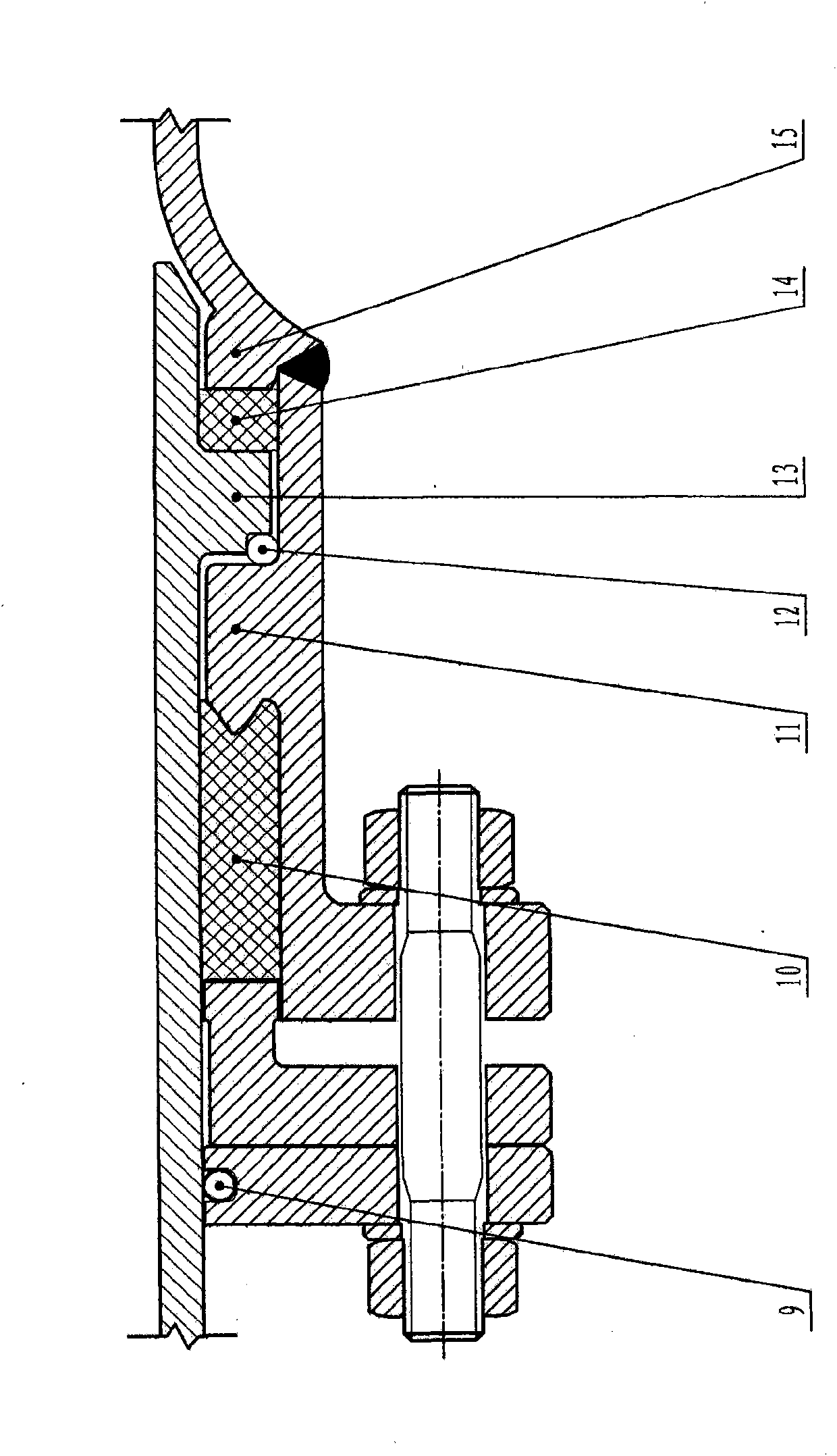

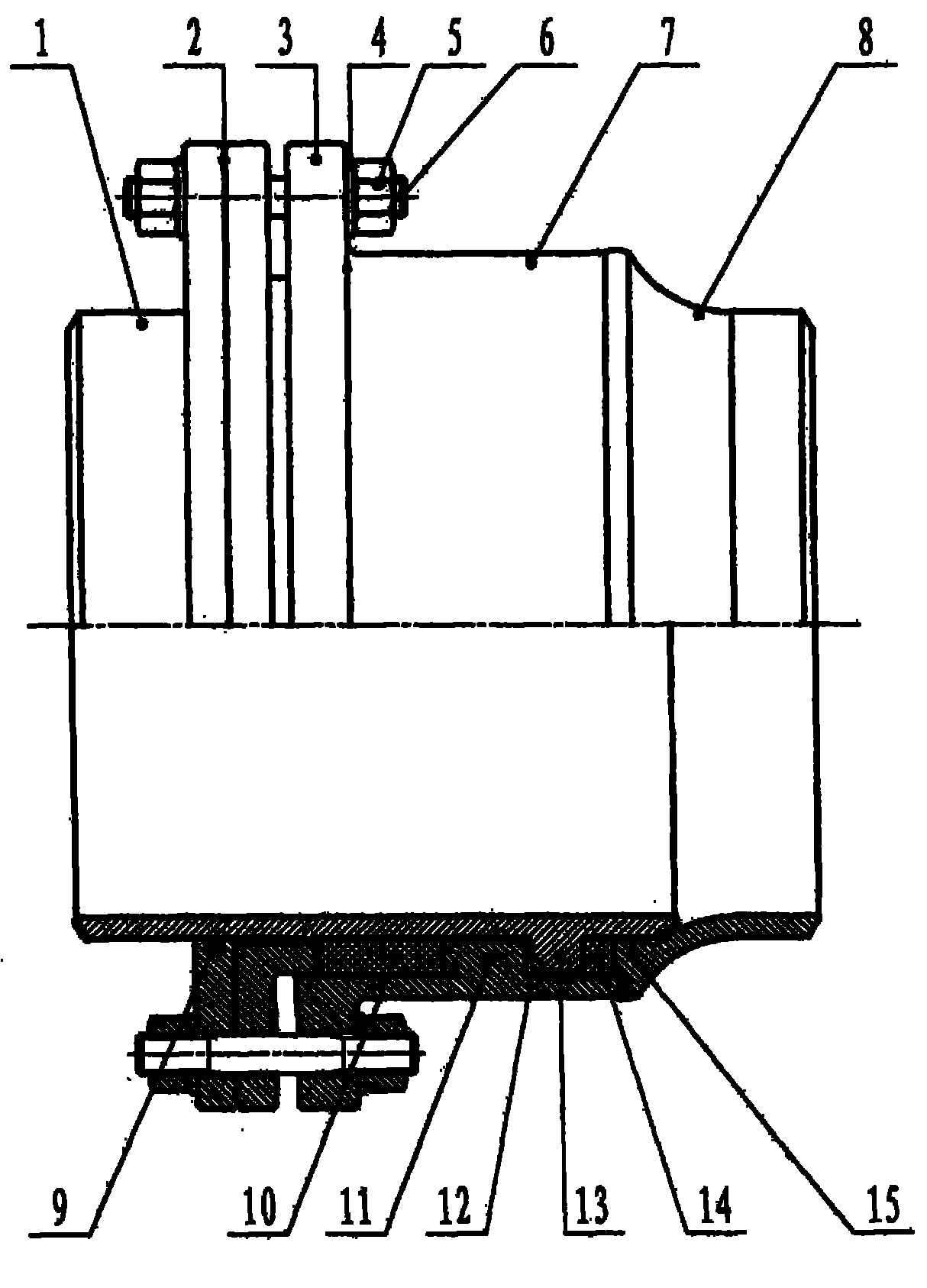

Novel double-gland high-pressure pipeline displacement compensator

ActiveCN102003592AReduce gapGuaranteed uptimePipeline expansion-compensationChemical industryHigh pressure

The invention discloses a novel double-gland high-pressure pipeline displacement compensator, which belongs to the technical field of heat distribution pipeline compensating device structures used in petroleum, chemical industry, light industry, heating power, metallurgy and other industries. The compensator comprises an inner tube, a follower flange, an outer sleeve, a reducing extension pipe, asealing filler, an outer sleeve internal bearing platform, an inner tube convex outer ring, a composite sealing ring, a reducing tube bearing platform and the like, wherein the inner tube convex outer ring is integrally arranged on the inner tube; one end of the inner tube is inserted into the outer sleeve; the inner tube convex outer ring is positioned between the outer sleeve internal bearing platform and the reducing tube bearing platform; the composite sealing ring is pressed against between the inner tube convex outer ring and the reducing tube bearing platform; and a convex end face of the outer sleeve internal bearing platform is pressed against the other end of the inner tube so as to press the sealing filler of the follower flange. By the structure, the novel double-gland high-pressure pipeline displacement compensator has the characteristics of high precision, lower friction coefficient, smaller torque, lower pressure loss, higher bending resistance and bearing capacity, unlimited medium flow direction, reliable sealing, high performance and convenience of pipeline maintenance.

Owner:陈墅庚

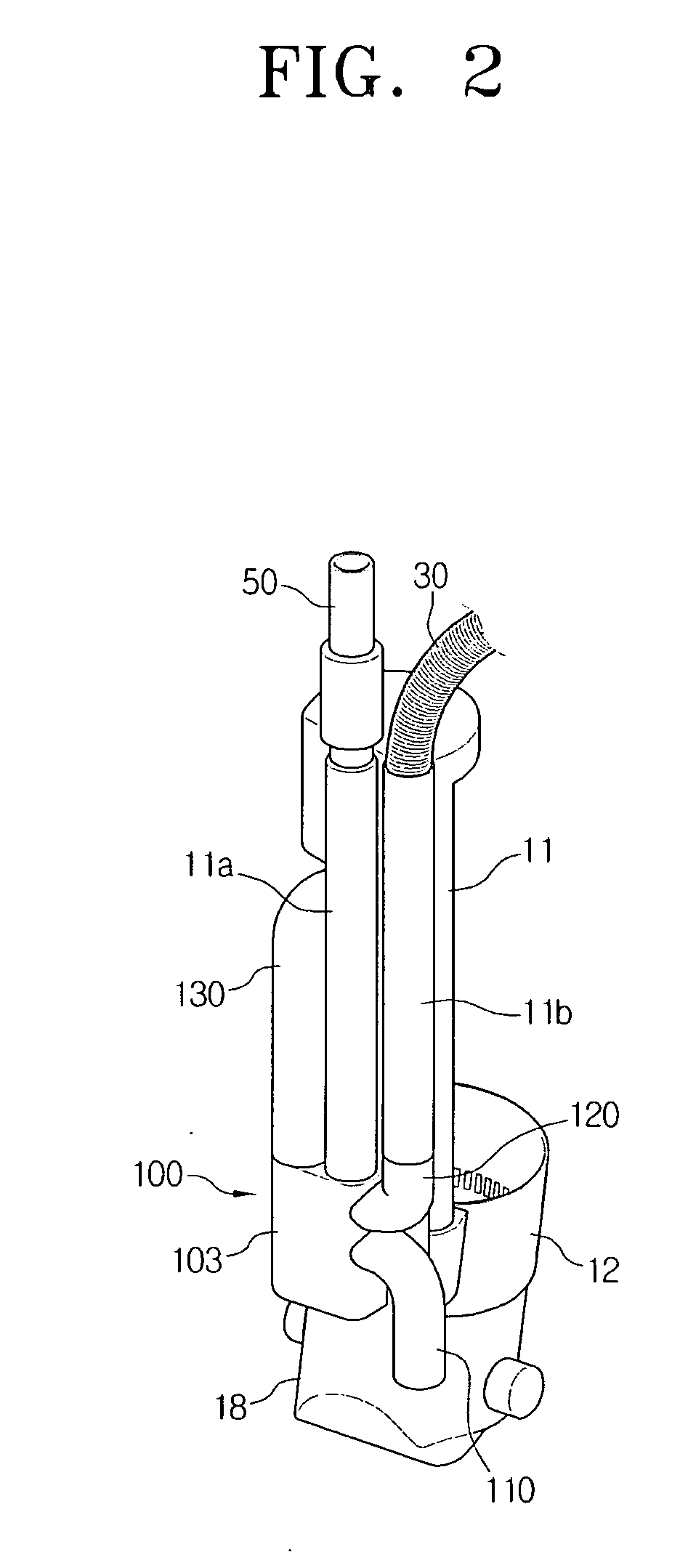

Cyclone dust collecting apparatus and hand-held cleaner having the same

ActiveUS10517449B2Reduce total pressure lossImprove efficiencyCombination devicesSuction filtersCycloneHand held

The hand-held cleaner includes a body, and a cyclone dust collecting apparatus detachably mounted in the body. The cyclone dust collecting apparatus includes a pre-motor filter unit having a filter grill and a filter member, a dust collecting bin having one end to which the pre-motor filter unit is coupled and the other end opposite to the one end in which an cyclone inlet is formed, and a cyclone bin disposed in the dust collecting bin and having a spiral flow path-guide member integrally formed therein. A moving path of air drawn into the cyclone inlet is maintained in the same direction until the air is discharged through the pre-motor filter unit via the cyclone bin.

Owner:SAMSUNG ELECTRONICS CO LTD

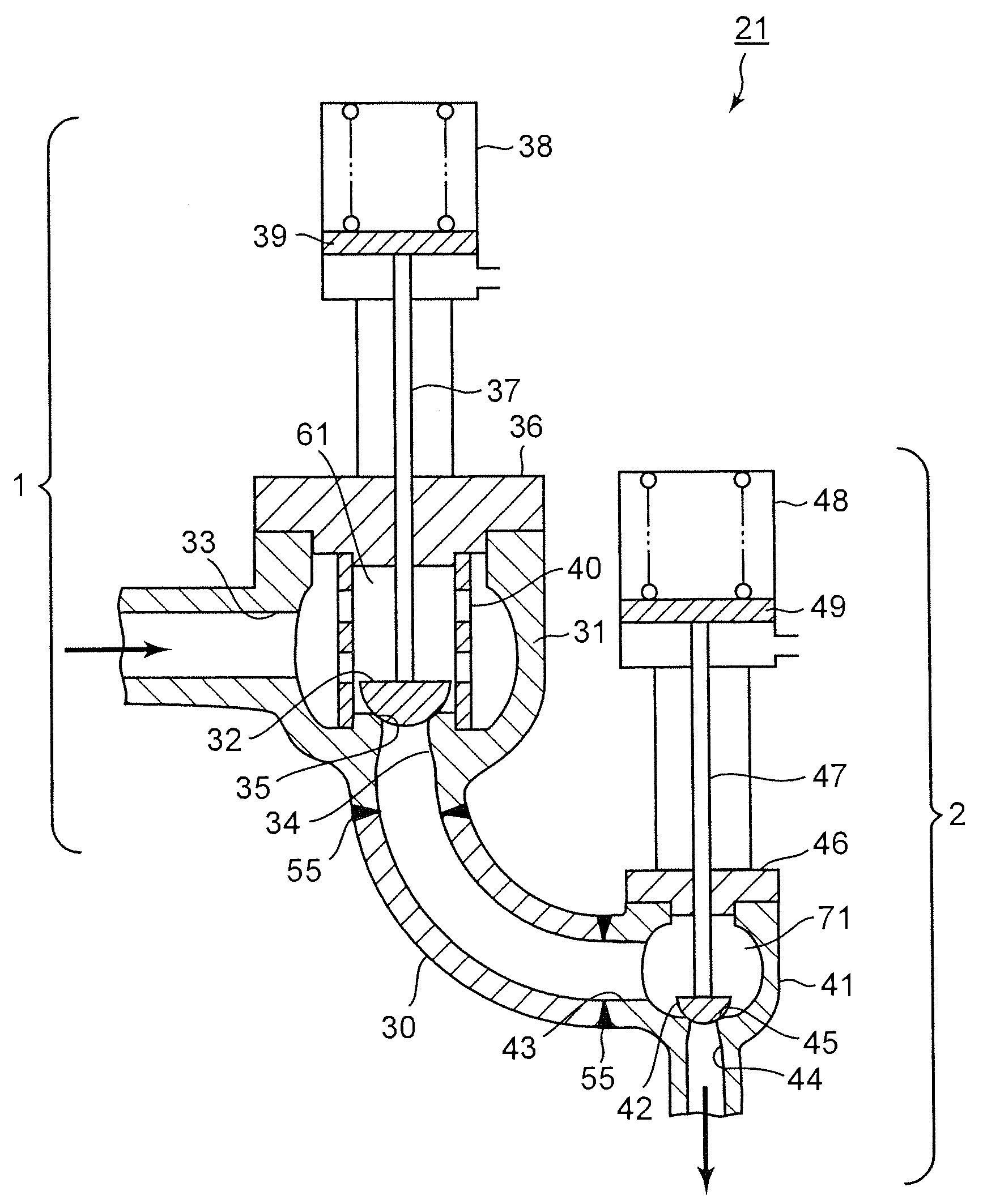

Steam valve assembly and steam turbine plant

ActiveUS20090159141A1Improve efficiencyPressure lossEngine manufactureMultiple way valvesEngineeringControl valves

A steam valve assembly has a main-steam stop valve, and a steam control valve connected downstream to the main-steam stop valve via an intermediate flow path. The two valves each has a casing having an inlet port directing horizontally, and an outlet port directing vertically. The valve bodies and the valve stems move up and down in the casings to open and close the flow paths in the valves. The intermediate flow path is configured to guide main steam from the outlet port of the main-steam stop valve in vertically downward direction to the inlet port of the steam control valve in horizontal direction.

Owner:KK TOSHIBA

Cooled aerofoil blade or vane

ActiveUS8662825B2Promoting a favourable pressure gradientPressure lossPropellersEngine manufactureEngineeringTurbine

An aerofoil blade or vane suitable for the turbine of a gas turbine engine includes an extending aerofoil portion having facing wall parts interconnected by a divider member to partially define first and second cooling fluid passage portions. The first and second passage portions are interconnected in a series fluid flow relationship by a bend passage portion. The first passage portion directs cooling fluid to the bend portion and the second passage portion exhausts cooling fluid from the bend portion. The divider member provides a localised contraction of the downstream end of the first passage portion to accelerate the cooling fluid flow before it enters the bend passage portion. The divider member provides a localised progressive series narrowing and opening of the upstream end of the second passage portion in the general direction of cooling fluid flow.

Owner:ROLLS ROYCE PLC

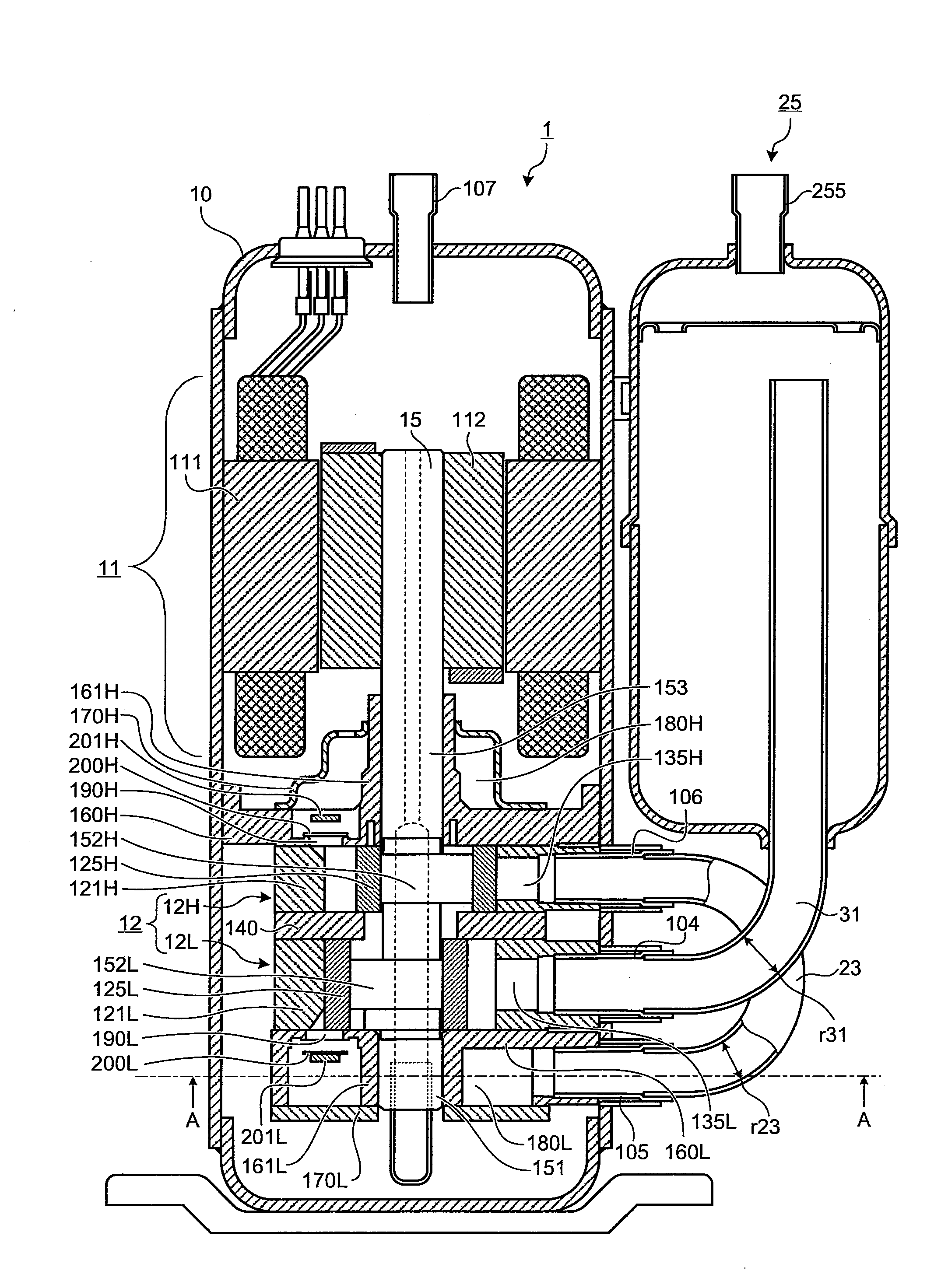

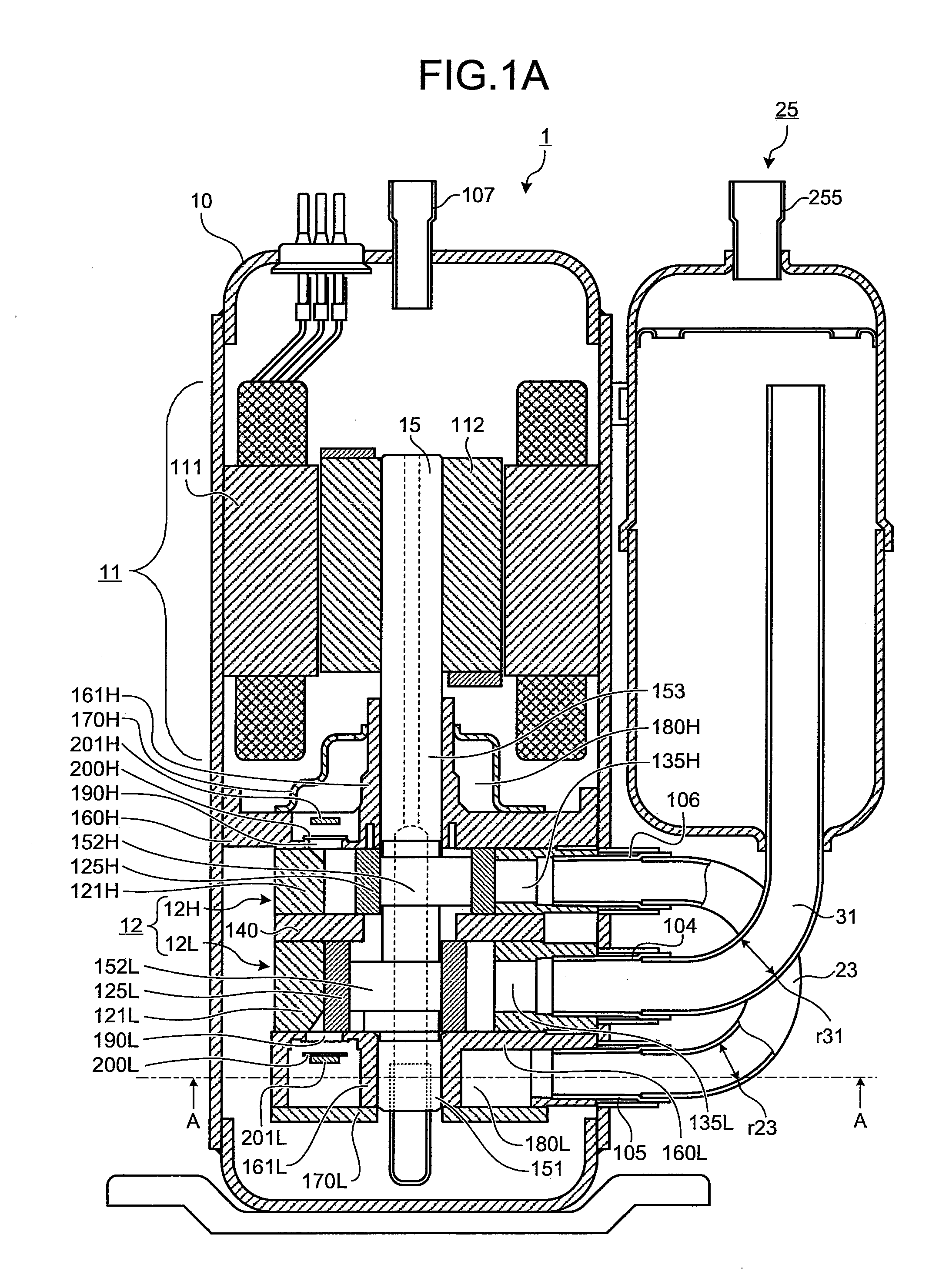

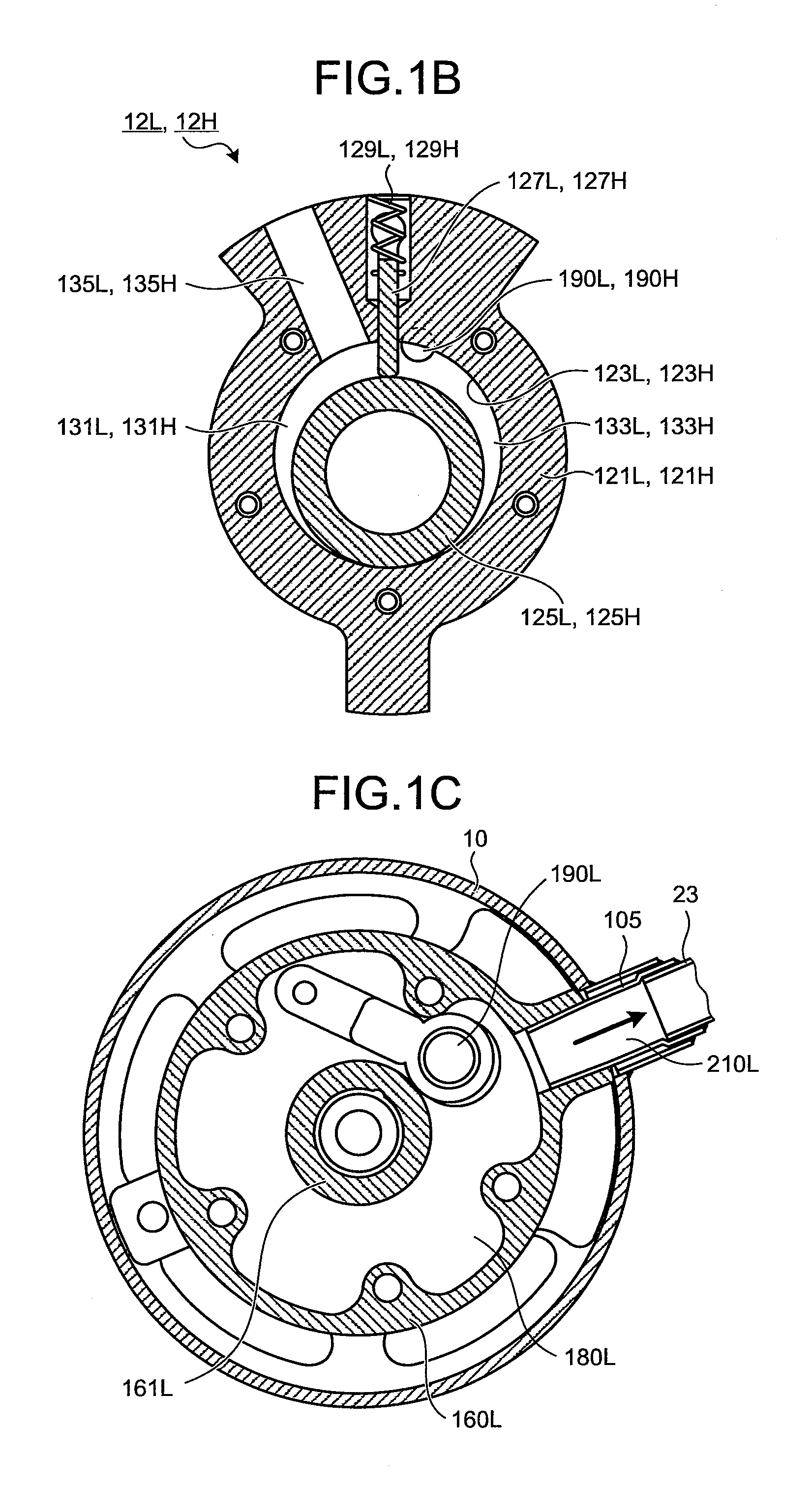

Two-stage compression rotary compressor

InactiveUS20090087321A1Solve problemsPressure lossRotary/oscillating piston combinations for elastic fluidsCompression machines with non-reversible cycleEngineeringRotary compressor

A two-stage compression rotary compressor is provided that includes a low-stage compressing section and a high-stage compressing section housed within a cylindrical sealed housing oriented vertically, a low-stage suction pipe that is connected to a suction side of the low-stage compressing section and sucks in a low-pressure refrigerant, a low-stage discharge pipe the is connected to a discharge side of the low-stage compressing section and discharges the refrigerant from the low-stage to outside of the sealed housing, a high-stage suction pipe that is connected to a suction side of the high-stage compressing section and sucks in the refrigerant discharged from the low-stage, a low-pressure connecting pipe that connects the low-stage suction pipe and an accumulator, and guides the refrigerant inside the accumulator to a suction side of a low-stage compressing section, and an intermediate connecting pipe that connects the low-stage discharge pipe and the high-stage suction pipe, wherein an inner diameter of the lower-stage connecting pipe is larger than an inner diameter of the intermediate connecting pipe.

Owner:FUJITSU GENERAL LTD

Method of manufacturing heat exchanger and heat exchanger

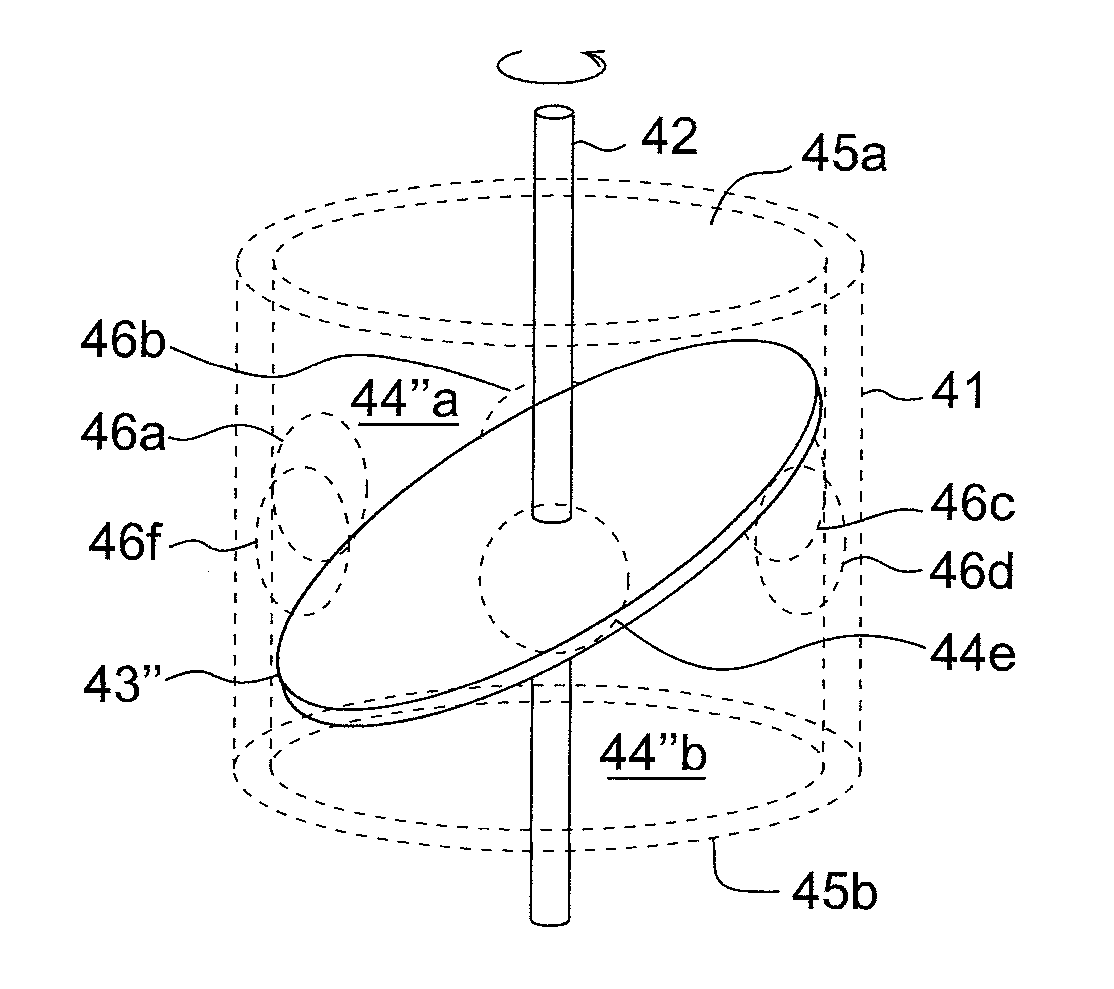

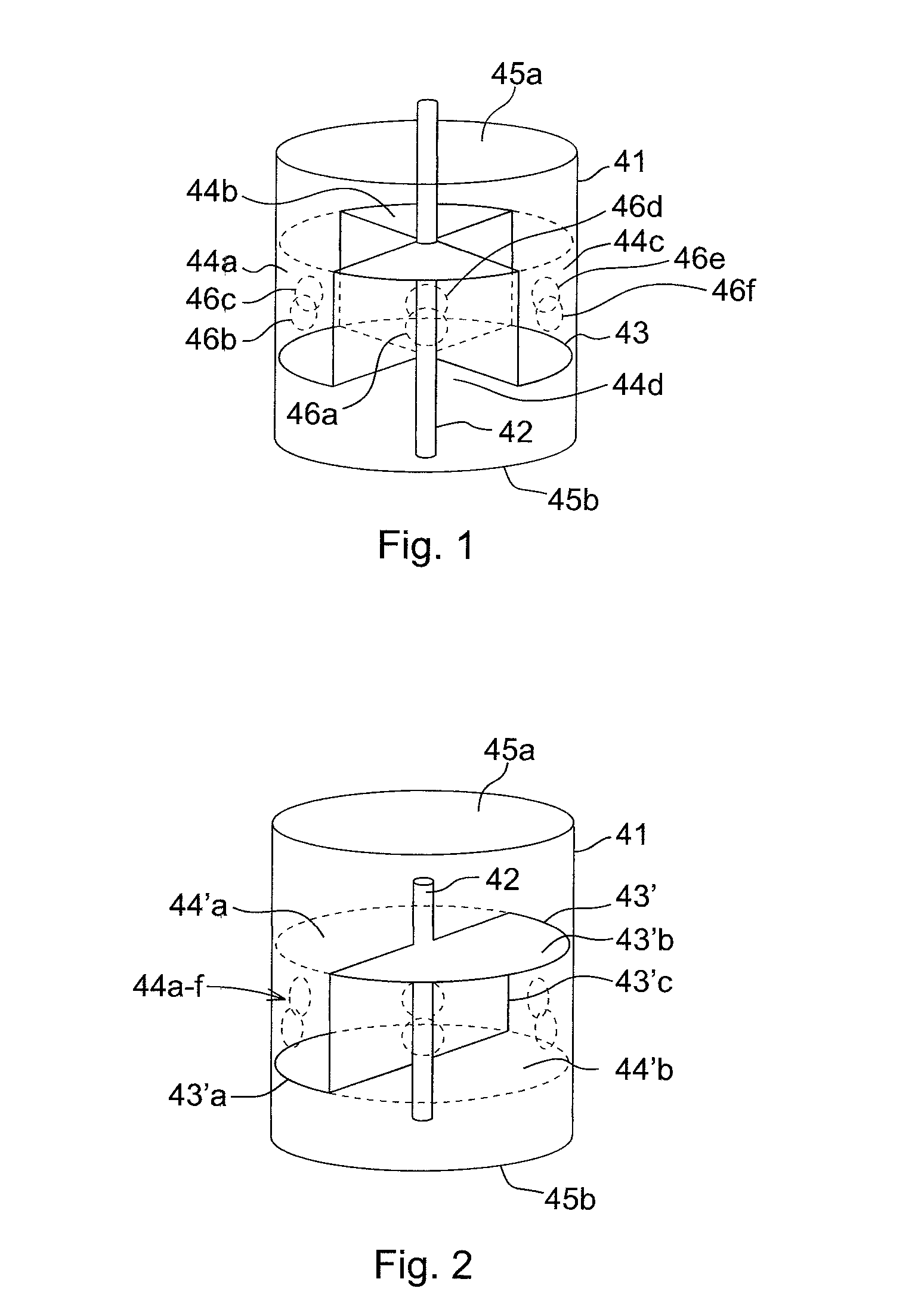

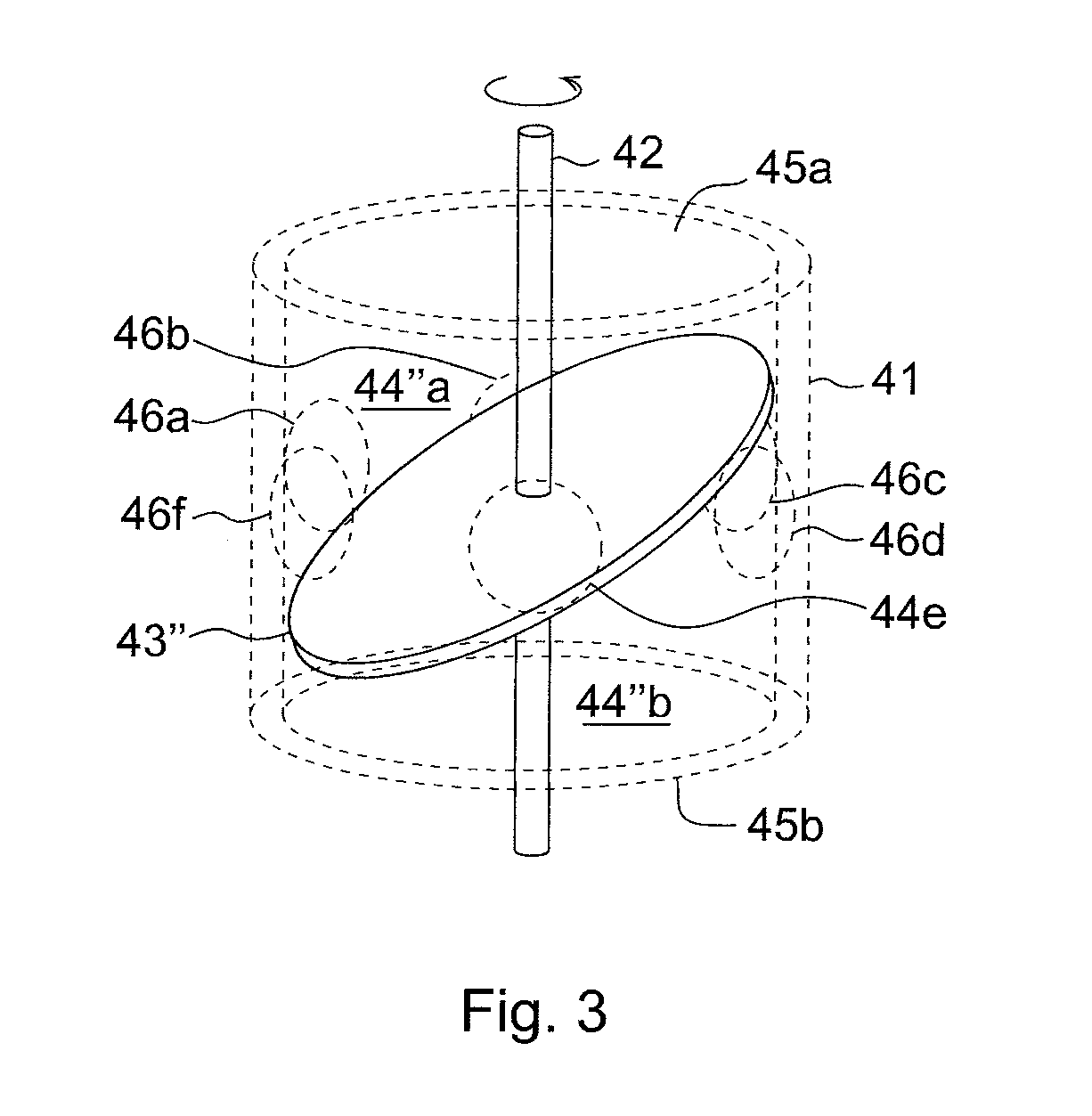

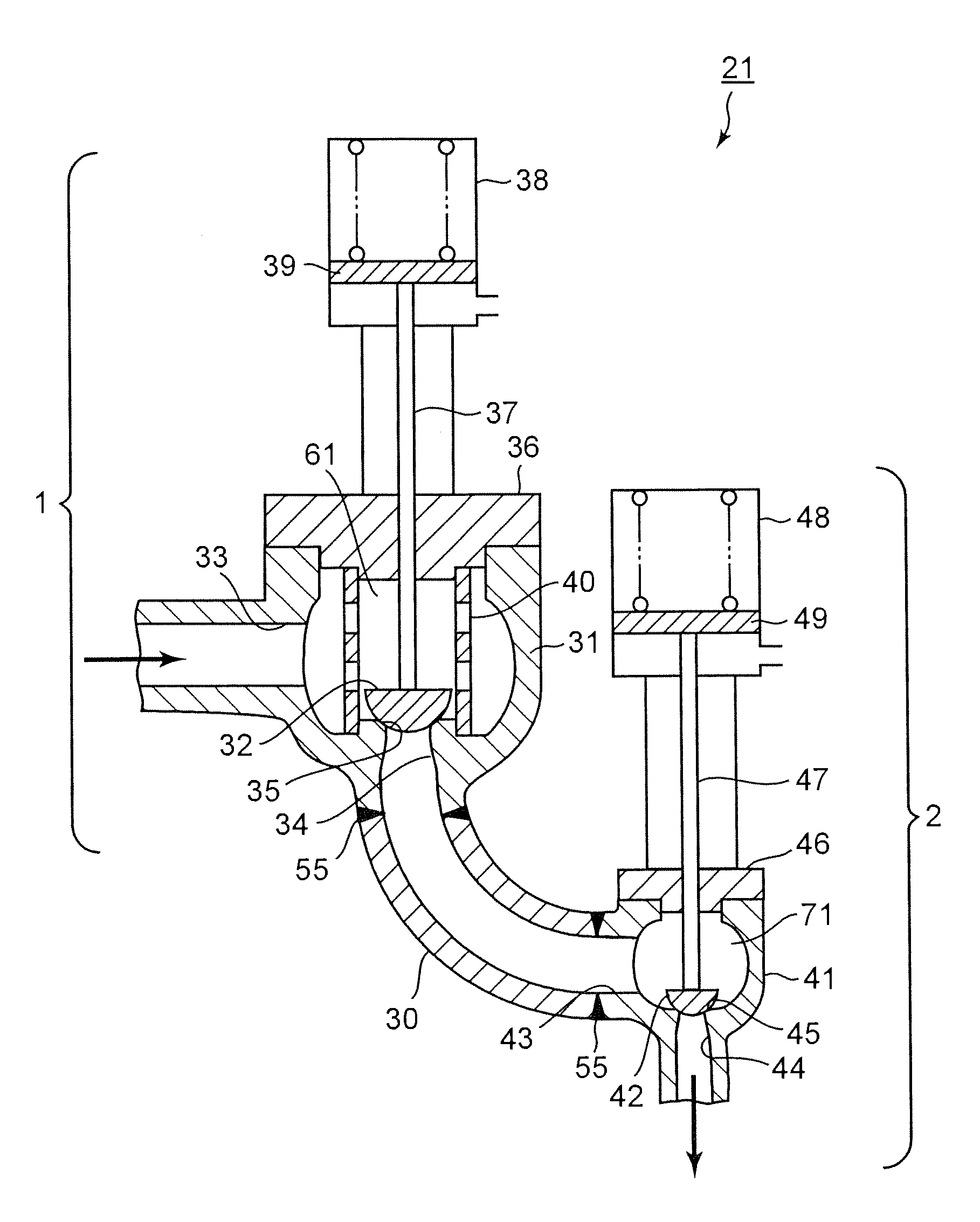

ActiveUS20160331882A1Excellent in heat exchanger effectivenessShorten the lengthSemi-permeable membranesMembranesEngineeringMechanical engineering

A heat exchanger has a hollow fiber membrane layer comprised of a plurality of hollow fiber membrane conduits each of which has a hollow portion allowing a heat medium to pass therethrough. The conduits are derived by winding a base cord of the hollow fiber membrane onto a cylindrical body. The winding follows a generally helical trajectory around the longitudinal axis of the cylindrical body with a plurality of continuous round trips from the first end to the second end and turning back at each respective end, wherein each round trip completes a number of circumferential revolutions N, wherein N is greater than or equal to one, and wherein N is less than two.

Owner:TERUMO KK

Valve Apparatus

InactiveUS20110095647A1Smooth and energetically efficientLow costPlug valvesThermoelectric deivce with magnetic permeability thermal changePath lengthEngineering

A rotating valve apparatus includes a cylindrical casing; a shaft arranged symmetrically in the casing; a member fixedly attached to the shaft and in close fit with the cylindrical casing, defining separated chambers within the casing; at least one outlet fixedly arranged along the circumference of the casing; and a plurality of axially arranged inlets, each of which being constantly in fluid communication with a respective one of the separated chambers, wherein the axially arranged inlets are alternately in fluid connection with the outlet fixedly arranged along the circumference of the casing in response to rotation of the shaft and the member with respect to the casing. The outlet(s) has / have a fluid path length that varies along the circumference of the casing depending on the rotational speed of the shaft such that the interfaces between fluids originating from different ones of the axially arranged inlets will be essentially vertical to the flow direction of the fluids.

Owner:ABB RES LTD

Steam valve assembly and steam turbine plant

ActiveUS8042570B2Improve efficiencyPressure lossEngine manufactureMultiple way valvesEngineeringControl valves

A steam valve assembly has a main-steam stop valve, and a steam control valve connected downstream to the main-steam stop valve via an intermediate flow path. The two valves each has a casing having an inlet port directing horizontally, and an outlet port directing vertically. The valve bodies and the valve stems move up and down in the casings to open and close the flow paths in the valves. The intermediate flow path is configured to guide main steam from the outlet port of the main-steam stop valve in vertically downward direction to the inlet port of the steam control valve in horizontal direction.

Owner:KK TOSHIBA

Ceramic porous membrane and ceramic filter

InactiveUS20100193438A1Less formation timeSmall and uniform thicknessMembranesSolid sorbent liquid separationUltrafiltrationHigh flux

There are disclosed a ceramic porous membrane formed with less membrane formation times and having less defects, a small and uniform thickness and a high flux, and a ceramic filter. A silica membrane is formed on a titania UF membrane as an ultrafiltration membrane (a UF membrane) formed on a porous base member which is a microfiltration membrane (also referred to as an MF membrane) and having an average pore diameter smaller than that of the porous base member, and the silica membrane has an average pore diameter smaller than that of the titania UF membrane, and does not substantially permeates the titania UF membrane.

Owner:NGK INSULATORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com