Gas turbine device

a gas turbine and gas turbine technology, applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of difficult reduction of low frequency noises generated by gas turbine devices, and achieve the effect of reducing exhaust pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

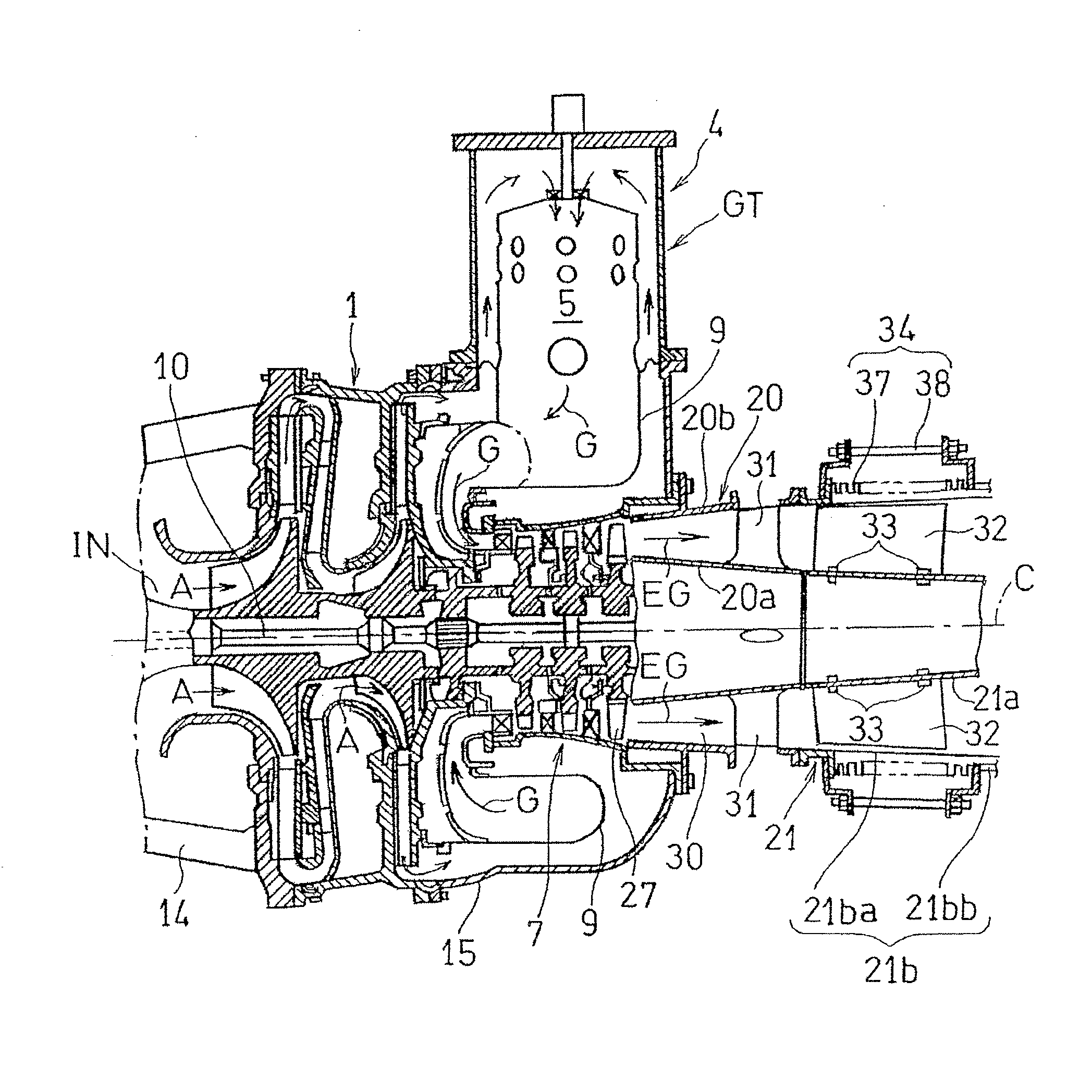

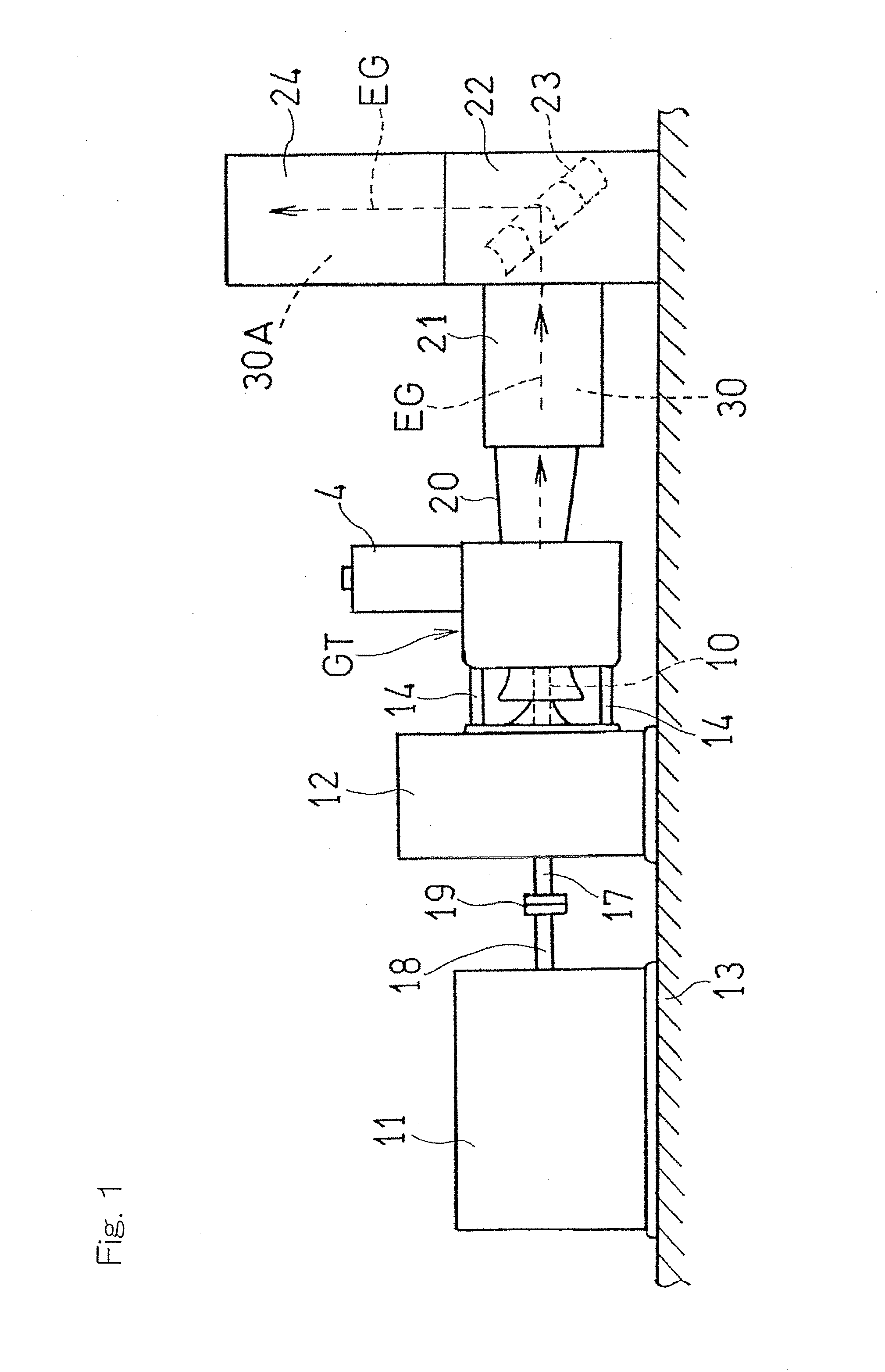

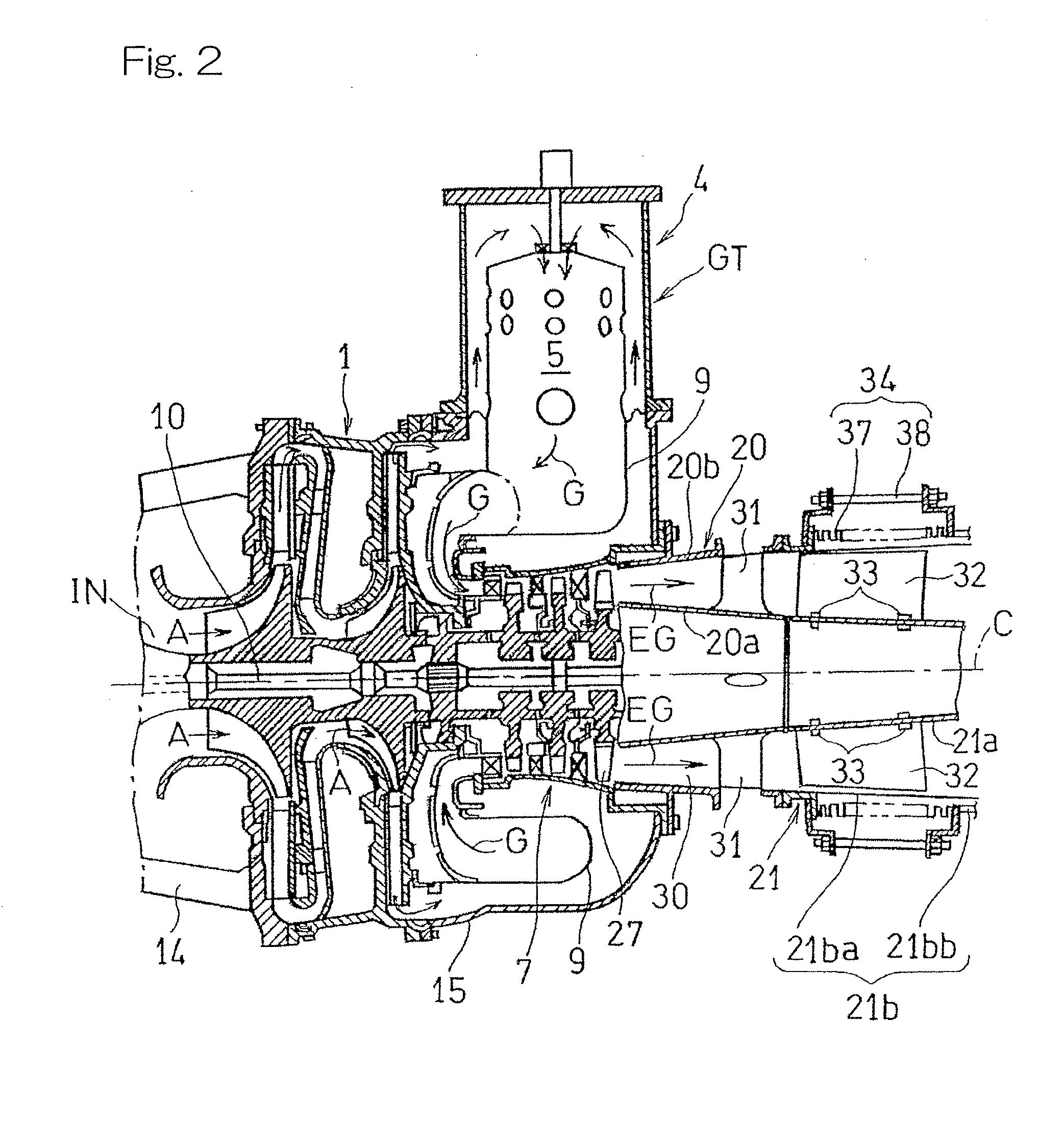

[0031]Hereinafter, an embodiment of the present invention will be described in detail with reference to the accompanying drawings. In particular as shown in FIG. 1, a reduction gear unit 12 having a large weight is fixedly placed on a foundation bed 13, and a gas turbine engine GT is supported by the reduction gear unit 12 in a cantilevered manner through a plurality of, for example, four in the illustrated embodiment, stays 14. The reduction gear unit 12 has a connecting shaft on an input side drivingly connected with a rotary shaft 10 of the gas turbine engine GT and also has a connecting shaft 17 on an output side connected with a drive shaft 18 of an electric generator 11, which forms a load of the gas turbine engine GT, through a coupling 19. An exhaust gas EG discharged substantially horizontally from the gas turbine engine GT is guided into an exhaust chamber 22 through an exhaust diffuser 20 and an exhaust duct 21, subsequently deflected in a substantially vertical direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com