Mobile industrial production system of urea for vehicles

A urea for vehicles, mobile technology, applied in the direction of dissolving system, mixer, dissolving, etc., can solve the problems of large production equipment, single production of production equipment, high production energy consumption, etc., to achieve small production equipment, prevent Swirl and aeration, no return loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

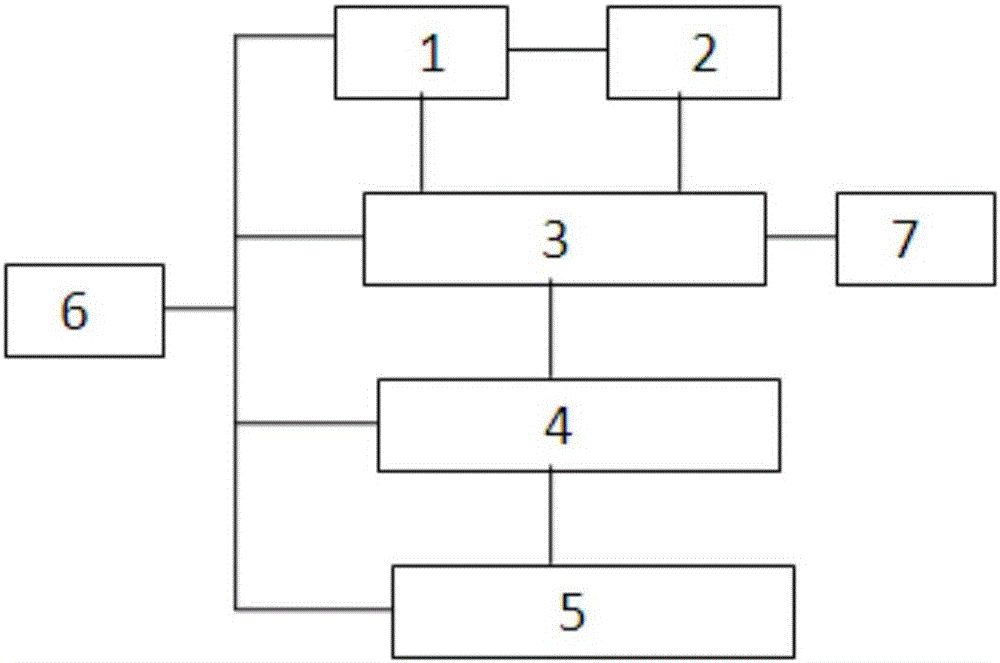

[0024] Such as figure 1 As shown, a mobile vehicle urea industrial production system includes a batching module 1, a water production module 2, a jet mixing module 3, a canning module 4, a post-processing module 5, a heat exchange module 6 and a concentration real-time monitoring module 7; The batching module 1 is connected to the water production module 2, and the batching module 1 and the water production module 2 are connected to the jet mixing module 3 at the same time, the jet mixing module 3 is connected to the canning module 4, and the canning module 4 is connected to the post-processing module 5; The jet stirring module 3 is connected to the concentration real-time monitoring module 7 at the same time; the batching module 1, the water production module 2, the jet stirring module 3, the filling module 4, and the post-processing module 5 are connected to the heat exchange module 6 at the same time.

[0025] The batching module 1 includes a transport belt, a urea granule ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com