Preparation of cationic polyacrylamide reverse microemulsion

A technology of polyacrylamide and inverse microemulsion, which is applied in the field of preparation of cationic polyacrylamide inverse microemulsion, which can solve the problems of easy fluctuation of polymerization temperature and long polymerization reaction time, and achieve easy control of polymerization temperature and particle size The effect of narrow distribution range and moderate molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0006] A preparation method of cationic polyacrylamide inverse microemulsion, the steps are as follows:

[0007] (1) Preparation of monomer solution

[0008] Mix acrylamide and dimethyl diallyl ammonium chloride in a molar ratio of 100:(40-5), add deionized water to form an aqueous solution with a mass concentration of 50%-65%;

[0009] (2) Preparation of oil phase

[0010] Mix and dissolve the non-ionic surfactant and kerosene in a weight ratio (27-43): 100 to form an oil phase; the non-ionic surfactant uses sorbitan oleate (Span80) and alkylphenol polyoxyethylene ether (OP-10), adjust the weight ratio of Span80 and OP-10 to make the lipophilic and hydrophilic balance value of the system 6.24-8.18;

[0011] (3) Inverse microemulsion polymerization

[0012] Add the oil phase prepared in step (2) into the reactor, place the reactor in a constant temperature water bath at 30-45°C, pass nitrogen and stir for 15-20 minutes; Place the reducing agent and sodium formate in a sepa...

Embodiment 1

[0026] Mix and dissolve acrylamide, dimethyl diallyl ammonium chloride, and deionized water to make a monomer aqueous solution; mix and dissolve surfactant and kerosene at a weight ratio of 33:100 to make an oil phase and add it to the reactor , wherein the surfactant is made by mixing Span80 and OP-10; the reactor is placed in a 35°C constant temperature water bath, nitrogen is passed and stirred for 15-20 minutes, and the monomer aqueous solution, potassium persulfate and sodium formate are placed in a separatory funnel In the process, add sodium thiosulfate directly into the oil phase, under the protection of nitrogen, slowly drop the aqueous monomer solution into the reactor, after 1 hour the dropwise addition is completed, continue to pass nitrogen and stir for 10-15 minutes, then stop nitrogen flow; continue After 2 hours of reaction, the polymerization reaction was completed, wherein the monomer aqueous solution concentration was 60%, the molar percentages of dimethyl di...

Embodiment 2

[0033] Mix and dissolve acrylamide, dimethyl diallyl ammonium chloride, and deionized water to make a monomer aqueous solution; mix and dissolve surfactant and kerosene at a weight ratio of 33:100 to make an oil phase and add it to the reactor , wherein the surfactant is made by mixing Span80 and OP-10; the reactor is placed in a 35°C constant temperature water bath, nitrogen is passed and stirred for 15-20 minutes, and the monomer aqueous solution, potassium persulfate and sodium formate are placed in a separatory funnel In the process, add sodium thiosulfate directly into the oil phase, under the protection of nitrogen, slowly drop the aqueous monomer solution into the reactor, after 1 hour the dropwise addition is completed, continue to pass nitrogen and stir for 10-15 minutes, then stop nitrogen flow; continue After 2 hours of reaction, the polymerization reaction was complete. Wherein, the monomer aqueous solution concentration is 60%, the mole percent of dimethyl diallyl...

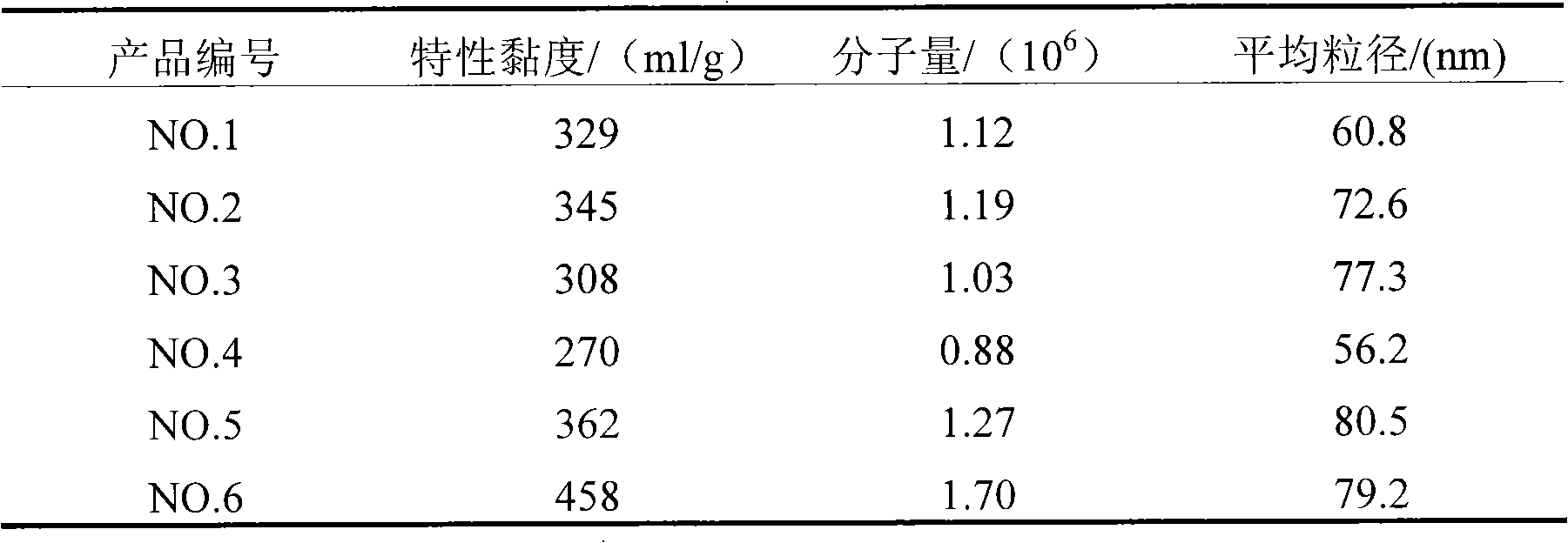

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com