Patents

Literature

105results about How to "Reduce charge density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LbL-coated medical device and method for making the same

InactiveUS6926965B2Reduce charge densityImprove hydrophilicitySynthetic resin layered productsOptical articlesMedical deviceBiomedical engineering

The present invention provides a medical device, preferably an ophthalmic device, more preferably a contact lens, which comprises a core material and a biocompatible LbL coating non-covalently attached to said core material. The biocompatible LbL coating comprises at least one charge / non-charge bilayer, wherein said charge / non-charge bilayer is composed of, in no particular order, one layer of a charged polymeric material and one layer of a non-charged polymeric material which is capable of being non-covalently bond to the charged polymeric material.

Owner:ALCON INC

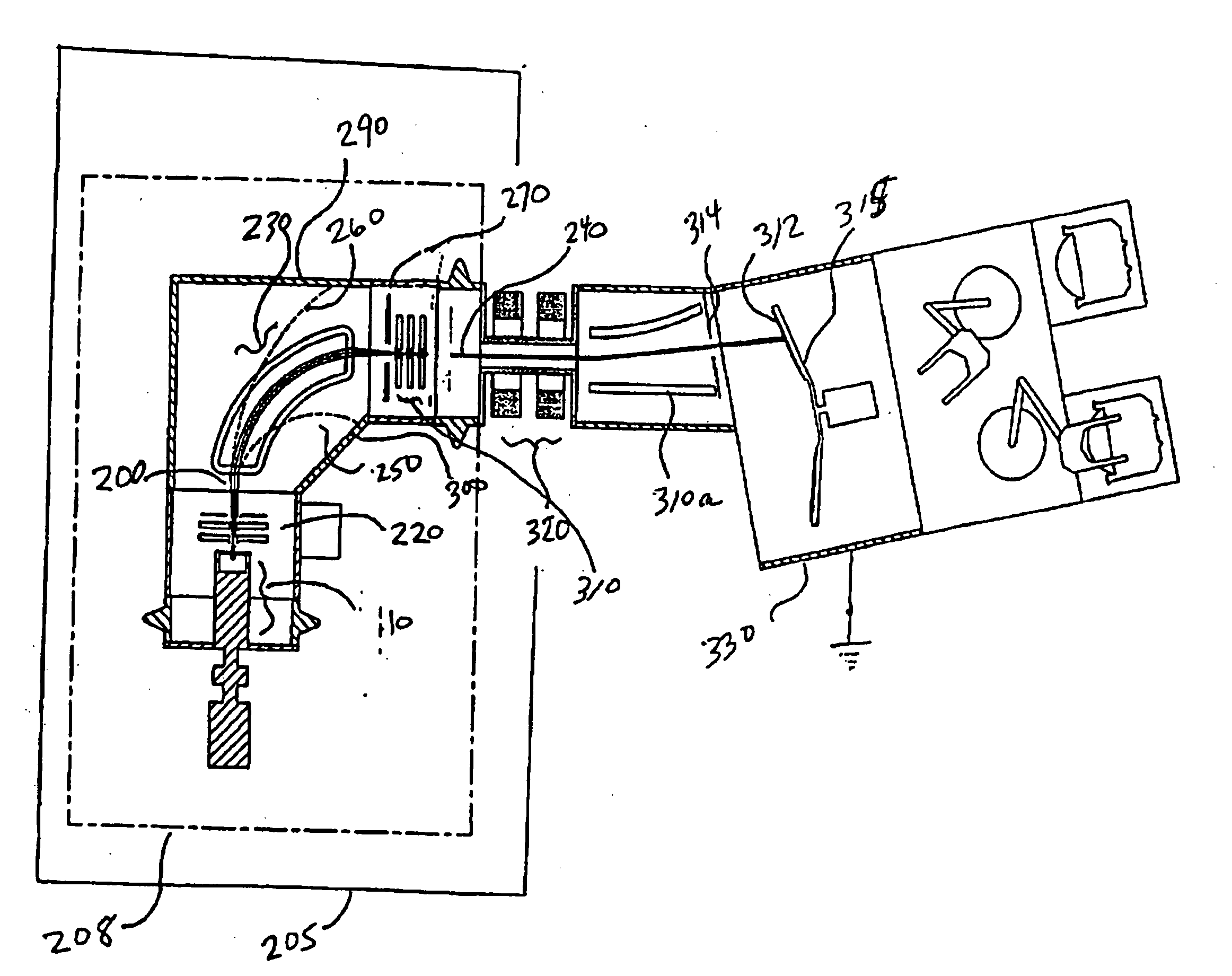

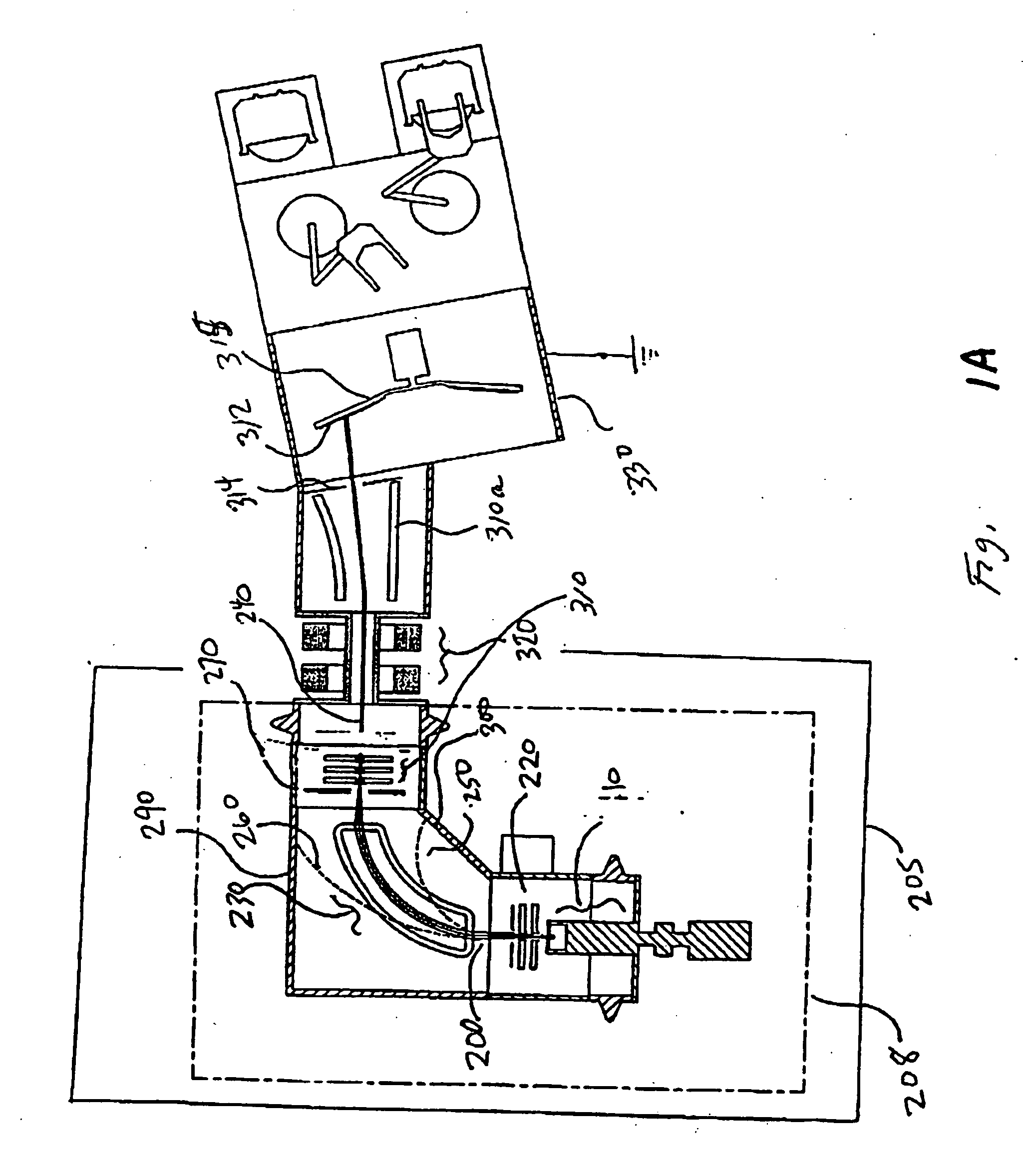

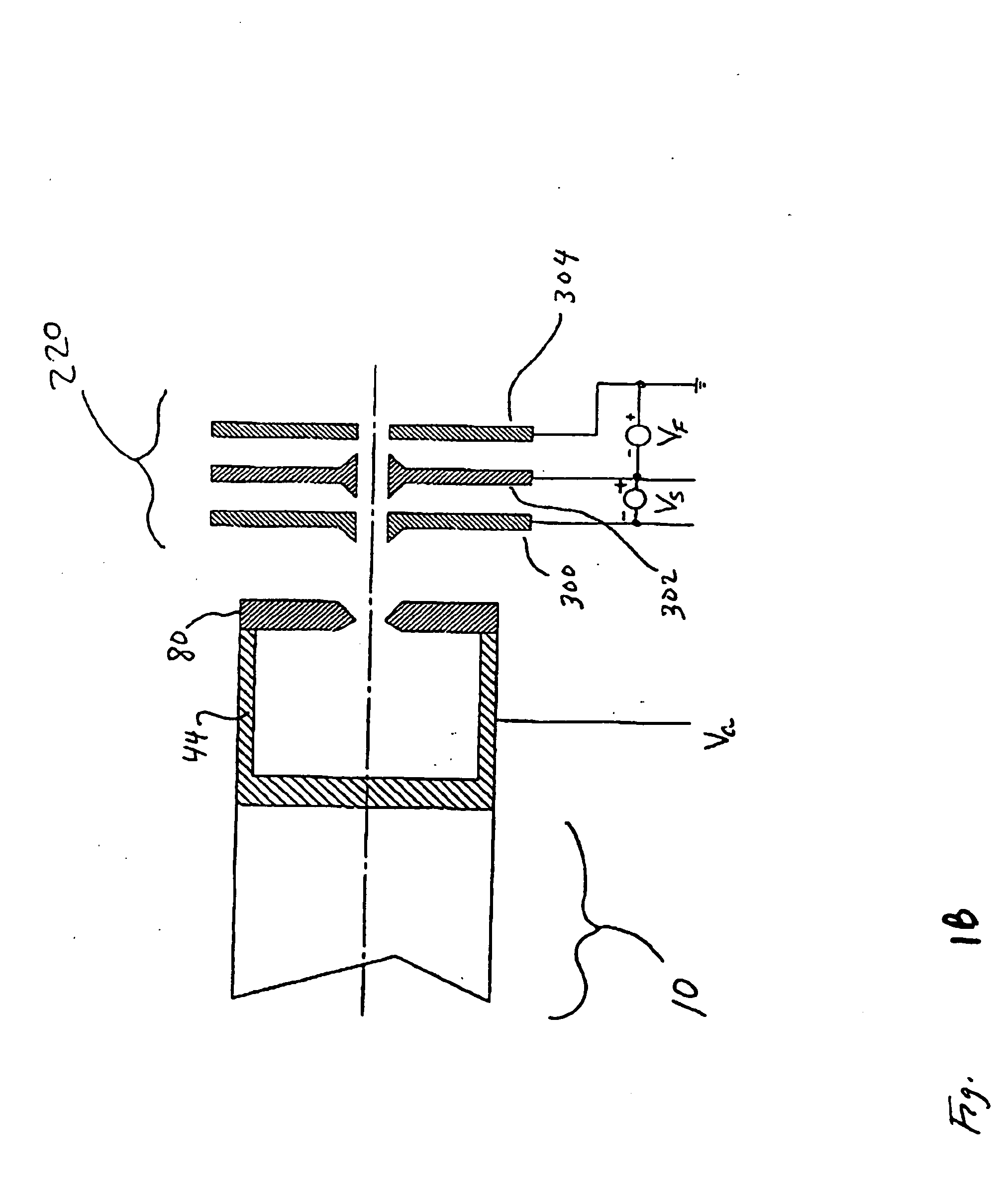

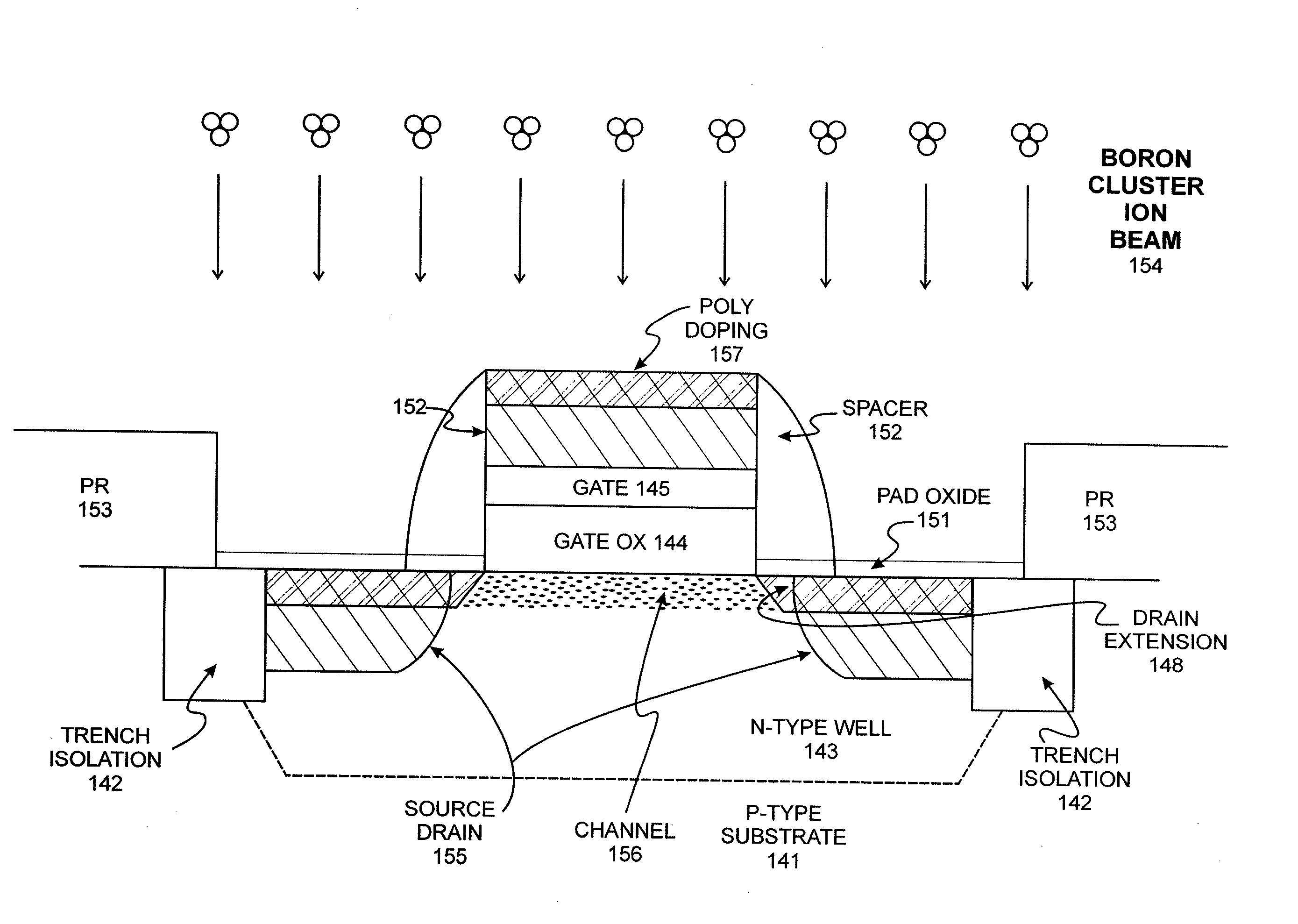

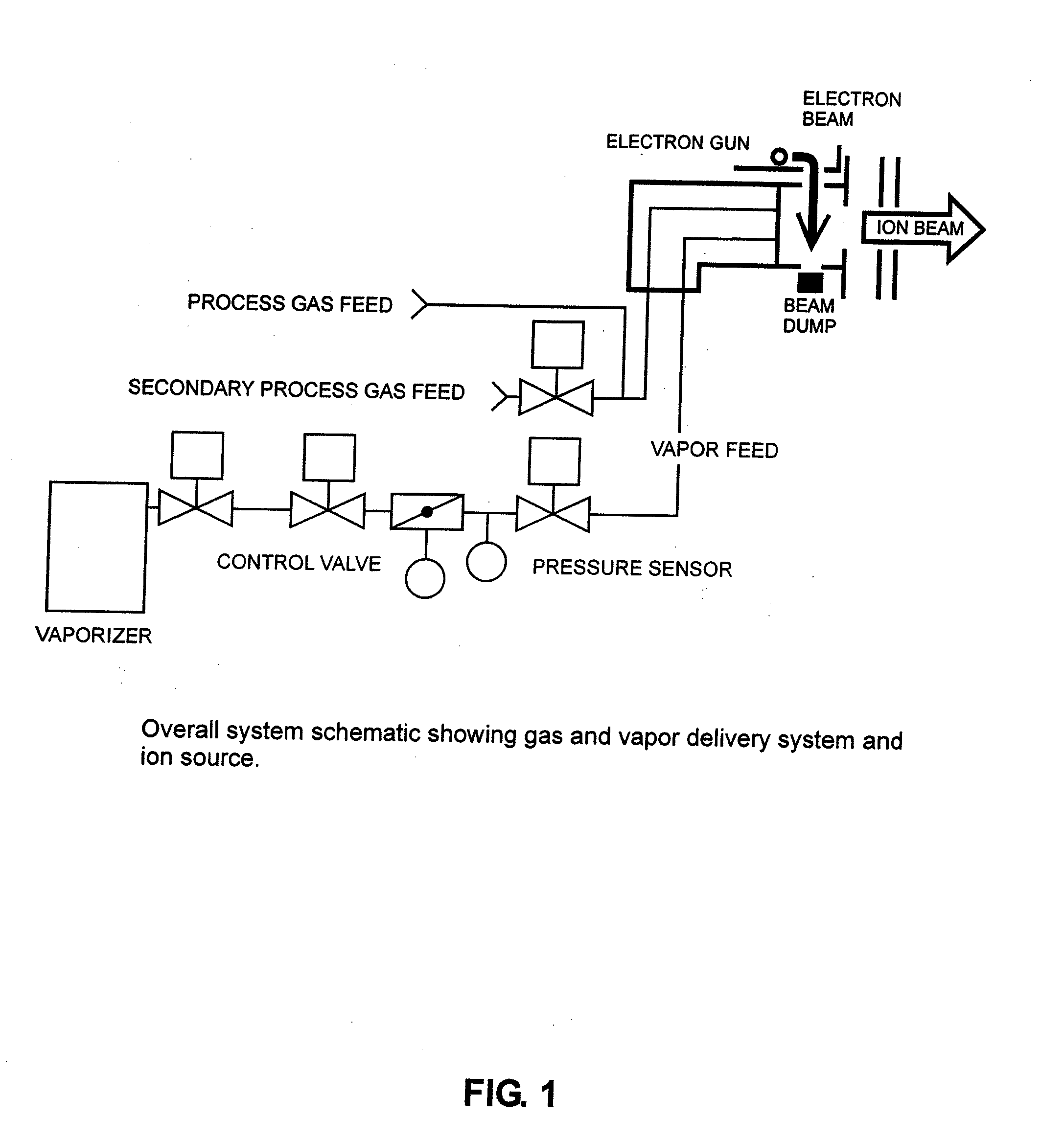

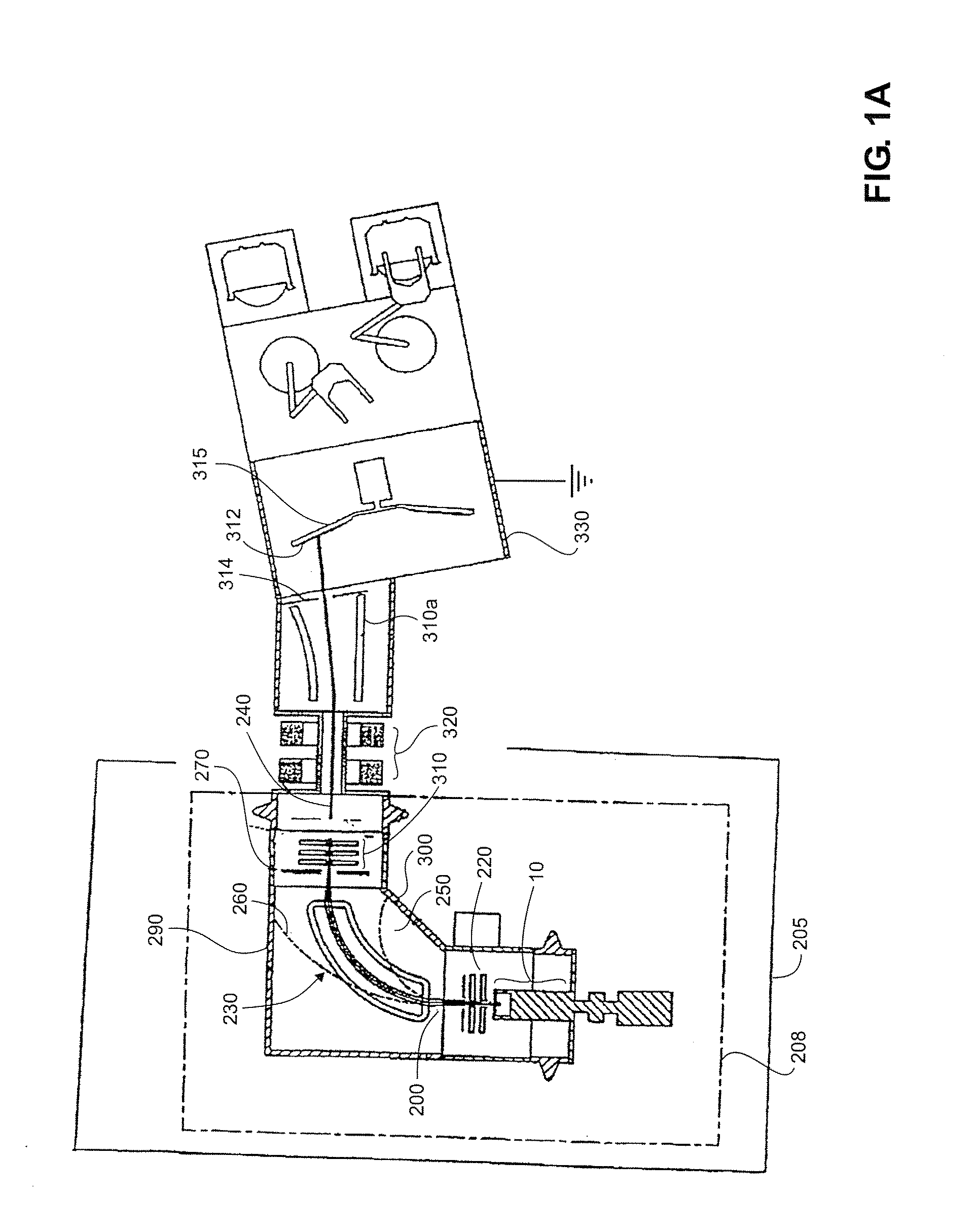

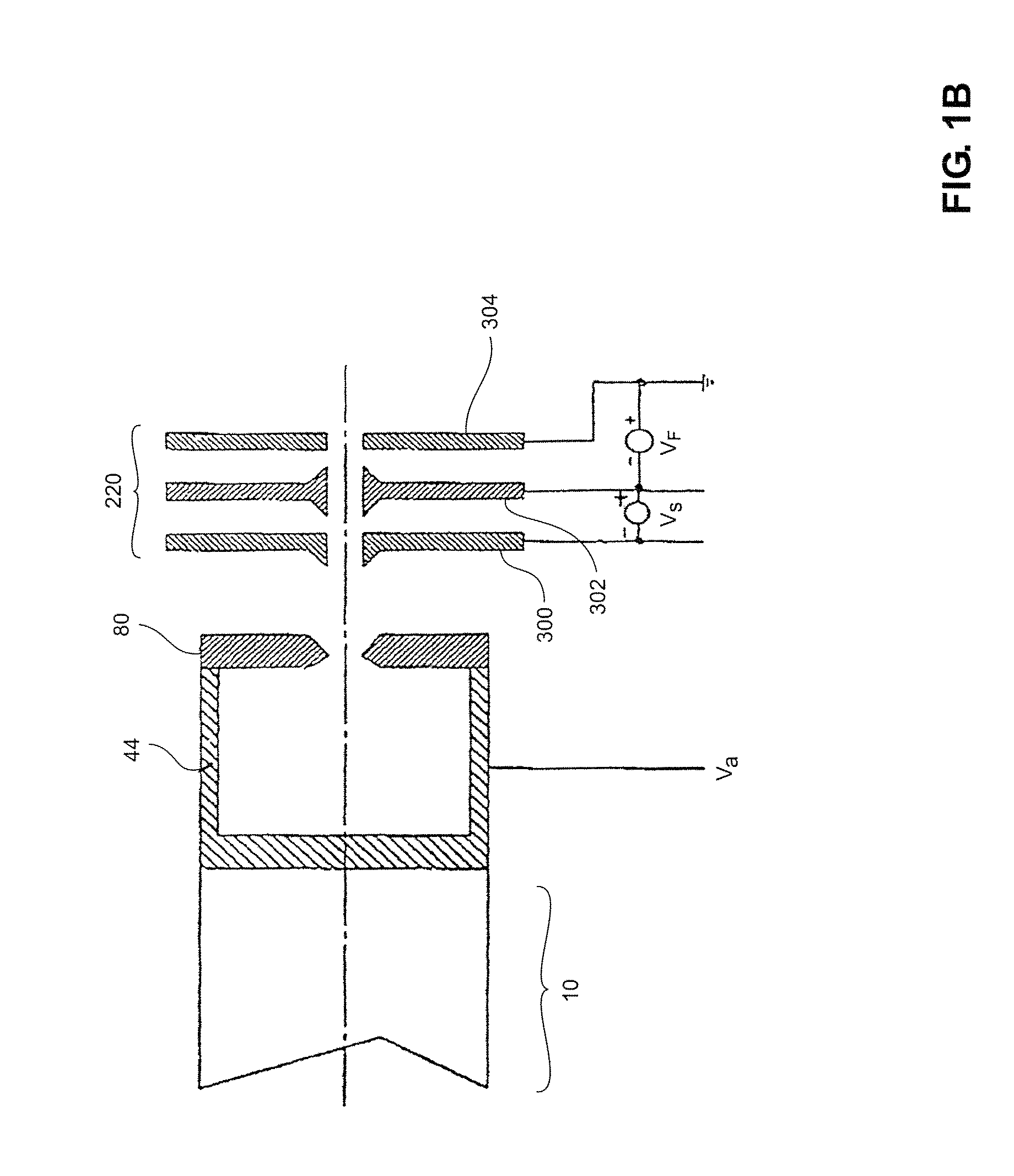

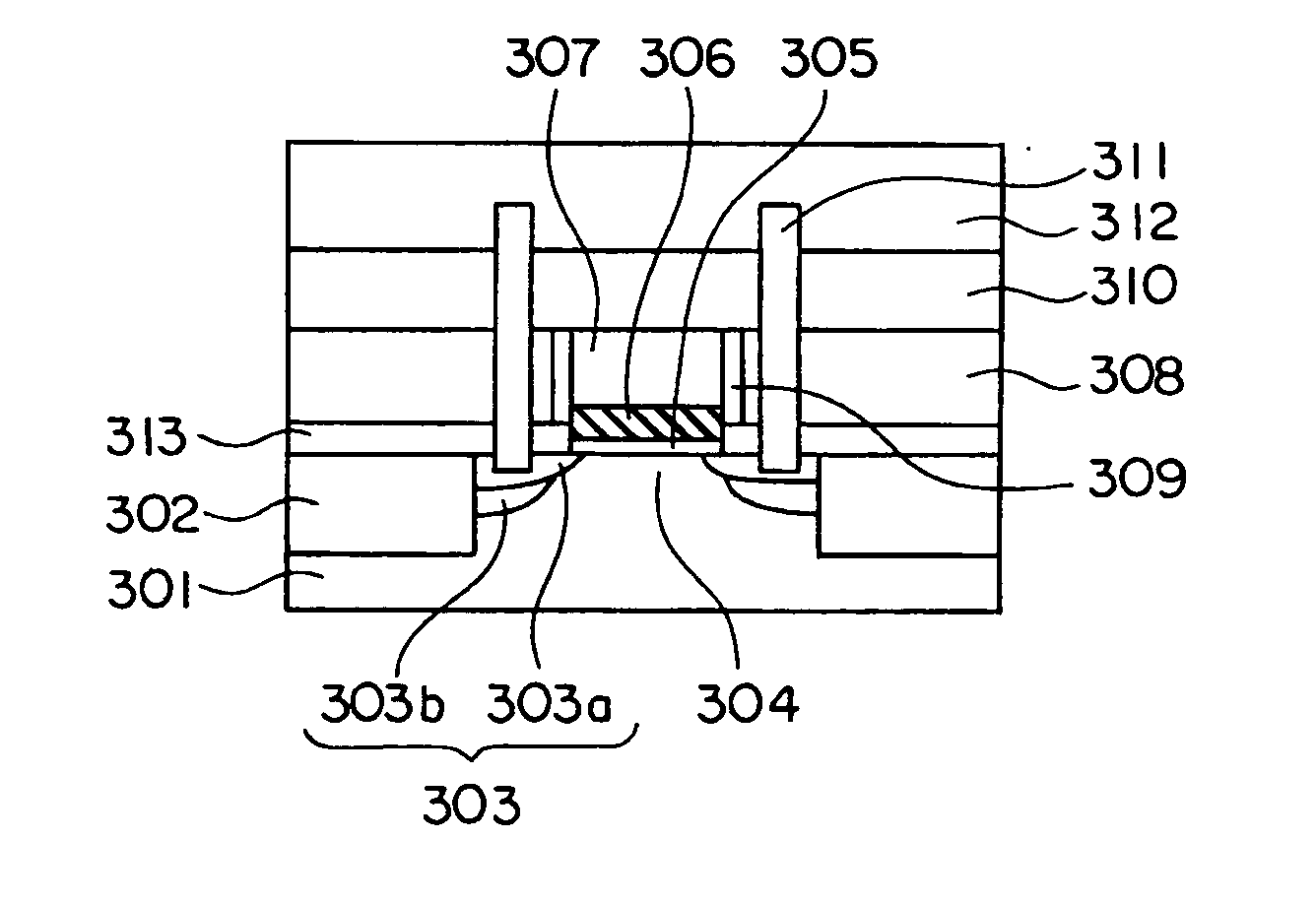

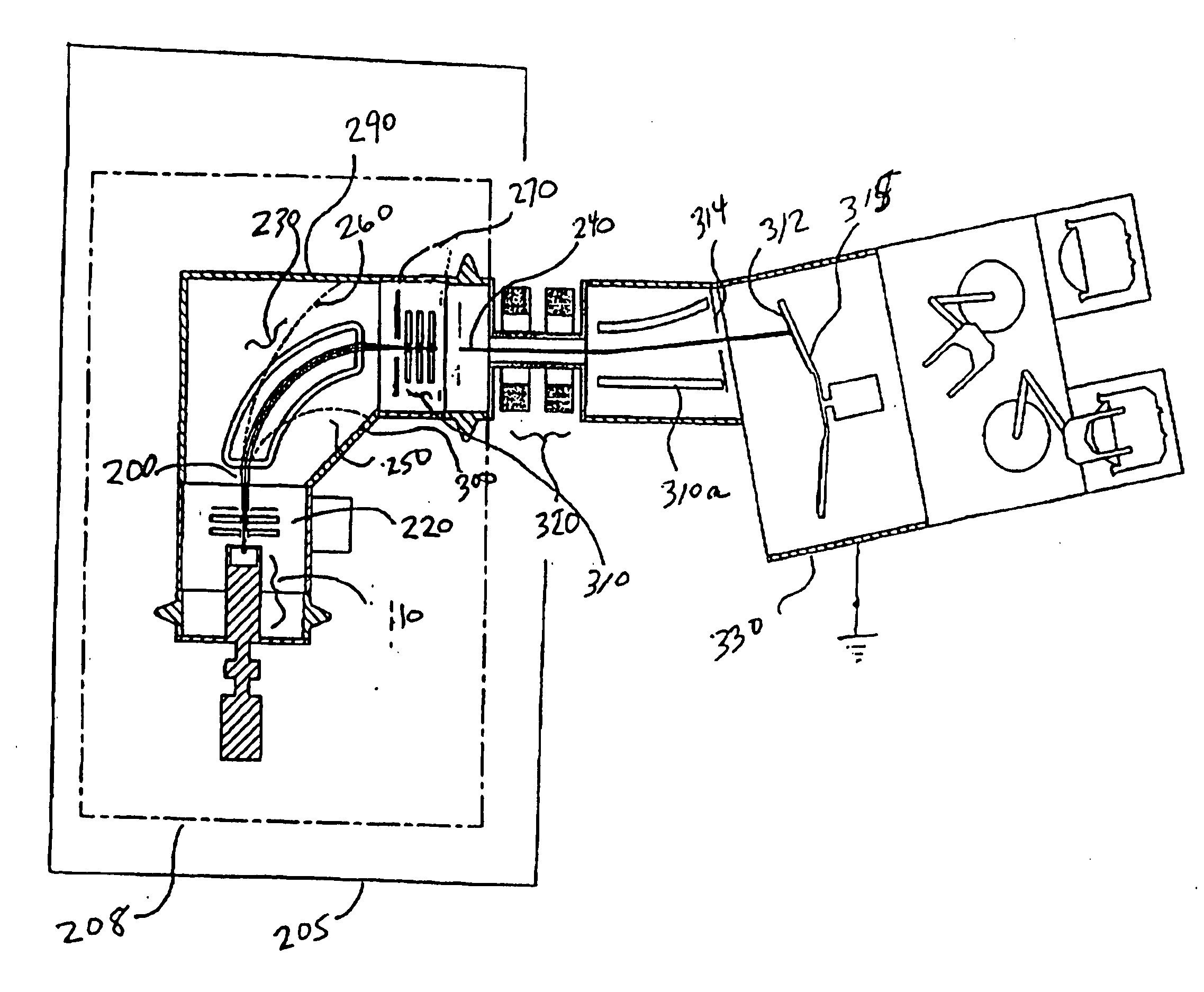

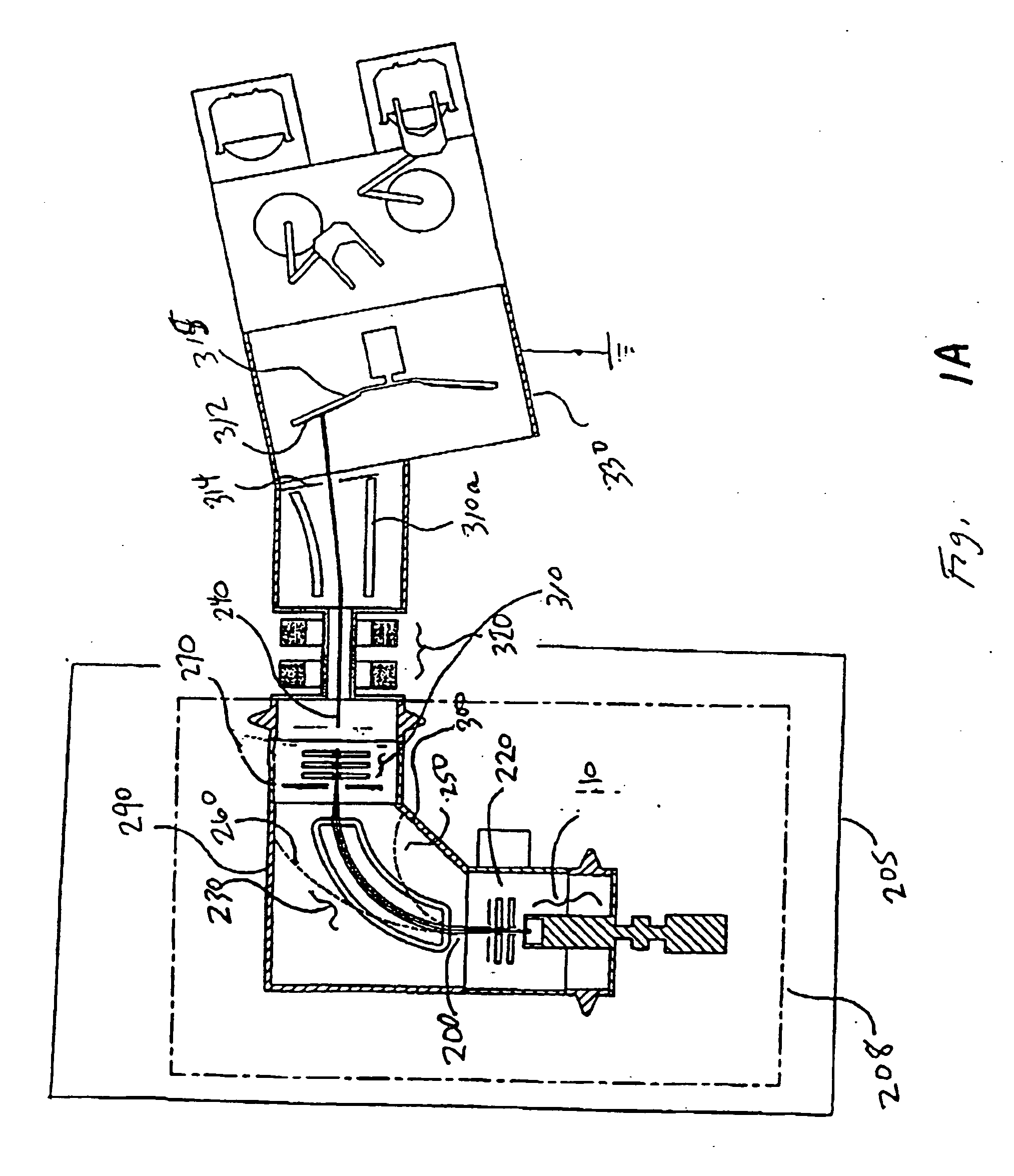

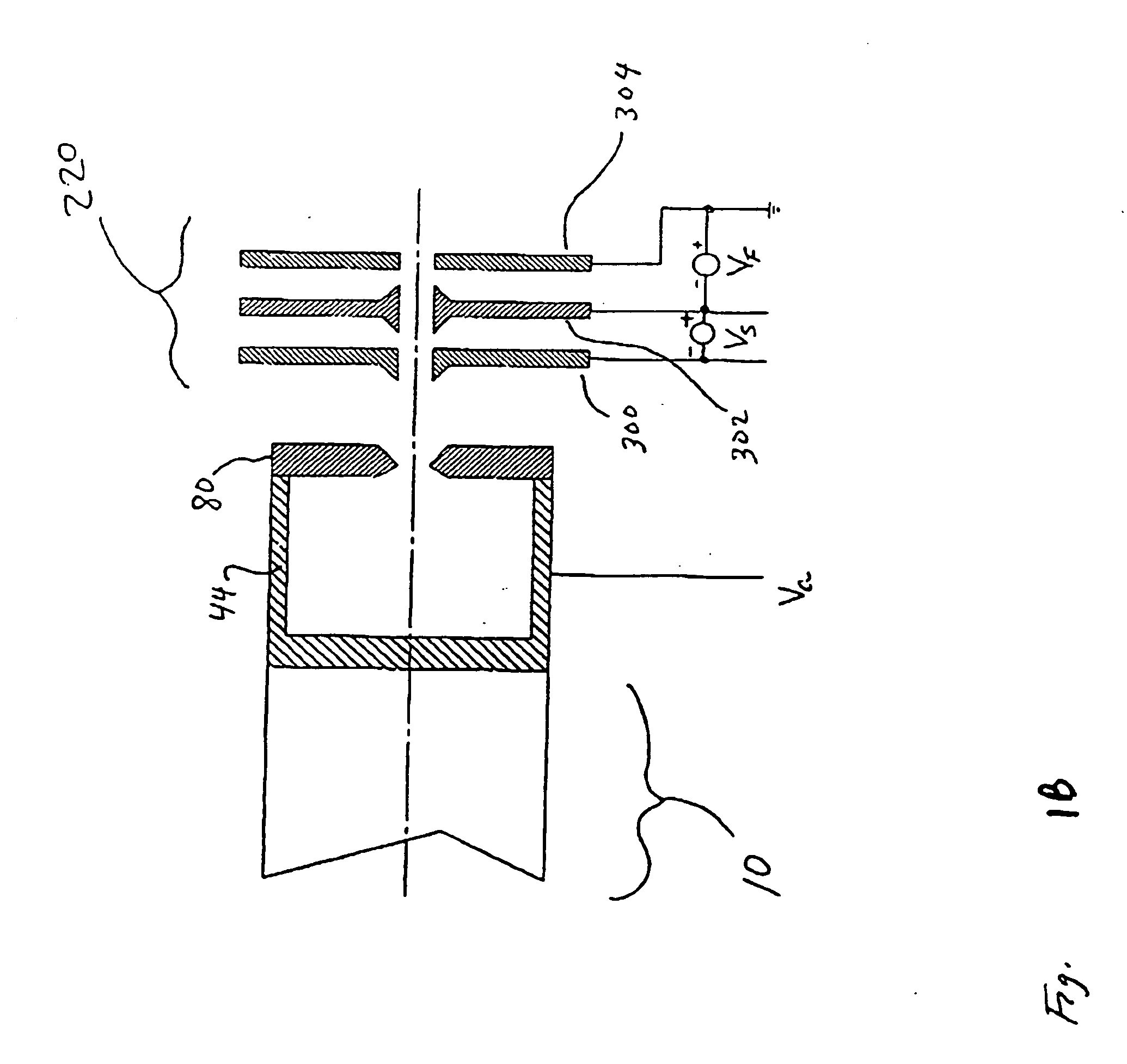

Ion implantation device and a method of semiconductor manufacturing by the implantation of boron hydride cluster ions

InactiveUS20060097193A1Improve productivityLow costTransistorSemiconductor/solid-state device manufacturingMolecular clusterDevice material

An ion implantation device and a method of manufacturing a semiconductor device is described, wherein ionized boron hydride molecular clusters are implanted to form P-type transistor structures. For example, in the fabrication of Complementary Metal-Oxide Semiconductor (CMOS) devices, the clusters are implanted to provide P-type doping for Source and Drain structures and for Polygates; these doping steps are critical to the formation of PMOS transistors. The molecular cluster ions have the chemical form BnHx+ and BnHx− where 10

Owner:SEMEQUIP

Ion implantation device and a method of semiconductor manufacturing by the implantation of ions derived from carborane molecular species

InactiveUS20080305598A1High doseLow-energy implantTransistorElectric discharge tubesImpact ionizationHigh doses

An ion implantation device and a method of manufacturing a semiconductor device is described, wherein ionized carborane cluster ions are implanted into semiconductor substrates to perform doping of the substrate. The carborane cluster ions have the chemical form C2B10Hx+, C2B8Hx+ and C4B18Hx+and are formed from carborane cluster molecules of the form C2B10H12 ,C2B8H10 and C4B18H22 The use of such carborane molecular clusters results in higher doping concentrations at lower implant energy to provide high dose low energy implants. In accordance with one aspect of the invention, the carborane cluster molecules may be ionized by direct electron impact ionization or by way of a plasma.

Owner:SEMEQUIP

Ion implantation device and a method of semiconductor manufacturing by the implantation of boron hydride cluster ions

InactiveUS20070194252A1Improve productivityLow costTransistorSemiconductor/solid-state device manufacturingMolecular clusterDevice material

An ion implantation device and a method of manufacturing a semiconductor device is described, wherein ionized boron hydride molecular clusters are implanted to form P-type transistor structures. The molecular cluster ions have the chemical form BnHx+and BnHx−, where 10<n<100 and 0≦x≦n+4. The use of such boron hydride clusters results in a dramatic increase in wafer throughput, as well as improved device yields through the reduction of wafer charging. A method of manufacturing a semiconductor device is further described, comprising the steps of: providing a supply of molecules containing a plurality of dopant atoms into an ionization chamber, ionizing said molecules into dopant cluster ions, extracting and accelerating the dopant cluster ions with an electric field, selecting the desired cluster ions by mass analysis, modifying the final implant energy of the cluster ion through post-analysis ion optics, and implanting the dopant cluster ions into a semiconductor substrate.

Owner:SEMEQUIP

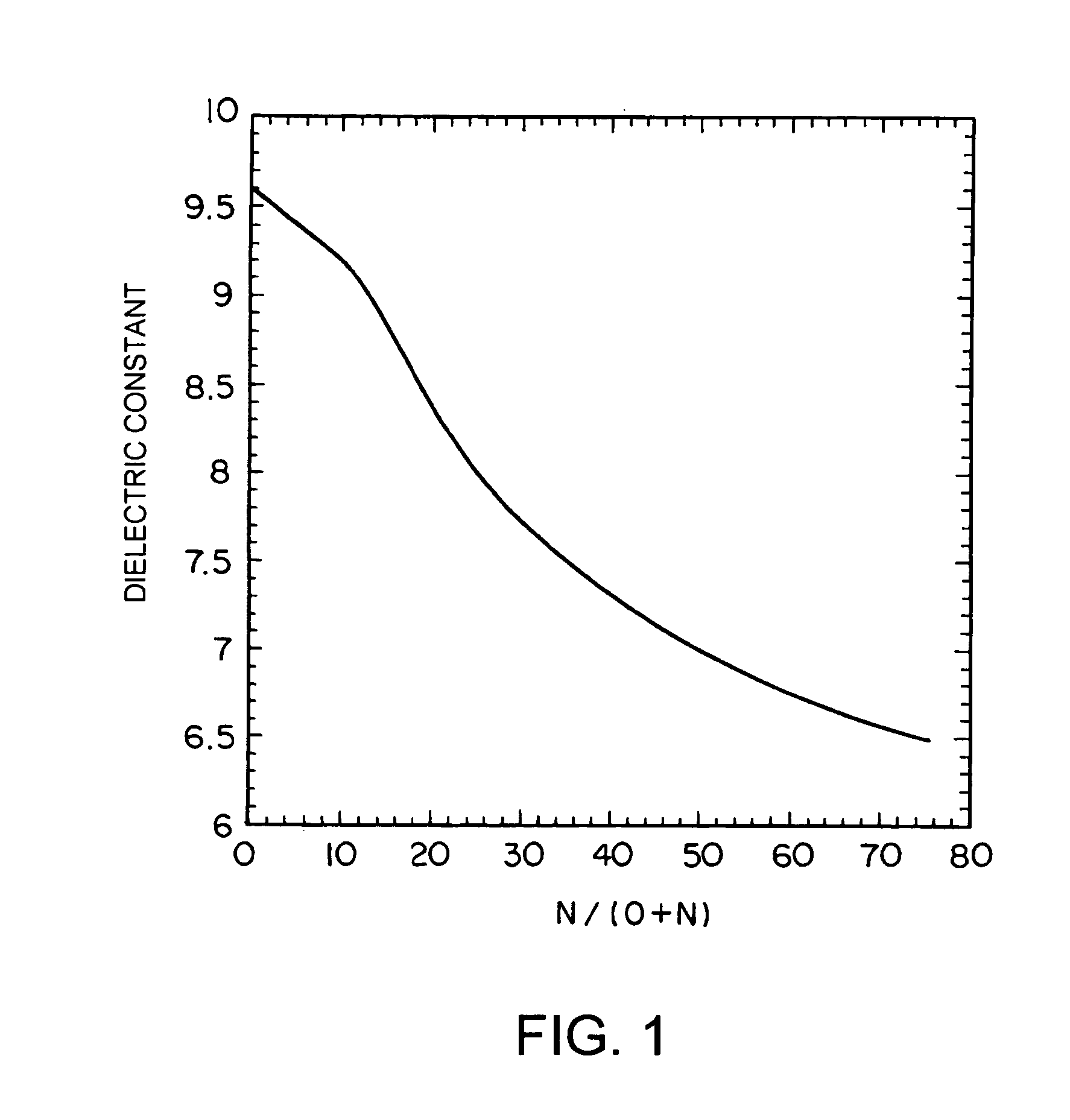

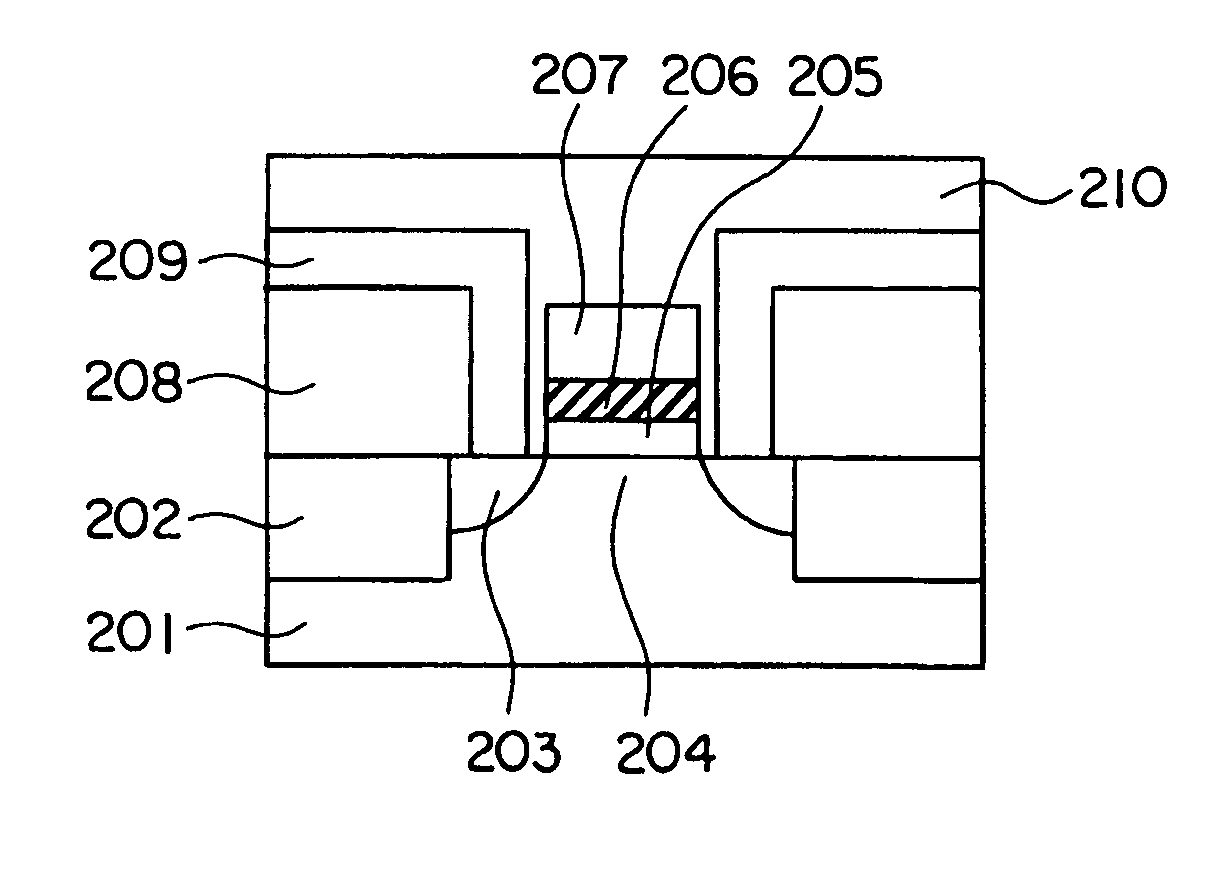

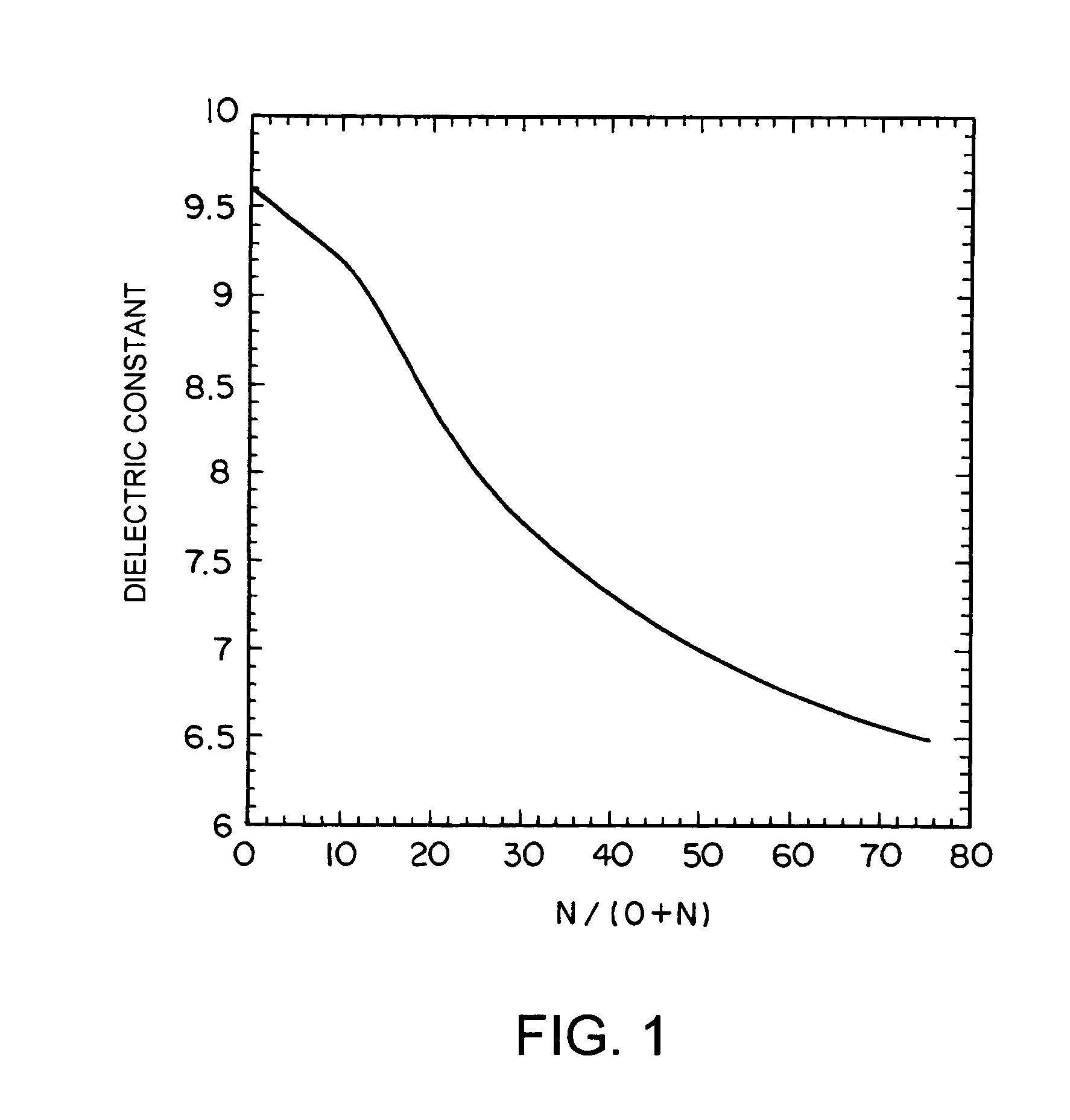

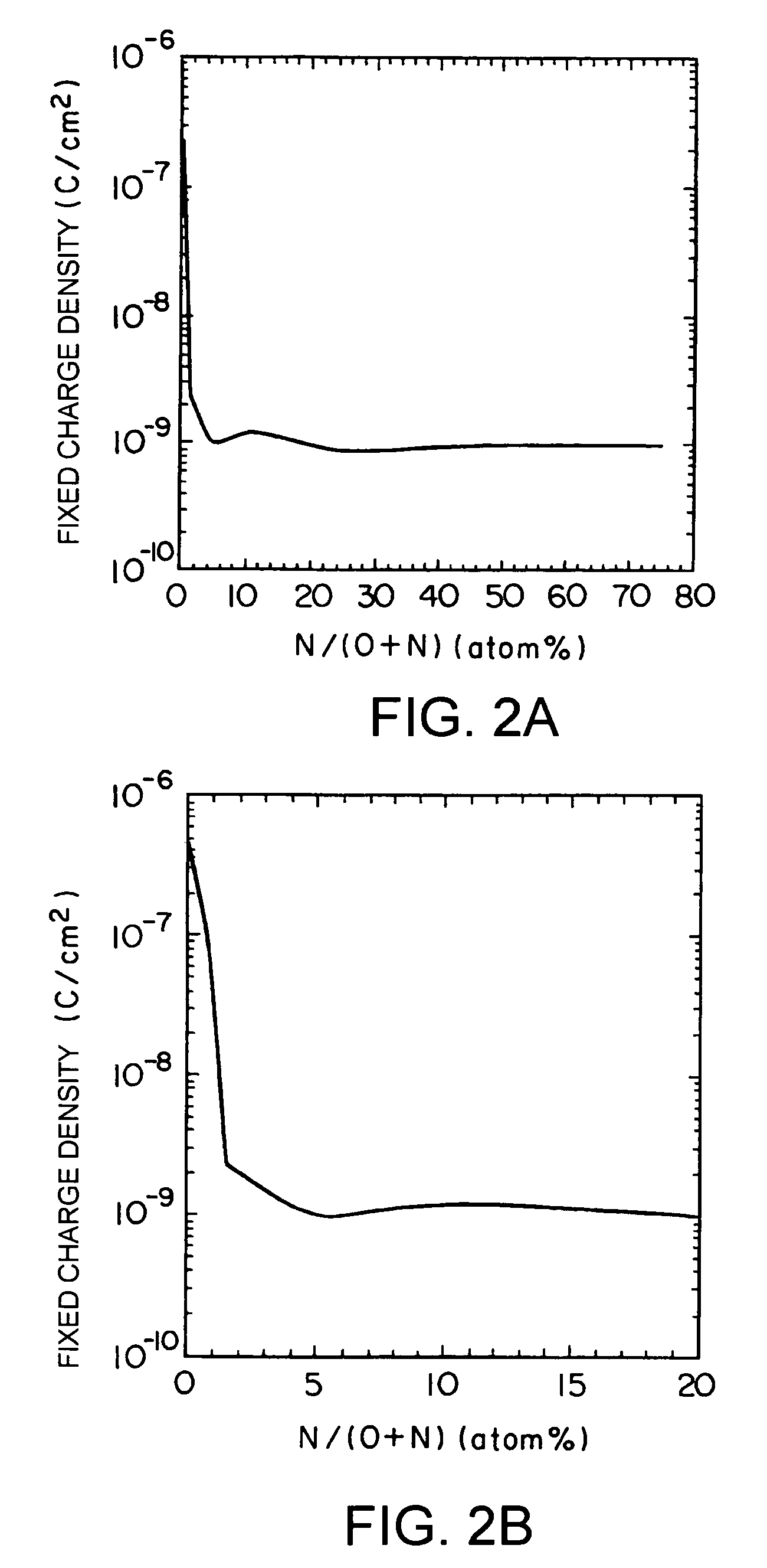

Semiconductor device and production method therefor

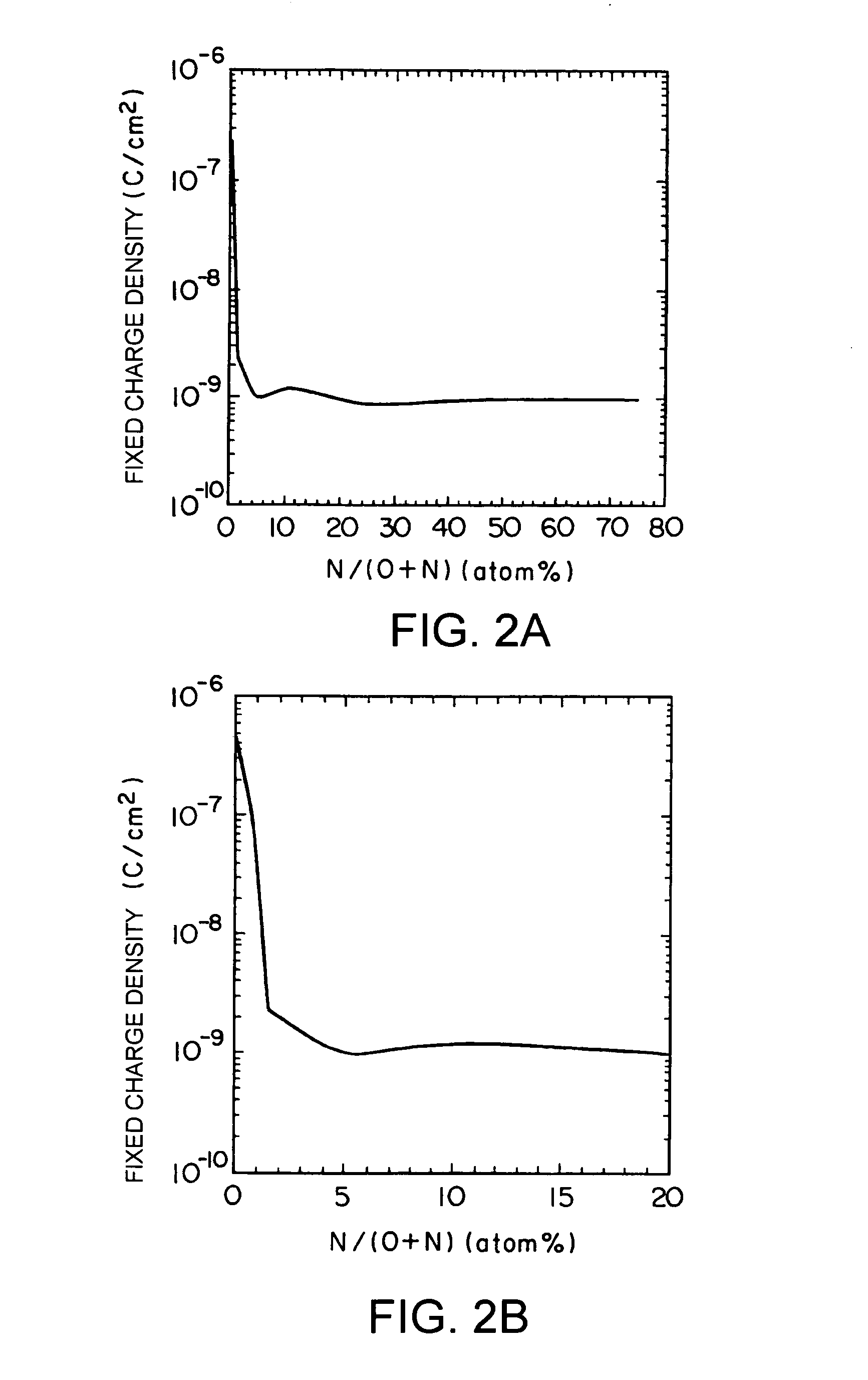

InactiveUS20050017319A1Improve responseVoltageSemiconductor/solid-state device manufacturingSemiconductor devicesImpurity diffusionDevice material

A semiconductor device has an MIS (metal-insulating film-semiconductor) structure, and a film mainly containing Al, O, and N atoms is used on a semiconductor. Alternatively, a semiconductor device has an MIS structure, and a film mainly containing Al, O, and N atoms is provided as a gate insulating film on a channel region between a source and a drain. Characteristics required of a gate insulating film of a 0.05 μm-gate-length-generation semiconductor transistor are satisfied. In particular, no fixed charge is included in the film, and impurity diffusion is reduced.

Owner:GK BRIDGE 1

Method for providing a nanocellulose involving modifying cellulose fibers

ActiveUS20110036522A1Increases anionic charge densityReduce energy consumptionNanostructure manufacturePulp properties modificationAqueous electrolyteCellulose fiber

A method for the manufacturing of nanocellulose. The method includes a first modification of the cellulose material, where the cellulose fibres are treated with an aqueous electrolyte-containing solution of an amphoteric cellulose derivative. The modification is followed by a mechanical treatment. By using this method for manufacturing nanocellulose, clogging of the mechanical apparatus is avoided. Also the nanocellulose is manufactured in accordance with the method and uses of the cellulose.

Owner:INNVENTIA

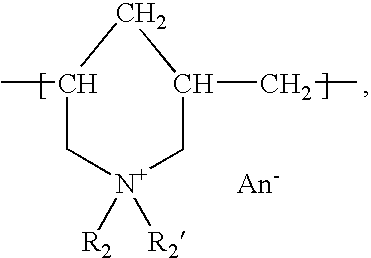

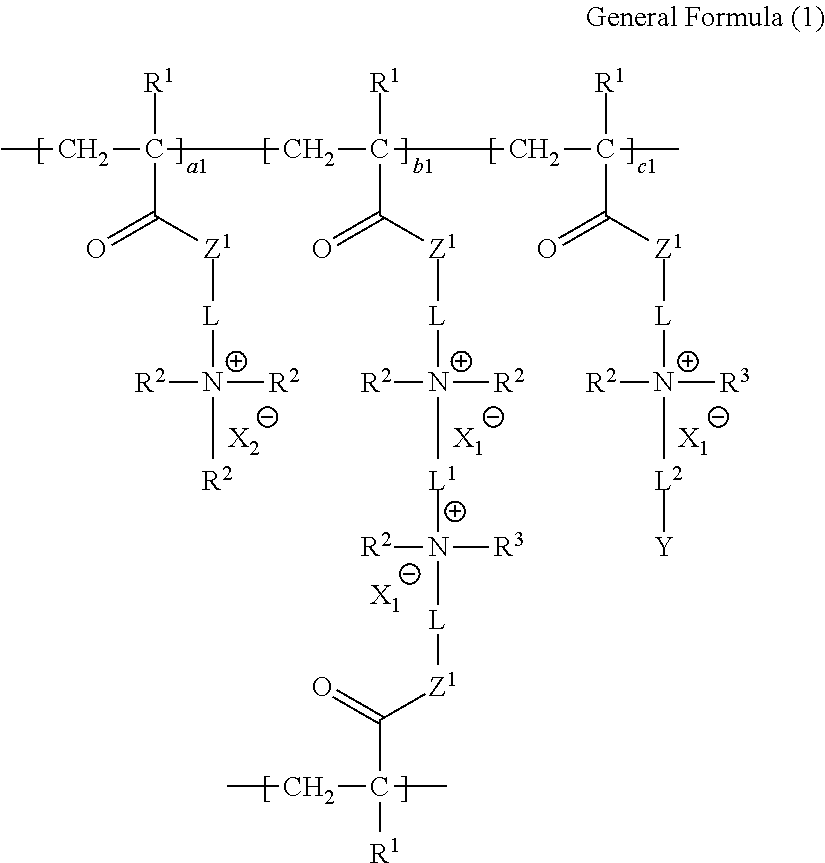

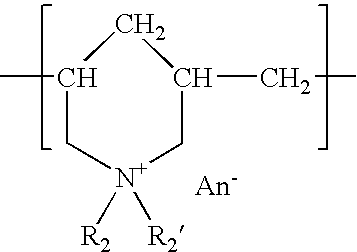

Ion-exchange polymer and production method therefor, electrolyte membrane and production method therefor, and composition for producing ion-exchange polymer

ActiveUS20160367980A1Reduce membrane resistanceReduce water permeabilityIon-exchange process apparatusSolid electrolytesHydrogen atomHalogen

There are provided an ion-exchange polymer including a structure represented by the following General Formula (1) and a production method therefor, an electrolyte membrane and a production method therefor, and a composition for producing an ion-exchange polymer.In a case where the sum of a1, b1, and c1 is 1.000, a1 is 0.000 to 0.750, b1 is 0.240 to 0.990, and c1 is 0.001 to 0.100. L represents an alkylene group, L1 and L2 each represent a divalent linking group, R1 is a hydrogen atom or an alkyl group, R2 and R3 each represent an alkyl group or an allyl group, X1− and X2− each represent an inorganic or organic anion, and Y represents a halogen atom. Z1 represents —O— or —NRa—, and Ra represents a hydrogen atom or an alkyl group.

Owner:FUJIFILM CORP

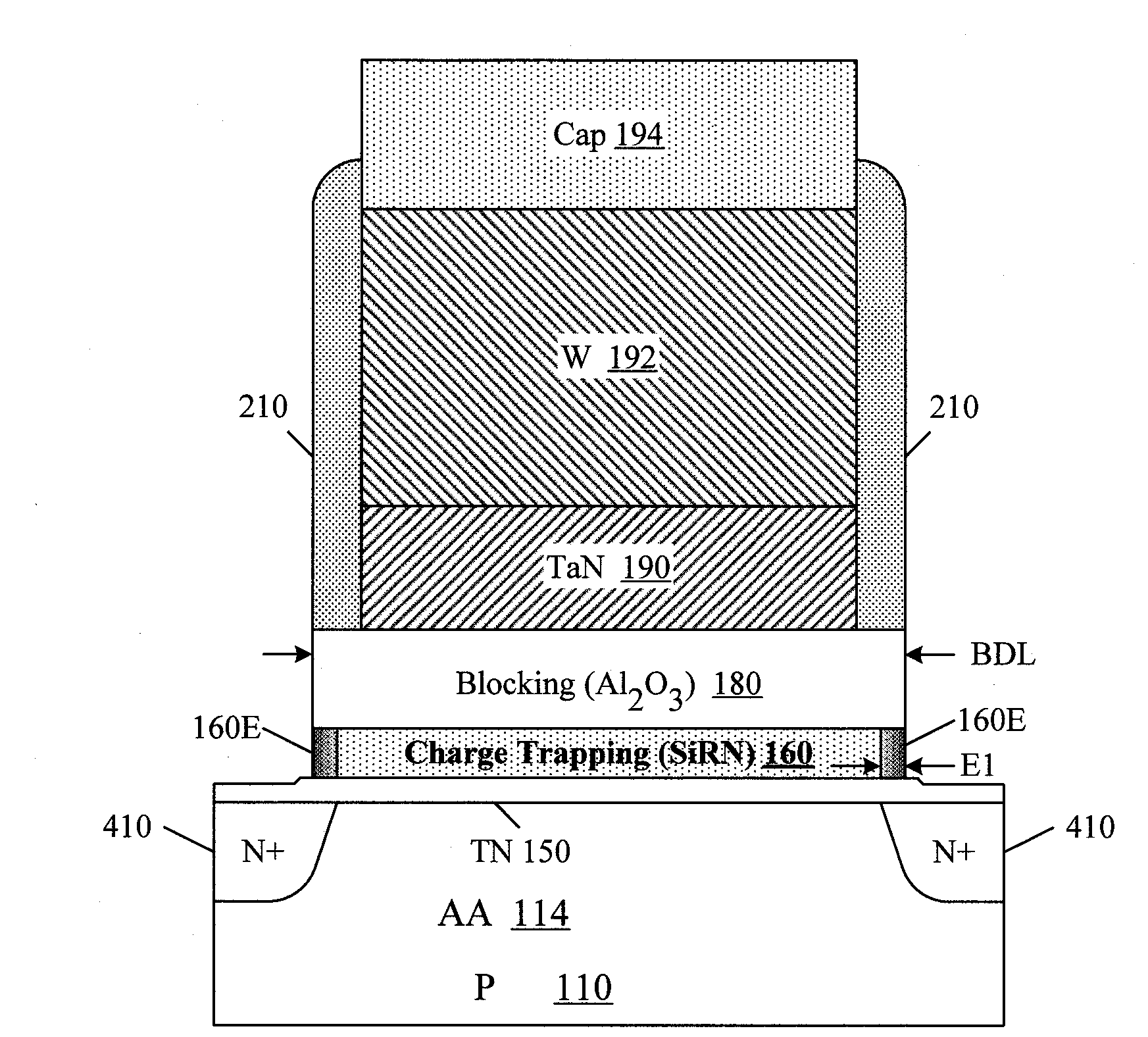

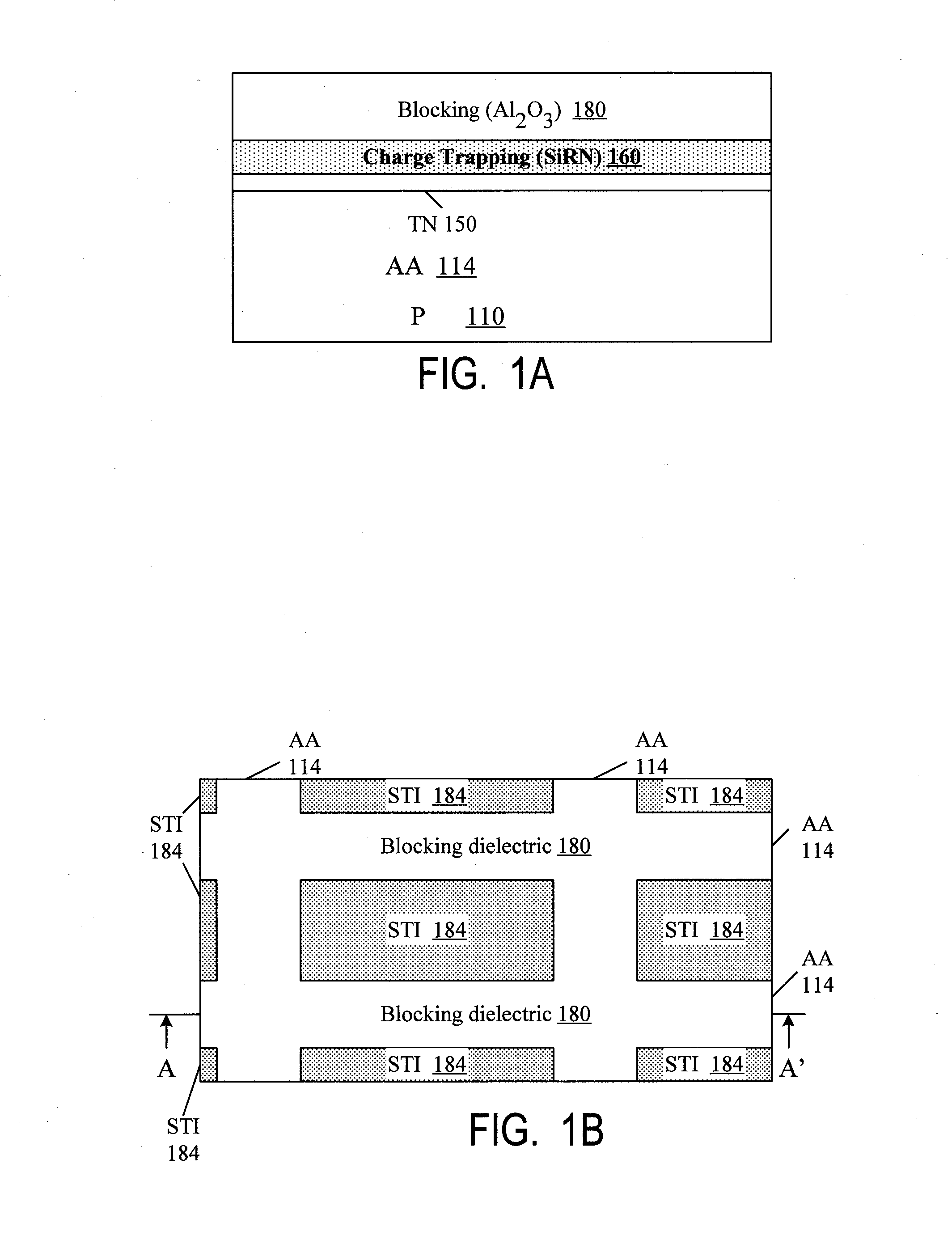

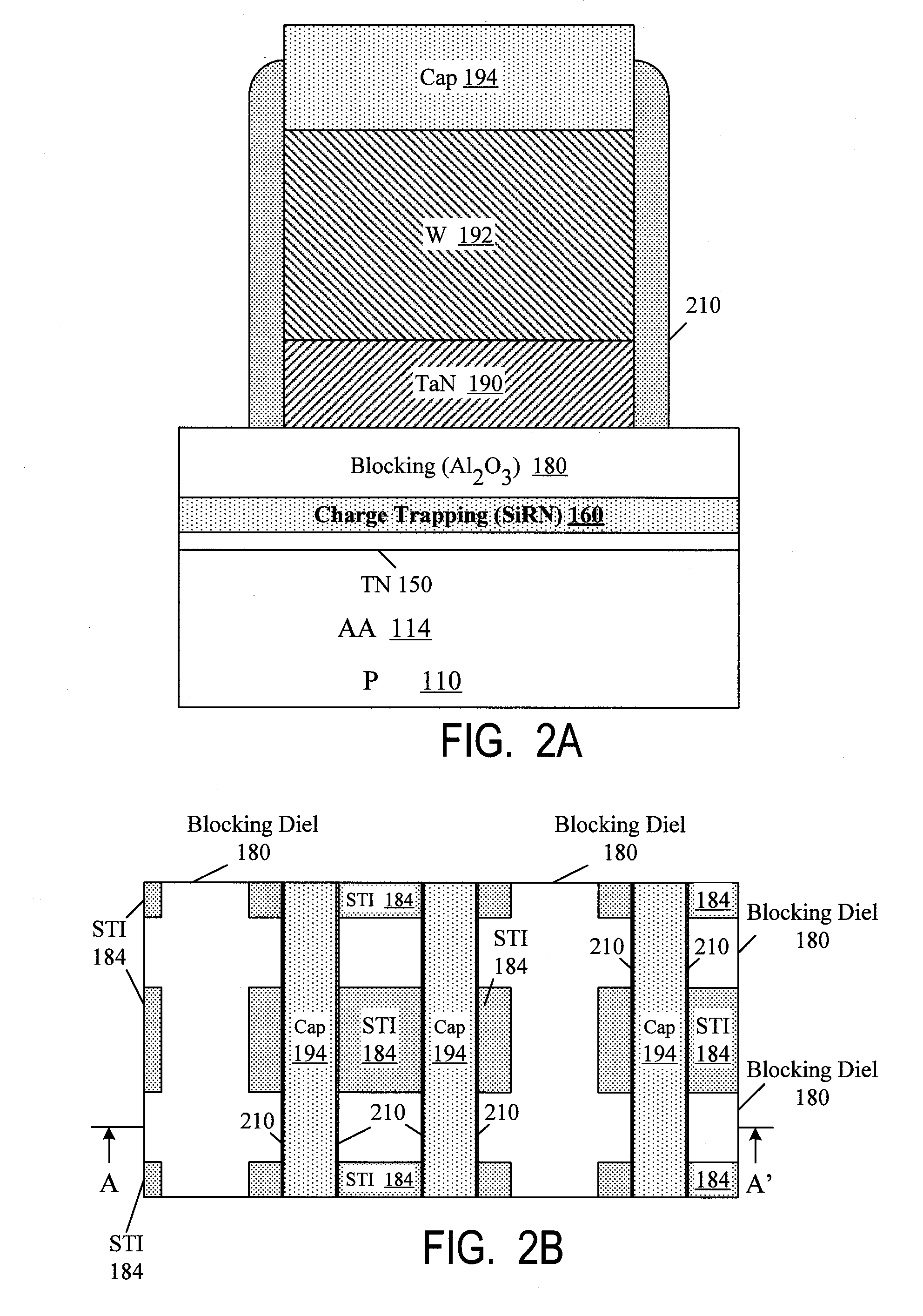

Nonvolatile memories with charge trapping dielectric modified at the edges

InactiveUS20100059808A1Reduce charge densityTotal current dropTransistorSolid-state devicesDielectricTrapping

A nonvolatile memory cell has charge trapping dielectric (160) which has been modified (i.e. oxidized) adjacent to edges of blocking dielectric (180). The modification reduces the charge-trapping density adjacent to the edges of the blocking dielectric, and hence reduces the leakage current at the edges. Other features are also provided.

Owner:PROMOS TECH PTE LTD

Ion implantation device and a method of semiconductor manufacturing by the implantation of boron hydride cluster ions

InactiveUS20070181830A1Improve productivityLow costTransistorSemiconductor/solid-state device manufacturingMolecular clusterDevice material

An ion implantation device and a method of manufacturing a semiconductor device is described, wherein ionized boron hydride molecular clusters are implanted to form P-type transistor structures. The molecular cluster ions have the chemical form BnHx+ and BnHx−, where 10<n<100 and 0≦x≦n+4. The use of such boron hydride clusters results in a dramatic increase in wafer throughput, as well as improved device yields through the reduction of wafer charging. A method of manufacturing a semiconductor device is further described, comprising the steps of: providing a supply of molecules containing a plurality of dopant atoms into an ionization chamber, ionizing said molecules into dopant cluster ions, extracting and accelerating the dopant cluster ions with an electric field, selecting the desired cluster ions by mass analysis, modifying the final implant energy of the cluster ion through post-analysis ion optics, and implanting the dopant cluster ions into a semiconductor substrate.

Owner:SEMEQUIP

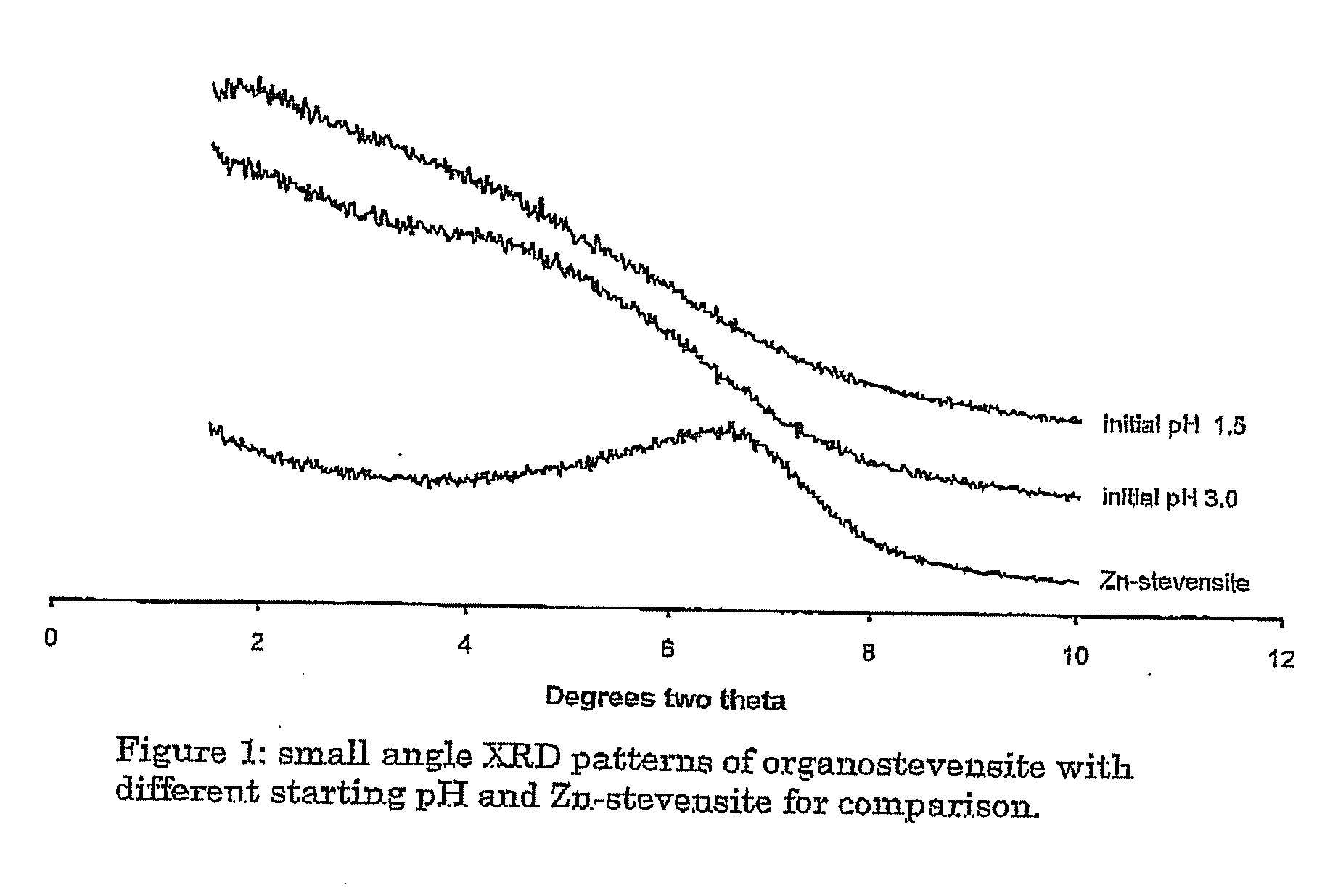

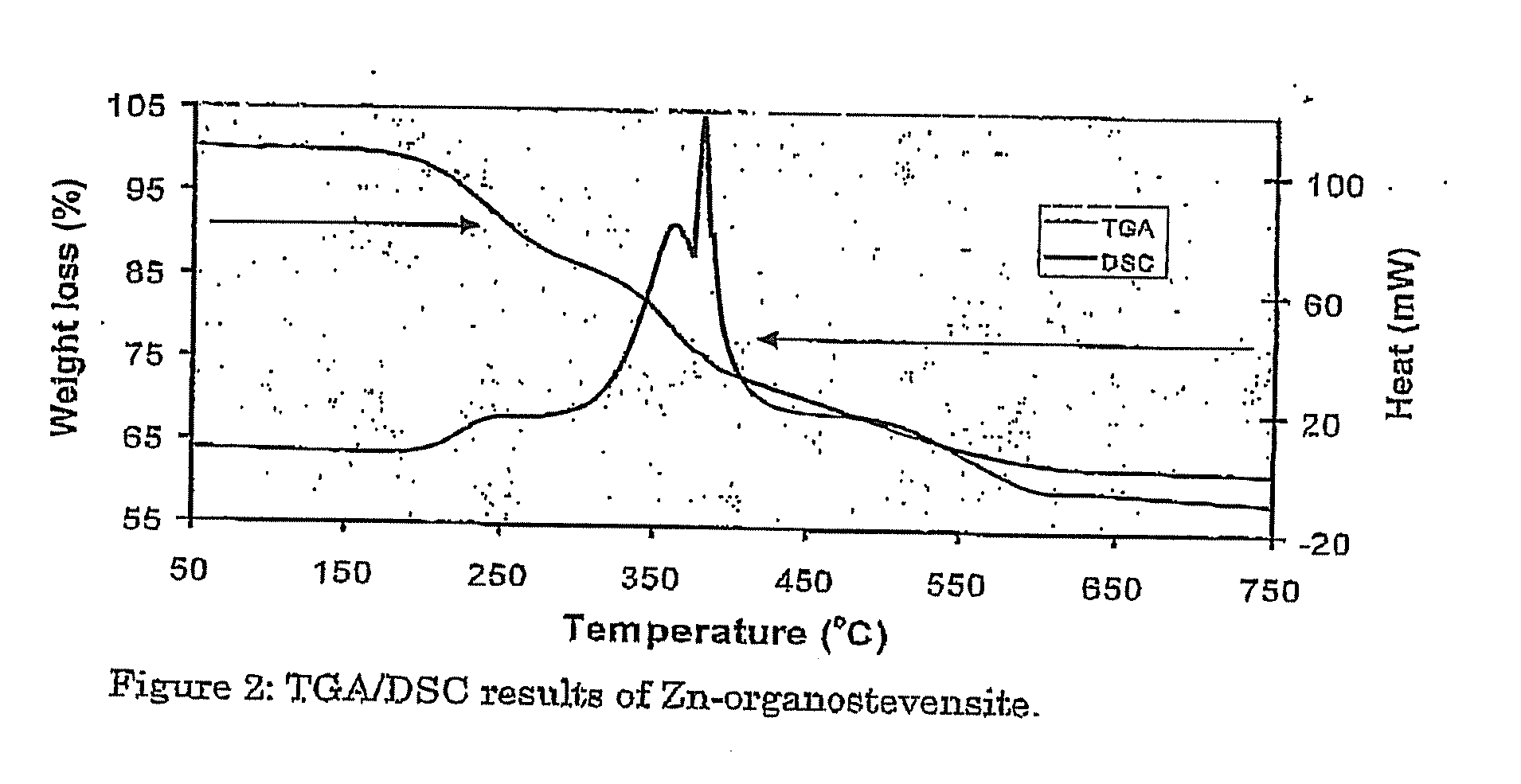

Synthetic Organoclay Materials

InactiveUS20070199481A1Easy to produceReadily dispersibleSilicon compoundsMedicinal chemistryNanocomposite

Owner:BASF CATALYSTS LLC

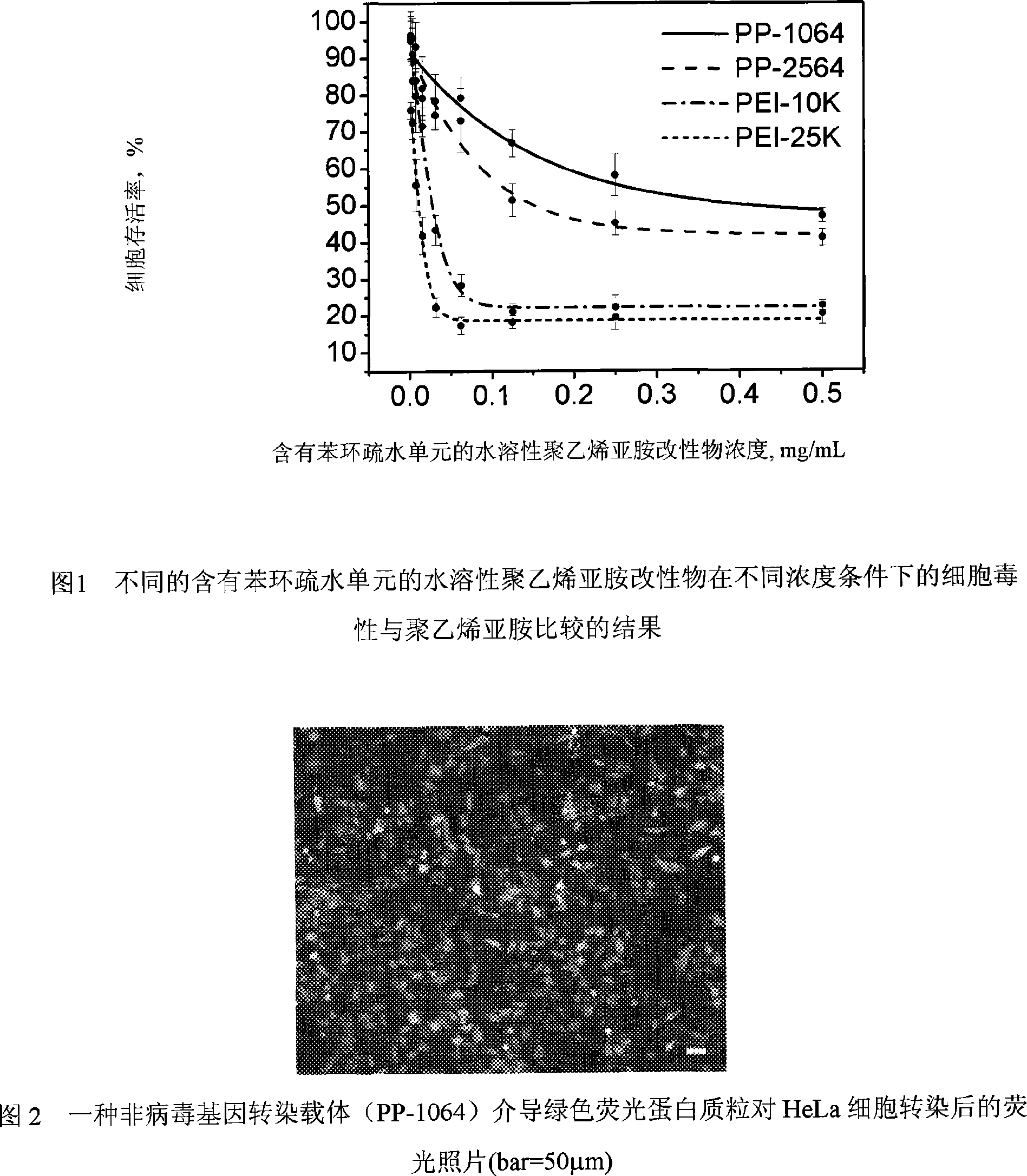

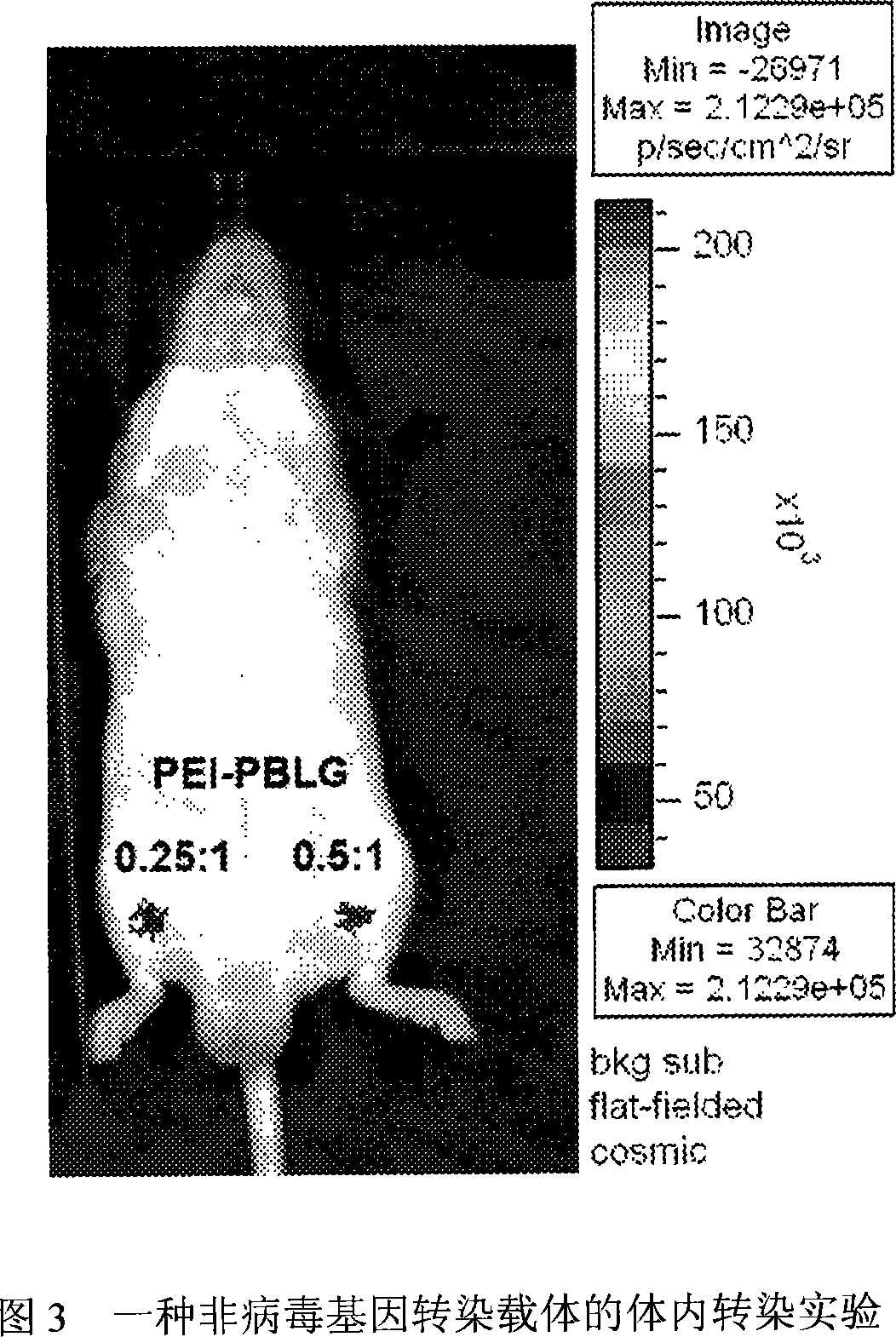

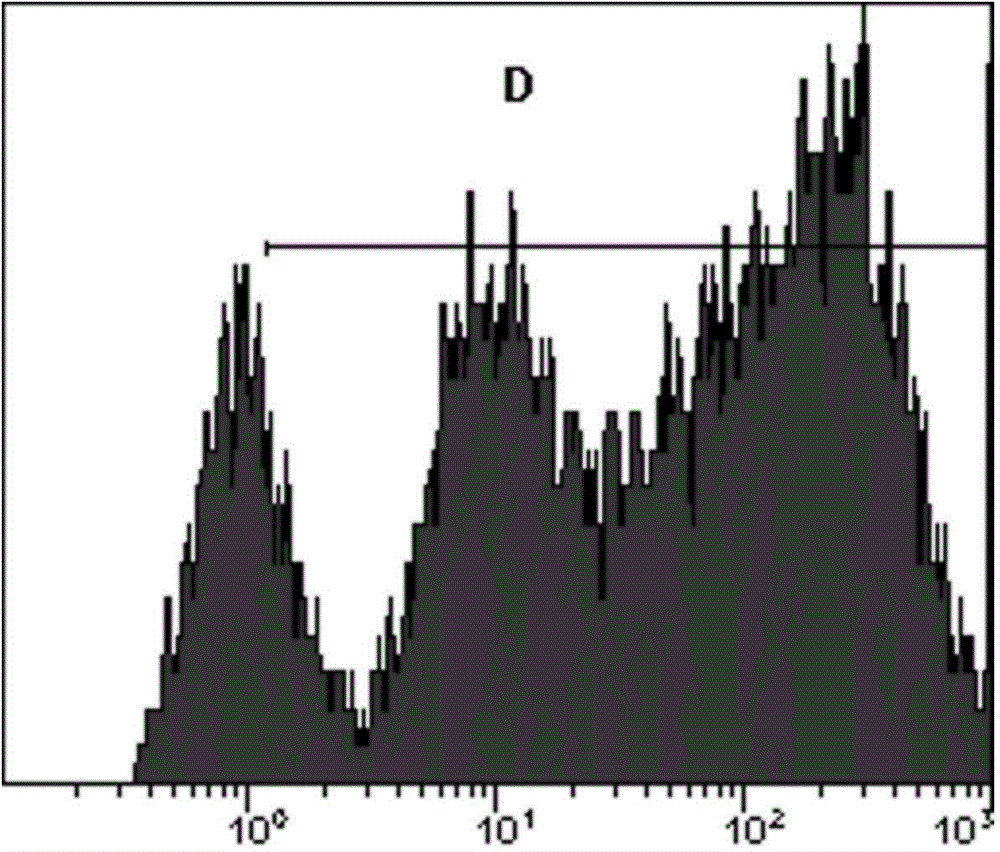

Non-virogene transfection carrier, complex particles of the same and plasmid DNA, preparing method and using method

InactiveCN101085356ALow toxicityHigh transfection efficiencyGenetic material ingredientsPharmaceutical non-active ingredientsPlasmid dnaIn vivo

The invention belongs to technology field of carrier material for non-viral gene transfection, and relates to a carrier material for non-viral gene transfection, plasmid DNA compound particle and preparation method and administration. The weight ratio of polyethylene imine and hydrophobic unit containing benzene ring is 1:9-4:6.The polyethylene imine is superbranched polyethylene imine (PEI) with average molecular weight of 1.8K-25K.The hydrophobic unit containing benzene ring is one or more of gamma -benzyl-L-glutamic acid, epsi -carbobenzoxy lysine and phenylalanine at any ratio. The water soluble polyethylene imine modified substance of hydrophobic unit containing benzene ring can compound with genic material to form a particle with positive charge on surface and particle diameter of 50-300nm.The compound particle can transfer loaded genic material into cell to realize expression of genic material and complete transfection process. The invention prepared non-gene transfection carrier material has the advantages of low toxicity and high up transfection efficiency; and can be used as transfection agent in vivo and in vitro.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

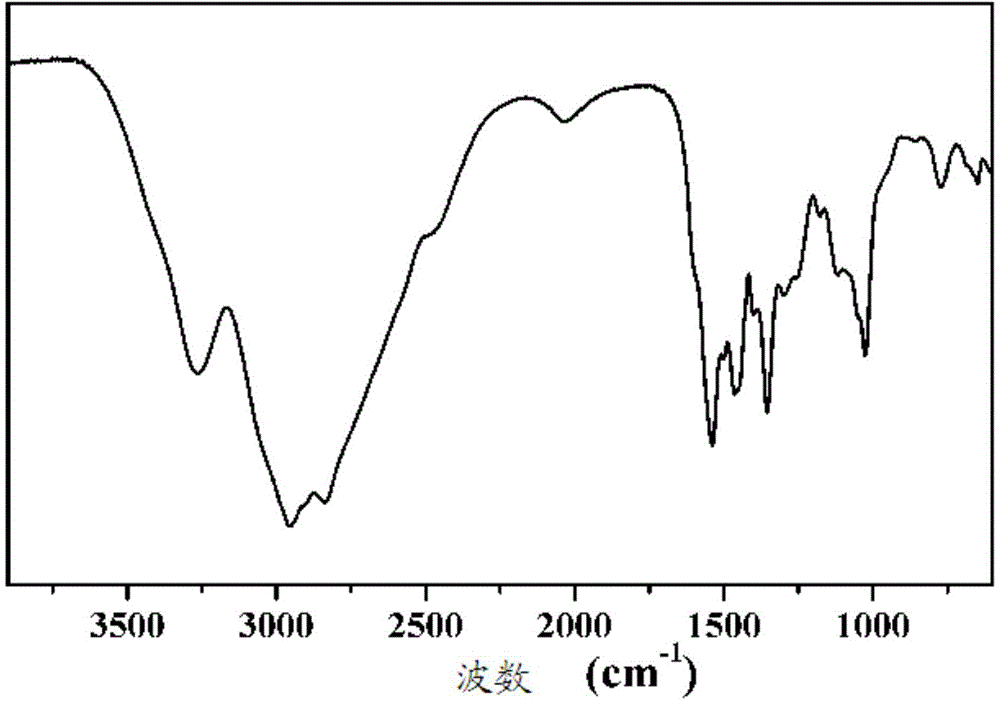

Paper-plastic lamination adhesive and method for preparing same

InactiveCN1632029AImprove freeze-thaw resistanceReduce charge densitySurface covering paperEster polymer adhesivesPolymer scienceAdhesive

Disclosed are a paper-plastic glue and its preparing method,comprising of high polymer latex 70-90%,resin 5-15%,inorganic powder filler 3-15%,dispersant 0.5-0.8%,thickener 0.2-0.5% and deformer 0.1-0.3%. Its preparing method is:1.pre the deformer with high polymer latex; 2. disperse; 3. add into inorganic filler and disperse;4.add into resin and disperse;5. add into thickener for adjusting the viscosity to be the construction one,the output and package the material.

Owner:SOUTH CHINA UNIV OF TECH

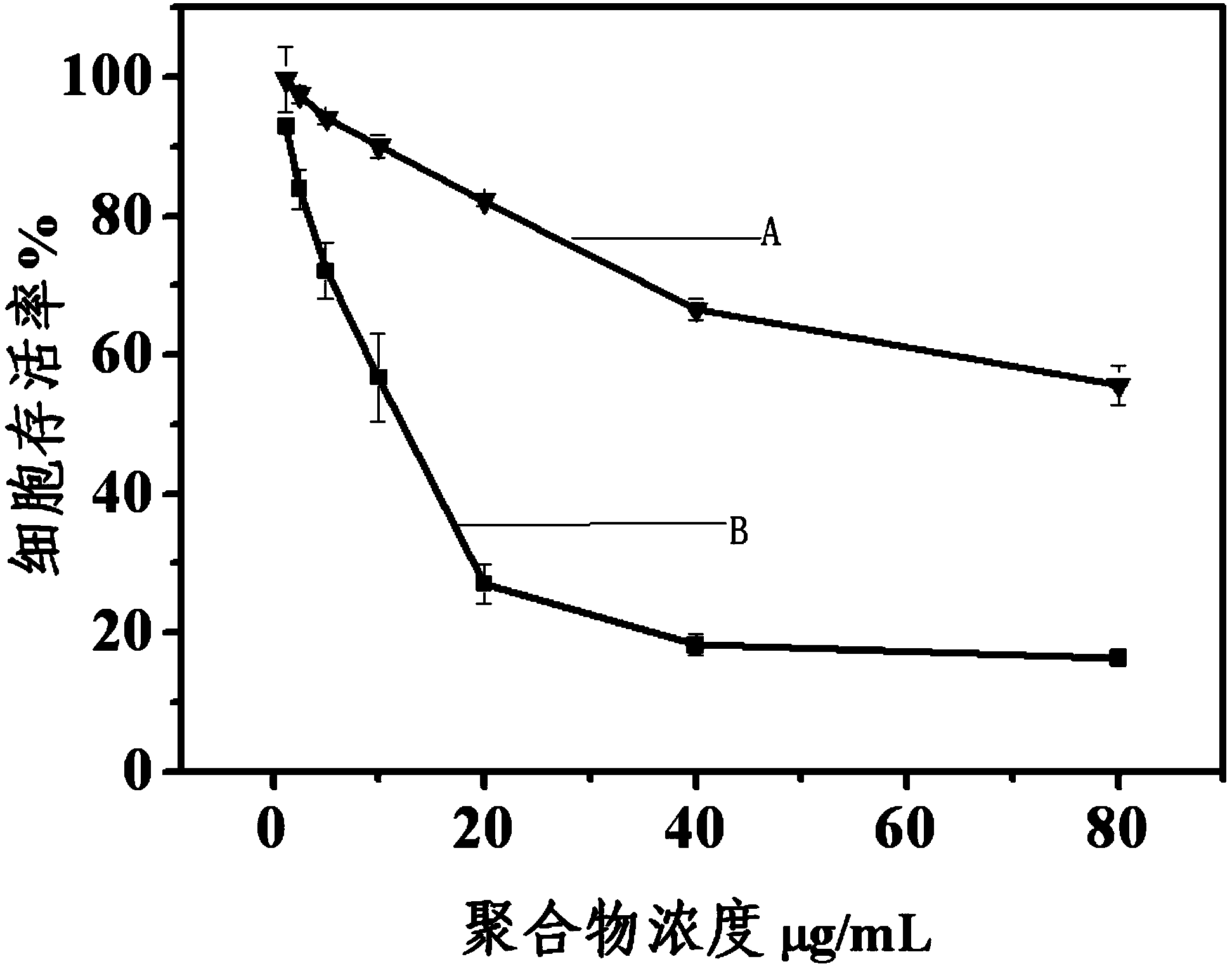

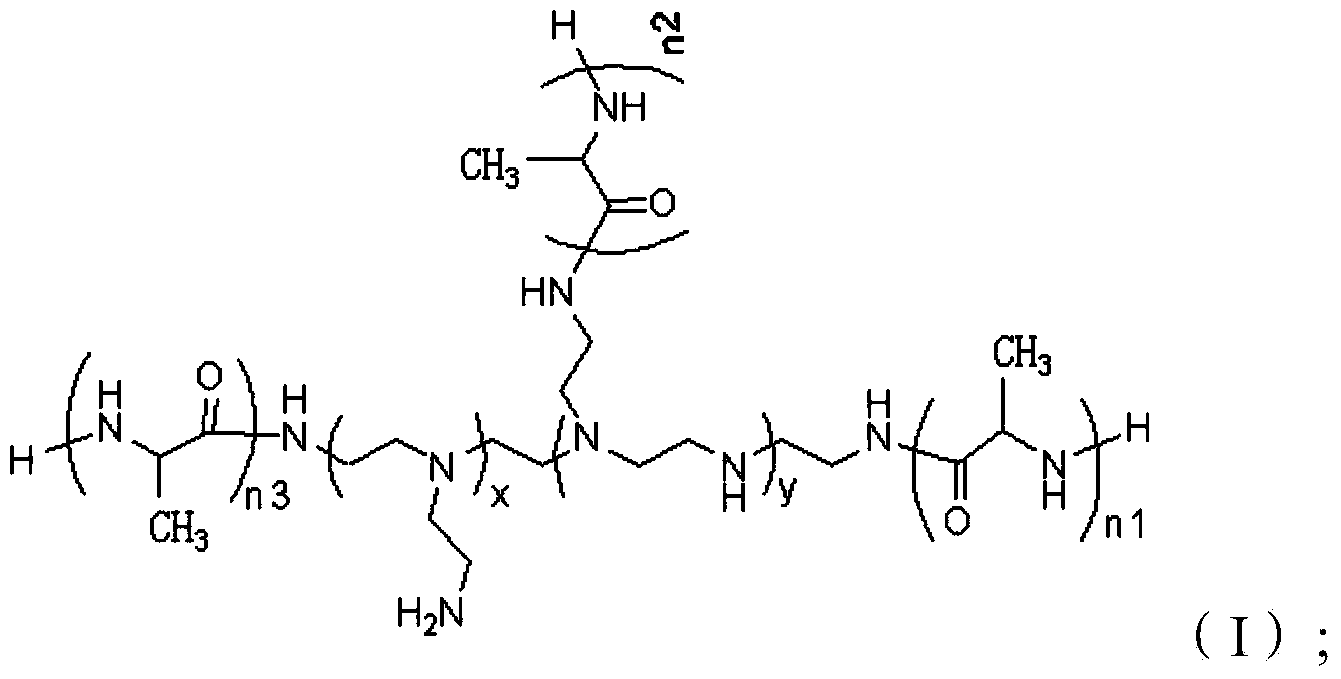

Hyperbranched polyethylene imine-grafted polyalanine copolymer and preparation method thereof

ActiveCN103709400ALow cytotoxicityEasy to manufactureOther foreign material introduction processesVector-based foreign material introductionPolymer scienceCarboxylic acid

The invention discloses a hyperbranched polyethylene imine-grafted polyalanine copolymer as shown in formula (I). Hydrophobic polyalanine is grafted on the hyperbranched polyethylene imine, so that integral quantity of electric charge of the copolymer is reduced, and charge density is effectively lowered, and therefore, cytotoxicity of the copolymer is lowered. While being taken as a gene carrier for application, the copolymer can be tightly combined with a gene substance, so that transfection efficiency is high. According to the invention, the hyperbranched polyethylene imine-grafted polyalanine is taken as macro-initiator to initiate L-alanine N-carboxylic acid anhydride to carry out ring opening polymerization to obtain the hyperbranched polyethylene imine-grafted polyalanine copolymer; the preparation process is simple.

Owner:长春金传科技有限公司

High dielectric constant MOSFET device

InactiveUS7385265B2Improve insulation performanceReduce charge densitySemiconductor/solid-state device manufacturingSemiconductor devicesDielectricMOSFET

A semiconductor device has an MIS (metal-insulating film-semiconductor) structure, and a film mainly containing Al, O, and N atoms is used on a semiconductor. Alternatively, a semiconductor device has an MIS structure, and a film mainly containing Al, O, and N atoms is provided as a gate insulating film on a channel region between a source and a drain. Characteristics required of a gate insulating film of a 0.05 μm-gate-length-generation semiconductor transistor are satisfied. In particular, no fixed charge is included in the film, and impurity diffusion is reduced.

Owner:GK BRIDGE 1

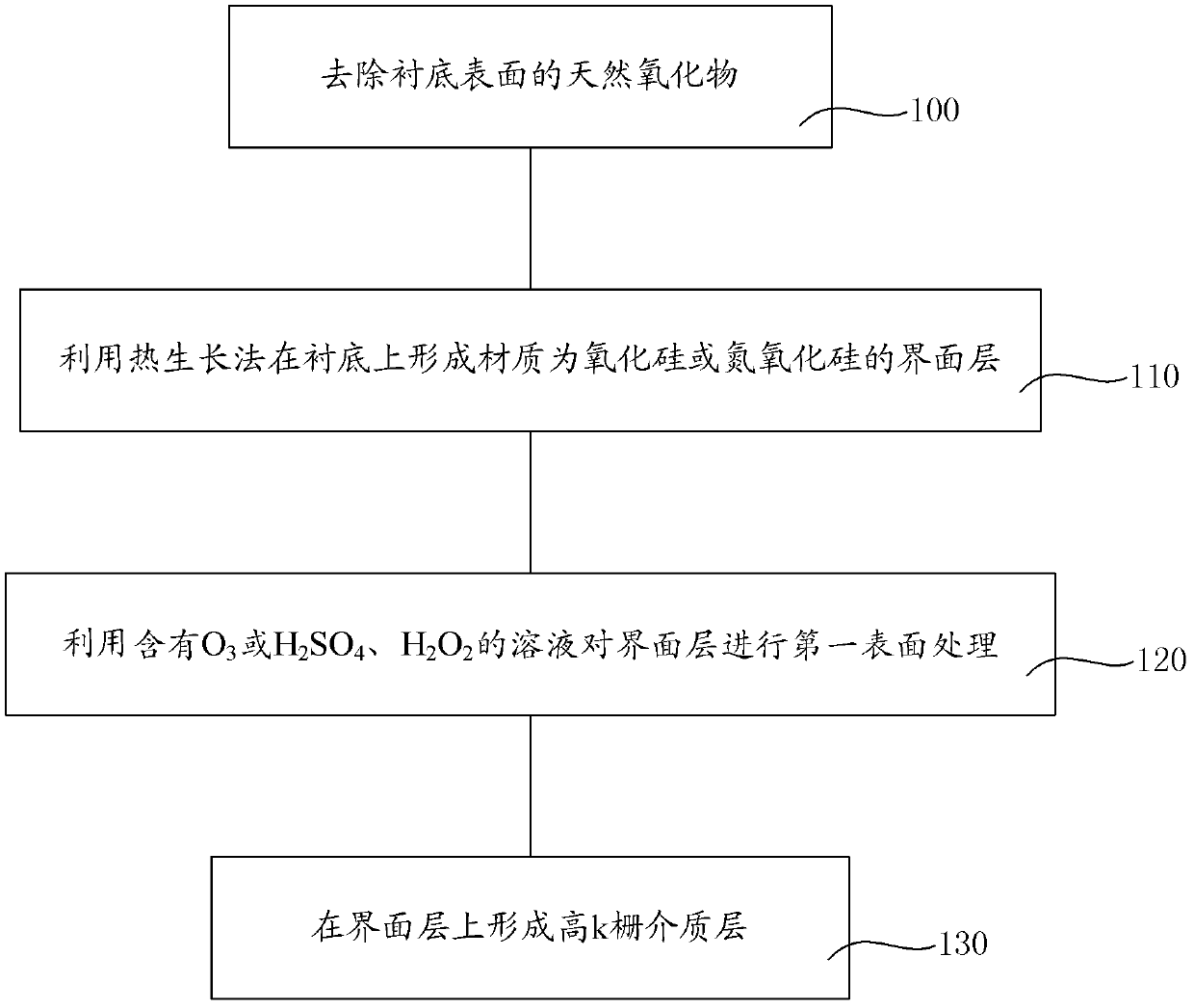

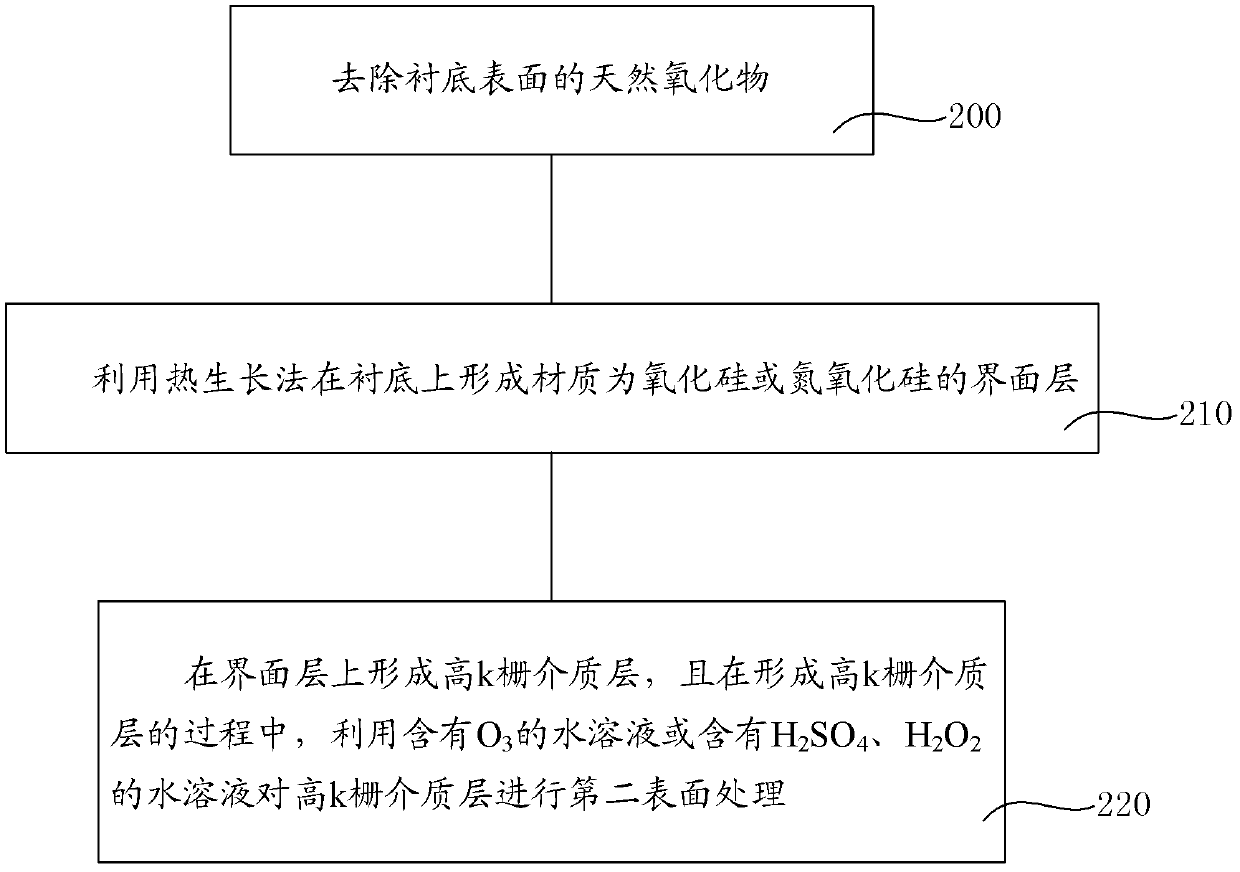

Manufacturing method for gate dielectric layer and manufacturing method for transistor

ActiveCN103295891AIncrease OH bondNucleation is easySemiconductor/solid-state device manufacturingGate dielectricInterface layer

The invention provides a manufacturing method for a gate dielectric layer and a manufacturing method for a transistor. The manufacturing method for the gate dielectric layer comprises the steps that an interface layer is formed on a substrate by the adoption of a thermal growth method; a high-k gate dielectric layer is formed on the interface layer; surface processing is conducted on the interface layer or the high-k gate dielectric layer by the adoption of aqueous solution containing O3 or H2SO4 and H2O2. According to the manufacturing method for the gate dielectric layer and the manufacturing method for the transistor, due to the facts that the best interface layer is formed by the adoption of the thermal growth method, and the surface processing is conducted on the interface layer or the high-k gate dielectric layer by the adoption of the aqueous solution containing O3 or H2SO4 and H2O2, a large number of OH keys which are suitable for improving the coverage rate of the high-k gate dielectric layer are formed on the surface of the interface layer or the high-k gate dielectric layer, the high-k gate dielectric layer can nucleate more easily on the interface layer, and interfacial characterization between the interface layer and the high-k gate dielectric layer is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

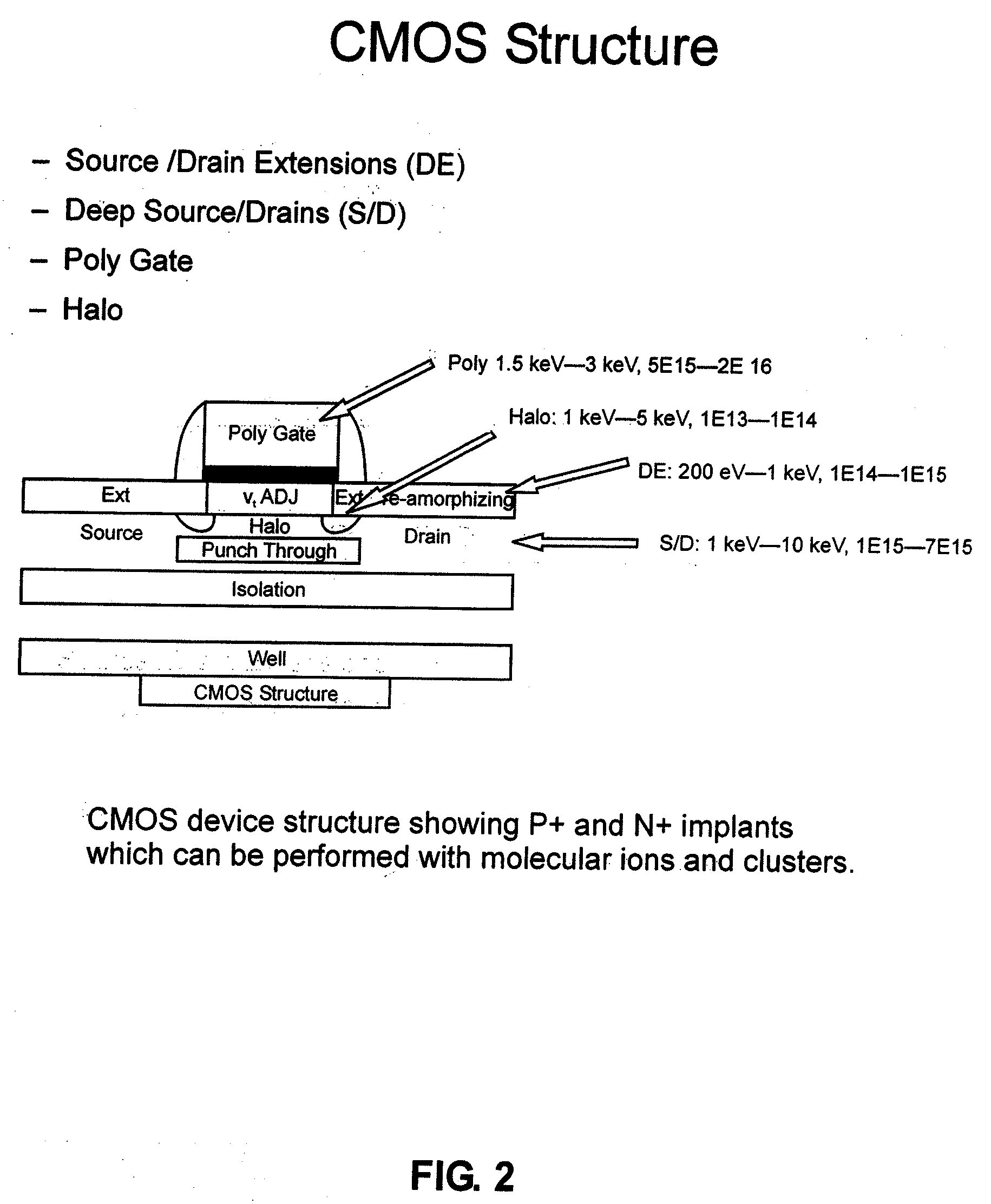

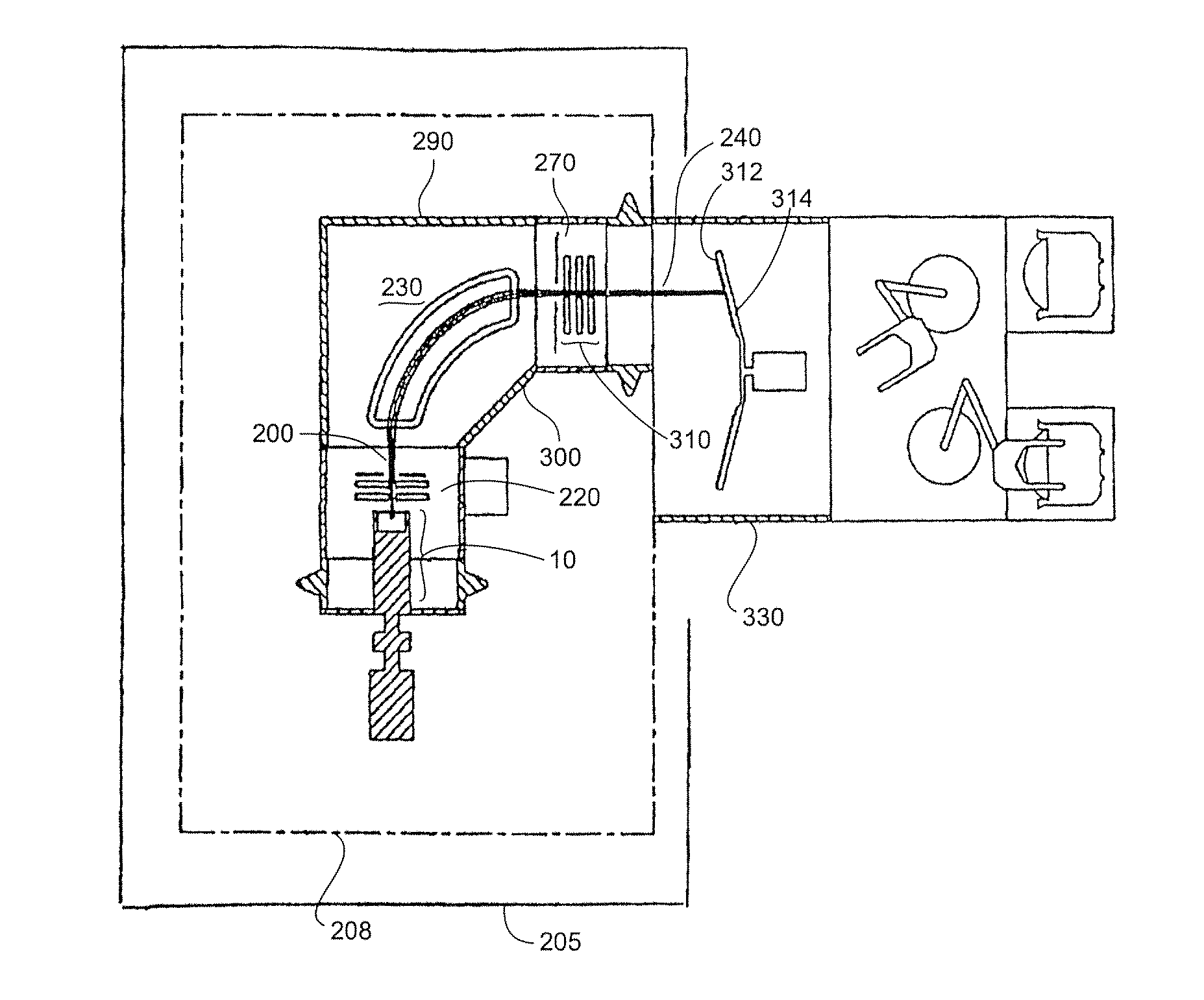

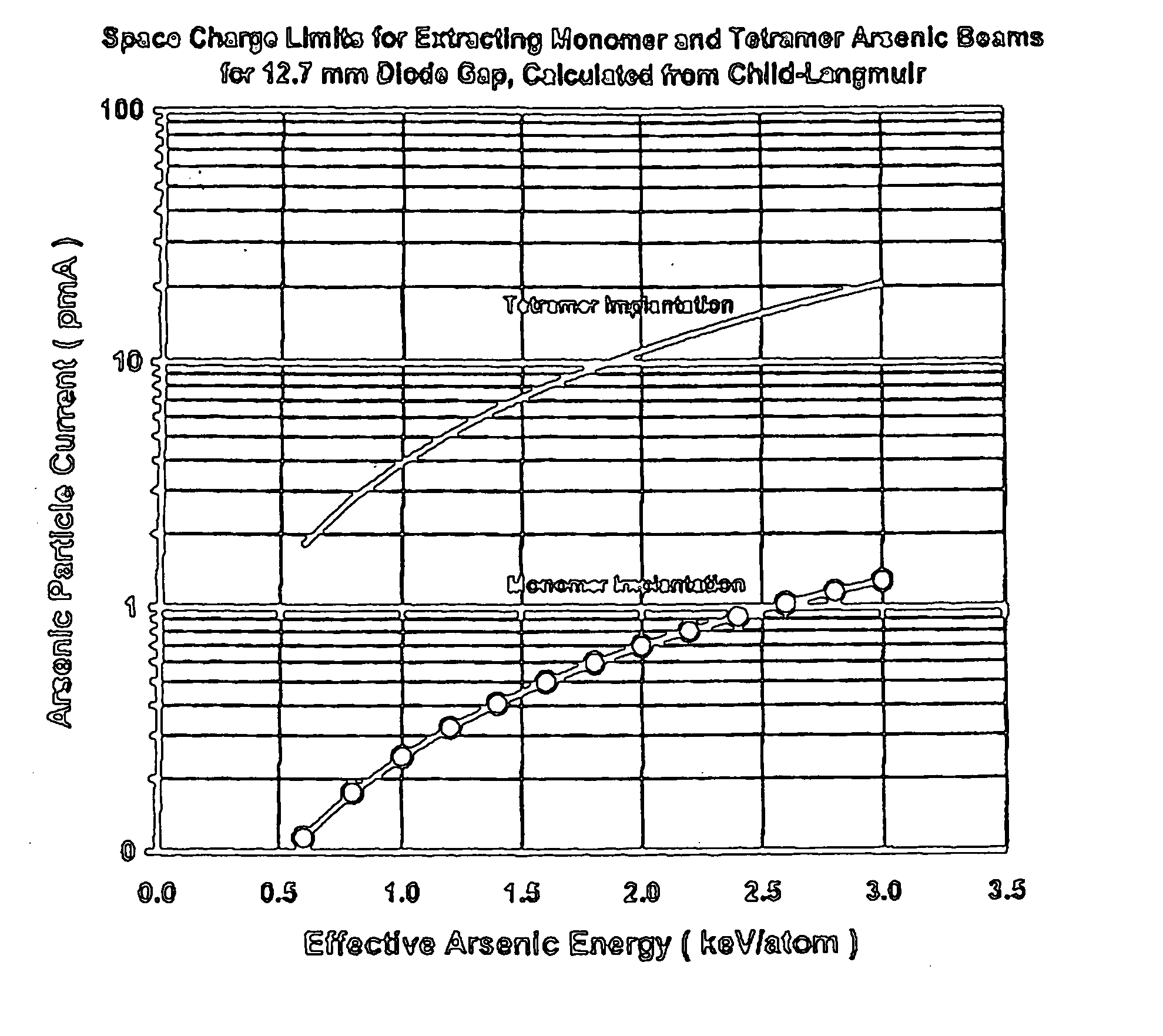

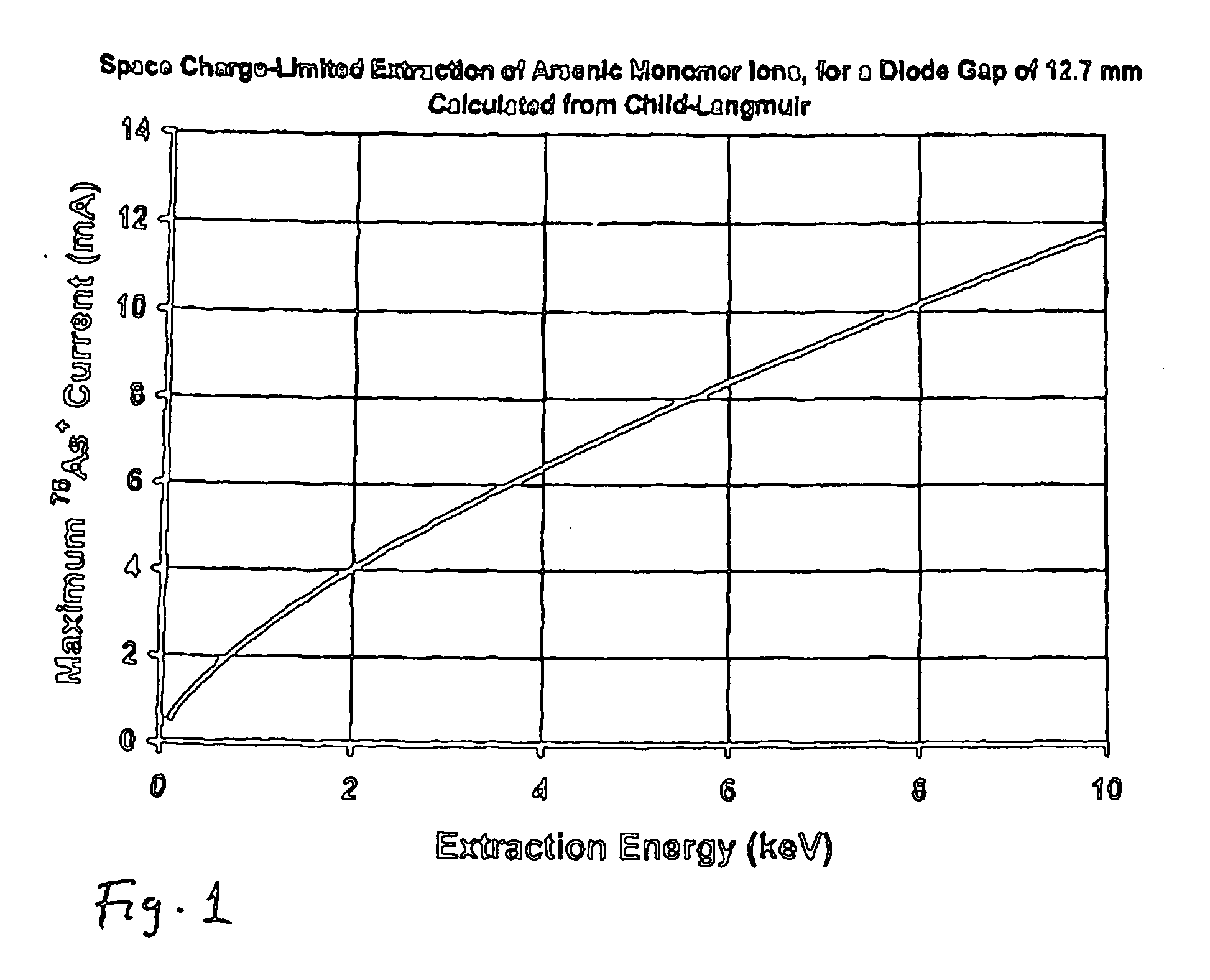

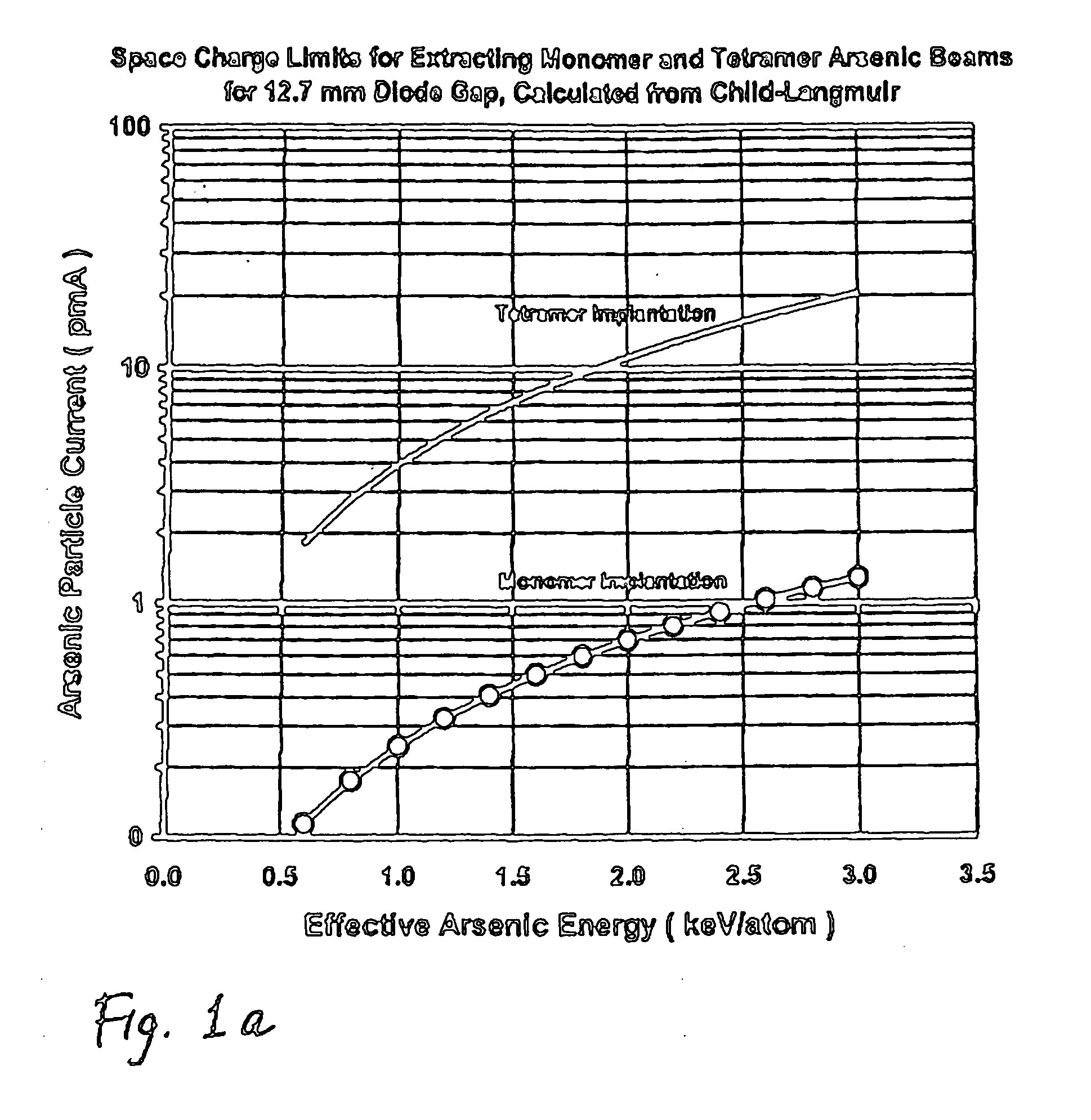

Method of manufacturing CMOS devices by the implantation of N- and P-type cluster ions

InactiveUS20070105325A1Reduce currentHigh throughputTransistorElectric discharge tubesCMOSIon source

A method of manufacturing a semiconductor device is described, wherein clusters of N- and P-type dopants are implanted to form the transistor structures in CMOS devices. For example, As4Hx+clusters and either B10Hx− or B10Hx+ clusters are used as sources of As and B doping, respectively, during the implants. An ion implantation system is described for the implantation of cluster ions into semiconductor substrates for semiconductor device manufacturing. A method of producing higher-order cluster ions of As, P, and B is presented, and a novel electron-impact ion source is described which favors the formation of cluster ions of both positive and negative charge states. The use of cluster ion implantation, and even more so the implantation of negative cluster ions, can significantly reduce or eliminate wafer charging, thus increasing device yields. A method of manufacturing a semiconductor device is further described, comprising the steps of providing a supply of dopant atoms or molecules into an ionization chamber, combining the dopant atoms or molecules into clusters containing a plurality of dopant atoms, ionizing the dopant clusters into dopant cluster ions, extracting and accelerating the dopant cluster ions with an electric field, selecting the desired cluster ion by mass analysis, modifying the final implant energy of the cluster ion through post-analysis ion optics, and implanting the dopant cluster ions into a semiconductor substrate. In general, dopant clusters contain n dopant atoms where n can be 2, 3, 4 or any integer number. This method provides the advantages of increasing the dopant dose rate to n times the implantation current with an equivalent per dopant atom energy of 1 / n times the cluster implantation energy. This is an effective method for making shallow transistor junctions, where it is desired to implant with a low energy per dopant atom.

Owner:SEMEQUIP

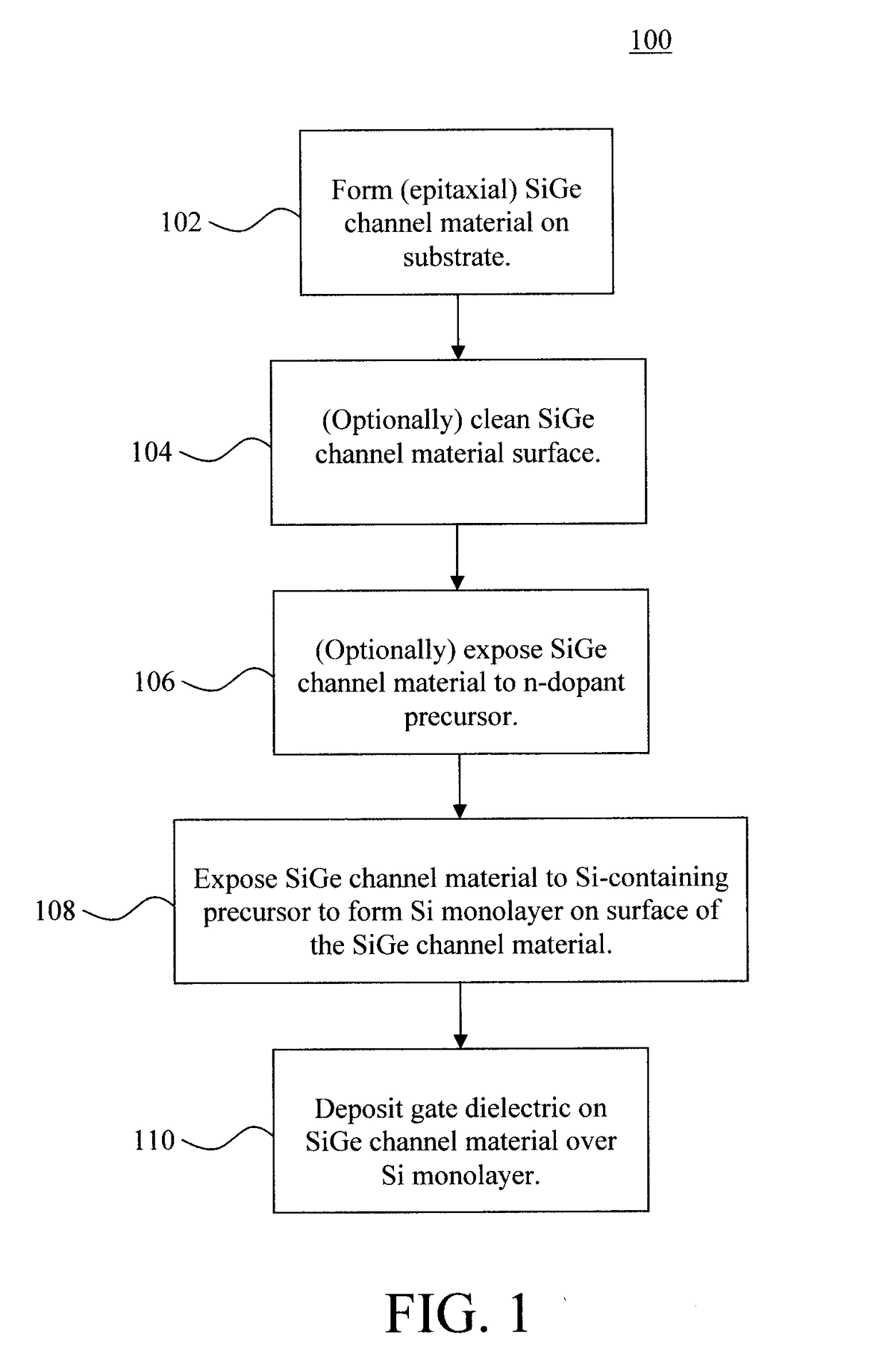

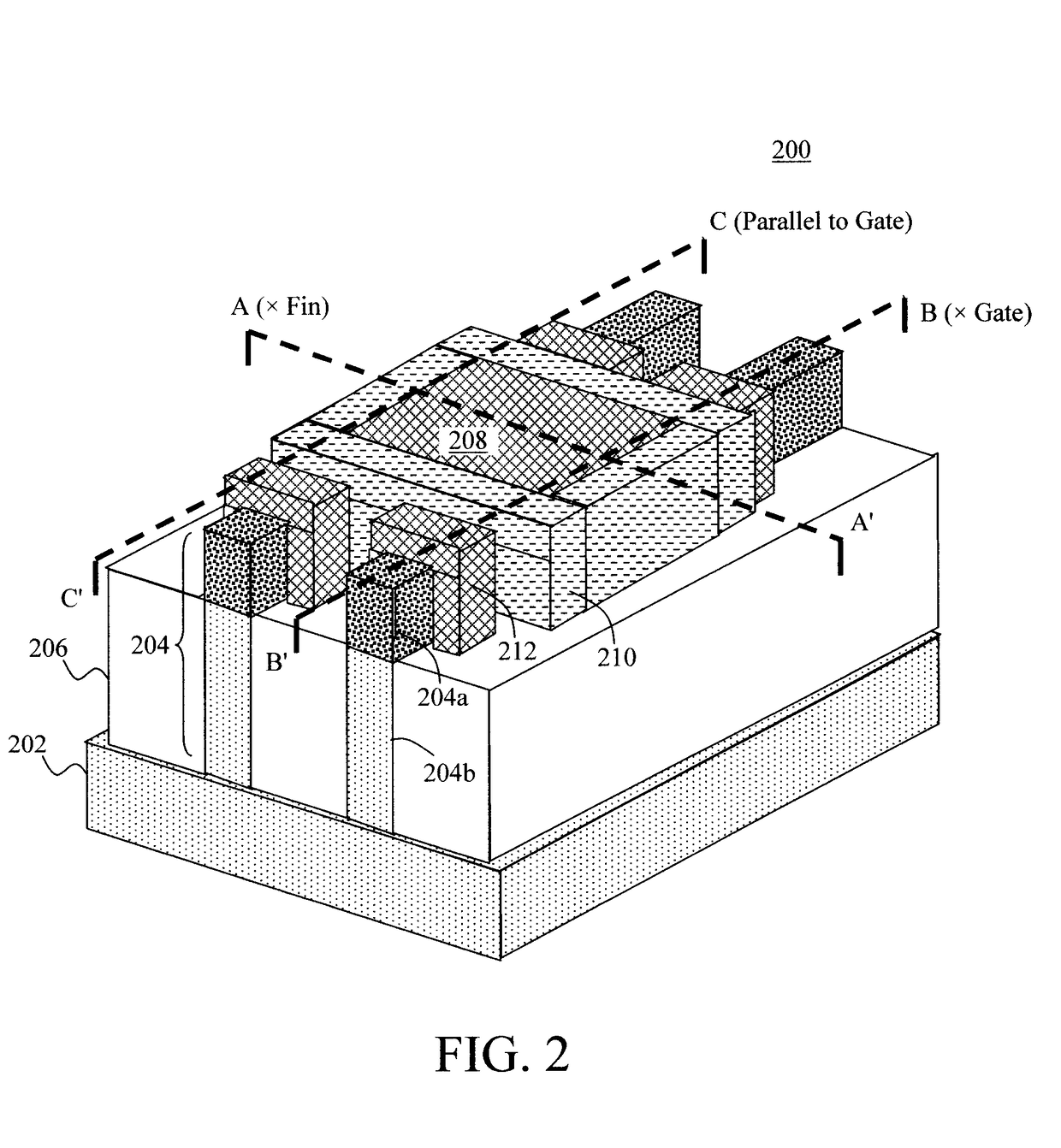

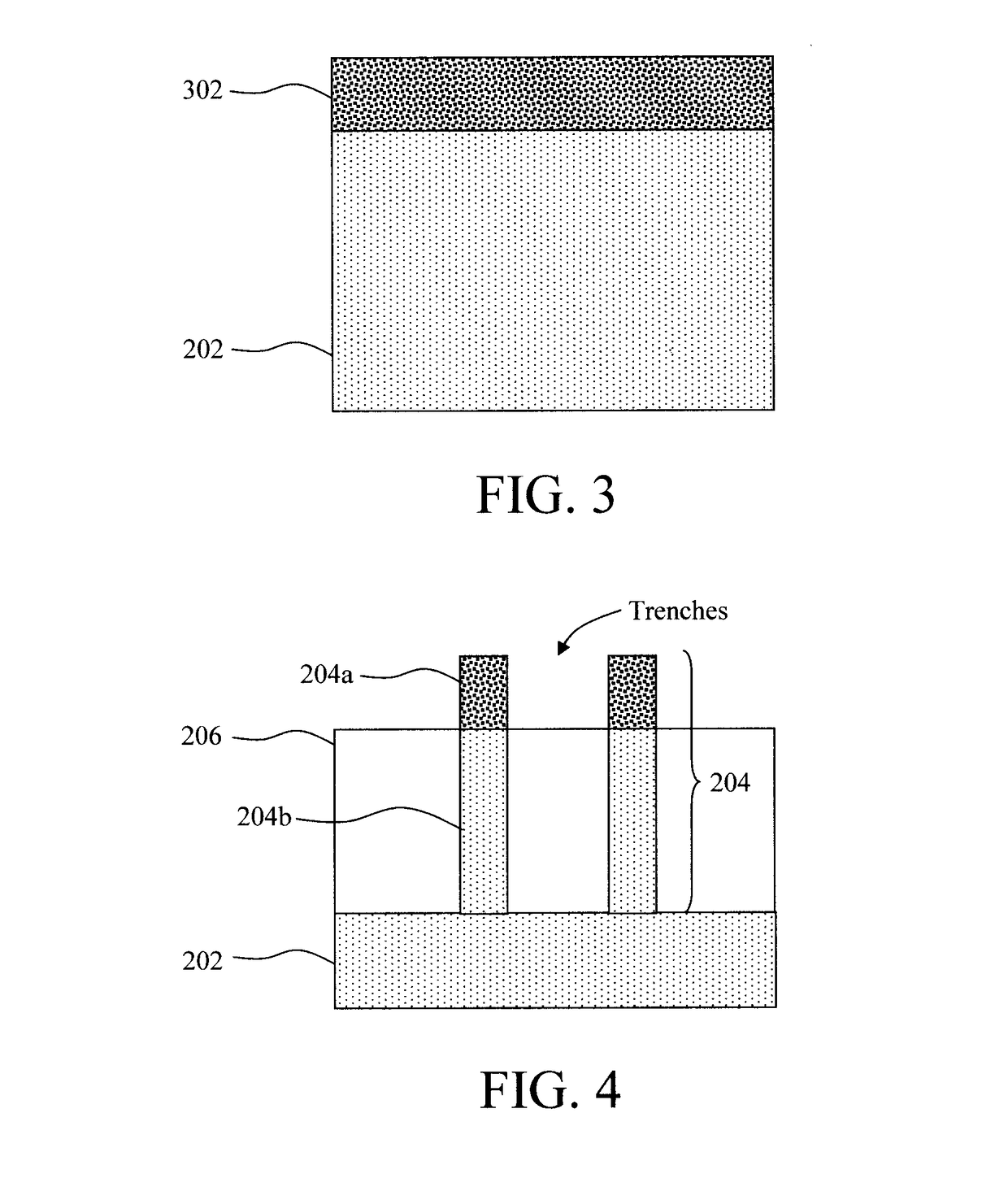

Interface Charge Reduction for SiGe Surface

ActiveUS20190035923A1Improve performanceReduce charge densitySemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricMaterials science

Techniques for interface charge reduction to improve performance of SiGe channel devices are provided. In one aspect, a method for reducing interface charge density (Dit) for a SiGe channel material includes: contacting the SiGe channel material with an Si-containing chemical precursor under conditions sufficient to form a thin continuous Si layer, e.g., less than 5 monolayers thick on a surface of the SiGe channel material which is optionally contacted with an n-dopant precursor; and depositing a gate dielectric on the SiGe channel material over the thin continuous Si layer, wherein the thin continuous Si layer by itself or in conjunction with n-dopant precursor passivates an interface between the SiGe channel material and the gate dielectric thereby reducing the Dit. A FET device and method for formation thereof are also provided.

Owner:IBM CORP

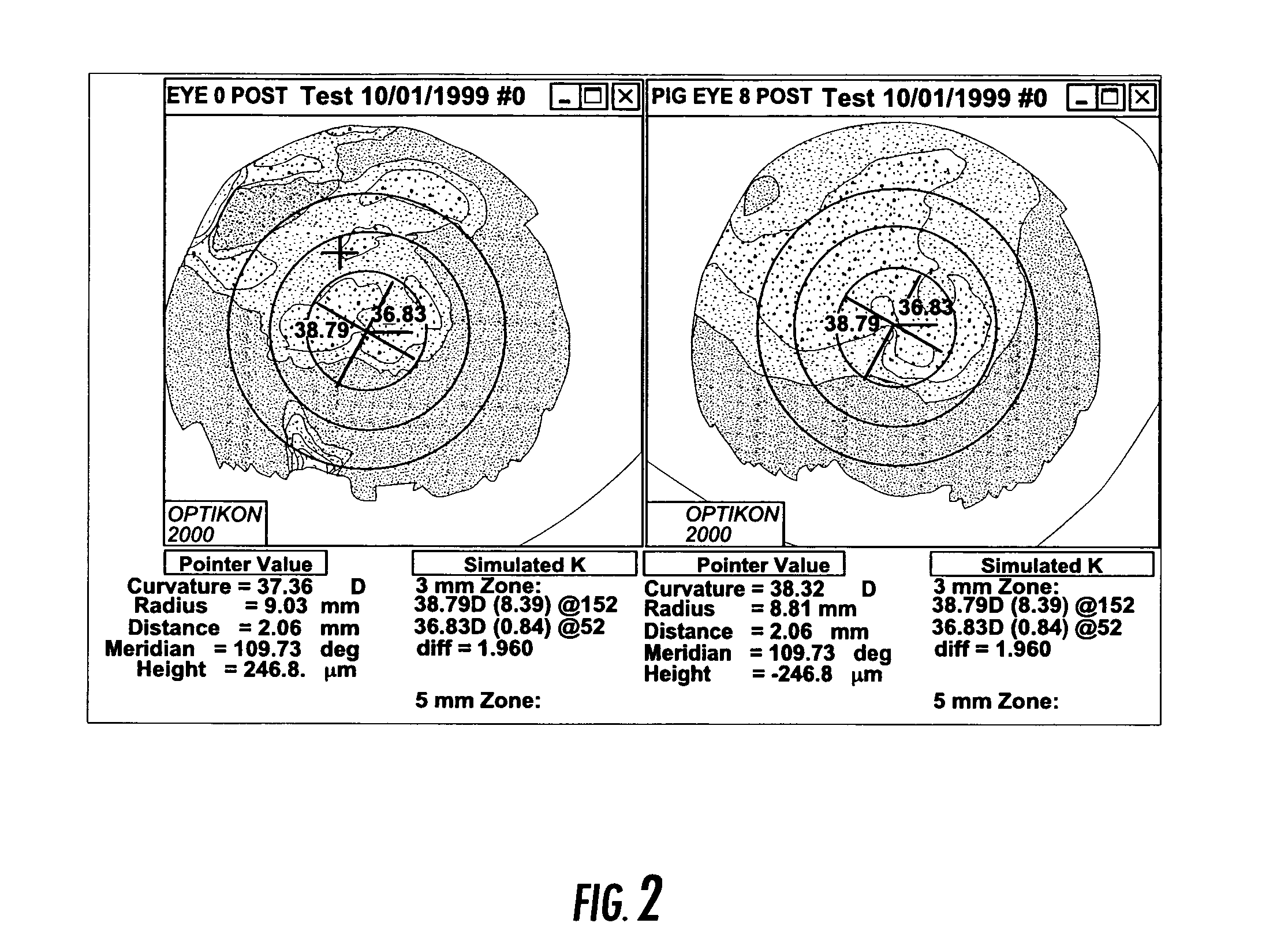

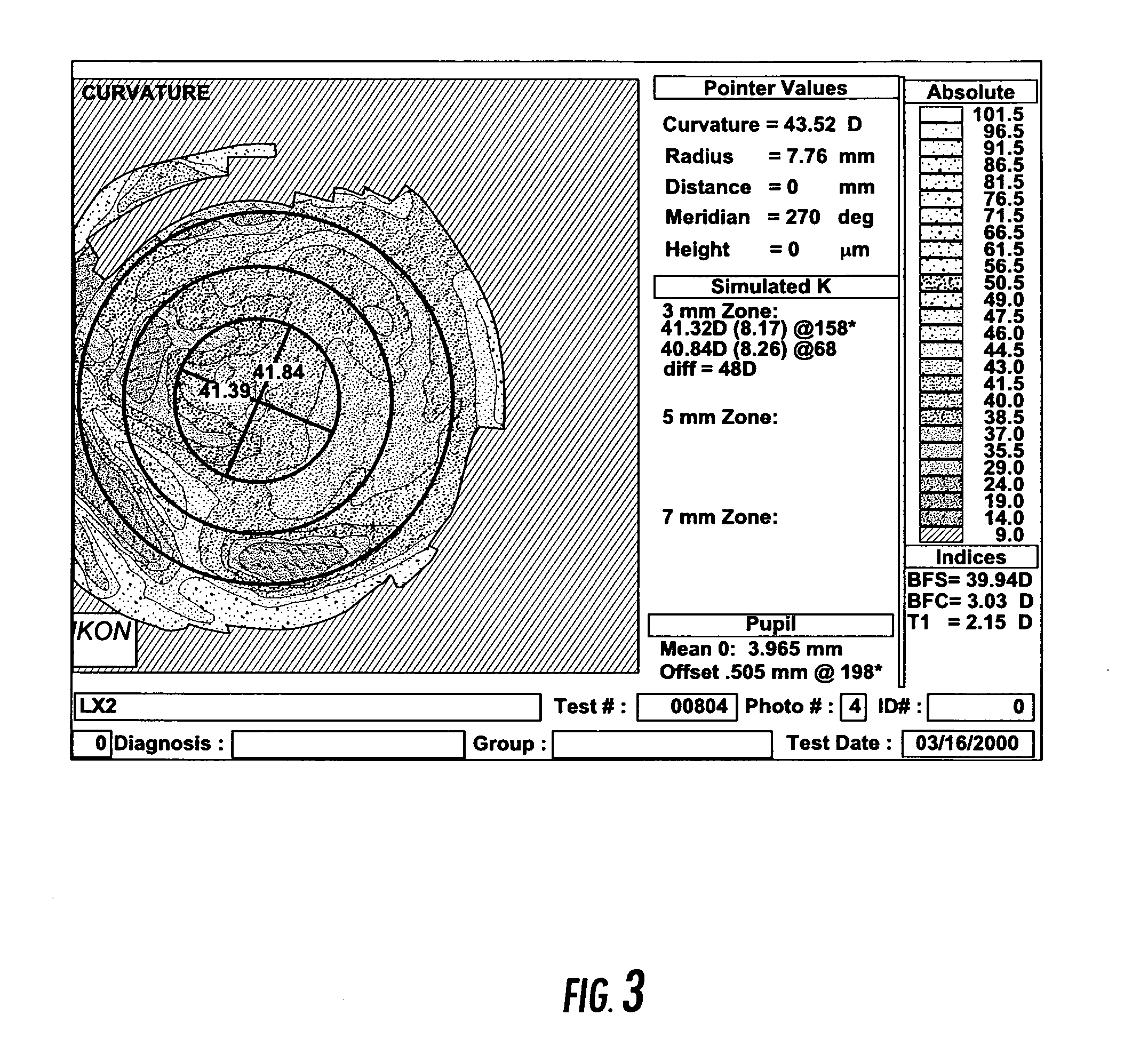

Chemical treatment of in vivo tissue to alter charge and net charge density characteristics

InactiveUS20050106270A1High charge densityHigh modulusBiocideInorganic active ingredientsChemical treatmentTissue protein

A method for treating animal tissue with acylation agents to alter the net charge and net charge density of the treated tissue for therapeutic applications is provided. The method involves applying an alkaline solution to the exposed tissue surface area. This results in deprotonation of ε-amino groups of lysine residues on the exposed tissue proteins so that the tissue proteins have a net charge. Then, an acylating agent is applied and the acylating agent reacts with the tissue protein to form a protein complex having an altered net charge. Acylating agents such as sulfonic acids, sulfonyl chlorides, and acid chlorides can be used. The method can be used to treat a wide variety of human tissues including the human cornea for correcting myopia. The method can also be used to treat skin tissue, so that there is an increase in dermal thickness and pliability. The method can be further used to treat articular cartilage.

Owner:DEVORE DALE PAUL +1

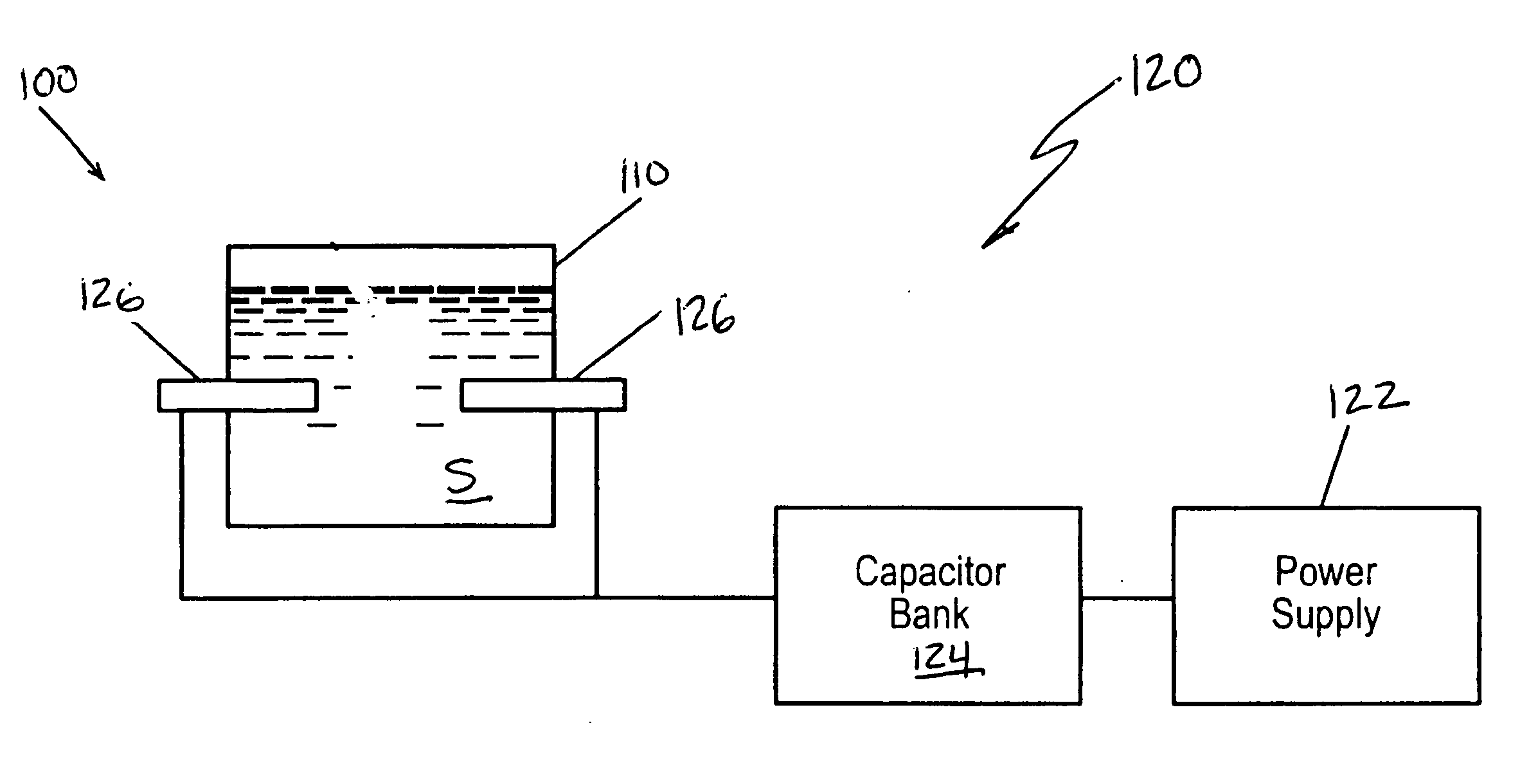

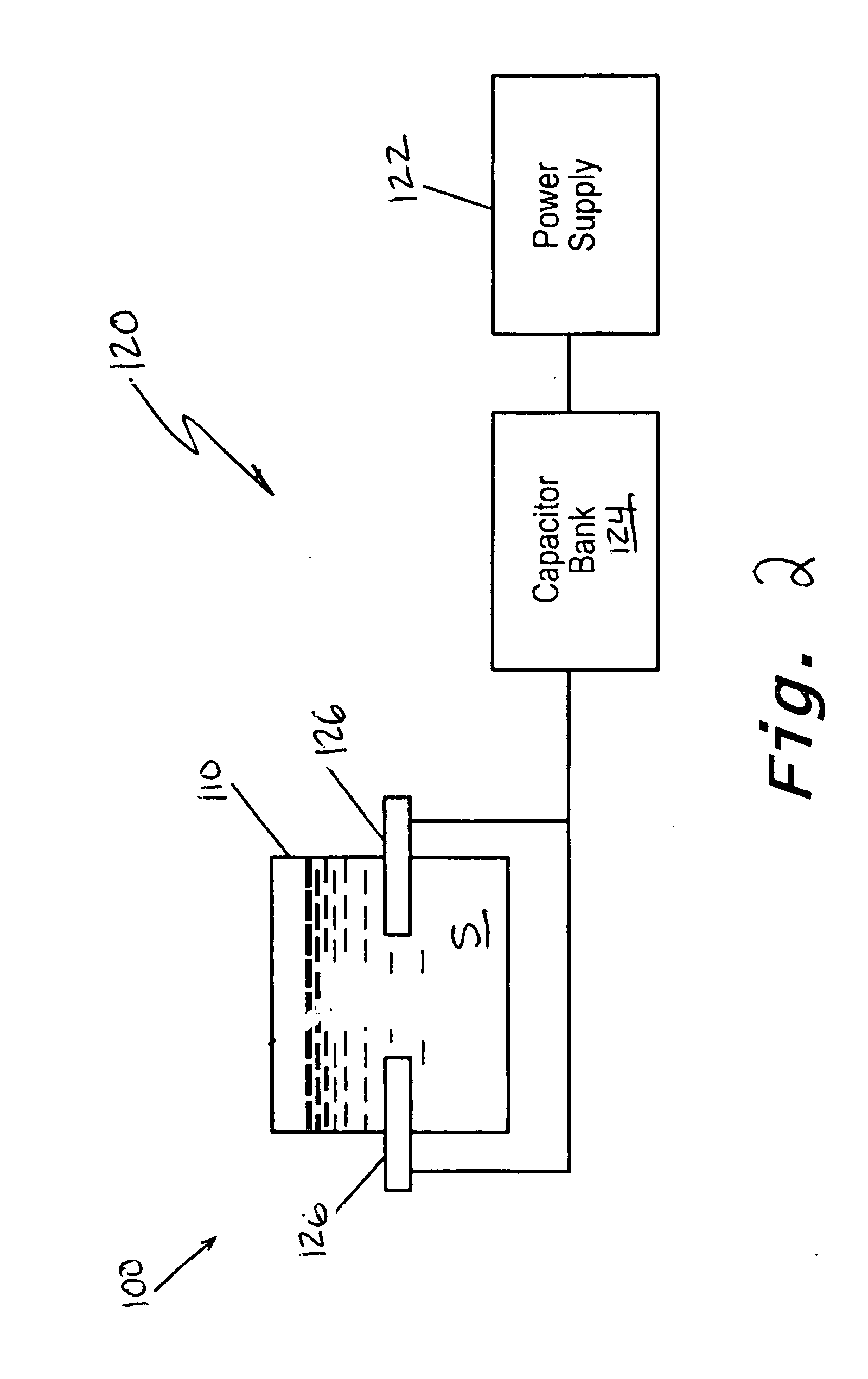

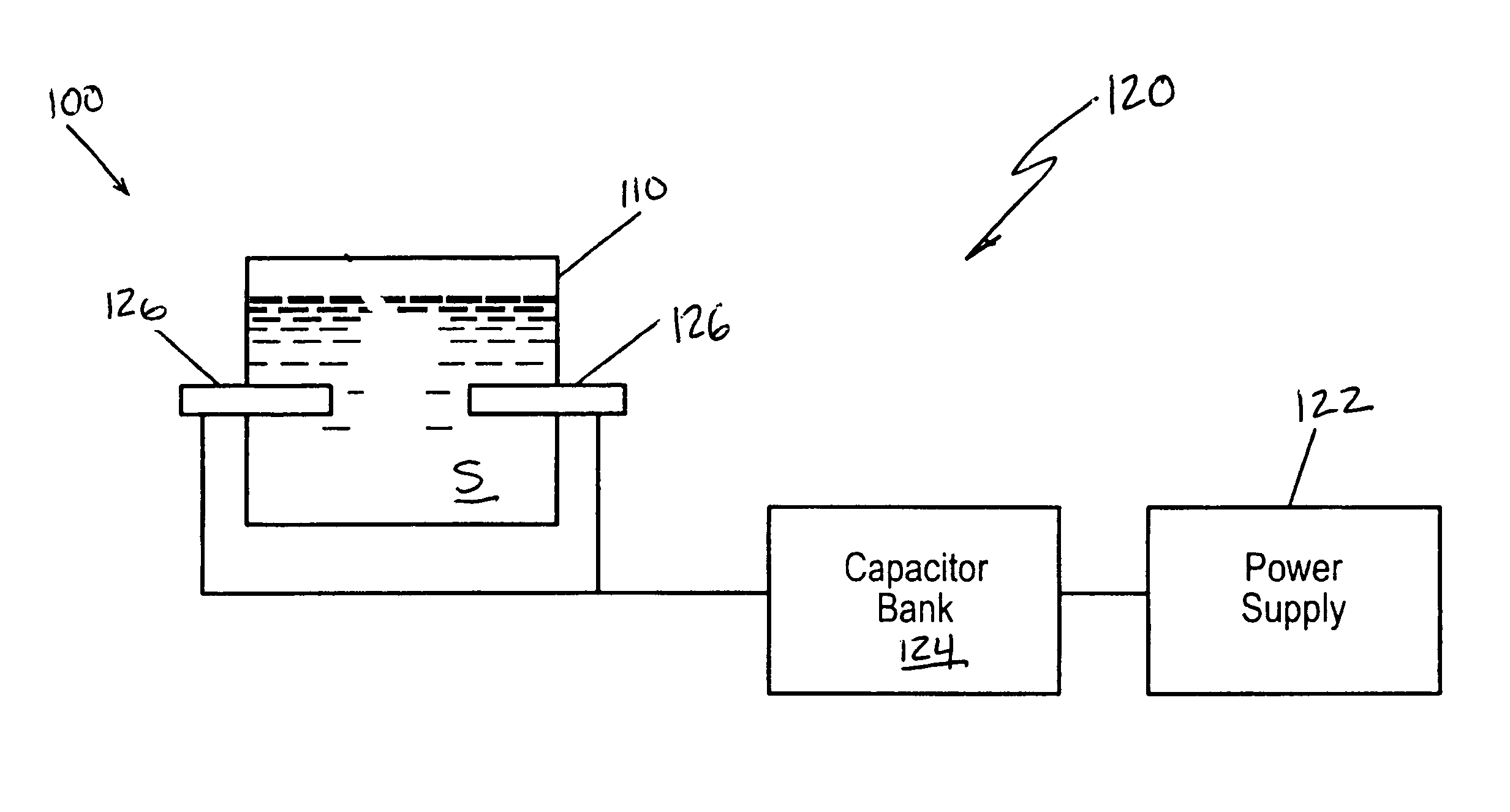

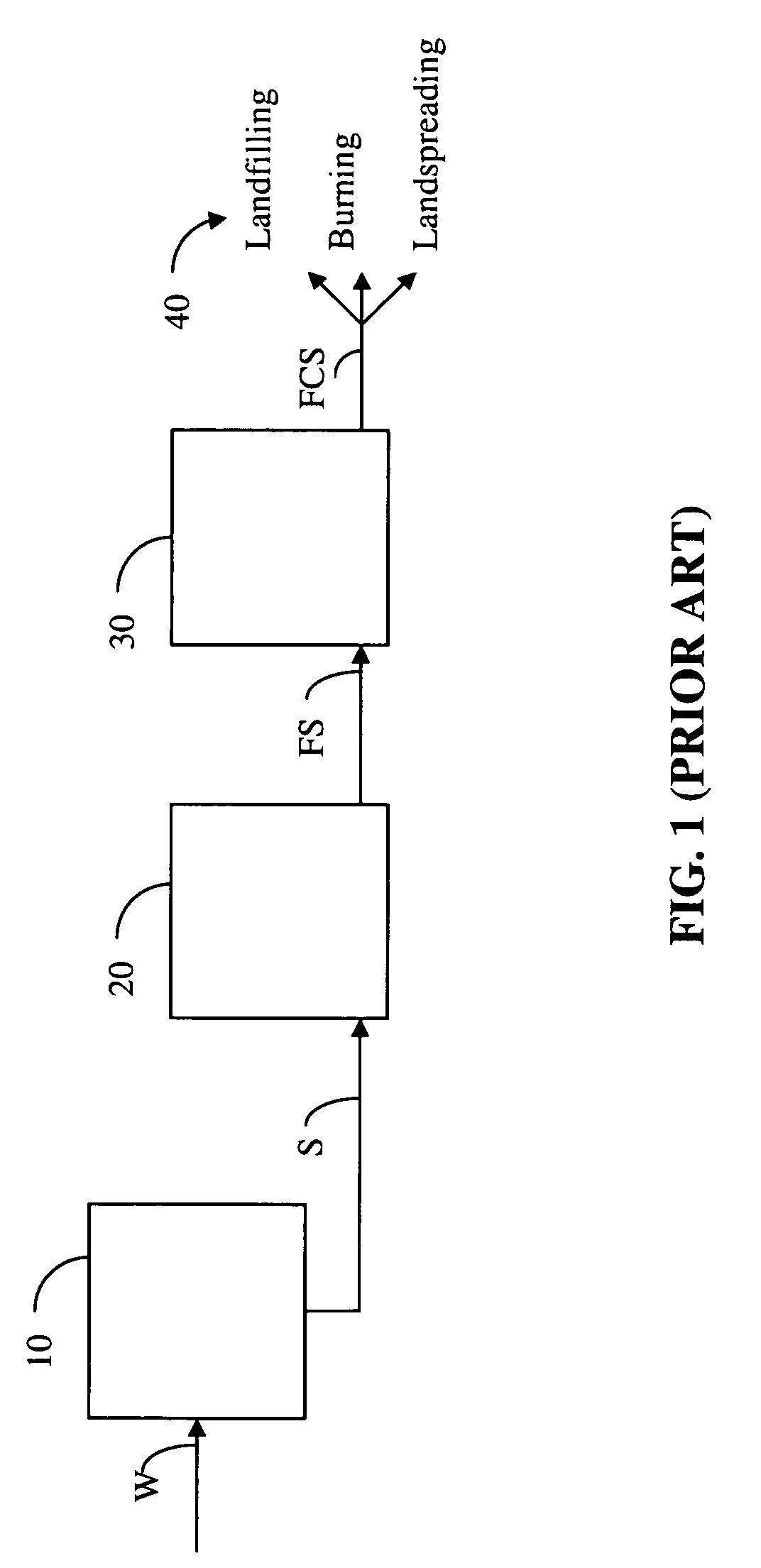

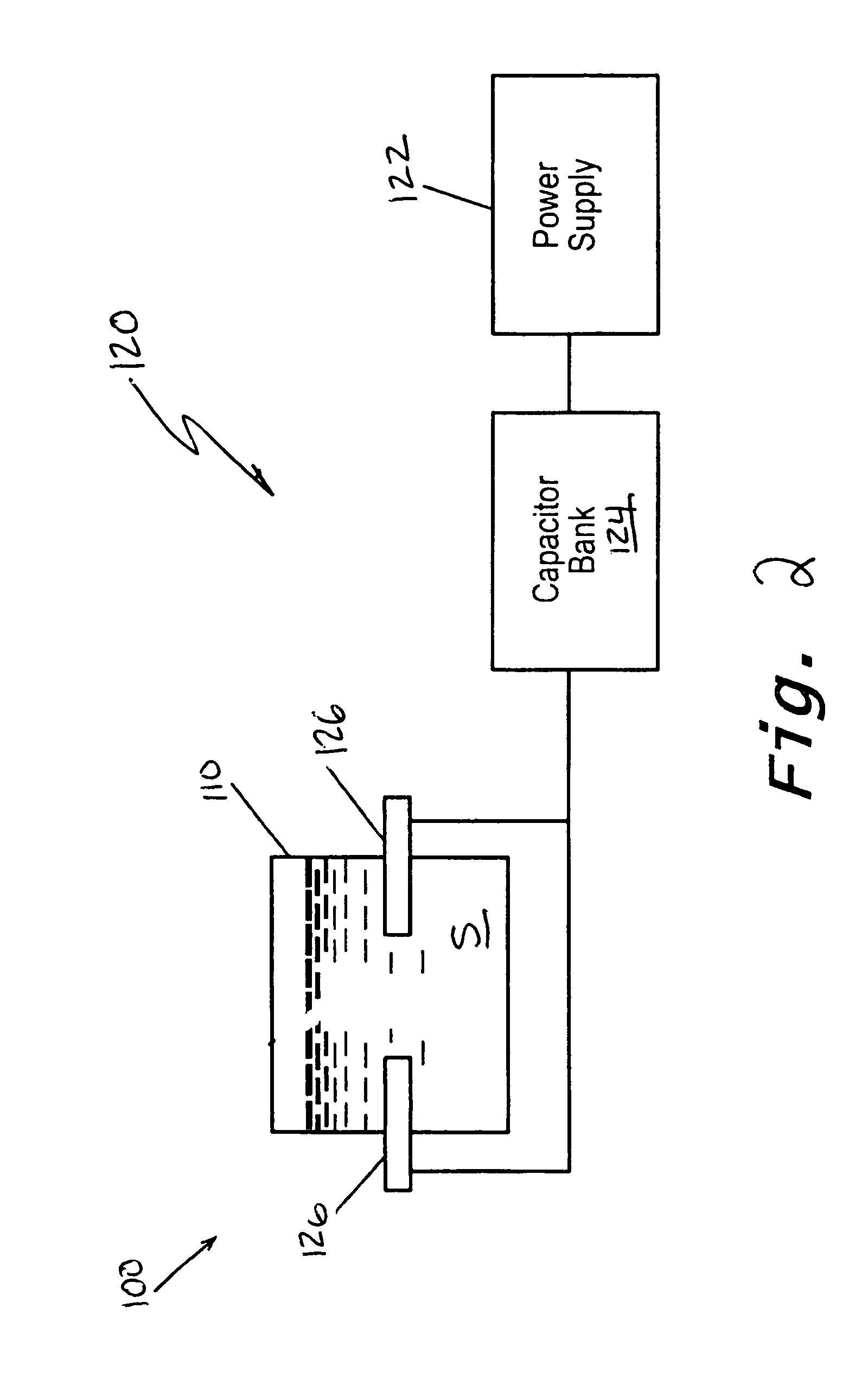

Spark-induced consolidation of sludge

InactiveUS20060032822A1Increase ratingsReduce charge densitySludge treatment by de-watering/drying/thickeningWater/sewage treatment with mechanical oscillationsSludgeHigh intensity

Exposing sludge to underwater, high-intensity sparks, to increase cake solids, provide faster settling, and increase the rate of dewatering.

Owner:GEORGIA TECH RES CORP

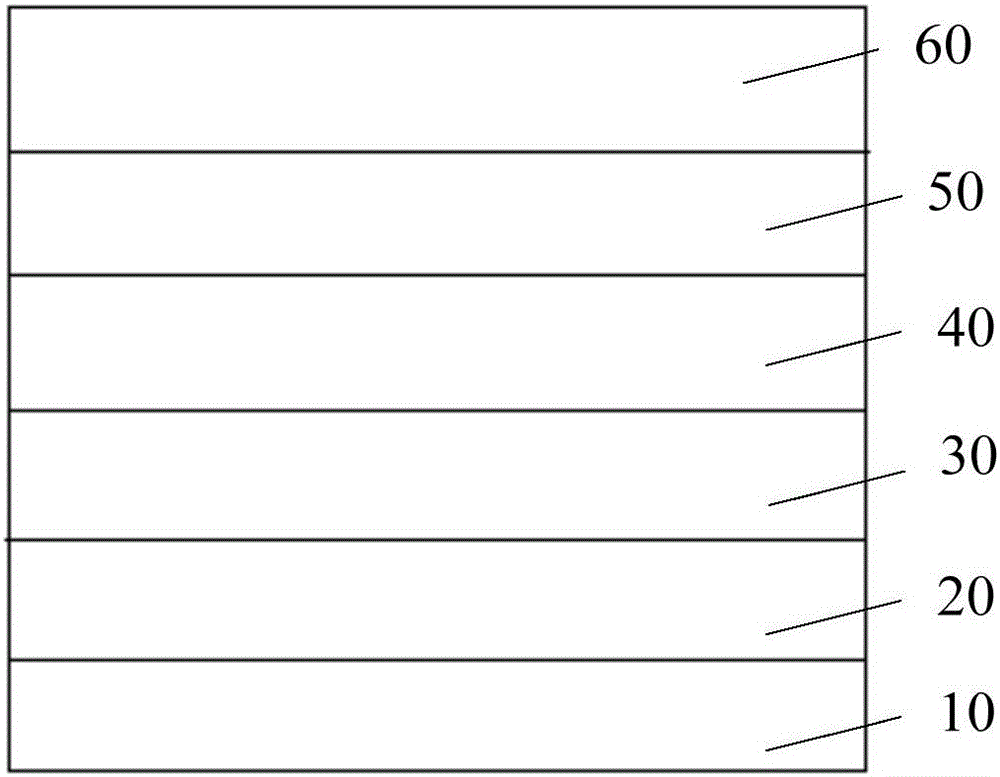

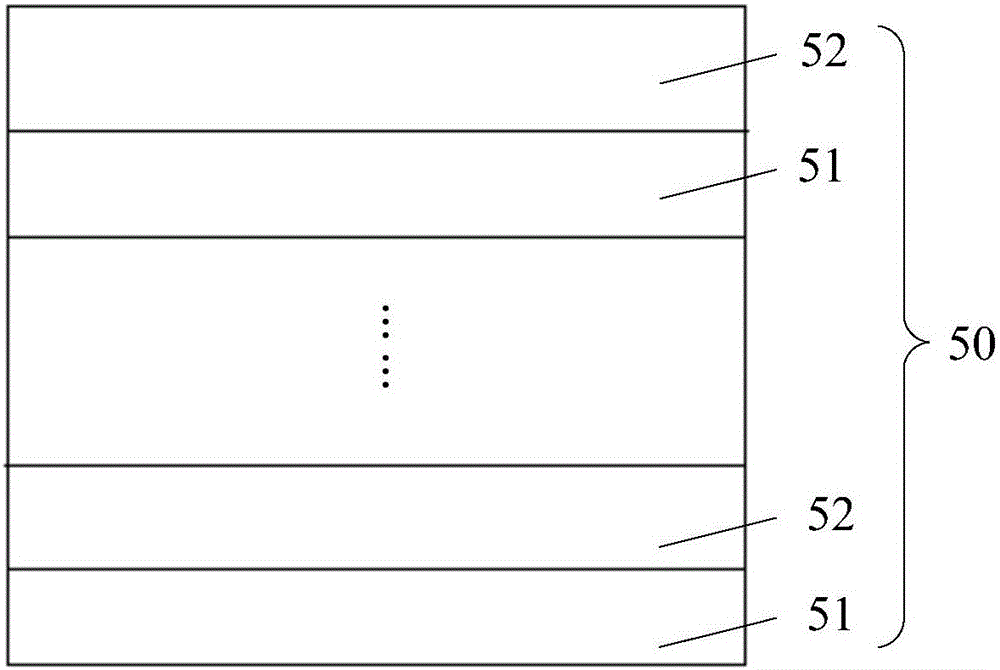

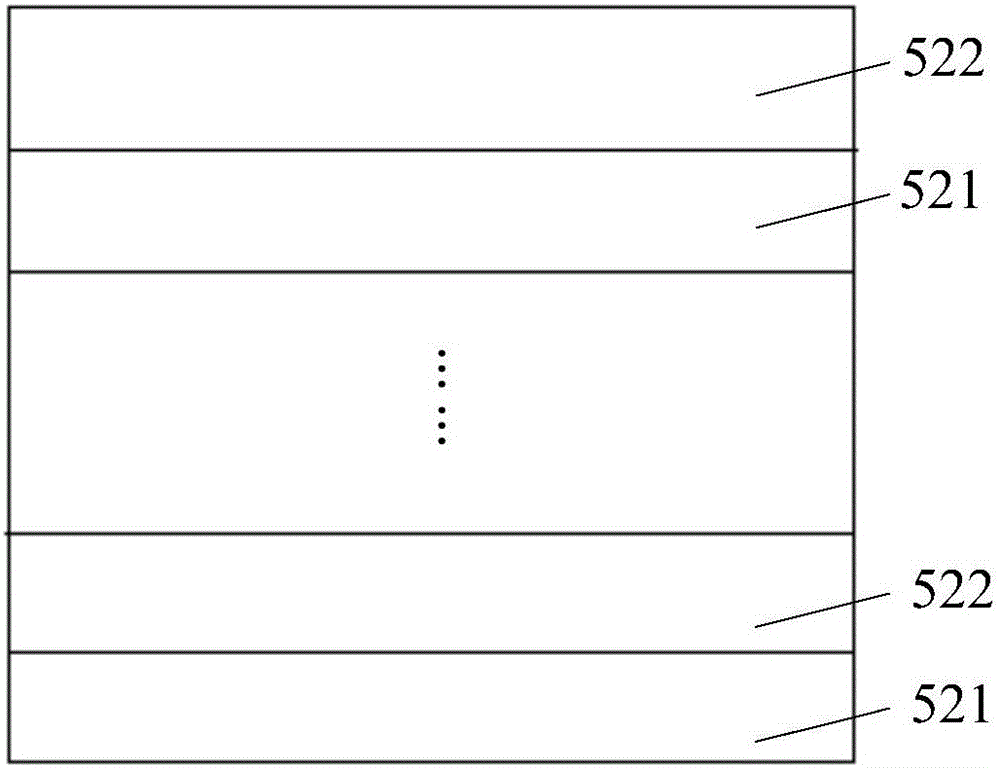

Light-emitting diode epitaxial wafer

ActiveCN104993028AImprove internal quantum efficiencyPrevent overflowSemiconductor devicesQuantum efficiencyQuantum well

The invention discloses a light-emitting diode epitaxial wafer and belongs to the technical field of semiconductors. The epitaxial wafer comprises a substrate, and a buffer layer, a non-impurity-doped GaN layer, an N-type layer, a multi-quantum well layer and a P-type layer which successively cover the substrate. The multi-quantum well layer is of a multi-period structure, and each period structure comprises a quantum well layer and a quantum barrier layer covering the quantum well layer. The quantum barrier layer closest to the P-type layer is of a superlattice structure. The superlattice structure comprises a plurality of AlxGal-xN sub-layers and GaN sub-layers which grow in an alternating manner, wherein x is larger than zero and less than 1, and the components of Al in the AlxGal-xN sub-layers gradually changes with the growth sequence. According to the invention, the quantum barrier layer, closest to the P-type layer, in the multi-quantum well layer of the epitaxial wafer is set as the superlattice structure, electronic overflow is effectively prevented on one hand, and on the other hand, the cavity injection rate is increased, so that the internal quantum efficiency of the epitaxial wafer is further increased, and the light-emitting efficiency of the light-emitting diode is improved.

Owner:HC SEMITEK SUZHOU

LbL-coated medical device and method for making the same

InactiveUS20050221092A1Reduce charge densityImprove hydrophilicityPretreated surfacesAntithrombogenic treatmentMedical deviceBiomedical engineering

The present invention provides a medical device, preferably an ophthalmic device, more preferably a contact lens, which comprises a core material and a biocompatible LbL coating non-covalently attached to said core material. The biocompatible LbL coating comprises at least one charge / non-charge bilayer, wherein said charge / non-charge bilayer is composed of, in no particular order, one layer of a charged polymeric material and one layer of a non-charged polymeric material which is capable of being non-covalently bond to the charged polymeric material.

Owner:ALCON INC

Spark-induced consolidation of sludge

InactiveUS7374688B2Increase ratingsReduce charge densitySludge treatment by de-watering/drying/thickeningWater/sewage treatment with mechanical oscillationsSludgeHigh intensity

Exposing sludge to underwater, high-intensity sparks, to increase cake solids, provide faster settling, and increase the rate of dewatering.

Owner:GEORGIA TECH RES CORP

Gene vector system containing targeted shading system, preparation and use thereof

InactiveCN101302532AImprove performanceLow toxicityVector-based foreign material introductionGene deliveryCytotoxicity

The invention relates to a gene delivery system containing a target shielding system and a preparation method and application thereof. The gene delivery system consists of a shielding system with a target ligand, a cation polymer material and plasmid DNA, wherein, the cation polymer material and the plasmid DNA are compounded to form compound particles, and the shielding system with the target ligand is shielded on the surface of the compound through electrostatic effect. The gene delivery system containing the target shielding system can transfer a loaded genic material into cells to realize the expression of the genic material and finish a transfection process, and the targeting of gene transfection can be improved. The preparation method has the advantages that: the target ligand is grafted onto the shielding system; on the one hand, the targeting strategy can not affect the compound ability of a cationic polymer to the DNA, on the other hand, the targeting strategy can also guarantee that the target ligand is extended to the periphery of the gene delivery system so as to improve the combination efficiency of the target ligand and a cell surface receptor. The highest transfection efficiency of the gene delivery system to a HeLa cell is 73 percent, and the toxicity of the cell is small.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Carbon powder and production method thereof

The invention provides carbon powder. The carbon powder is prepared from the following components in parts by mass: 85-95 parts of bonding resin, 2-8 parts of a coloring agent, 0.1-5 parts of an electric charge control agent, 1-6 parts of de-molding agent and 1-10 parts of a magnetic material. A magnetic material is successfully used in non-magnetic powder, and the related properties of the magnetic material, such as high rigidity, large density and strong dispersity can be utilized, so that the defects of the carbon powder in a developing and photographic fixing process are improved. The effects of the carbon powder are mainly represented in the following two aspects: firstly, the magnetic material is added so that the density of carbon powder particles becomes large, and a powder flying problem in a high-speed printing material can be improved; secondly, the magnetic material is oxide of iron so that the specific resistance of the carbon powder particles can be reduced by the magnetic material, and furthermore, the electric charge uniformity of each carbon powder particle is better and the stability is better; and the problem of shallow color at the later period is well solved.

Owner:ICMI CHINA

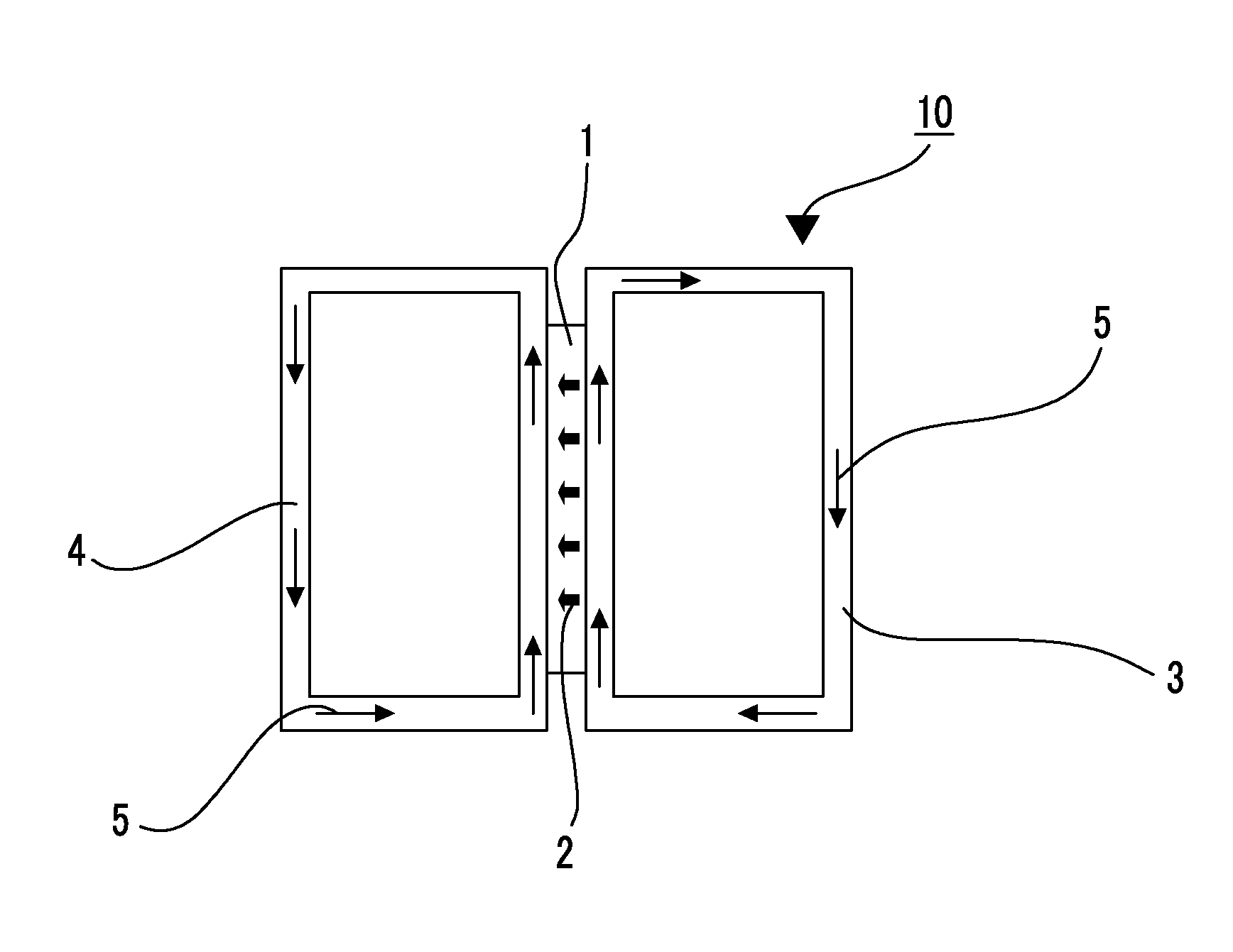

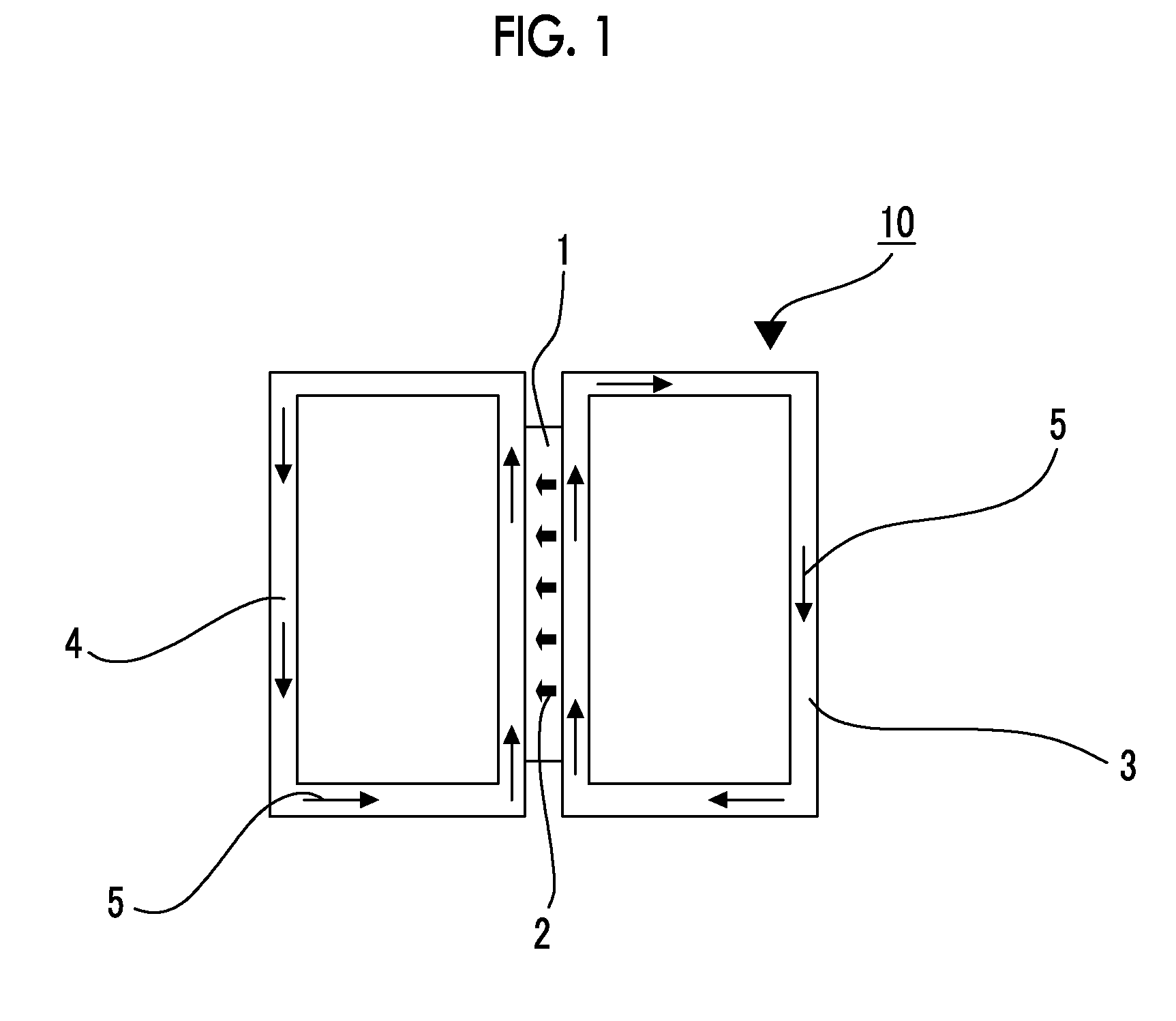

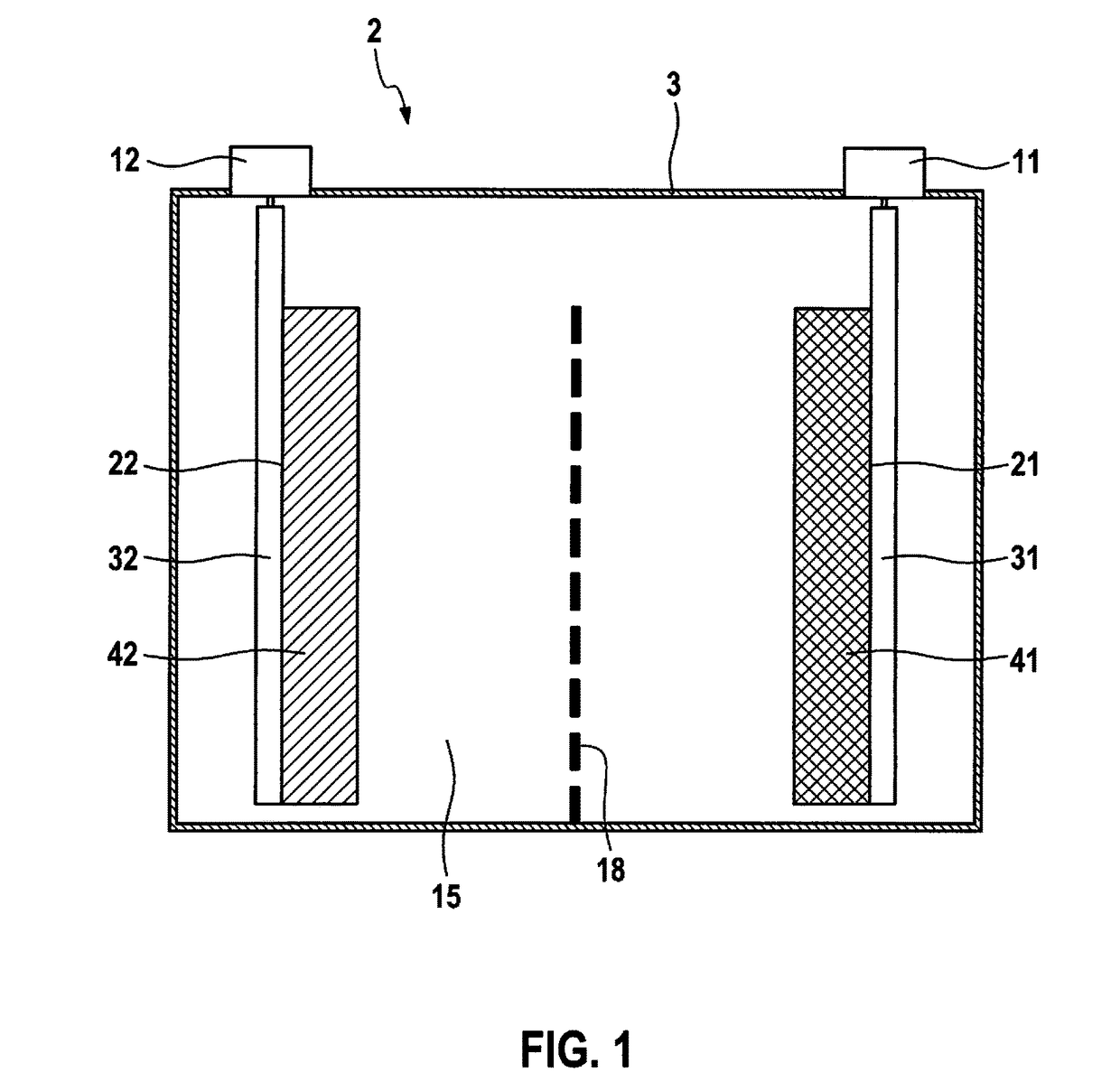

Hybrid supercapacitor, including an electrolyte composition, having improved conductivity

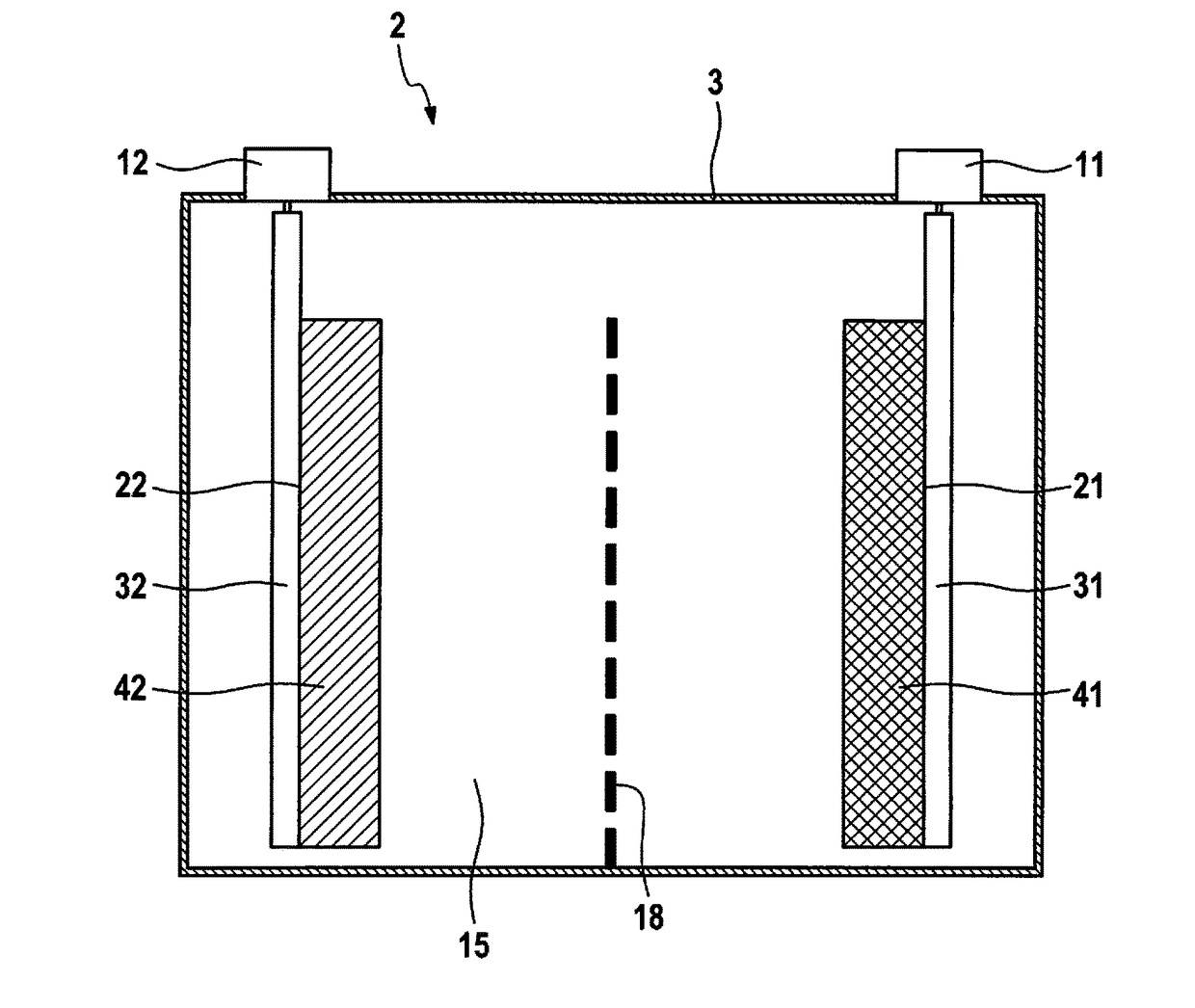

InactiveUS20170352498A1Improve stabilityImprove conductivityHybrid capacitor separatorsHybrid capacitor electrolytesOrganic solventSupercapacitor

A hybrid supercapacitor, including at least one negative electrode that includes a statically capacitive active material, an electrochemical redox active material, or a mixture thereof, at least one positive electrode that includes a statically capacitive active material, an electrochemical redox active material, or a mixture thereof, at least one separator that is situated between the at least one negative electrode and the at least one positive electrode, and an electrolyte composition, with the condition that at least one electrode includes a statically capacitive active material, and at least one electrode includes an electrochemical redox active material, the electrolyte composition being a liquid electrolyte composition and including at least one liquid, aprotic, organic solvent, at least one conducting salt, and at least one additive.

Owner:ROBERT BOSCH GMBH

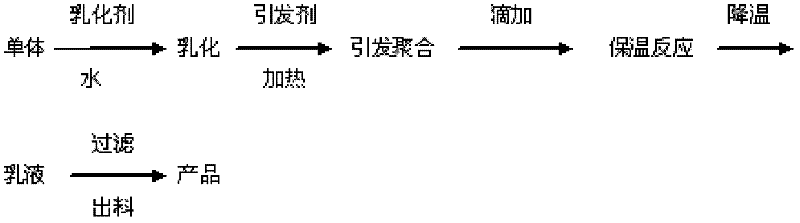

Process of synthesizing heat resistant copolymer

The improved emulsion polymerization process of preparing heat resistant alpha-methylstyrene-acrylonitrile copolymer features that 30-50 wt% of the monomers, emulsion and initiator are pre-emulsified; and the rest monomers, emulsion and initiator are emulsified, heated to 65-70 deg.c and polymerized while adding the pre-emulsion until to obtain solid content higher than 36 %, where, the initiator is oil soluble azo diisobutyronitrile or azo diisoheptonitrile. The present invention has stable emulsion system, complete and homogeneous copolymerization, copolymerizing conversion rate as high as 98 %, low residual monomer rate, high Vicat temperature and other advantages.

Owner:LILAI CHEM YIXING

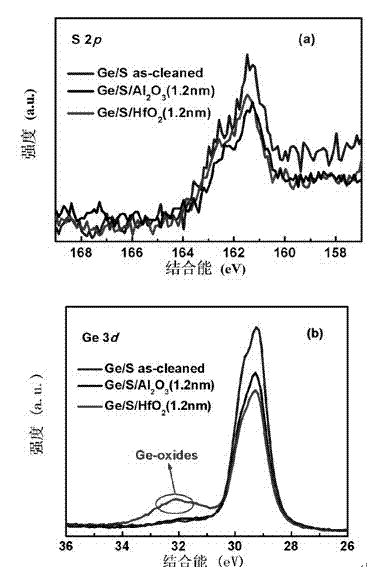

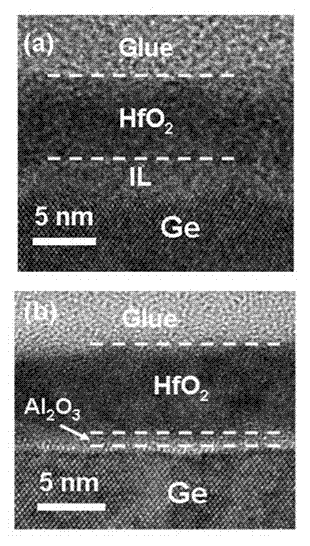

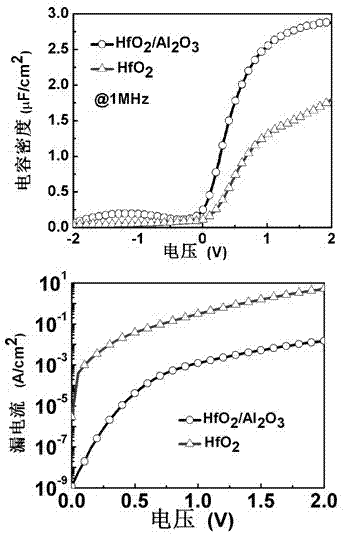

Preparation method of Ge-based Metal Oxide Semiconductor (MOS) device with sub-nanometer equivalent to oxide thickness

InactiveCN102543751AImprove thermal stabilityAvoid generatingSemiconductor/solid-state device manufacturingEquivalent oxide thicknessGate dielectric

The invention discloses a preparation method of a Ge-based Metal Oxide Semiconductor (MOS) device with sub-nanometer equivalent to oxide thickness, comprising the steps of 1) cleaning a Ge substrate; 2), performing S passivating; 3), depositing an Al2O3 film on the surface of the Ge substrate in situ;4), depositing an HfO2 film; 5), putting the substrate to a quick annealing furnace to anneal to obtain a finished product. The method obtains a thin aluminum oxide film by in-situ atomic layer deposition, improves interface quality of a gate dielectric film and the Ge substrate, notably improves the electric property of the gate dielectric film and obtains Ge-based MOS device with the Equivalent Oxide Thickness (EOT) of less than 1nm and the leakage current density of less than 2mA / cm2.

Owner:NANJING UNIV

Method for providing a nanocellulose involving modifying cellulose fibers

ActiveUS8911591B2Increases anionic charge densityReduce energy consumptionNanostructure manufacturePulp properties modificationAqueous electrolyteCellulose fiber

Owner:INNVENTIA

Thiourea modified polyethyleneimine copolymer as well as method thereof

ActiveCN103554492AReduce charge densityEfficient releaseOther foreign material introduction processesThioureaCytotoxicity

The invention provides a thiourea modified polyethyleneimine copolymer which is shown in a formula (I) or a formula (II). The preparation method comprises the following step: under an anhydrous condition, reacting polyethyleneimine shown in the formula (I) or the formula (II) with a compound shown in a formula (III) in an organic solvent to obtain the thiourea modified polyethyleneimine copolymer which is shown in the formula (I) or the formula (II). Due to introduction of the thiourea structure, the polyethyleneimine copolymer has low electric density, so that the cytotoxicity caused by high electric density of polyethyleneimine is reduced, and the biocompatibility is good. Meanwhile, the thiourea modified polyethyleneimine copolymer used as a gene carrier can interact with generic matters through non-charge attracted hydrogen bonds. The nanoparticles formed are slightly slack in structure. After entering cells, the nanoparticles can more effectively release the generic matters into cytoplasm and cell nucleus, so that the transfection efficiency is improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

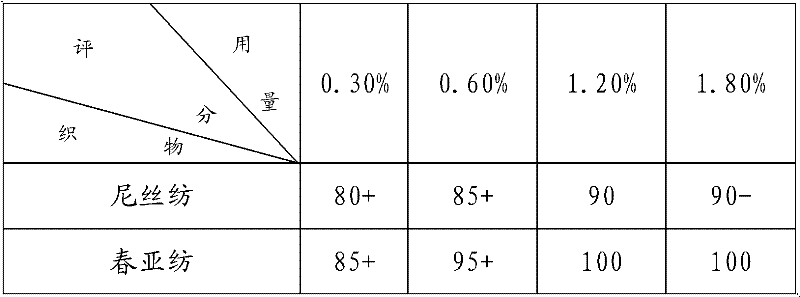

Three-proofing fabric finishing agent and preparation method thereof

ActiveCN102643386AMitigation of Orientation ChangesReduce charge densityFibre treatmentSolventChemistry

The invention relates to a preparation method of a three-proofing fabric finishing agent, which comprises the following steps: (1) evenly mixing raw material monomers for later use, weighing a composite emulsifier and an acetone-water mixed solvent, and evenly mixing the raw material monomers with the composite emulsifier and the mixed solvent to form a mixed solution; (2) stirring the mixed solution, pouring the mixed solution into a homogenizer, and homogenizing to obtain a milk white preemulsion; (3) dropwisely adding a 10 wt% initiator solution into the preemulsion at 50-90 DEG C; and (4) after finishing the dropwise addition, reacting for 5-10 hours while keeping the temperature, cooling to room temperature, and filtering to obtain the product. In comprehensive consideration of raw material sources, functionality, convenience, economy and the like, the invention has the advantages of simple synthesis, low price, low krafft point, wide temperature limit and the like. The invention also discloses a three-proofing fabric finishing agent produced according to the preparation method.

Owner:武汉松石科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com